Beruflich Dokumente

Kultur Dokumente

Stamtec PressComparison WP v6

Hochgeladen von

thaivinhtuyOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Stamtec PressComparison WP v6

Hochgeladen von

thaivinhtuyCopyright:

Verfügbare Formate

METAL STAMPING & FORMING EQUIPMENT

Mechanical vs. Servo vs.

Hydraulic Presses

Solutions Essay / 2013

METAL STAMPING & FORMING EQUIPMENT

Mechanical vs. Hydraulic

vs. Servo Presses

Which press is right for you? The answer is it depends. There are many variables that can affect your

decision, but the following rules generally apply:

The traditional mechanical press can achieve the highest production speeds...

The hydraulic press offers versatility...

The mechanical servo press offers versatility and higher production speeds...

Traditional Mechanical Press Lee Ellard

National Sales Manager

The traditional mechanical press can achieve the greatest production speeds, especially when running Stamtec, Inc.

relatively flat parts with simpler, shallower forming requirements. These parts are typically processed 4160 Hillsboro Highway

from coil stock through a progressive or transfer die. Many automotive, appliance, and hardware parts fall Manchester, Tennessee 37355

1-855-871-0561

into this category. Characteristics of a traditional mechanical press:

fixed stroke length (although variable stroke length presses are available

from some press manufacturers)

special slide motions (i.e. link motions) are available, specific to a particular press

variable slide velocity, although slide velocity profile within a single cycle

of the press is fixed

working energy is dependent on flywheel mass and speed

full press capacity near bottom dead center of stroke

simplicity of set up and operation

in general, the highest stroking speeds

high accuracy and repeatability

relatively low initial cost

Hydraulic Press

The hydraulic press does not generally achieve the high cycling speeds of a similar-sized mechanical

press, but it does offer greater versatility with its variable stroke length, die space, and pressure. The

hydraulic press is often the best choice when producing parts with deep, complex forms that require a lot

of material flow and are not dependent on production speed.

Parts such as tanks, cylinders, and bowl shapes, as well as parts that require a dwell at the bottom of the

stroke (including plastics), are often run on hydraulic presses. Characteristics of a typical hydraulic press:

variable stroke length

slide motion and position control throughout the range of the stroke length

variable slide velocity, even within a single cycle of the press (typically configured as fast approach,

slow press, fast return)

full working energy at any speed

full press capacity at any point in the stroke

adjustability of all the above

in general, slower than a mechanical or servo press

in general, lower accuracy and repeatability than a mechanical or servo press

relatively low initial cost

Solutions Essay / 2013

METAL STAMPING & FORMING EQUIPMENT

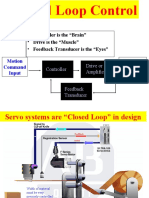

Mechanical Servo Press

The mechanical servo press offers much of the versatility of the hydraulic press, at production speeds

often approaching traditional mechanical presses. The stroke, slide motion, slide position, and speed are

programmable to allow many different combinations that can work with a wide variety of dies, part types,

and production speeds. Characteristics of a mechanical servo press (flywheel, clutch & brake are replaced Examples of stroke profiles and

by high-capacity motors): parts that can be achieved with a

servo press.

variable stroke profiles

precise slide motion and position control throughout the range of the stroke length

variable, precise slide velocity control, even within a single cycle of the press stroke.

full working energy at any speed

programmability of all the above

full press capacity near bottom dead center of stroke

in general, greater cycle speeds than a hydraulic press, in many cases approaching

the speeds of a traditional mechanical press

high accuracy and repeatability

relatively high initial cost

The two types of current servo press drive technologies:

Link-assisted

The link-assisted type of drive system is a cost-effective solution which utilizes standard, off-the-shelf

A.C. servo motors. A link or toggle mechanism coupled with the motors creates mechanical ratios

which allow for standard motor sizes from proven motor and control suppliers. No proprietary

motors or motor controllers are required.

Direct Drive

A direct drive system employs proprietary, high-torque, low-rpm motors especially designed for press

applications. These motors replace the standard motor, flywheel, and clutch/brake in an otherwise

traditional crankshaft type of mechanical press.

In either type of servo press, proprietary press controls specifically designed for the servo press achieve a

wide variety of stroke and slide movement profiles, while supplying full working energy even at low

speeds. Unique profiles can be created by the user and preprogrammed profiles can include:

cycle deep drawing

swing general forming

multi-pass perforation/blanking

Simulation of link motion warm forming

compound pressing and forging deep drawing

With full working energy at any speed and the ability to dwell anywhere in the stroke, servo presses are

taking a big bite out of the drawn and formed parts pie. However, servos are still mechanical presses at

heart, and therefore achieve full tonnage capacity near the bottom of the stroke. So in many cases Stamtec, Inc.

4160 Hillsboro Highway

hydraulic presses, with full tonnage and energy throughout the entire stroke, still have the advantage.

Manchester, Tennessee 37355

1-855-871-0561

In summary, mechanical presses are still the fastest, but they lack flexibility. Hydraulic machines allow

more versatility in drawing and forming of complex parts but theyre slow. A servo press has many of

the best characteristics of both. If you have additional questions, contact Stamtec at 1-855-871-0561

for more information.

Solutions Essay / 2013

Das könnte Ihnen auch gefallen

- Muscular System Coloring Book: Now You Can Learn and Master The Muscular System With Ease While Having Fun - Pamphlet BooksDokument8 SeitenMuscular System Coloring Book: Now You Can Learn and Master The Muscular System With Ease While Having Fun - Pamphlet BooksducareliNoch keine Bewertungen

- Electromechanical ActuatorsDokument4 SeitenElectromechanical ActuatorsMohammed Asif NNoch keine Bewertungen

- Operator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowVon EverandOperator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowBewertung: 2 von 5 Sternen2/5 (1)

- Perhitungan Gearbox Part-1 PDFDokument32 SeitenPerhitungan Gearbox Part-1 PDFHermawan SuwantoNoch keine Bewertungen

- E&i QC Inspector Resum and DocumentsDokument24 SeitenE&i QC Inspector Resum and DocumentsIrfan 786pakNoch keine Bewertungen

- 908 CatDokument12 Seiten908 CatLuis Fernando Vasquez Ramos100% (1)

- Mechanical Power PressDokument157 SeitenMechanical Power PressthaivinhtuyNoch keine Bewertungen

- Design Information: Planning Conventional MountingDokument7 SeitenDesign Information: Planning Conventional Mountingmcad12Noch keine Bewertungen

- Week 5 - Project 2 - Ilogic Part 1 PDFDokument17 SeitenWeek 5 - Project 2 - Ilogic Part 1 PDFKhairun Nisa100% (1)

- Power Curber 5700-D: #1 in The WorldDokument20 SeitenPower Curber 5700-D: #1 in The WorldMohamed MohamedNoch keine Bewertungen

- UNIT-II - 2.servo, Hydraulics and PneumaticsDokument33 SeitenUNIT-II - 2.servo, Hydraulics and PneumaticsSgsksbskxvxk100% (1)

- Axes Design Basics-Apr2018Dokument76 SeitenAxes Design Basics-Apr2018Srinivas MurthyNoch keine Bewertungen

- Element of CNC MachinesDokument60 SeitenElement of CNC MachinesGururaj Gadad100% (3)

- S.No Topic Link: Ilogic - Content CentreDokument21 SeitenS.No Topic Link: Ilogic - Content CentrethaivinhtuyNoch keine Bewertungen

- Studies On The Benefits of Using Linear Motors Insted To Ball Screws Used in Drive of The Machine ToolsDokument8 SeitenStudies On The Benefits of Using Linear Motors Insted To Ball Screws Used in Drive of The Machine ToolsVASILIINoch keine Bewertungen

- Mechanical Failure of Materials 9789814560375-c2Dokument23 SeitenMechanical Failure of Materials 9789814560375-c2Recep Vatansever0% (1)

- VISCOLAM202 D20 Acrylic 20 Thickeners 202017Dokument33 SeitenVISCOLAM202 D20 Acrylic 20 Thickeners 202017Oswaldo Manuel Ramirez MarinNoch keine Bewertungen

- Sund StrandDokument16 SeitenSund StrandropmachadoNoch keine Bewertungen

- Hydraulic PressesDokument13 SeitenHydraulic PressesAhmed Adel ShatlaNoch keine Bewertungen

- Aida-StandardsDokument14 SeitenAida-StandardsthaivinhtuyNoch keine Bewertungen

- Materials Selection in Mechanical Design - EPDF - TipsDokument1 SeiteMaterials Selection in Mechanical Design - EPDF - TipsbannetNoch keine Bewertungen

- Selection of Presses and Its SettingDokument21 SeitenSelection of Presses and Its SettingVipul MetaNoch keine Bewertungen

- Takeover Strategies and DefencesDokument20 SeitenTakeover Strategies and DefencesJithu JoseNoch keine Bewertungen

- PVP2016 Final ProgramDokument76 SeitenPVP2016 Final Programthaivinhtuy100% (1)

- Midsize 5-Axis Buyer's Guide: A Survey of Midsize Full 5-Axis Machine Tools From The Top ManufacturersDokument12 SeitenMidsize 5-Axis Buyer's Guide: A Survey of Midsize Full 5-Axis Machine Tools From The Top Manufacturerswulfgang66Noch keine Bewertungen

- Antonov 225 - The Largest - Airliner in The WorldDokument63 SeitenAntonov 225 - The Largest - Airliner in The WorldFridayFunStuffNoch keine Bewertungen

- Nanomedicine Lecture 2007Dokument59 SeitenNanomedicine Lecture 200778912071Noch keine Bewertungen

- Sauer DanfossDokument112 SeitenSauer DanfossCesar Quintanilla100% (1)

- Injection Nozzle Opening Pressure: Lmbo QFKD Fkpqor'qflkDokument1 SeiteInjection Nozzle Opening Pressure: Lmbo QFKD Fkpqor'qflkAlexanderNoch keine Bewertungen

- RM 1016 US-e HM Series Modular Balancing MachinesDokument26 SeitenRM 1016 US-e HM Series Modular Balancing MachinesHuilber MartínezNoch keine Bewertungen

- Moog ServoMotors MDSeries Catalog enDokument63 SeitenMoog ServoMotors MDSeries Catalog enArsonval FleuryNoch keine Bewertungen

- Sheet Metal Stamping Presses: Training ObjectiveDokument6 SeitenSheet Metal Stamping Presses: Training ObjectiveSileno DiasNoch keine Bewertungen

- Hydraulic Press Broschuere Hydraulische Tryoutpressen eDokument14 SeitenHydraulic Press Broschuere Hydraulische Tryoutpressen emuhendisabiNoch keine Bewertungen

- High-Torque Direct Drives: Permanent-Field Synchronous MotorsDokument12 SeitenHigh-Torque Direct Drives: Permanent-Field Synchronous MotorsCesare LucchiniNoch keine Bewertungen

- HSB Horizontal Axially Split Single Stage Between Bearing PumpDokument8 SeitenHSB Horizontal Axially Split Single Stage Between Bearing Pumpziad atfeNoch keine Bewertungen

- Forging Broschuere Exzenterpressen eDokument12 SeitenForging Broschuere Exzenterpressen ecarpolotesNoch keine Bewertungen

- Introduction To SectionsDokument10 SeitenIntroduction To Sectionssuresh100% (1)

- SALOMIXandScabaSide Mountedagitators E10269 PDFDokument8 SeitenSALOMIXandScabaSide Mountedagitators E10269 PDFethem akovaNoch keine Bewertungen

- Double Acting Shapper Too LDokument22 SeitenDouble Acting Shapper Too LGopuNoch keine Bewertungen

- RCBDokument35 SeitenRCBNesarNoch keine Bewertungen

- Turning and Machining CentresDokument26 SeitenTurning and Machining CentresBhado GagoNoch keine Bewertungen

- Hydraulic RevitingDokument29 SeitenHydraulic RevitingDinesh KumarNoch keine Bewertungen

- Hydraulic-Powered Robotic Arm PDFDokument8 SeitenHydraulic-Powered Robotic Arm PDFsaurabh satsangiNoch keine Bewertungen

- 1Dokument17 Seiten1Darryl Santos100% (1)

- BOSCH Preferred Products CatalogDokument33 SeitenBOSCH Preferred Products CatalogJamin SmtpngNoch keine Bewertungen

- Hydraulic Punching Machine: Akshdeep SinghDokument18 SeitenHydraulic Punching Machine: Akshdeep SinghPriyansh MalikNoch keine Bewertungen

- KN Hydraulic SolutionsDokument36 SeitenKN Hydraulic SolutionsSCHWARTZ. A cseNoch keine Bewertungen

- SchulerDokument8 SeitenSchuleraguswNoch keine Bewertungen

- CM20170405 41563 50972Dokument22 SeitenCM20170405 41563 50972Rafael MartinezNoch keine Bewertungen

- Morse Mechanical ClutchesDokument129 SeitenMorse Mechanical ClutchesIsmael GarciaNoch keine Bewertungen

- ARBURG Packaging Technology 680582 en GBDokument16 SeitenARBURG Packaging Technology 680582 en GBketan yadavNoch keine Bewertungen

- 1 Pump-90 Technical 10029 eDokument64 Seiten1 Pump-90 Technical 10029 eKadir Koray BozyelNoch keine Bewertungen

- Bomba Hidráulica (Ppal) Serie 16.55 - 17.55 y 21.55 Sauer 90 PumpDokument63 SeitenBomba Hidráulica (Ppal) Serie 16.55 - 17.55 y 21.55 Sauer 90 PumpIngenieriaNoch keine Bewertungen

- M315DDokument28 SeitenM315Dvicky beastNoch keine Bewertungen

- Haas Vertik BrochureDokument40 SeitenHaas Vertik BrochureAmer SkiljanNoch keine Bewertungen

- Fabrication of Cylindrical Cam Shaper MachineDokument11 SeitenFabrication of Cylindrical Cam Shaper MachineretechNoch keine Bewertungen

- Flux-Vector DriveDokument58 SeitenFlux-Vector DrivePablo LimachiNoch keine Bewertungen

- India Road Traffic SignsDokument17 SeitenIndia Road Traffic Signsjivan tidakeNoch keine Bewertungen

- Lamp IranDokument8 SeitenLamp IranKristine KellerNoch keine Bewertungen

- OMSW With Brake NoseDokument28 SeitenOMSW With Brake NoseDoral247Noch keine Bewertungen

- Rapida 105 - Innovative Rapida 106 Technology InsideDokument32 SeitenRapida 105 - Innovative Rapida 106 Technology Insideomar elctNoch keine Bewertungen

- Volkmann CTwisterDokument20 SeitenVolkmann CTwisterimma coverNoch keine Bewertungen

- AC DC Drives Application ConsiderationDokument8 SeitenAC DC Drives Application Considerationvatsalshah24Noch keine Bewertungen

- Ceco Brochure PDFDokument8 SeitenCeco Brochure PDFNguyễn Thanh Bình50% (2)

- VSD Advantages, Disadvantages, Selection Criteria and Installation Tips and TricksDokument18 SeitenVSD Advantages, Disadvantages, Selection Criteria and Installation Tips and TricksMike CerreroNoch keine Bewertungen

- VMC 4020Dokument11 SeitenVMC 4020Arul SakthiNoch keine Bewertungen

- HMC BasicDokument14 SeitenHMC BasicShashankNoch keine Bewertungen

- MultiCam 7000-Series CNC RouterDokument10 SeitenMultiCam 7000-Series CNC RouterDaniel AustinNoch keine Bewertungen

- Orbital Motors: Technical InformationDokument20 SeitenOrbital Motors: Technical InformationSathishkumar ChandranNoch keine Bewertungen

- Application Center Forestry Machines: Head: Jacques MaffiniDokument6 SeitenApplication Center Forestry Machines: Head: Jacques MaffiniStar SealNoch keine Bewertungen

- Catálogo - Nordco TRIPP - Tie Remover-InserterDokument4 SeitenCatálogo - Nordco TRIPP - Tie Remover-InserterMaurício SousaNoch keine Bewertungen

- Haus Environmental EngDokument16 SeitenHaus Environmental EngVishartan NayeemuddinNoch keine Bewertungen

- TTM FlowDivider PDFDokument5 SeitenTTM FlowDivider PDFColinNoch keine Bewertungen

- Cat336D DL PDFDokument36 SeitenCat336D DL PDFMohd AidilNoch keine Bewertungen

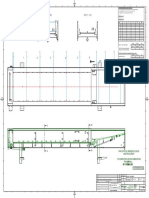

- Pan Assy, Weldment - 31724680Dokument1 SeitePan Assy, Weldment - 31724680thaivinhtuyNoch keine Bewertungen

- Buffer Tank 400 L-Phi600Dokument1 SeiteBuffer Tank 400 L-Phi600thaivinhtuyNoch keine Bewertungen

- DS5 enDokument14 SeitenDS5 enthaivinhtuyNoch keine Bewertungen

- Velocity VectorDokument91 SeitenVelocity VectorShriyash KamatNoch keine Bewertungen

- NASA Open Source Agreement-NASTRANDokument6 SeitenNASA Open Source Agreement-NASTRANthaivinhtuyNoch keine Bewertungen

- LeaspurcDokument52 SeitenLeaspurcthaivinhtuyNoch keine Bewertungen

- Agma CatalogDokument64 SeitenAgma CatalogTrung Thanh100% (1)

- Crankshaft Deflection Analysis PDFDokument55 SeitenCrankshaft Deflection Analysis PDFthaivinhtuyNoch keine Bewertungen

- Aida-StandardsDokument10 SeitenAida-StandardsthaivinhtuyNoch keine Bewertungen

- File 54Dokument492 SeitenFile 54Daniel DiasNoch keine Bewertungen

- DIN-58405-3-1972 Spur Gear Drives For Fine Mechanics - Indication in Drawings, Examples For Calculation PDFDokument20 SeitenDIN-58405-3-1972 Spur Gear Drives For Fine Mechanics - Indication in Drawings, Examples For Calculation PDFthaivinhtuyNoch keine Bewertungen

- Solid-State Recycling of Aluminium Alloy Swarf Through Cold Profile Extrusion and Cold RollingDokument42 SeitenSolid-State Recycling of Aluminium Alloy Swarf Through Cold Profile Extrusion and Cold RollingthaivinhtuyNoch keine Bewertungen

- Press GlassaryDokument23 SeitenPress Glassaryjass200910Noch keine Bewertungen

- Tiêu Chuẩn Máy Dập Ấn ĐộDokument9 SeitenTiêu Chuẩn Máy Dập Ấn ĐộthaivinhtuyNoch keine Bewertungen

- Improved Key Cards4Dokument20 SeitenImproved Key Cards4thaivinhtuyNoch keine Bewertungen

- Robotics and Servo PressDokument7 SeitenRobotics and Servo PressthaivinhtuyNoch keine Bewertungen

- BoschHeft9 E 01 PDFDokument42 SeitenBoschHeft9 E 01 PDFdiegomilitojNoch keine Bewertungen

- Structural DesignDokument14 SeitenStructural DesignthaivinhtuyNoch keine Bewertungen

- (Codientu - Org) - Huong Dan Su Dung AutoCAD ElectricalDokument43 Seiten(Codientu - Org) - Huong Dan Su Dung AutoCAD ElectricalthaivinhtuyNoch keine Bewertungen

- Cavity Plugs: Standard Hydraforce Cavity Plugs Seal All Access To A CavityDokument1 SeiteCavity Plugs: Standard Hydraforce Cavity Plugs Seal All Access To A CavitythaivinhtuyNoch keine Bewertungen

- GearDokument30 SeitenGearthaivinhtuyNoch keine Bewertungen

- TYDokument2 SeitenTYthaivinhtuyNoch keine Bewertungen

- p2813 PDFDokument1 Seitep2813 PDFgoodspeed_phNoch keine Bewertungen

- Eat Something DifferentDokument3 SeitenEat Something Differentsrajendr200100% (1)

- Topics For AssignmentDokument2 SeitenTopics For AssignmentniharaNoch keine Bewertungen

- W1 - V1 MultipleWorksheets SolnDokument3 SeitenW1 - V1 MultipleWorksheets SolnAKHIL RAJ SNoch keine Bewertungen

- Zoomlion Gulf FZE Introduction: 1.1 ME Service Support 1.2 Construction CasesDokument13 SeitenZoomlion Gulf FZE Introduction: 1.1 ME Service Support 1.2 Construction CasesArk TradingNoch keine Bewertungen

- CP R80.10 Installation and Upgrade GuideDokument246 SeitenCP R80.10 Installation and Upgrade GuideAlejandro OrtìzNoch keine Bewertungen

- BDC Based Phase ControlDokument14 SeitenBDC Based Phase ControlTiewsoh LikyntiNoch keine Bewertungen

- S L Dixon Fluid Mechanics and Thermodynamics of TurbomachineryDokument4 SeitenS L Dixon Fluid Mechanics and Thermodynamics of Turbomachinerykuma alemayehuNoch keine Bewertungen

- Sample Heat Sheets June 2007Dokument63 SeitenSample Heat Sheets June 2007Nesuui MontejoNoch keine Bewertungen

- Glossario - GETTY - IngDokument24 SeitenGlossario - GETTY - IngFabio ZarattiniNoch keine Bewertungen

- Grammar and Oral Language Development (GOLD) : Reported By: Melyn A. Bacolcol Kate Batac Julie Ann OcampoDokument17 SeitenGrammar and Oral Language Development (GOLD) : Reported By: Melyn A. Bacolcol Kate Batac Julie Ann Ocampoclara dupitasNoch keine Bewertungen

- Miso Soup Miso Soup Miso Soup: Ingredients Ingredients IngredientsDokument8 SeitenMiso Soup Miso Soup Miso Soup: Ingredients Ingredients IngredientsEllie M.Noch keine Bewertungen

- BCSS Sec Unit 1 Listening and Speaking SkillsDokument16 SeitenBCSS Sec Unit 1 Listening and Speaking Skillsjiny benNoch keine Bewertungen

- Amazon Tax Information InterviewDokument2 SeitenAmazon Tax Information Interviewasad nNoch keine Bewertungen

- Far 2 Quiz 03212024Dokument6 SeitenFar 2 Quiz 03212024red118831Noch keine Bewertungen

- PhysioEx Exercise 1 Activity 1Dokument3 SeitenPhysioEx Exercise 1 Activity 1edvin merida proNoch keine Bewertungen

- Goodman Aula 1 e 2Dokument17 SeitenGoodman Aula 1 e 2Danilo TetNoch keine Bewertungen

- Sample Database of SQL in Mysql FormatDokument7 SeitenSample Database of SQL in Mysql FormatsakonokeNoch keine Bewertungen

- AXIOM75 50 25 1B - Rev.6 10.000MHzDokument4 SeitenAXIOM75 50 25 1B - Rev.6 10.000MHzTürkay PektürkNoch keine Bewertungen

- Steinecker Boreas: Wort Stripping of The New GenerationDokument16 SeitenSteinecker Boreas: Wort Stripping of The New GenerationAlejandro Javier Delgado AraujoNoch keine Bewertungen

- Preparation of Kevlar-49 Fabric/E-Glass Fabric/Epoxy Composite Materials and Characterization of Their Mechanical PropertiesDokument10 SeitenPreparation of Kevlar-49 Fabric/E-Glass Fabric/Epoxy Composite Materials and Characterization of Their Mechanical PropertiesIndhu ElangoNoch keine Bewertungen

- English Literature Coursework Aqa GcseDokument6 SeitenEnglish Literature Coursework Aqa Gcsef5d17e05100% (2)

- RAMSCRAM-A Flexible RAMJET/SCRAMJET Engine Simulation ProgramDokument4 SeitenRAMSCRAM-A Flexible RAMJET/SCRAMJET Engine Simulation ProgramSamrat JanjanamNoch keine Bewertungen