Beruflich Dokumente

Kultur Dokumente

Blank Thickness Calculator

Hochgeladen von

Nopparut0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

590 Ansichten1 SeiteBlank Thickness Calculator

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenBlank Thickness Calculator

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

590 Ansichten1 SeiteBlank Thickness Calculator

Hochgeladen von

NopparutBlank Thickness Calculator

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

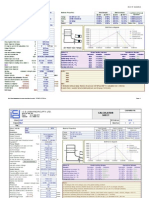

Blind Flange Thickness Calculation

DOCUMENT NO

NOTE: WHEN USED AS A FORMAL RECORD, SIGNATURE BOXES SHALL BE PAGE 1 OF 1

COMPLETED IN ACCORDANCE WITH DISCIPLINE QC PROCEDURES.

NO. 0 1 2 3 4 JOB NO:

REVISIONS

DATE FOR:

BY LOCATION:

CHECK SUBJECT:

APPROVE

Calculation based on ASME B31.3 (Chemical Plant and Petroleum Refinery Piping)

Section 304.5.3 equation 15:

3P Where: tm = Minimum Thickness

tm dg c dg = Effective gasket diameter

16SE

SE = Allowable Stress

c = Sum of Allowances

P = Design Pressure

Values: SE = 205 MPa

c = 1 mm

P = 180 Bar

dg = Average Raised face diameter

for flat gaskets on STD wt. Flanges

Line Size Flange Rating Gasket dg tm

NB Standard Type mm in mm

2 ASME B16.5 150# Flat 72.3 2.845 11

3 ASME B16.5 150# Flat 102.5 4.035 15

4 ASME B16.5 150# Flat 129.8 5.11 18

6 ASME B16.5 150# Flat 185.0 7.285 25

8 ASME B16.5 150# Flat 236.2 9.3 32

10 ASME B16.5 150# Flat 289.2 11.385 39

12 ASME B16.5 150# Flat 342.9 13.5 45

14 ASME B16.5 150# Flat 374.7 14.75 50

16 ASME B16.5 150# Flat 428.6 16.875 56

18 ASME B16.5 150# Flat 485.8 19.125 64

20 ASME B16.5 150# Flat 536.6 21.125 70

24 ASME B16.5 150# Flat 641.4 25.25 84

30 ASME B16.47 (B) 150# Flat 800.1 31.5 104

32 ASME B16.47 (B) 150# Flat 854.1 33.625 111

36 ASME B16.47 (B) 150# Flat 958.9 37.75 125

40 ASME B16.47 (B) 150# Flat 1060.5 41.75 138

Blank-Thickness-Calculator

Das könnte Ihnen auch gefallen

- Blank Thickness CalculatorDokument5 SeitenBlank Thickness CalculatorKelvin ThengNoch keine Bewertungen

- Piping Stress Critical Lines - Basis For Piping Critical Line ListDokument4 SeitenPiping Stress Critical Lines - Basis For Piping Critical Line Listashish.mathur1Noch keine Bewertungen

- 7-12-0005 Rev6 (Skirt Opening Details)Dokument2 Seiten7-12-0005 Rev6 (Skirt Opening Details)sumit kumarNoch keine Bewertungen

- Pipe Wall Thickness Sample CalculationDokument1 SeitePipe Wall Thickness Sample CalculationjkahamedNoch keine Bewertungen

- ASME PipingOffice - Piping CalculatorsDokument5 SeitenASME PipingOffice - Piping CalculatorsJohn PaulNoch keine Bewertungen

- Nozzle and Flange Check Calculation at OWT For CN-3-02 (Heavy Duty Pump)Dokument17 SeitenNozzle and Flange Check Calculation at OWT For CN-3-02 (Heavy Duty Pump)SingoNoch keine Bewertungen

- Jacketed Piping CalculationDokument9 SeitenJacketed Piping CalculationKamran Shaikh0% (1)

- Ancor Flanges Asme ViiiDokument3 SeitenAncor Flanges Asme ViiiAnjani PrabhakarNoch keine Bewertungen

- New Storage Tanks Design GuidelinesDokument6 SeitenNew Storage Tanks Design GuidelinespaaryNoch keine Bewertungen

- Modeling Pressure Balance Expansion BellowsDokument4 SeitenModeling Pressure Balance Expansion Bellowsbrunomorena50% (2)

- FlangeCalc AS1210 v1.5Dokument28 SeitenFlangeCalc AS1210 v1.5Ben100% (1)

- SIF CalculatorDokument4 SeitenSIF CalculatorKannaphat Wattanaphan100% (1)

- CSTI - Solving AIV Problems in The Design Stage (2013) - Design CurveDokument4 SeitenCSTI - Solving AIV Problems in The Design Stage (2013) - Design CurveromerobernaNoch keine Bewertungen

- ANSI FlangeDokument10 SeitenANSI FlangemechftpNoch keine Bewertungen

- Piping Engineering - Tank Nozzle Loads 1Dokument1 SeitePiping Engineering - Tank Nozzle Loads 1Nasrul AdliNoch keine Bewertungen

- Asme BPVC II Part D Material Strengths 01Dokument7 SeitenAsme BPVC II Part D Material Strengths 01bakellyNoch keine Bewertungen

- Asme Viii D Table 2aDokument9 SeitenAsme Viii D Table 2aHugoNoch keine Bewertungen

- Api 602 Forged Steel Valve PDFDokument4 SeitenApi 602 Forged Steel Valve PDFThomasFrenchNoch keine Bewertungen

- Stress Intensification For Lateral TeeDokument8 SeitenStress Intensification For Lateral TeeTejas DesaiNoch keine Bewertungen

- M PL 033Dokument19 SeitenM PL 033Ali ClubistNoch keine Bewertungen

- Pressure & Temperature ClassificationDokument1 SeitePressure & Temperature Classificationkeo85100% (1)

- Pipíng & Stress Analysis Ref - Sofware Caesar II. 06-09-2017 Autor - Ing R L Morard - U T N 1Dokument9 SeitenPipíng & Stress Analysis Ref - Sofware Caesar II. 06-09-2017 Autor - Ing R L Morard - U T N 1Oswaldo GuerraNoch keine Bewertungen

- Velan Triple Offset Butterfly L - BF - 2006aDokument24 SeitenVelan Triple Offset Butterfly L - BF - 2006amfcramerNoch keine Bewertungen

- Floating and Trunnion Ball Valves PDFDokument15 SeitenFloating and Trunnion Ball Valves PDFAlienshowNoch keine Bewertungen

- Pipe Support IndexDokument4 SeitenPipe Support IndexxkokarcaxNoch keine Bewertungen

- Piping Flexibility AnalysisDokument1 SeitePiping Flexibility Analysisข้าวเม่า ทอด100% (1)

- Mitered BendsDokument1 SeiteMitered BendsTsouki TsoukiNoch keine Bewertungen

- Nozzle Pipe Length CalculatorDokument5 SeitenNozzle Pipe Length CalculatorRyan Goh Chuang HongNoch keine Bewertungen

- SampleCalculationspipingB3132008 PDFDokument13 SeitenSampleCalculationspipingB3132008 PDFsosatlantiqueNoch keine Bewertungen

- FlangeCalculationASMEVIII Version5Dokument13 SeitenFlangeCalculationASMEVIII Version5madodandembe100% (3)

- Flange DesignDokument6 SeitenFlange DesignDinesh VaghelaNoch keine Bewertungen

- FlangeCalculationASMEVIII Version5Dokument3 SeitenFlangeCalculationASMEVIII Version5alvinchuan100% (1)

- Trunnion & Shoe Temp. Calculation.Dokument27 SeitenTrunnion & Shoe Temp. Calculation.Bharat Bellad100% (1)

- Fatigue Analysis in Caesar IIDokument4 SeitenFatigue Analysis in Caesar IIsj22100% (1)

- YoussefDokument1 SeiteYoussefhhgjdfNoch keine Bewertungen

- Asme Pipe Wall ThicknessDokument3 SeitenAsme Pipe Wall ThicknessYoke ShuNoch keine Bewertungen

- Calculation of PipeReinforcement ASMEB31 1Dokument4 SeitenCalculation of PipeReinforcement ASMEB31 1threedlabsNoch keine Bewertungen

- Pipe Support BasisDokument4 SeitenPipe Support BasisBabyface888Noch keine Bewertungen

- Asme Viii D Table 2aDokument16 SeitenAsme Viii D Table 2aJohakim974100% (1)

- Common Materilas For CS PipingDokument2 SeitenCommon Materilas For CS PipingValiullah SarpanchNoch keine Bewertungen

- PSV Sizing (Steam)Dokument2 SeitenPSV Sizing (Steam)Saeid Rahimi Mofrad100% (1)

- Flange Leakage Test As Per Asme Boiler & Pressure Vessel CodeDokument12 SeitenFlange Leakage Test As Per Asme Boiler & Pressure Vessel CoderssambhiNoch keine Bewertungen

- BE-WI-248-01-F19 Datasheet Breather ValveDokument3 SeitenBE-WI-248-01-F19 Datasheet Breather Valvemika cabelloNoch keine Bewertungen

- Air Cooler Piping Stress Analysis Using Caesar IIDokument5 SeitenAir Cooler Piping Stress Analysis Using Caesar IIsemin prsesNoch keine Bewertungen

- Flange Leakage L&TDokument48 SeitenFlange Leakage L&Tmidnightcowboy100% (1)

- Trun CalcDokument215 SeitenTrun CalcmohamedeliasNoch keine Bewertungen

- FLANGEDokument1 SeiteFLANGEscrbdgharavi50% (2)

- ASME B16.5 Class 150 & 300 Flanges Studbolt LengthDokument3 SeitenASME B16.5 Class 150 & 300 Flanges Studbolt LengthbakellyNoch keine Bewertungen

- Needle ValveDokument8 SeitenNeedle ValveMuhammad Chilmi100% (1)

- Nozzle Load AnalysisDokument2 SeitenNozzle Load Analysisvm153748763Noch keine Bewertungen

- Spectacle Blind FlangeDokument3 SeitenSpectacle Blind Flangel kishoreNoch keine Bewertungen

- ASME B16.5 2013 FlangeRating 1.0Dokument4 SeitenASME B16.5 2013 FlangeRating 1.0sanjaysyNoch keine Bewertungen

- ESLCS150-01 Pipe ScheduleDokument3 SeitenESLCS150-01 Pipe Schedulethomas.jaggerNoch keine Bewertungen

- Flange Calculation ASMEVIII-Custom WNRF (Alternate Check)Dokument11 SeitenFlange Calculation ASMEVIII-Custom WNRF (Alternate Check)Kashif Kazi100% (1)

- Data Sheet Válvula de Seguridad y AlivioDokument4 SeitenData Sheet Válvula de Seguridad y Aliviorenzo condeNoch keine Bewertungen

- Kitz Complete Ball Valve Catalog PDFDokument132 SeitenKitz Complete Ball Valve Catalog PDFDinifaanNoch keine Bewertungen

- Flange Asmeviii Div.1 App.2 Rev0Dokument10 SeitenFlange Asmeviii Div.1 App.2 Rev0lk700615100% (1)

- Qdoc - Tips - Flange Asme VIIIDokument41 SeitenQdoc - Tips - Flange Asme VIIIHormedo RodriguezNoch keine Bewertungen

- Piping Class - AG70Dokument2 SeitenPiping Class - AG70Дмитрий Рыбаков100% (1)

- Design CalDokument4 SeitenDesign CalNopparutNoch keine Bewertungen

- Design Simple Support Beam With 2-Load (Created by Bundit S.)Dokument2 SeitenDesign Simple Support Beam With 2-Load (Created by Bundit S.)Nopparut100% (1)

- Sttad Cal DesignDokument1 SeiteSttad Cal DesignNopparutNoch keine Bewertungen

- Analysis of Moment Resisting ConnectionsDokument30 SeitenAnalysis of Moment Resisting ConnectionsNopparutNoch keine Bewertungen

- AAA Variable Spring Hangers CatalogDokument31 SeitenAAA Variable Spring Hangers CatalogNopparut0% (1)

- Loads On FlangesDokument16 SeitenLoads On Flangesccoollest100% (3)

- Autopipe New Features & Enhancements (v9.61 To v6.20)Dokument17 SeitenAutopipe New Features & Enhancements (v9.61 To v6.20)NopparutNoch keine Bewertungen

- WeldingDokument4 SeitenWeldingNopparutNoch keine Bewertungen

- Nema SM23-1991 PDFDokument64 SeitenNema SM23-1991 PDFmarsulex67% (9)

- Create A ValveDokument15 SeitenCreate A ValveBruno AssisNoch keine Bewertungen

- UndergroundDokument8 SeitenUndergroundNopparutNoch keine Bewertungen

- Iso Fill InstructionsDokument1 SeiteIso Fill InstructionsNopparutNoch keine Bewertungen

- Loads On FlangesDokument16 SeitenLoads On Flangesccoollest100% (3)

- Stats FormulasDokument3 SeitenStats FormulasPeter PhamNoch keine Bewertungen

- Welding SignDokument20 SeitenWelding SignNopparutNoch keine Bewertungen

- FRP PipingDokument12 SeitenFRP PipingNopparutNoch keine Bewertungen

- An Abaqus Extension For Welding Simulations: M. Shubert, M. Pandheeradi, F. Arnold, and C. HaburaDokument15 SeitenAn Abaqus Extension For Welding Simulations: M. Shubert, M. Pandheeradi, F. Arnold, and C. HaburaSudersanSridharNoch keine Bewertungen

- Staad Pro TutorialsDokument17 SeitenStaad Pro Tutorialsrandhir981Noch keine Bewertungen

- 050 - Inspection Paint ReportDokument2 Seiten050 - Inspection Paint ReportNopparutNoch keine Bewertungen

- Full Text 01Dokument55 SeitenFull Text 01Zahi AekNoch keine Bewertungen

- Materials Comparison DIN / EN / ASTM: Pipes / Tubes Flanges Buttwelding FittingsDokument1 SeiteMaterials Comparison DIN / EN / ASTM: Pipes / Tubes Flanges Buttwelding Fittingsnaseema1Noch keine Bewertungen

- 050 - Inspection Paint ReportDokument2 Seiten050 - Inspection Paint ReportNopparutNoch keine Bewertungen

- Stats FormulasDokument3 SeitenStats FormulasPeter PhamNoch keine Bewertungen

- Beskrivning Av ExpansionsbalgarDokument25 SeitenBeskrivning Av ExpansionsbalgarNopparutNoch keine Bewertungen

- Bridge Hydraulic Design (2000)Dokument60 SeitenBridge Hydraulic Design (2000)ArmandoNoch keine Bewertungen

- Mechanics of Materials: Third EditionDokument17 SeitenMechanics of Materials: Third EditionNopparutNoch keine Bewertungen

- ความเค้นและความเครียด แรงตามแนวแกนDokument26 Seitenความเค้นและความเครียด แรงตามแนวแกนNopparutNoch keine Bewertungen

- Accommodating Expansion in Piping SystemsDokument52 SeitenAccommodating Expansion in Piping SystemsBeomHee LeeNoch keine Bewertungen

- Shank Area SpecificationsDokument3 SeitenShank Area SpecificationsychodnekerNoch keine Bewertungen

- Solved Problems Axial DeformationDokument6 SeitenSolved Problems Axial DeformationChristopher Largado100% (1)

- Compact Valves 2016Dokument32 SeitenCompact Valves 2016Tuan BuivietNoch keine Bewertungen

- Manual: Operator Maintenance InstallationDokument48 SeitenManual: Operator Maintenance InstallationRene Ramos Meneses100% (1)

- 0242 0001 4@1Dokument4 Seiten0242 0001 4@1Polaris BridgemanNoch keine Bewertungen

- Wellhead For Oil and Gas WellDokument49 SeitenWellhead For Oil and Gas Wellerwan100% (3)

- Open End SpinningDokument8 SeitenOpen End SpinningAmir Shahzad75% (4)

- Test2 21 22iiDokument15 SeitenTest2 21 22iijocker's informationsNoch keine Bewertungen

- Design, Fabrication and Development of Portable Oxygen GeneratorDokument4 SeitenDesign, Fabrication and Development of Portable Oxygen GeneratorBotch BelmiNoch keine Bewertungen

- How To Make Quick & Easy Amtgard-Legal Arrows'Dokument4 SeitenHow To Make Quick & Easy Amtgard-Legal Arrows'Royce A R PorterNoch keine Bewertungen

- Topic 2.1 Formative Answer KeyDokument2 SeitenTopic 2.1 Formative Answer KeyŁØNoch keine Bewertungen

- Kidde Mounting Straps and Wall Brackets For Clean Agent and Nitrogen Pilot and Driver Cylinders K-85-1230Dokument6 SeitenKidde Mounting Straps and Wall Brackets For Clean Agent and Nitrogen Pilot and Driver Cylinders K-85-1230Isa KumNoch keine Bewertungen

- 20004O CRTi2 4.5 Specification Summary JULY 2020Dokument4 Seiten20004O CRTi2 4.5 Specification Summary JULY 2020Muhammad SaiedNoch keine Bewertungen

- ASTM F606-02 - Propiedades Mecanicas TornillosDokument14 SeitenASTM F606-02 - Propiedades Mecanicas TornillosedwinsazzzNoch keine Bewertungen

- BS5950 End Plate DesignDokument4 SeitenBS5950 End Plate DesignFodor ZoltanNoch keine Bewertungen

- Front Elevation: A B C D E FDokument1 SeiteFront Elevation: A B C D E FAnony MousNoch keine Bewertungen

- Alesis Studio 32-x4 Schematics-BomDokument36 SeitenAlesis Studio 32-x4 Schematics-BomAiryck Sterrett100% (2)

- SG Iron GradesDokument2 SeitenSG Iron GradesSagarKBL100% (1)

- Design Basis - Package - B224-999-80-43 EDB-1002Dokument12 SeitenDesign Basis - Package - B224-999-80-43 EDB-1002Esakki muthu100% (1)

- VRM Basic FBDokument1 SeiteVRM Basic FBbluesweiNoch keine Bewertungen

- BNR-CEK-Terrace Floor PlanDokument3 SeitenBNR-CEK-Terrace Floor PlanSuresh DNoch keine Bewertungen

- Problems s2Dokument6 SeitenProblems s2zangue billy jamesNoch keine Bewertungen

- Design of Tension MembersDokument70 SeitenDesign of Tension MembersAbdallahNoch keine Bewertungen

- ILUK 33, 44, 55, 66: Parts Break DownDokument14 SeitenILUK 33, 44, 55, 66: Parts Break DownAlexNoch keine Bewertungen

- MRF StatusDokument4 SeitenMRF StatusbanglvhNoch keine Bewertungen

- Pertemuan 11 Sambungan Keling: Matakuliah: D0164 /perancangan Elemen Mesin Tahun: 2006Dokument21 SeitenPertemuan 11 Sambungan Keling: Matakuliah: D0164 /perancangan Elemen Mesin Tahun: 2006Muhammad YusufNoch keine Bewertungen

- Spare Parts List: Forward and Reversible PlateDokument44 SeitenSpare Parts List: Forward and Reversible PlatealmirNoch keine Bewertungen

- Asl Ga5-10 1997 PDFDokument28 SeitenAsl Ga5-10 1997 PDFWender Silva100% (2)

- Roustabo UT: S.SivarajDokument4 SeitenRoustabo UT: S.Sivarajjohn MNoch keine Bewertungen

- Inline Helical Geared Motor CatalogueDokument49 SeitenInline Helical Geared Motor CatalogueM Hamdy EladwyNoch keine Bewertungen