Beruflich Dokumente

Kultur Dokumente

O-P20 Broken Glass Incident

Hochgeladen von

Tinny SumardiCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

O-P20 Broken Glass Incident

Hochgeladen von

Tinny SumardiCopyright:

Verfügbare Formate

BROKEN GLASS INCIDENT

STANDARD OPERATING PROCEDURE Form O-P20

Page 1 of 3

Issued on: Version No: 1 Revised:

Issued by: Supersedes:

PURPOSE: This procedure applies when an incident of broken glass is

discovered within the plant (all areas except the offices). Broken glass is an

extremely dangerous foreign material and any incident involving it must be

investigated thoroughly.

PERSON MONITORING

FREQUENCY CORRECTIVE ACTIONS RECORDS

RESPONSIBLE ACTIVITY

When findings deviate from

written standards the QA

designate will document

findings on the Daily / Monthly

GMP Audit Form and notify the

Daily GMP General Manager of the Daily GMP Audit,

Audit, Monthly deviation. Monthly GMP

According to

GMP Audit, Audit,

QA Designate, Audit

Daily Cleaning Short term action will be Daily Cleaning &

Cleaning staff Schedule,

& Sanitation initiated and recorded on the Sanitation

As Required

Checklists Daily / Monthly GMP audit Checklists

form. Long term action

required, will be discussed by

management and corrective

actions / responsibilities and

time frames will be agreed and

documented.

EQUIPMENT & CHEMICALS: Broom, brush, dustpan, Hold Tags.

NOTE: Broom & dustpan labeled FOR GLASS CLEANUP ONLY located in

the Janitors rooms

PROCEDURE DESCRIPTION:

1. In the event of an incident involving broken glass anywhere in the plant,

the immediate area must be secured so that glass fragments are not

inadvertently transferred to other areas of the facility.

2. The person discovering the broken glass must stop their work (shut down

equipment if necessary) and notify the Production Manager, Production

Supervisor or Quality Control Manager or Quality Assurance Technician

immediately.

3. The Manager, Supervisor or Technician will determine the risk to the

operations and how to proceed with cleaning.

BROKEN GLASS INCIDENT

STANDARD OPERATING PROCEDURE Form O-P20

Page 2 of 3

Issued on: Version No: 1 Revised:

Issued by: Supersedes:

4. If a metal-halide or florescent bulb falls from its fixture, the radius of risk is

assumed to be double the height of the fixture above the floor. For

example, if a bulb drops 10 feet, the minimum area to be secured should

be a circle with a 20-foot radius. The person investigating may broaden

the area of risk at their discretion. If broken glass is discovered in contact

with food ingredients received into the plant, a complete shutdown of all

operations using that ingredient must occur immediately.

5. If glass is broken atop a packing line, the line must be shut down

immediately and the following steps taken:

a. All personnel are to stop working on the line affected. Examine your

clothing and hair coverings for fragments of glass (if necessary).

Change your uniform if you suspect contamination with glass particles.

b. With the assistance of an Investigator (Supervisor, Q.C. etc.) tag all

finished goods, packaging materials and bags / containers / totes of

ingredients affected with a HOLD tag (see HOLD procedure). Remove

these to the hold area.

c. Clean the line from the top and move downward, removing as much of

the visible fragments as possible. Do not sweep large, visible fragments

onto the floor where they break into smaller pieces collect in a

dustpan.

d. Quality Control will examine all materials on HOLD and decide

disposition. Any material that is suspect is to be disposed of as non-food

grade scrap.

e. The investigator is to examine the packing line and ensure that the

sanitation steps were adequate.

f. The investigator is to complete an Incident form and copy to the

Operations and Quality Assurance managers.

6. If glass is discovered in contact with food product or food-contact

materials the following steps must be taken:

BROKEN GLASS INCIDENT

STANDARD OPERATING PROCEDURE Form O-P20

Page 3 of 3

Issued on: Version No: 1 Revised:

Issued by: Supersedes:

a. All personnel are to stop working on the line affected (if applicable).

b. With the assistance of an Investigator (Supervisor, Q.C. etc.) tag all

materials affected with a HOLD tag (see HOLD procedure). Remove

these to the hold area.

c. Quality Control will examine all materials on HOLD and decide

disposition. Any material that is suspect is to be disposed of as non-food

grade scrap.

c. The investigator is to complete an Incident form and copy to the

Operations and Quality Assurance managers.

7. If glass is discovered in the facility where no risk to food or food-

contact surfaces is suspected, it should be cleaned up immediately

and the incident recorded in the Glass & Brittle Plastics Breakages

Log

Das könnte Ihnen auch gefallen

- SOP Receiving and Storage of Raw MaterialsDokument2 SeitenSOP Receiving and Storage of Raw MaterialsBadethdeth1290% (10)

- Good GMP PolicyDokument5 SeitenGood GMP Policyglen_Noch keine Bewertungen

- Environmental Monitioring Risk AssessmentDokument4 SeitenEnvironmental Monitioring Risk AssessmentGaganpreet KaurNoch keine Bewertungen

- Glass and Brittle Plastics RegisterDokument3 SeitenGlass and Brittle Plastics RegisterAdnan Meghani100% (3)

- Glass Policy SampleDokument1 SeiteGlass Policy SamplePreethi Janani100% (1)

- Chemical Control ProgramDokument3 SeitenChemical Control Programkyunjae Jetomo100% (5)

- SOP Storage and Handling of ChemicalsDokument2 SeitenSOP Storage and Handling of ChemicalsAdenike Majekodunmi100% (1)

- Metal Detection: Quality Systems ManualDokument8 SeitenMetal Detection: Quality Systems ManualNaizil Kareem100% (1)

- QM 6.9.3c Glass & Brittle Material Breakage ProcedureDokument2 SeitenQM 6.9.3c Glass & Brittle Material Breakage ProcedureDaniel Modica100% (2)

- 3 Sample GMP TemplateDokument4 Seiten3 Sample GMP TemplateJulius MuhimboNoch keine Bewertungen

- Good Manufacturing Practices PolicyDokument3 SeitenGood Manufacturing Practices PolicyJon Mark100% (1)

- Quality Manual: Pt. Ani Mitra Jaya Frozen ChepalopodDokument1 SeiteQuality Manual: Pt. Ani Mitra Jaya Frozen ChepalopodMia AgustinNoch keine Bewertungen

- Good GMP PolicyDokument4 SeitenGood GMP PolicyAgnes Alulod BuenaaguaNoch keine Bewertungen

- Final - Rigid Plastic - May 6 2010Dokument30 SeitenFinal - Rigid Plastic - May 6 2010Abdul Mueed100% (1)

- Safe System Of Work A Complete Guide - 2020 EditionVon EverandSafe System Of Work A Complete Guide - 2020 EditionNoch keine Bewertungen

- Rule 8. Fire Safety Enforcers Chapter 1. Qualifications of Fire Safety Enforcers Division 1. Minimum RequirementsDokument13 SeitenRule 8. Fire Safety Enforcers Chapter 1. Qualifications of Fire Safety Enforcers Division 1. Minimum Requirementspatitay036817Noch keine Bewertungen

- 21 Century Mind ControlDokument7 Seiten21 Century Mind ControltrswartzNoch keine Bewertungen

- Glass Policy: Ameliorating This Policy Applies To All Glass and Hard Plastic Used On Site, Including Lights, and WindowsDokument3 SeitenGlass Policy: Ameliorating This Policy Applies To All Glass and Hard Plastic Used On Site, Including Lights, and WindowsMATTHEW MUNGAI100% (3)

- QSM Glass PolicyDokument3 SeitenQSM Glass PolicyAdmin QC100% (2)

- Glass and Brittle Plastics Breakage Incident ReportDokument2 SeitenGlass and Brittle Plastics Breakage Incident ReportCassilda Carvalho100% (1)

- Glass Breakage SOP-SatyaDokument5 SeitenGlass Breakage SOP-SatyaSRI VYJAYANTHI QANoch keine Bewertungen

- GMP ChecklistDokument12 SeitenGMP ChecklistMikkaelaNoch keine Bewertungen

- Glass Policy & Hard Plastic PolicyDokument2 SeitenGlass Policy & Hard Plastic PolicySRI VYJAYANTHI QANoch keine Bewertungen

- Prerequisite Program Our CompanyDokument29 SeitenPrerequisite Program Our CompanysridharanNoch keine Bewertungen

- QA 5.17 Handling, Storage and DeliveryDokument2 SeitenQA 5.17 Handling, Storage and DeliveryangeldrandevNoch keine Bewertungen

- Glass and Plastic Breakage PolicyDokument1 SeiteGlass and Plastic Breakage PolicyKriston EdwardNoch keine Bewertungen

- Foreign Material Control PolicyDokument5 SeitenForeign Material Control Policymonik manuelNoch keine Bewertungen

- Sop Gen 18Dokument3 SeitenSop Gen 18cervantessejNoch keine Bewertungen

- GMP's For Ice MakingDokument6 SeitenGMP's For Ice MakingmailmeaeNoch keine Bewertungen

- Haccp PDFDokument11 SeitenHaccp PDFKhaled SaidNoch keine Bewertungen

- 38-SOP-Layout of Work Place and PremisesDokument4 Seiten38-SOP-Layout of Work Place and Premisesarun100% (1)

- Waste Management SOPDokument30 SeitenWaste Management SOPEtta JeneeNoch keine Bewertungen

- Finished ProductDokument4 SeitenFinished ProductDilip ChaudharyNoch keine Bewertungen

- MORL-IMS-POL-001 Quality and Food Safety POLICYDokument1 SeiteMORL-IMS-POL-001 Quality and Food Safety POLICYPeter Osundwa Kiteki50% (2)

- FMCQMS-002 Prerequisite ProgramDokument4 SeitenFMCQMS-002 Prerequisite Programveejee tangalin100% (1)

- Bodily Fluids Spillage: Standard Operating ProcedureDokument5 SeitenBodily Fluids Spillage: Standard Operating ProcedureLinda Setya Wati100% (1)

- Haccp ManualDokument51 SeitenHaccp ManualJack Mata100% (2)

- Pest Control Service ChecklistDokument1 SeitePest Control Service ChecklistMustafa & Kamal Ashraf Trading Co. LLCNoch keine Bewertungen

- Food Defense PlanDokument22 SeitenFood Defense PlanJorge Gregorio SeguraNoch keine Bewertungen

- Wood PolicyDokument1 SeiteWood PolicyMATTHEW MUNGAINoch keine Bewertungen

- Hazardous Substances & Dangerous Goods WHSPRO-007 CMDokument7 SeitenHazardous Substances & Dangerous Goods WHSPRO-007 CMJason McIntoshNoch keine Bewertungen

- Food Defense Self-Assessment FormDokument4 SeitenFood Defense Self-Assessment FormLynn GeiseNoch keine Bewertungen

- The Food Safety Enhancement Program Approach To A Preventive Control Plan - Canadian Food Inspection AgencyDokument39 SeitenThe Food Safety Enhancement Program Approach To A Preventive Control Plan - Canadian Food Inspection AgencyAndreiNoch keine Bewertungen

- 33-SOP-Measures For Prevention of Cross ContaminationDokument2 Seiten33-SOP-Measures For Prevention of Cross ContaminationarunNoch keine Bewertungen

- Recall Plan Example PAGE 1 of 12 Plant Name: Issue Date Address: SupersedesDokument12 SeitenRecall Plan Example PAGE 1 of 12 Plant Name: Issue Date Address: SupersedesDiana BlueseaNoch keine Bewertungen

- A Food Safety Approach For Suppliers To The Food IndustryDokument23 SeitenA Food Safety Approach For Suppliers To The Food IndustryMasthan GM100% (1)

- Sample Chemical Management PlanDokument2 SeitenSample Chemical Management PlansimsonNoch keine Bewertungen

- Transport and Logistics Standard Operating ProceduresDokument3 SeitenTransport and Logistics Standard Operating ProceduresHaresh B. RaneNoch keine Bewertungen

- Moisture SOPDokument2 SeitenMoisture SOPMosharaf Ripon100% (1)

- 4.2 Understanding Interested Parties NeedsDokument3 Seiten4.2 Understanding Interested Parties NeedsYen Trang Vo NhiNoch keine Bewertungen

- RSOP1 Health and Personal HygieneDokument3 SeitenRSOP1 Health and Personal Hygienepriyo_sikNoch keine Bewertungen

- Example HACCP StudyDokument9 SeitenExample HACCP Studycassilda_carvalho@hotmail.comNoch keine Bewertungen

- Radium Creation Limited: 1. Personal Hygiene RequirementsDokument6 SeitenRadium Creation Limited: 1. Personal Hygiene RequirementsStanley RascalNoch keine Bewertungen

- Sharp Tool PolicyDokument7 SeitenSharp Tool PolicyVijay Baskar SNoch keine Bewertungen

- WINEWISE-Water Management ChecklistDokument3 SeitenWINEWISE-Water Management ChecklistCCR100% (1)

- Waste Management SopDokument8 SeitenWaste Management SopLibérée Rumagihwa100% (1)

- Sv. Dimdang Nyos Form 1. Sanitation Audit FormDokument20 SeitenSv. Dimdang Nyos Form 1. Sanitation Audit FormDira SeptianaNoch keine Bewertungen

- Sanitation & Food Safety Standard Operating Procedure ManualDokument15 SeitenSanitation & Food Safety Standard Operating Procedure ManualPong CanosaNoch keine Bewertungen

- SOP For Cleaning of Packing AreaDokument2 SeitenSOP For Cleaning of Packing AreaBejoy Karim100% (3)

- QSM Glass PolicyDokument2 SeitenQSM Glass PolicyHussnain AliNoch keine Bewertungen

- Glass Policy 1-2Dokument2 SeitenGlass Policy 1-2Pushpendra kumarNoch keine Bewertungen

- Vibration ProcedureDokument6 SeitenVibration Procedurematam natarajNoch keine Bewertungen

- Cheaper Raw Materials Sugar and Starch: For Europe'S IndustriesDokument22 SeitenCheaper Raw Materials Sugar and Starch: For Europe'S IndustriesTinny SumardiNoch keine Bewertungen

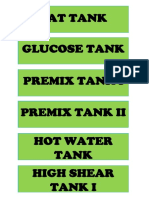

- Fat Tank Glucose Tank Premix Tank I Premix Tank Ii Hot Water Tank High Shear Tank IDokument1 SeiteFat Tank Glucose Tank Premix Tank I Premix Tank Ii Hot Water Tank High Shear Tank ITinny SumardiNoch keine Bewertungen

- CXP 057eDokument33 SeitenCXP 057eArunee KongpengNoch keine Bewertungen

- Clostridium BotulismDokument32 SeitenClostridium BotulismlassieladdieNoch keine Bewertungen

- Gerber Test For Fat % in Raw Milk Gerber Test For Fat % in Raw MilkDokument2 SeitenGerber Test For Fat % in Raw Milk Gerber Test For Fat % in Raw MilkGerald KwinjoNoch keine Bewertungen

- XecutiveDokument74 SeitenXecutiveTinny SumardiNoch keine Bewertungen

- 22 Session, Washington, DC Metro Area, U.S.A., 27 September - 1 October 2004Dokument11 Seiten22 Session, Washington, DC Metro Area, U.S.A., 27 September - 1 October 2004Tinny SumardiNoch keine Bewertungen

- Persandingan Standar Edisi 2011 2009Dokument9 SeitenPersandingan Standar Edisi 2011 2009Tinny SumardiNoch keine Bewertungen

- Daftar PustakaDokument6 SeitenDaftar PustakaTinny SumardiNoch keine Bewertungen

- Dropdown Option:: Please Fill Out This Form For Online AssessmentDokument3 SeitenDropdown Option:: Please Fill Out This Form For Online AssessmentTinny SumardiNoch keine Bewertungen

- Comparison of Anti Inflammatory Effect Between Anthocyanins Extract of Black RiceDokument8 SeitenComparison of Anti Inflammatory Effect Between Anthocyanins Extract of Black RiceTinny SumardiNoch keine Bewertungen

- TableDokument1 SeiteTableTinny SumardiNoch keine Bewertungen

- Jurnal KenampakanDokument11 SeitenJurnal KenampakanTinny SumardiNoch keine Bewertungen

- Data 2 Ulangan Color of KamabokoDokument32 SeitenData 2 Ulangan Color of KamabokoTinny SumardiNoch keine Bewertungen

- Form Ethical Clearance 13 ManusiaDokument5 SeitenForm Ethical Clearance 13 ManusiaTinny SumardiNoch keine Bewertungen

- Terje MahanDokument2 SeitenTerje MahanTinny SumardiNoch keine Bewertungen

- ChecklistSubyekManusia Indeks GlikemikDokument5 SeitenChecklistSubyekManusia Indeks GlikemikTinny SumardiNoch keine Bewertungen

- Asam Oleat ASLIDokument3 SeitenAsam Oleat ASLITinny SumardiNoch keine Bewertungen

- Asam Linolenat Part 1Dokument3 SeitenAsam Linolenat Part 1Tinny SumardiNoch keine Bewertungen

- Glycemic Control and Insulin Therapy in Sepsis and Critical IllnessDokument1 SeiteGlycemic Control and Insulin Therapy in Sepsis and Critical IllnessTinny SumardiNoch keine Bewertungen

- Food Chemistry: Tingting Zhao, Da Som No, Byung Hee Kim, Hugo S. Garcia, Yangha Kim, In-Hwan KimDokument9 SeitenFood Chemistry: Tingting Zhao, Da Som No, Byung Hee Kim, Hugo S. Garcia, Yangha Kim, In-Hwan KimTinny SumardiNoch keine Bewertungen

- Stephanie A. Coronadoa, Graham R. Troutb, Frank R. Dunsheac, Nagendra P. ShahaDokument2 SeitenStephanie A. Coronadoa, Graham R. Troutb, Frank R. Dunsheac, Nagendra P. ShahaTinny SumardiNoch keine Bewertungen

- 50Dokument6 Seiten50Tinny SumardiNoch keine Bewertungen

- Get TRDocDokument31 SeitenGet TRDocTinny SumardiNoch keine Bewertungen

- Margari NDokument12 SeitenMargari NTinny SumardiNoch keine Bewertungen

- TiketDokument12 SeitenTiketTinny SumardiNoch keine Bewertungen

- Tungku Sierra Leone LeleDokument1 SeiteTungku Sierra Leone LeleTinny SumardiNoch keine Bewertungen

- Tugas Kelompok Toksikologi Hasil Perikanan: Keracunan Yang Disebabkan Oleh MolluscaDokument1 SeiteTugas Kelompok Toksikologi Hasil Perikanan: Keracunan Yang Disebabkan Oleh MolluscaTinny SumardiNoch keine Bewertungen

- SOAL UAS Kelas 12Dokument8 SeitenSOAL UAS Kelas 12amirNoch keine Bewertungen

- Hearst Tower - New York City: Frank J. Dimauro Envs 662-660 Richard W. Berman Project: BuildingsDokument6 SeitenHearst Tower - New York City: Frank J. Dimauro Envs 662-660 Richard W. Berman Project: BuildingsMohamed FawzyNoch keine Bewertungen

- Book of Bible Answers (Volume 1) - by Doug-BatchelorDokument138 SeitenBook of Bible Answers (Volume 1) - by Doug-BatchelorAdventist_Truth100% (3)

- Zbus and Symmetrical Fault AnalysisDokument20 SeitenZbus and Symmetrical Fault Analysishj203800Noch keine Bewertungen

- Installation Instructions: Harley-Davidson Softail Saddlebag Mount Bracket PART# 21946Dokument4 SeitenInstallation Instructions: Harley-Davidson Softail Saddlebag Mount Bracket PART# 21946Justin StewartNoch keine Bewertungen

- Genmega G2500Dokument103 SeitenGenmega G2500tchindaforentNoch keine Bewertungen

- Safety Data Sheet: 1. IdentificationDokument7 SeitenSafety Data Sheet: 1. IdentificationKhobeb MuslimNoch keine Bewertungen

- Introduction On Photogrammetry Paul R WolfDokument33 SeitenIntroduction On Photogrammetry Paul R Wolfadnan yusufNoch keine Bewertungen

- Enzymes MCQsDokument2 SeitenEnzymes MCQsNobody's PerfectNoch keine Bewertungen

- Volume 15, Number 2 February 2011Dokument154 SeitenVolume 15, Number 2 February 2011Nicolai BabaliciNoch keine Bewertungen

- Rangtong Shentong ViewDokument19 SeitenRangtong Shentong Viewlongjim31100% (1)

- ED1021 - I/O Expander With UART Interface & Analog Inputs: PreliminaryDokument9 SeitenED1021 - I/O Expander With UART Interface & Analog Inputs: PreliminaryMilan NovakovićNoch keine Bewertungen

- Documentation ExamplesDokument5 SeitenDocumentation ExamplesErika HarveryNoch keine Bewertungen

- INTERVIEW QUESTIONS - Verilog - PART-1Dokument9 SeitenINTERVIEW QUESTIONS - Verilog - PART-1charan tejaNoch keine Bewertungen

- Geotechnical Laboratory: Open-Ended LabDokument7 SeitenGeotechnical Laboratory: Open-Ended LabNoorshahira Md IsaNoch keine Bewertungen

- Pictionary Unit 12 - IGMSDokument4 SeitenPictionary Unit 12 - IGMSNadia Jimenez HernandezNoch keine Bewertungen

- A Review of The Opportunities For Desalination in Agriculture PDFDokument15 SeitenA Review of The Opportunities For Desalination in Agriculture PDFMilind KshirsagarNoch keine Bewertungen

- Ffu 0000034 01Dokument8 SeitenFfu 0000034 01Karunia LestariNoch keine Bewertungen

- UD11T4107 English Maritime History Human FactorDokument4 SeitenUD11T4107 English Maritime History Human FactorParminder singh parmarNoch keine Bewertungen

- Slides Arrays Two Dimensional ArraysDokument12 SeitenSlides Arrays Two Dimensional ArraysPratham MishraNoch keine Bewertungen

- Chapter 11Dokument10 SeitenChapter 11NungkiwidyasNoch keine Bewertungen

- Inhalation AnestheticsDokument27 SeitenInhalation AnestheticsMarcelitaTaliaDuwiriNoch keine Bewertungen

- EN 301.908-2 Ver 3.2.1Dokument37 SeitenEN 301.908-2 Ver 3.2.1DHDIDIDNoch keine Bewertungen

- Euroncap 2017 Audi q5 DatasheetDokument13 SeitenEuroncap 2017 Audi q5 DatasheetCosmin AnculiaNoch keine Bewertungen

- Green Revolution: It's Acheivements and FailuresDokument24 SeitenGreen Revolution: It's Acheivements and FailuresSingh HarmanNoch keine Bewertungen

- Bock09 - Video Compression SystemsDokument300 SeitenBock09 - Video Compression SystemsWong_Ngee_SengNoch keine Bewertungen

- Key-Sentence Writing 1Dokument23 SeitenKey-Sentence Writing 1Thảo VyNoch keine Bewertungen

- Interzinc 2280 Product BrochureDokument4 SeitenInterzinc 2280 Product BrochureAshish Raul CIENoch keine Bewertungen