Beruflich Dokumente

Kultur Dokumente

E 881511 Om GSCTP C P RC GBR 6-A4

Hochgeladen von

winarnobOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

E 881511 Om GSCTP C P RC GBR 6-A4

Hochgeladen von

winarnobCopyright:

Verfügbare Formate

GSC TP

for Chiller/ Packages with one Reciprocating Compressor

Operating Manual (Translation of the original text)

E_881511_6

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

COPYRIGHT

All Rights reserved.

No part of this publication may be copied or pub-

lished by means of printing, photocopying, microfilm

or otherwise without prior written consent of

GEA Refrigeration Germany GmbH

herein after called manufacturer. This restriction

also applies to the corresponding drawings and dia-

grams.

LEGAL NOTICE

This documentation has been written in all con-

science. However, the manufacturer cannot be held

responsible, neither for any errors occurring in this

documentation nor for their consequences.

2 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

SYMBOLS USED IN THIS MANUAL

Danger!

Stands for an immediate danger which

leads to heavy physical injuries or to

the death.

Warning!

Stands for a possibly dangerous situa-

tion which leads to heavy physical

injuries or to the death.

Caution!

Stands for a possibly dangerous situa-

tion which could lead to light physical

injuries or to damages to property.

Hint!

Stands for an important tip whose

attention is important for the designa-

ted use and function of the device.

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 3

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

4 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

TABLE OF CONTENTS

1 DESCRIPTION OF THE CONTROLLER 9

1.1 Safety note concerning the connection of the controller with the power panel 9

1.2 GSC TP, general 9

1.2.1 View 10

1.2.2 Lamps/ Push buttons 11

1.3 TouchPanel 13

1.3.1 General screen layout 13

1.3.2 Function key bar 14

1.3.3 Display and input boxes 15

1.3.3.1 Numerical value input 15

1.3.3.2 Selective list 17

1.3.3.3 Password level 18

1.3.4 Information bar 19

1.3.4.1 Status messages 19

1.3.4.2 Operation mode 21

1.3.5 Navigation bar 22

2 MAIN DISPLAY WITH SELECTION AREAS 24

3 INDICATION OF ACTUAL VALUES AND DELAY TIMES 25

4 CONTROL 28

4.1 Selective list "Operation mode" 28

4.2 Selective list "Control on" 30

4.3 Selective list "Power return" 31

4.4 Selective list "Network fault" 31

4.5 Control Parameters 32

5 COMPRESSOR SPEED CONTROL 34

6 TIMER SETTINGS 35

7 SENSOR VALUES (LIMIT VALUES AND SENSOR SCALING) 37

8 SEQUENCE CONTROL 45

8.1 Actual values 45

8.2 Settings 46

9 CONFIGURATION 48

9.1 Type 48

9.2 Refrigerant 49

9.3 Compressor 50

9.4 Coolant injection 51

9.5 Valve type 51

9.6 Motor valve suction line 51

9.7 Nominal speed 51

9.8 Auxiliary output 52

9.9 Frequency inverter 52

9.10 Motor current 52

9.11 Crankcase pressure 52

9.12 Suction temperature 52

9.13 Oil temperature 53

9.14 Oil separator temperature 53

9.15 Cooling agent inlet temperature 53

9.16 Cooling agent outlet temperature 53

9.17 Coolant inlet 53

9.18 Coolant out temp 53

9.19 External setpoint analog (HW) 54

9.20 External temperature 54

9.21 Communication 54

9.22 Thermomaster 54

9.23 Acknowledgement configuration 54

10 PASSWORD 55

11 DATE AND TIME 56

12 LANGUAGE 57

13 START UP MANAGER 58

14 ALARMS AND WARNINGS 59

14.1 Alarms 59

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 5

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

14.1.1 Alarm window 59

14.1.2 Alarm overview 60

14.1.3 Alarm histogram 60

14.1.4 Overview of all possible alarm messages 61

14.2 Warnings 64

14.2.1 Warning banner 64

14.2.2 Overview of all possible warning messages 65

15 THERMOMASTER 67

16 COMPRESSOR MAINTENANCE 69

16.1 Maintenance intervals 69

16.2 Average values 69

16.3 History 70

16.4 Pending inspections 70

16.5 Maintenance settings 70

16.5.1 Reset 71

16.5.2 Backing up the history 71

16.5.3 Loading the history 71

16.6 Calculating the maintenance intervals 71

6 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

TABLE OF FIGURES

fig. 1 Front view 10

fig. 2 White indicator light (Running compressor) 11

fig. 3 Yellow indicator light (Warning) 11

fig. 4 Red indicator light (Alarm) 12

fig. 5 Emergency stop button 12

fig. 6 TouchPanel 13

fig. 7 General screen layout 13

fig. 8 Function key bar 14

fig. 9 Numeric input window 15

fig. 10 Selective list 17

fig. 11 Information bar 19

fig. 12 Navigation bar 22

fig. 13 Representation of the main process values 24

fig. 14 Indication of actual values and delay times 25

fig. 15 Input and selection areas 28

fig. 16 Setting the compressor speed control 34

fig. 17 Timer Settings 35

fig. 18 Sensor values 37

fig. 19 Sequence control settings 45

fig. 20 Configuration 48

fig. 21 Password 55

fig. 22 Date/Time 56

fig. 23 Language 57

fig. 24 Start up manager 58

fig. 25 Alarm report 59

fig. 26 Alarm overview 60

fig. 27 Alarm histogram 60

fig. 28 Warning message 64

fig. 29 Thermomaster (product-dependent variations possible) 67

fig. 30 Wire break (product-dependent variations possible) 68

fig. 31 Data at the time of the last failure (product-dependent variations possible) 68

fig. 32 Display of the maintenance intervals (product-dependent variations possible) 69

fig. 33 Average values (product-dependent variations possible) 69

fig. 34 History (product-dependent variations possible) 70

fig. 35 Maintenance settings (product-dependent variations possible) 71

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 7

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

8 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Description of the controller

GSC TP

1 DESCRIPTION OF THE CONTROLLER

1.1 Safety note concerning the connection of the controller with the power panel

Hint!

It is not permitted to add an external controller between the controller and the power panel;

this would extend the safety chain to be achieved. All control signals between the controllers

and the power panel must be processed directly and must not flow indirectly via an external

controller. GEA Refrigeration Germany GmbH cannot otherwise guarantee the safe operation

of the system.

1.2 GSC TP, general

The GSC TP consists of the control unit with operator and display unit, indicator lights for "Running", "Warning"

and "Alarm", emergency stop button, output relays, power unit, main switch as well as the housing.

The standard version of the GSC TP for chillers with reciprocating compressors is mounted directly on the

chiller.

The GSC TP performs the following functions as standard:

Display of all important physical and technical parameters, e.g. pressure, temperature, output, number of run

hours, operating mode and status signals

Hint!

Some parameters will be hidden if not used.

Automatic startup and shutdown of the chiller as well as capacity control depending on the following values:

Suction pressure

Inlet temperature

External temperature (value via MPI network)

Outlet temperature (option)

Monitoring of all operating parameters

Compressor capacity limitation if the measured discharge pressure, discharge temperature, motor current

(optional) or suction pressure indicate an overload

Fault memory with date and time

Wire failure detection for analogue input signals

Password protection for preventing unauthorised access to important parameters

Control of the chiller by a master controller via potential free contacts

Possibility of communication via MPI or Modbus RTU with master controller or building management system.

(The MPI communication is not recommended when using a successor model)

10-minute trend display with display of all actual values which existed just before alarm shutdown

Remote maintenance via Ethernet connection (TCP/IP)

The GSC TP optionally performs the following functions:

Frequency-controlled compressor drive motor

Motor current sensor

Outlet temperature sensor

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 9

Description of the controller Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

Winter mode to protect the secondary cooling agent against freezing (evaporator block by motor valves) -

only Ingenium Compact.

Electronic flow switch for refrigerant circuit

Electronic flow switch for heating agent circuit

Remote setpoint adjustment (analogue signal)

Profibus DP communication

1.2.1 View

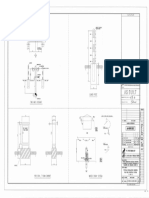

fig.1: Front view

10 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Description of the controller

GSC TP

1.2.2 Lamps/ Push buttons

White indicator light (Running compressor)

This indicator lamp flashes slowly when the compres-

sor package/ chiller is in the "Standby" state.

This lamp flashes quickly during start up of the com-

pressor.

Once the compressor has started, the light becomes

steady.

This lamp flashes quickly during the shut down opera-

tion, until the compressor drive motor is switched off.

fig.2: White indicator light (Running compressor)

Yellow indicator light (Warning)

This lamp flashes if an operating condition reaches a

preset value (Warning/Pre-alarm).

Detection of this warning can be acknowledged at the

operator panel. Warnings are automatically reset after

the cause has gone.

After the warning has been acknowledged at the oper-

ator panel, this flashing light changes over to a steady

light, as long as the warning condition remains.

fig.3: Yellow indicator light (Warning)

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 11

Description of the controller Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

Red indicator light (Alarm)

This lamp flashes if an operating condition exceeds its

permitted value, the machine shuts down on alarm.

This state is signalled by a red flashing light.

After the alarm has been acknowledged at the opera-

tor panel, this flashing light changes over to a steady

light, as long as the alarm condition remains.

Once the cause of the alarm has been corrected, this

indicator light switches off (after it has been acknowl-

edged).

fig.4: Red indicator light (Alarm)

Emergency stop button

This red button can be used to switch the compressor

off at any time in case of an emergency.

The operator terminal controls remain functional.

fig.5: Emergency stop button

12 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Description of the controller

GSC TP

1.3 TouchPanel

The TouchPanel is the interface between the man and the machine.

All switching, operating and control actions are carried out via this TouchPanel.

The TouchPanel is available in different languages.

fig.6: TouchPanel

1.3.1 General screen layout

The image format is identical in all the images. The images shown are examples and can vary in the actual

project!

Hint!

Coloured highlighted buttons can be operated.

Grey marked push buttons can't be activated, a finger touch will not initiate any action.

fig.7: General screen layout

1 Information bar

2 Navigation bar with "Pull down" menus

3 Main display with selection areas

4 Function key bar

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 13

Description of the controller Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

1.3.2 Function key bar

The product is operated manually via the push buttons of the function key bar.

fig.8: Function key bar

1 Function key bar

Only push buttons on a coloured background can also be operated. Grey push buttons are not active.

Pushing the buttons gives a visual feedback, a colour change to "light green".

Key Function

Start

Switch off and start disabled

Start compressor (press key for 5 sec. in "Manual" operation mode)

Increase output of compressor

(in case of manual capacity control only)

Switch off compressor (press key for 5 sec. in "Manual" operation mode)

Reduce output of compressor

(in case of manual capacity control only)

Show/hide help text

Show/hide navigation bar with pull-down menu

14 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Description of the controller

GSC TP

Hint!

As an additional feature, the control deviation is displayed within the push buttons for manual

output control as a simulated LED.

Example:

- Control deviation (+) of compressor (more output is required)1)

- Control deviation (-) of compressor (less output is required)1)

1) These control signals will be displayed if the compressor is controlled by the internal sequence control.

The push buttons , , , and have a contactor characteristic (state switches).

The push buttons and have a key characteristic, e.g. as long as touched by a finger.

1.3.3 Display and input boxes

1.3.3.1 Numerical value input

Display of the actual value only, value input not possible

The input box is inactive.

Operation is not possible. A higher password level is needed.

The actual value is displayed.

The input box is active.

Operation is possible.

The actual value is displayed and can be changed.

If an active input box has been actuated, the numeric input window opens.

fig.9: Numeric input window

Use the keypad to enter values. All inputs will be acknowledged by pressing the button. The

button will only become active when the value is changed.

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 15

Description of the controller Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

The actual value as well as the minimum and maximum limits are displayed in addition to the input value.

Deleting or correcting an entered value can be done using the button.

Press the button to quit the numerical value input window without changes.

16 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Description of the controller

GSC TP

1.3.3.2 Selective list

The selection box is inactive.

Operation is not possible. A higher password level is needed.

The actual value is displayed.

The selection box is active.

Operation is possible.

The actual value is displayed and can be changed.

If an active selection box has been actuated, a selective list opens.

fig.10: Selective list

The buttons and can be used to leaf through the list here. The active selection has a green

background. The selection will be made by confirming with the button.

Press the button to quit the list selection and the entry window will close.

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 17

Description of the controller Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

1.3.3.3 Password level

The access rights within the menu structure are protected by different passwords.

Hint!

Changing parameters without entering a password is not possible!

The password consists of an up to six-character number.

Each password level has a different number allocated to it.

The passwords for Levels 1 to 3 can be freely allocated by the user.

Password level 0 doesn't need a password.

The password for the highest password level 4 is specified by the manufacturer on delivery and cannot be sub-

sequently changed.

If no operation is executed at the operator panel for a longer period (approx. 10 mins), the operator panel auto-

matically logs out from the password level.

The following password levels have been allocated:

Password at

Delivery

Password level 0 Information level -- On/Off possible, no parameter

changes possible

Password level 1 Operator level 1 1000 in addition to level 0

Change to the set point values and

operation modes possible

Password level 2 Operator level 2 2000 in addition to level 1

Changes to all timers possible

Password level 3 Service Please enquire at GEA in addition to level 2

Refrigeration Germany Changes to all limiting values and

GmbH! changes in the configuration menu

possible

Password level 4 Administrator Please enquire at GEA

Refrigeration Germany

GmbH!

18 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Description of the controller

GSC TP

1.3.4 Information bar

Hint!

The information bar gives a general overview of the product status.

The information bar is always visible.

fig.11: Information bar

1 Status

2 Selected operation mode

1.3.4.1 Status messages

List of Status messages

Status message Remark

INITIALISATION Initialisation of the control after switching on the power supply or before the trans-

fer of the new settings.

COMPRESSOR OFF The compressor is switched off and the start is disabled.

EXTERNAL START The controller is waiting for an external signal to enable the start of the unit.

START TO START A starting frequency limiter of the compressor drive motor is still active.

STOP TO START Start delay after each stop.

BOOSTER WAIT The booster compressor will start as soon as the suction pressure drops below the

"Booster pressure". After achieving booster pressure the compressor will be

approved for starting.

LOW SUCTION PRES-

The suction pressure is too low. The compressor is not allowed to start.

SURE

DISCHARGE PRES-

The discharge pressure is too high. The compressor is not allowed to start.

SURE TOO HIGH

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 19

Description of the controller Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

List of Status messages

Status message Remark

LOW OIL TEMPERA-

The oil temperature is too low. The compressor is not allowed to start.

TURE

STANDBY Product ready for switching on, but one or more starting conditions are still not ful-

filled e.g. process variable still below set point.

MOTOR FEEDBACK Compressor drive motor has been started, however the running feedback signal

from the starter panel has not yet been received or the start-up is not yet complete.

STARTING Compressor drive motor has been started, but the compressor still runs without

load (one and two-stage compressor) or the low pressure cylinder is still not active

(only two-stage compressors)

STARTING PULL DOWN More capacity is needed, but the next capacity steps are blocked due to high suc-

tion pressure. Low pressure cylinders are still not activated (two-stage compres-

sors only)

RUNNING The compressor drive motor is running in the starter panel or start-up has been

completed, product is in operation.

RUNNING PULL DOWN The compressor drive motor is running in the starter panel or start-up has been

completed. Product is in operation and more capacity is needed. However, the

next capacity steps are blocked due to high suction pressure (two-stage compres-

sors only).

SUCTION PRESSURE A capacity limitation is active (suction pressure too low). The capacity cannot be

LIM increased. In case the suction pressure increases, the capacity will be decreased.

DISCHARGE PRES- A capacity limitation is active (discharge pressure too high). The capacity cannot

SURE LIM be increased. In case the discharge pressure increases, the capacity will be

decreased.

DISCHARGE TEMPERA- A capacity limitation is active (discharge temperature too high). The capacity can-

TURE LIMITATION not be decreased or increased. In case the discharge temperature increases, the

capacity will be increased or decreased.

EXTERNAL TEMPERA- A capacity limitation is active (external temperature or outlet temperature too low).

TURE LIMITATION The capacity cannot be increased. In case the external temperature decreased,

the capacity will be decreased.

MOTOR CURRENT LIMI- A capacity limitation is active (motor current too high). The capacity cannot be

TATION increased. In case the motor current increases, the capacity will be decreased.

LIMIT TIMER The delay time after a limitation is still active.

PUMP DOWN Before starting and stopping the compressor, the suction pressure is decreased

until the "Stop pressure" is reached (if the pump down sequence is activated only).

20 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Description of the controller

GSC TP

List of Status messages

Status message Remark

STOPPING The product has received a shut-down command, the capacity is decreased to a

minimum.

FAILURE Alarm condition active, compressor stopped.

START BLOCKED Compressor is blocked due to a start restriction

(with GSC TP from version 8.1.0)

1.3.4.2 Operation mode

Hint!

see chapter 2 "Main display with selection areas", Control/ Operation mode

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 21

Description of the controller Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

1.3.5 Navigation bar

The navigation bar can be shown/hidden by pressing the key.

If the navigation bar is hidden, the active arrow keys are still visible and the screen title is displayed.

fig.12: Navigation bar

1 Navigation bar

Symbols of navigation bar

Key Function

Back to previous screen

Call up of the menu overview

Call up of the display of actual values

Call up of the settings Submenus:

Control (operation mode)

Compressor speed control

Timer settings

Sensor values (limit values and sensor scaling)

Options (sequence control)

Call up of the events Submenus:

Alarm messages (alarms and warnings)

Trend

Datalogger (in preparation)

22 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Description of the controller

GSC TP

Symbols of navigation bar

Key Function

Call up of the Extras Submenus:

(setting) Configuration (compressor type, refrigerant, etc.)

Password

Date/Time

Language

Service (status indication, forcen etc.)

Start up manager

Move to next screen

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 23

Main display with selection areas Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

2 MAIN DISPLAY WITH SELECTION AREAS

Overview screen with representation of the main process values

Press the button to call up this screen.

fig.13: Representation of the main process values

Display of active set point and process value

The screen "set point input" will be reached by pressing the green push button.

No set point is displayed in the manual operation mode.

24 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Indication of actual values and delay times

GSC TP

3 INDICATION OF ACTUAL VALUES AND DELAY TIMES

Press the button to call up this screen.

fig.14: Indication of actual values and delay times

Symbol Remark

Suction pressure in bar (a) and the corresponding evaporation temperature in

Suction pressure

C

Discharge pressure in bar (a) and the corresponding condensation temperature

Discharge pressure

in C

Oil pressure Oil pressure in bar(a)

Oil diff. pressure Oil differential pressure in bar

Crankcase pressure Crankcase pressure in bar (a)

Intermediate pressure Intermediate pressure in bar (a)

Suction temperature Suction temperature in C

Discharge temperature Discharge temperature in C

Oil temperature Oil temperature in C

External temperature External temperature in C

External setpoint value Ext. setpoint HW in C

Interm temp LP Intermediate temperature low pressure in C

Interm temp HP Intermediate temperature high pressure in C

Inlet temperature Cooling agent inlet temperature in C

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 25

Indication of actual values and delay times Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

Symbol Remark

Outlet temperature Cooling agent outlet temperature in C

Condenser temp.

Condenser temperature in C

(up to TP Version 7.2.0)

Cooling medium inlet

temp. Heating agent inlet temperature in C

(from TP Version 7.3.0)

Cooling medium outlet

temp. Heating agent outlet temperature in C

(from TP Version 7.3.0)

Oil separator temp. Oil separator temperature in C

Injection Injection in %

Feedback Injection Feedback injection in %

Suction gas superheat Suction gas superheat in K

Interm. gas superheat Interm. gas superheat in K

Ref. high level Refrigerant upper level

Ref. low level Refrigerant lower level

Capacity LP Capacity low pressure in %

Capacity HP Capacity high pressure in %

Motor current Motor current in A

Motor speed Motor speed in rpm

Run hours Running hours

Start to start Start to start, remaining time between two starts of the compressor in sec.

Stop to start Stop to start timer, remaining time in sec.

Auto start delay Remaining time for auto start delay in sec.

unloaded Starting Unloaded start in s, remaining time

Motor feedback Motor feedback in s, remaining time

26 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Indication of actual values and delay times

GSC TP

Symbol Remark

Step time Step time in s, remaining time

Limit Time Limit Time in sec., remaining time.

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 27

Control Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

4 CONTROL

To call up this screen press the button + select "Control".

fig.15: Input and selection areas

Hint!

A numerical value input or a selective list opens after pressing the push button if the opera-

tion of the input and selection areas are possible.

4.1 Selective list "Operation mode"

Password

Remark

level

Operation Service (0) Compressor motor blocked 1

mode

Manual + Manual (1) Manual control via display

Manual + Auto (2) Manual start/stop via display and full automatic local

capacity control

Auto + Auto (3) Full automatic start/stop and local capacity control

Remote + HW (cont) (4) Start/stop and capacity demand via digital contacts

(hardware) from a remote master controller. The

control derives from the continuous +/- signals the

pulses for capacity (indirect).

Remote + HW (pulse) (5) Start/stop and capacity demand via digital contacts

(hardware) from a remote master controller. The

master also generates the +/- signals as pulses for

controlling the slide capacity directly.

Remote + HW (loc. SW) (6) Start/Stop from a remote master controller via digital

contacts (hardware). The control adjusts the output

depending on a local setpoint (display) and from this

setpoint also automatically switches the product ON/

OFF.

28 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Control

GSC TP

Password

Remark

level

Remote + HW (ext. SW) (7) Start/Stop from a remote master controller via digital

contacts (hardware). The control adjusts the output

depending on an external setpoint (analog input)

and from this setpoint also automatically switches

the package ON/OFF.

Remote + Net (cont) (8) Start/stop and capacity demand via network from a

remote master controller. The control derives from

the continuous +/- signals the pulses for controlling

the capacity (indirect).

Remote + Net (pulse) (9) Start/stop and capacity demand via network (MPI or

Profibus-DP) from a remote master controller. The

master also generates the +/- signals as pulses for

controlling the slide position directly.

Remote + Bus (loc. SW) (10) Start/stop from a central master controller via a bus

signal. The control adjusts the output depending on

a local setpoint (display) and from this setpoint also

automatically switches the product ON/OFF.

Remote + Bus (net. SW) (11) Start/stop from a central master controller via a bus

signal. The control adjusts the output depending on

an external setpoint sent externally via the network

and from this setpoint also automatically switches

the package ON/OFF.

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 29

Control Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

4.2 Selective list "Control on"

Control variable 1 is significant for setpoint 1

Control variable 2 is significant for setpoint 2

Password

Remark

level

Control- Suction pressure Automatic capacity control depends on suction pres- 2

led varia- sure.

bles

External temperature Automatic capacity control depends on external tem-

perature.

Discharge pressure Automatic capacity control depends on discharge

pressure.

Inlet temperature Automatic capacity control depends on inlet temper-

ature.

Outlet temperature Automatic capacity control depends on cooling

agent outlet temperature.

Network temperature Automatic capacity control depends on a tempera-

ture transferred via the network from the remote

master controller to the controller.

Coolant inlet temperature Automatic capacity control depends on condenser

inlet temperature.

Coolant outlet temperature Automatic capacity control depends on condenser

outlet temperature.

30 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Control

GSC TP

4.3 Selective list "Power return"

Password

Remark

level

Power Fault No automatic restart after power return 2

return

Warning Warning message only after power return

Automatic restart is possible (dependent on selected

operation mode)

4.4 Selective list "Network fault"

Parameter is only valid, if an operation mode is selected, that uses an exchange of Bussignals.

Password

Remark

level

Network Fault If a network fault occurs the product will be switched 2

fault off.

Auto + Auto (3) If a network fault occurs the operation mode is

switched to "3"

Remote + HW (cont) (4) If a network fault occurs the operation mode is

switched to "4"

Remote + HW (pulse) (5) If a network fault occurs the operation mode is

switched to "5"

Remote + HW (loc. SW) (6) If a network fault occurs the operation mode is

switched to "6"

Remote + HW (ext. SW) (7) If a network fault occurs the operation mode is

switched to "7"

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 31

Control Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

4.5 Control Parameters

Password

Compressor Remark Unit Range

level

Setpoint 1 Display of 1st setpoint C -75.0 ... +85.0 1

Setpoint 2 Display of 2nd setpoint C -75.0 ... +85.0 1

Neutral zone Neutral zone of capacity controller K 0.1 ... 10.0 1

Proportional zone Proportional zone of capacity controller K 2.0 ... 50.0 2

Correction P Zone Correction of proportional zone K -10.0 ... 10.0 2

For capacity decreasing only (+ in setpoint

direction / - from setpoint away)

Inlet/outlet diff. SW1 Temperature difference between inlet and K 0.0 ... 30.0 2

outlet temperatures at 100% capacity for the

1st setpoint

Inlet/outlet diff. SW2 Temperature difference between inlet and K 0.0 ... 30.0 2

outlet temperatures at 100% capacity for the

2nd setpoint

Capacity incr. min. minimum step time to increase capacity s 15 ... 600 1

Capacity incr. max. maximum step time to increase capacity s 15 ... 600 1

Capacity decr. min. minimum step time to decrease capacity s 15 ... 600 1

Capacity decr. max. maximum step time to decrease capacity s 15 ... 600 1

Auto start delay Length of delay in sec before automatic start s 1 ... 1800 1

up

Auto stop delay Length of delay in sec before automatic s 1 ... 1800 1

switch off

D -factor D-Factor, minimum temperature change K 0.0 ... 10.0 2

within 5 sec., without forced capacity change

in opposite direction.

This function is switched off if input equals

"0.0".

32 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Control

GSC TP

Password

Compressor Remark Unit Range

level

Pump down Switching on/off the pump down logic (DX 2

on/ off

Systems only)

Stop pressure After reaching this pressure the compressor bar (a) 0.3 ... 51.0 2

will be stopped.

Booster pressure Booster pressure bar (a) 0.3 ... 51.0 2

After reaching this pressure the booster com-

pressor will be enabled.

Chiller start Chiller start release value, based on the inlet C 1

-65.0 ... 65.0

temperature

Chiller stop Chiller stop value, based on the inlet tempera- C 1

-65.0 ... 65.0

ture

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 33

Compressor speed control Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

5 COMPRESSOR SPEED CONTROL

Hint!

To call up this screen press the button + select "Compressor speed control".

fig.16: Setting the compressor speed control

(figure varies from TP version 8.0.0)

Password

Title Remark Unit Range

level

Min speed Value of minimum speed rpm 0 ... 1800 2

Start speed Value of start speed rpm 0 ... 1800 2

Max speed Value of maximum speed rpm 0 ... 1800 2

Lim control deviation

Lim control deviation K 0.0 ... 25.5 2

(from TP Version 8.0.0)

Kp Gain factor of speed controller 0.01 ... 50.00 2

Ti 0.01 ...

I-factor of speed controller 2

320.00

Td D-factor of speed controller 0.01 ... 20:00 2

Step Speed control step size at manual operation rpm 1 ... 500 2

34 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Timer settings

GSC TP

6 TIMER SETTINGS

Hint!

To call up this screen press the button + select "Timer Settings".

fig.17: Timer Settings

Password

Title Remark Unit Range

level

Start to start (EHB) Start to start s 600A 1800 2

delay between two starts of the compressor

Stop to start Delay between stop and next start s 300A 1800 2

Oil diff. start Oil circuit alarm delay during start up s 1 ... 30 2

Oil diff. run Oil circuit alarm delay during running s 1 ... 30 2

unloaded Starting Time, unloaded compressor start-up s 20A 150 2

Motor feedback Motor start-up time s 1 ... 20A 2

Run hours Number of run hours h 0 ... 999999 8

Suction gas super- Monitoring time suction gas superheat s 5 ... 40 2

heat

Interm. gas superheat dTm alarm delay s 5 ... 40 2

Pump down Pump down delay s 5 ... 21600 2

Flow switch Delay of flow switch alarm s 1 ... 21600 2

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 35

Timer settings Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

Password

Title Remark Unit Range

level

Feedback condenser Delay of condenser and refrigerant pump s 1 ... 21600 2

feedback

Pump stop delay Stop delay of secondary refrigerant pump s 1 ... 21600 2

Oil return Oil return time s 1 ... 3600 2

Return delay Return delay following oil return s 1 ... 21600 2

Oil drain Oil drain, charging time s 1 ... 3600 2

Drain delay following Drain delay following charging s 1 ... 21600 2

charging

A = dependent on selected refrigerant and compressor type

Hint!

Press the button "Actual values" to display all remaining times of elapsed timers.

36 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Sensor values (limit values and sensor scaling)

GSC TP

7 SENSOR VALUES (LIMIT VALUES AND SENSOR SCALING)

Hint!

To call up this screen press the button + select "Sensor values".

fig.18: Sensor values

All values that can be assigned to a sensor can be set or changed in this screen.

Warning levels, limitations and injection level values must be entered as an offset to the alarm value without any

sign.

Overview of all possible sensor values

Password

Sensor Remark Unit Range

level

Suction Low alarm Alarm limit for minimum suc- bar (a) 0.30A ... 10.0A 3

pressure tion pressure

Warning Warning value "minimum suc- bar 0.00 ... 03:00 3

tion pressure" as an offset to

the alarm value

Limit Begin of the suction pressure bar 0.00 ... 03:00 3

limitation

enter value as an offset to the

alarm value

Force Begin of forced adjustment to bar 0.00 ... 03:00 3

minimum due to low suction

pressure

enter value as an offset to the

alarm value

Scale 4 mA bar (a) -3200 ... +3200 3

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 37

Sensor values (limit values and sensor scaling) Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

Overview of all possible sensor values

Password

Sensor Remark Unit Range

level

Scale 20 mA bar (a) -3200 ... +3200 3

Suction Alarm (max) n1 Input alarm limit for "maxi- bar (a) 0.30A ... 10.0A 3

pressure mum suction pressure" for

low speed

Alarm (max) n2 Input alarm limit for "maxi- bar (a) 0.30A ... 10.0A 3

mum suction pressure" for

high speed

Warning Warning value "maximum bar 0.00 ... 03:00 3

suction pressure" as an offset

to the alarm value

Suction gas Low alarm Input alarm limit for "minimum K 0.0A 25.0 3

superheat suction superheat"

Warning Input warning value "mini- K 0.0 ... 10.0 3

mum suction superheat" as

an offset to the alarm value

Suction tem- Scale offset K -3200 ... +3200 3

perature

Scale span % -3200 ... +3200 3

Intermediate Scale 4 mA bar (a) -3200 ... +3200 3

pressure

(two-stage Scale 20 mA bar (a) -3200 ... +3200 3

compressors

only)

Interm. gas Low alarm Input alarm limit for "minimum K 0.0 ... 25.0 3

superheat Intermediate superheat

(two-stage alarm"

compressors

only)

38 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Sensor values (limit values and sensor scaling)

GSC TP

Overview of all possible sensor values

Password

Sensor Remark Unit Range

level

Warning Input warning value "mini- K 0.00 ... 10.0 3

mum intermediate superheat

alarm" as an offset to the

alarm value

Interm temp Scale offset K -3200 ... +3200 3

LP

(two-stage Scale span % -3200 ... +3200 3

compressors

only)

Interm temp Scale offset K -3200 ... +3200 3

HP

(two-stage Scale span % -3200 ... +3200 3

compressors

only)

Discharge High alarm Input alarm limit for "maxi- bar (a) 3.0 ... 51.0A 3

pressure mum discharge pressure"

Warning Input warning value "maxi- bar 0.0 ... 5.0 3

mum discharge pressure" as

an offset to the alarm value

Limit Begin of the max. discharge bar 0.0 ... 5.0 3

pressure limitation

enter value as an offset to the

alarm value

Force Begin of forced adjustment to bar 0.0 ... 5.0 3

minimum due to high dis-

charge pressure

enter value as an offset to the

alarm value

Scale 4 mA bar (a) -3200 ... +3200 3

Scale 20 mA bar (a) -3200 ... +3200 3

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 39

Sensor values (limit values and sensor scaling) Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

Overview of all possible sensor values

Password

Sensor Remark Unit Range

level

Discharge High alarm Alarm limit for "maximum dis- C 0 ... 170A 3

temperature charge temperature"

Warning Input warning value "maxi- K 0 ... 50 3

mum discharge temperature"

as an offset to the alarm

value

Limit Begin of the max. discharge K 0 ... 50 3

temperature limitation

enter value as an offset to the

alarm value

Force Begin of forced adjustment to K 0 ... 50 3

minimum or maximum due to

high discharge temperature

(reaction depends on G.016)

enter value as an offset to the

alarm value

Scale offset K -3200 ... +3200 3

Scale span % -3200 ... +3200 3

Oil diff. pres- Low alarm Input alarm limit for "minimum bar 1.3A 10.0A 3

sure oil differential pressure"

Warning Input warning value "mini- bar 0.0 ... 5.0 3

mum oil differential pressure"

as an offset to the alarm

value

Oil pressure Scale 4 mA bar (a) -3200 ... +3200 3

Scale 20 mA bar (a) -3200 ... +3200 3

Crankcase Scale 4 mA bar (a) -3200 ... +3200 3

pressure

Scale 20 mA bar (a) -3200 ... +3200 3

40 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Sensor values (limit values and sensor scaling)

GSC TP

Overview of all possible sensor values

Password

Sensor Remark Unit Range

level

Oil tempera- Low alarm Input alarm limit for "minimum C 10A 90A 3

ture oil temperature"

Warning Input warning value "mini- K 0 ... 30 3

mum oil temperature" as an

offset to the alarm value

High alarm Alarm limit for maximum oil C 10A 90A 3

temperature

Warning Input warning value "maxi- K 0 ... 30 3

mum oil temperature" as an

offset to the alarm value

Scale offset K -3200 ... +3200 3

Scale span % -3200 ... +3200 3

Oil separator Scale offset K -3200 ... +3200 3

temp.

Scale span % -3200 ... +3200 3

Motor cur- High alarm Input alarm limit for "maxi- A 0 ... 1500 3

rent mum motor current"

Warning Input warning value "maxi- A 0 ... 200 3

mum motor current" as an off-

set to the alarm value

Limit Begin of the motor current A 0 ... 200 3

limitation

enter value as an offset to the

alarm value

Force Begin of forced adjustment to % 0 ... 100 3

minimum due to high motor

current

enter value:

0 % = OFF

100% = linear interde-

pendence of motor current

and compressor capacity

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 41

Sensor values (limit values and sensor scaling) Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

Overview of all possible sensor values

Password

Sensor Remark Unit Range

level

Scale 4 mA A -3200 ... +3200 3

Scale 20 mA A -3200 ... +3200 3

Motor speed Low alarm Input alarm limit for "minimum min-1 400A 1800A 3

motor speed"

High alarm Input alarm limit for "maxi- min-1 400A 1800A 3

mum motor speed"

Scale 4 mA min-1 -3200 ... +3200 3

Scale 20 mA min-1 -3200 ... +3200 3

Motor speed Scale 4 mA min-1 -3200 ... +3200 3

setpoint

Scale 20 mA min-1 -3200 ... +3200 3

Capacity Minimum Input limit value for capacity % 0A 100 1

to activate the auxiliary output

(min. cap.), if the capacity

under-runs this value

Maximum Input limit value for capacity % 0 ... 100 1

to activate the auxiliary output

(max. cap.), if the capacity

exceeds this value

External tem- Scale 4 mA C -3200 ... +3200 3

perature

Scale 20 mA C -3200 ... +3200 3

Ext. setpoint Scale 4 mA C -3200 ... +3200 3

HW

Scale 20 mA C -3200 ... +3200 3

42 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Sensor values (limit values and sensor scaling)

GSC TP

Overview of all possible sensor values

Password

Sensor Remark Unit Range

level

Inlet temper- Scale offset K -3200 ... +3200 3

ature

Scale span % -3200 ... +3200 3

Coolant out- Scale offset K -3200 ... +3200 3

let tempera-

ture Scale span % -3200 ... +3200 3

External tem- Low alarm Alarm limit for "minimum C -65.0 ... 65.0 3

perature or external temperature"

outlet tem-

perature Warning Input warning value "mini- K 0.0 ... 10.0 3

mum external temperature"

as an offset to the alarm

value

Limit Begin of the temperature limi- K 0.0 ... 10.0 3

tation

enter value as an offset to the

alarm value

Force Begin of forced adjustment to K 0.0 ... 10.0 3

minimum due to low tempera-

ture

enter value as an offset to the

alarm value

Condenser Scale offset K -3200 ... +3200 3

temp.

(up to TP Ver- Scale span % -3200 ... +3200 3

sion 7.2.0)

Cooling Scale offset K -3200 ... +3200 3

medium inlet

temp. Scale span % -3200 ... +3200 3

(from TP Ver-

sion 7.3.0)

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 43

Sensor values (limit values and sensor scaling) Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

Overview of all possible sensor values

Password

Sensor Remark Unit Range

level

Cooling Scale offset K -3200 ... +3200 3

medium out-

let temp. Scale span % -3200 ... +3200 3

(from TP Ver-

sion 7.3.0)

Injection Scale 4 mA % -3200 ... +3200 3

feedback

Scale 20 mA % -3200 ... +3200 3

Injection set- Scale 4 mA % -3200 ... +3200 3

point

Scale 20 mA % -3200 ... +3200 3

44 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Sequence control

GSC TP

8 SEQUENCE CONTROL

Hint!

To call up this screens press the button + select "Options" and "Sequence control".

fig.19: Sequence control settings

8.1 Actual values

Title Remark Unit

Start-up sequence Current start/ stop sequence of active sequence control

Auto start delay Remaining time, start delay for next machine s

Switch delay Remaining time, switch delay machine s

Auto stop delay Remaining time, stop delay for last machine s

Network fault Remaining time until communication error s

connections Status of all MPI users of sequence control

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 45

Sequence control Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

8.2 Settings

Pass-

Title Remark Unit Range word

level

Operation Off Without sequence control 1

mode

Slave Control is defined as slave

Master Control is defined as master

Sequence num- Start-up sequence number at fixed start-up sequence. 1 ... 9 1

ber The sequence number is unique and must always be specified.

yes Fixed start-up sequence definition

Fixed sequence 1

Start-up sequence depends on the number

no

of run hours

Minimum Definition of the minimum compressor capacity, % 0 ... 1

value must correspond to capacity steps 100

Part load Definition of the compressor part load, % 0 ... 1

value must correspond to capacity steps 100

Maximum Definition of the maximum compressor capacity % 0 ... 1

100

Master process yes Send master process value to all slaves 1

value

no Each control uses its own process value

Auto start Auto start delay for the subsequent compressor (control devia- s 1 ... 1

delay tion larger than neutral zone) 3600

Switch delay Switch delay of control routine, e.g. forced adjustment to part s 1 ... 1

load or switching not required load off 1800

46 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Sequence control

GSC TP

Pass-

Title Remark Unit Range word

level

Auto stop delay Auto stop delay for the last current compressor (control devia- s 1 ... 1

tion smaller than neutral zone) 3600

Neutral zone Neutral zone for switching the next compressor on/ off. K 0 1 ... 1

Value must be equal or larger than the value of the local control 10.0

neutral zone, setted in the "Control" menu.

1 depending on the neutral zone under "Control"

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 47

Configuration Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

9 CONFIGURATION

Hint!

To call up this screens press the button + select "Configuration".

fig.20: Configuration

Hint!

The configutation is carried during the installation of the refrigerating plant only.

9.1 Type

Value Remark Selection Password level

Type Machine type selection Package 3

Ingenium

Ing. Compact

FX GC PP

FX GC LP

FX GC VP

DX Chiller

Ingenium Plus

(from TP Ver-

sion 7.1.0)

Ing. Comp. Plus

(from TP Ver-

sion 7.1.0)

BluGenium

48 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Configuration

GSC TP

9.2 Refrigerant

Value Remark Selection Password level

Refrigerant Refrigerant selection R22 3

R134a

R404A

R507

R717

R723

R744

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 49

Configuration Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

9.3 Compressor

Value Remark Selection Password level

Compr. frame size Compressor type selection Grasso 5 HP 3

Grasso 6

Grasso 7 S

Grasso 7 SW

Grasso 8 S

Grasso 8 SW

Grasso 9

Grasso 10

Grasso 11

Grasso 12

Grasso 12E

Grasso V (to TP

Version 7.3.0)

Grasso V-L

(from TP Ver-

sion 8.0.0)

Grasso V-M

(from TP Ver-

sion 8.0.0)

F14 1166

F14 1166W

F14 1366

F14 1366W

F16 1751

F16 1751W

F16 2051

F16 2051W

LP cylinder Enter the numbers of low pressure 1 ... 12 3

cylinders

HP cylinder Enter the numbers of high pressure 0 ... 12 3

cylinders

min. Capacity Enter the minimum capacity in % 0% ... 100% 3

(0% = standard)

additional Capacity Select "Off" (standard compressor) On / Off 3

and "On" (additional capacity steps

exist)

Booster Select between booster operating On / Off 3

"On" and "Off"

50 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Configuration

GSC TP

9.4 Coolant injection

Value Remark Selection Password level

Coolant injection Select between "LP" (Low pres- LP 3

sure) and "HP" (High Pressure) HP

9.5 Valve type

Password

Value Remark Selection

level

Valve type Select type of valve no 15-2 25-A 65-B 3

10-1 15-3 25-B 0.16N

10-2 15-4 32-A 0.40N

10-3 20-2 32-B 1.00N

10-4 20-3 40-A 2.50N

10-5 20-4 40-B 6.30N

10-6 20-5

50-A

10-7 20-A 50-B

10-8 20-B

10-8V 20-C

9.6 Motor valve suction line

Value Remark Selection Password level

Motor valve suction line Select without (Off) and with On 3

(On) motor valve Off

9.7 Nominal speed

Value Remark Selection Password level

Nominal speed Enter nominal speed in rpm 400 ... 1800 3

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 51

Configuration Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

9.8 Auxiliary output

Password

Value Remark Selection

level

Freely programmed Output Select the function of auxiliary Standby 2

output Starting

Limit

min. Capacity

max. Capacity

Neutral

Warning

More cap. +

9.9 Frequency inverter

Value Remark Selection Password level

Frequency inverter Select without (Off) and with On 3

(On) frequency inverter Off

9.10 Motor current

Value Remark Selection Password level

Motor current Select between "without (off) and On 2

"with (on) (sensor available) Off

9.11 Crankcase pressure

Value Remark Selection Password level

Crankcase pressure Select between "without (off) and On 2

"with (on) (sensor available) Off

9.12 Suction temperature

Value Remark Selection Password level

Suction temperature Select between "without (off) and On 2

"with (on) (sensor available) Off

52 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Configuration

GSC TP

9.13 Oil temperature

Value Remark Selection Password level

Oil temperature Select between "without (off) and On 2

"with (on) (sensor available) Off

9.14 Oil separator temperature

Value Remark Selection Password level

Oil separator temp. Select without (Off) and with On 2

(On) (Oil separator available) Off

9.15 Cooling agent inlet temperature

Value Remark Selection Password level

Cooling agent inlet temperature Select between "without (off) and On 2

"with (on) (sensor available) Off

9.16 Cooling agent outlet temperature

Value Remark Selection Password level

Cooling agent outlet temperature Select between "without (off) and On 2

"with (on) (sensor available) Off

9.17 Coolant inlet

Value Remark Selection Password level

Coolant inlet Select between "without (Off) and On 2

"with (On) (sensor available) Off

9.18 Coolant out temp

(from TP Version 7.3.0)

Value Remark Selection Password level

Coolant out temp Select between "without (Off) and On 3

"with (On) (sensor available) Off

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 53

Configuration Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

9.19 External setpoint analog (HW)

Value Remark Selection Password level

External setpoint analog (HW) Select between "without (Off) and On 2

"with (On) (sensor available) Off

9.20 External temperature

Value Remark Selection Password level

External temperature Select between "without (Off) and On 2

"with (On) (sensor available) Off

9.21 Communication

Value Selection Remark Password level

Communication MPI Select for "MPI communication" 3

Profibus Select for Profibus communication

is installed

Modbus RTU Select for Modbus RTU communi-

cation is installed

Modbus TCP Select for Modbus TCP communi-

cation is installed

9.22 Thermomaster

(from TP Version 7.0.0)

Value Selection Remark

without Thermomaster or evaluation carried out via

off/external

the Alfa 53 module

Thermomaster

integrated Evaluation carried out in the GSC

9.23 Acknowledgement configuration

Value Selection Remark Password level

Acknowledgement configuration Accept Select to accept the changed con- 3

figuration

Cancel Select to restore the configuration

54 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Password

GSC TP

10 PASSWORD

Hint!

See chapter "Password level".

To call up this screen press the button + select "Password".

fig.21: Password

(from TP version 6.2.0, figure varies)

Use this screen to log on to the different password levels.

Password level - factory setting

Password level Remark Password factory setting

1 Operator level 1 1000

2 Operator level 2 2000

3 Service ****

4 Administrator ******

The password levels are hierarchically structured. The password level "4 (Administrator)" is the highest level.

Change passwords of lower levels by using the active password level and pressing the "Edit" button.

The padlock symbol indicates the active password level.

Defined settings are released or blocked for each password level.

After 10 minutes of inactivity an automatic log-out is performed.

Pressing the button returns to the previous screen (from TP version 6.2.0).

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 55

Date and time Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

11 DATE AND TIME

Hint!

To call up this screen press the button + select "Date / Time".

fig.22: Date/Time

Date and time are required to display alarm messages in the alarm histogram correctly.

Applying the new values cause the automatic transfer of date and time to the control.

Confirm by pressing the display area "accept".

56 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Language

GSC TP

12 LANGUAGE

Hint!

To call up this screens press the button + select "Language".

fig.23: Language

All screens are multilingual. The screen can be displayed in native language as required.

Switching over between the blue coloured language selection is possible. The flag symbol identifies the activated

language.

Hint!

Changing the language does not require a restart of the display, except for the Chinese and

Japanese languages.

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 57

Start up manager Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

13 START UP MANAGER

fig.24: Start up manager

When the power is switched on, the Touch Panel starts and the "Start up manager" screen appears for approx.

10 seconds.

After that, the screen changes into the first screen layout of the project.

Hint!

Push "Select" "Browse" to start the project manually in case the project doesn't start

automatically.

If so, please contact GEA Refrigeration Germany GmbH, Service department!

58 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Alarms and Warnings

GSC TP

14 ALARMS AND WARNINGS

14.1 Alarms

14.1.1 Alarm window

fig.25: Alarm report

Hint!

If an impermissible operating status occurs, the product is stopped immediately. The display

will have an alarm window with report on the cause of the stop.

The alarm banner displays the cause for the alarm as well as the total number of active warn-

ings and alarms. The banner closes after pressing the red button, but the alarm is not yet

acknowledged!

At the same time a red LED will appear in the event push button in the navigation bar .

The LED provides the same function like the red indicator light at the control cabinet.

An alarm switches off the system.

The alarm overview will be shown automatically after closing the alarm banner.

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 59

Alarms and Warnings Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

14.1.2 Alarm overview

fig.26: Alarm overview

This screen shows all active alarms and warnings. Press the button to acknowledge (reset) alarms and

warnings. The border of the button flashes until an alarm or a warning is acknowledged.

If an alarm is acknowledged all inactive alarms and warnings will be deleted out of the list. Following only active

alarms and warnings will be displayed in the alarm overview.

The button appears instead of the button when switching to the alarm overview by closing the alarm

window.

Press the button to return to the previous screen (from TP version 6.2.0)

14.1.3 Alarm histogram

Activate the push button to select the alarm histogram.

fig.27: Alarm histogram

This screen shows the last 255 alarms and/or warnings with alarm numbers and matching date/ time information.

To see the plain text of the alarm number, select the alarm by finger touch directly on the item and press the

button then.

60 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Alarms and Warnings

GSC TP

Each alarm offers 3 states (actions):

Alarm ON Begin of the alarm (coming)

Alarm RESET Acknowledge the alarm (acknowledging)

Alarm OFF Begin of the alarm (gone)

Hint!

The alarm RESET and alarm OFF will always appier together within several seconds. This is

normal.

14.1.4 Overview of all possible alarm messages

Hint!

Not indicated alarm numbers are not used!

Display Remark

Alarm 000 No alarm messages active

Alarm 002 Wire failure coolant inlet temperature

Alarm 003 Wire failure condenser air temperature

Alarm 004 Separator level too high (evaporator)

Alarm 005 Refrigerant leak detected is active

Alarm 008 Feedback flow switch too late

Alarm 010 Wire failure external temperature sensor

Alarm 011 Wire failure external setpoint

Alarm 012 Wire failure outlet temperature (evaporator)

Alarm 013 Wire failure inlet temperature (evaporator)

Alarm 025 Low outlet temperature (evaporator)

Alarm 026 Separator level too high. Please check the injection valve.

Alarm 027 Emergency stop via network

Alarm 028 Faulty IO module

Alarm 030 MPI network failure, Modbus or Profibus DP communication

Alarm 032 Selected refrigerant is not available in the memory

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 61

Alarms and Warnings Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

Display Remark

Alarm 049 Wire failure crankcase pressure sensor

Alarm 050 Oil differential pressure too low

Alarm 051 Max. Differential pressure (Pk-Po)

Alarm 052 Max. Pressure ratio (Pk-Po)

Alarm 053 Suction temperature too low

Alarm 054 Suction temperature wire failure

Alarm 055 Superheat suction gas temperature too low

Alarm 057 Suction pressure too low

Alarm 058 Suction pressure too high

Alarm 060 Max. Discharge pressure

Alarm 061 Wire failure discharge pressure sensor

Alarm 063 Wire failure interm pressure sensor

Alarm 064 Wire failure oil pressure sensor

Alarm 065 Motor current too high

Alarm 066 Wire failure motor current sensor

Alarm 068 Motor speed too high

Alarm 069 Wire failure motor speed sensor

Alarm 070 Emergency stop active

Alarm 071 Motor feedback too late (start-up)

Alarm 072 Motor protection device active

Alarm 074 Max. Intermediate temperature LP

Alarm 075 Wire failure intermediate temperature LP

Alarm 076 Wire failure intermediate temperature HP

Alarm 077 Intermediate superheat too low

62 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Alarms and Warnings

GSC TP

Display Remark

Alarm 078 Oil temperature too low

Alarm 080 Wire failure oil temperature sensor

Alarm 081 Selected compressor is not valid with selected refrigerant

Alarm 082 Selected compressor is not available in the memory

Alarm 083 Configuration of compressor is not valid

Alarm 084 Motor running without start command

Alarm 089 Exceeded max (Tk - To)

Alarm 090 Cylinder head temperature monitoring active

Alarm 091 Motor feedback missing during operation

Alarm 092 Liquid in compressor! Discharge temperature LP too low

Alarm 093 Compressor heating! Discharge temperature LP too high

Alarm 094 Discharge temperature HP too low

Alarm 095 Discharge temperature HP too high

Alarm 096 Max. pump down time elapsed

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 63

Alarms and Warnings Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

14.2 Warnings

14.2.1 Warning banner

fig.28: Warning message

Hint!

The warning banner appears after the occurrence of a warning. The banner displays the cause

for the warning. The banner displays the cause for the warning as well as the number of all

active warnings and alarms.

The window closes after pressing the yellow warning symbol, but the warning is not yet

acknowledged.

An alarm and warning overview (see alarms) is automatically displayed after closing the warn-

ing banner. The warning can be acknowledged in the alarm overview only.

All warnings are acknowledged automatically as soon as the cause for the warning not longer

exists.

At the same time a yellow LED will appear in the event push button in the navigation bar

.

The LED provides the same function like the yellow indicator light at the control cabinet.

A warning does NOT cause switching off the unit!

64 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Alarms and Warnings

GSC TP

14.2.2 Overview of all possible warning messages

Hint!

Not indicated warning numbers are not used!

Display Remark

Warning 033 Heater oil return system faulty

Warning 034 Wire failure oil separator temperature

Warning 036 Injection valve feedback too late

Warning 038 Feedback flow switch cooling agent circuit too late

Warning 039 Condenser feedback too late

Warning 040 Wire failure injection valve feedback

Warning 041 PLC power supply was interrupted: restart

Warning 042 Wire failure condenser air temperature

Warning 043 PLC operation mode changed

Warning 044 Selection not permitted.

Warning 045 Network failure: operation mode changed

Warning 046 MPI sequence control network failure

Warning 047 Separator level too high

Warning 048 Capacity limitation active

Warning 098 High discharge temperature

Warning 099 Intermediate temperature LP too high

Warning 107 High discharge pressure!

Warning 108 Intermediate pressure too high

Warning 122 No motor current, motor not running

Warning 210 Pump feedback too late

Warning 211 Feedback fan step 1 too late

Warning 212 Discharge temperature HP too low

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 65

Alarms and Warnings Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

Display Remark

Warning 213 Motor protection pump motor

Warning 214 Motor protection fan step 1

Warning 215 Motor protection fan step 2

Warning 216 Water container level too low

Warning 224 Motor valve feedback too late (Open)

66 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Thermomaster

GSC TP

15 THERMOMASTER

(from TP Version 6.1.0 / control for products with 2 reciprocating compressors)

(from TP Version 7.0.0 / control for products with 1 reciprocating compressor)

Hint!

To call up this screen press the button + select "Options" and "Thermomaster".

The "Thermomaster" button is only active in the options screen when activated in the Thermo-

master configuration menu (select "integrated).

The Thermomaster integrated in the GSC TP communicates with the GSC via Modbus RTU.

For the communication to work, the parameters for Modbus RTU communication must be configured in the serv-

ice menu as follows:

Parameter Value

Modbus: Baudrate 19200

Modbus: Parity 2 (even)

Modbus: Data length 3 (8 Bit)

Modbus: Data length 1 (1 Bit)

Hint!

With a Thermomaster integrated in the GSC TP, external communication via Modbus RT is not

possible.

fig.29: Thermomaster (product-dependent variations possible)

All possible 12 cylinders are displayed on the Thermomaster screen.

Cylinders, which are not available due to compressor selected, are grey and not monitored.

All monitored cylinders appear in colour.

The current and maximum temperature can be read for each available cylinder.

The maximum temperature can be individually parameterised for each available cylinder (password level 3).

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 67

Thermomaster Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

If the temperature of a cylinder exceeds the maximum temperature, the GSC TP goes into the failure condition.

The cylinder, whose temperature has caused the fault becomes red and remains red until the cylinder tempera-

ture falls below the maximum temperature.

If there is a wire break in a temperature sensor, the GSC TP goes into the failure condition. The cylinder in

whose sensor there is a wire break, becomes red and an icon representing wire break appears in place of the

current temperature.

fig.30: Wire break (product-dependent variations possible)

If the "Alarm" button is pressed, the temperature at the time of the last Thermomaster failure are displayed

instead of the current temperatures.

The current temperatures are displayed again after 60 seconds or by pressing the "Current" button.

fig.31: Data at the time of the last failure (product-dependent variations possible)

A hint (in English only) regarding the communication between the Thermomaster and the GSC TP is displayed at

the bottom right in the "Thermomaster" figure. In case of a communication error, the GSC TP goes into fault con-

dition.

68 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Compressor maintenance

GSC TP

16 COMPRESSOR MAINTENANCE

(from TP Version 6.2.0 / control for products with 2 reciprocating compressors)

(from TP Version 9.0.0 / control for products with 1 reciprocating compressor)

The maintenance intervals are calculated only if "Grasso V-L" or Grasso "V-M" is selected as the compressor

frame size in the configuration menu.

Press the button to go to the maintenance menu.

Hint!

The is found on the Service 1 screen. If an inspection is due within the next 30 days, the

button appears instead of the button.

16.1 Maintenance intervals

fig.32: Display of the maintenance intervals (product-dependent variations possible)

The run hours, the age of the compressor (time since commissioning) and the hours to the next inspection are

displayed.

16.2 Average values

fig.33: Average values (product-dependent variations possible)

GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014 69

Compressor maintenance Operating Manual | for Chiller/ Packages with one Reciprocating Compressor

GSC TP

The current and the average values over the last 10, 100,1000 and the total hours of the suction temperature

(Tsuc), discharge temperature (Tdis), oil temperature (Toil), speed (Rpm) and the number of compressor starts

(Starts) are displayed.

16.3 History

fig.34: History (product-dependent variations possible)

The history shows the inspections which have been carried out. The inspection of unit type 0 indicates the time

of start-up. If an inspection was not carried out then this is automatically entered into the history after 2000

hours. In the "type" column this inspection receives the "X" in addition (e.g: XA or XB).

16.4 Pending inspections

The appearance of the button instead of the button indicates that an inspection is due within the next

30 days. The symbol also appears on the maintenance intervals screen.

To enter performed maintenance in the history, it is necessary to first login with the service password. The per-

formed inspection is selected in the maintenance intervals menu and the performance confirmed by pressing the

button. A prompt appears as to whether the maintenance has actually been carried out. Confirming with

OK enters the maintenance in the history.

16.5 Maintenance settings

Press the button to go to the maintenance screen. (Only with a logged-in service password)

If the "Calculation active" parameter is deactivated then the calculation of service intervals will still be carried out.

However, there is no hint regarding an upcoming inspection and it is only possible to change over to the mainte-

nance menu with a logged-in service password.

70 GEA Refrigeration Germany GmbH | E_881511_6 | Generated 20.11.2014

Operating Manual | for Chiller/ Packages with one Reciprocating Compressor Compressor maintenance

GSC TP

fig.35: Maintenance settings (product-dependent variations possible)

16.5.1 Reset