Beruflich Dokumente

Kultur Dokumente

Astm D979-12 PDF

Hochgeladen von

ErwinBasconOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Astm D979-12 PDF

Hochgeladen von

ErwinBasconCopyright:

Verfügbare Formate

Designation: D979/D979M 12

Standard Practice for

Sampling Bituminous Paving Mixtures1

This standard is issued under the fixed designation D979/D979M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon () indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D6307 Test Method for Asphalt Content of Hot-Mix As-

1.1 This practice covers sampling of bituminous paving phalt by Ignition Method

mixtures at points of manufacture, storage, delivery, or in D6925 Test Method for Preparation and Determination of

place. the Relative Density of Hot Mix Asphalt (HMA) Speci-

--`,,,`,````,,,,,,,,`,`````,,,`-`-`,,`,,`,`,,`---

1.2 The values stated in either SI units or inch-pound units mens by Means of the Superpave Gyratory Compactor

are to be regarded separately as standard. The values stated in D6926 Practice for Preparation of Bituminous Specimens

each system may not be exact equivalents; therefore, each Using Marshall Apparatus

system shall be used independently of the other. Combining D6927 Test Method for Marshall Stability and Flow of

values from the two systems may result in non-conformance Bituminous Mixtures

with the standard. E105 Practice for Probability Sampling of Materials

1.3 This standard does not purport to address all of the E122 Practice for Calculating Sample Size to Estimate,

safety concerns, if any, associated with its use. It is the With Specified Precision, the Average for a Characteristic

responsibility of the user of this standard to establish appro- of a Lot or Process

priate safety and health practices and determine the applica- E141 Practice for Acceptance of Evidence Based on the

bility of regulatory limitations prior to use. Results of Probability Sampling

2. Referenced Documents 3. Terminology

2.1 ASTM Standards:2 3.1 Definitions of Terms Specific to This Standard:

C702 Practice for Reducing Samples of Aggregate to Test- 3.1.1 field sample, na quantity of the material to be tested

ing Size of sufficient size to provide an acceptable estimate of the

D2041 Test Method for Theoretical Maximum Specific average quality of a unit.

Gravity and Density of Bituminous Paving Mixtures 3.1.2 increment, npart of a sample.

D2234/D2234M Practice for Collection of a Gross Sample 3.1.3 lot, na sizable isolated quantity of bulk material

of Coal from a single source, assumed to have been produced by the

D2726 Test Method for Bulk Specific Gravity and Density same process (for example, a days production or a specific

of Non-Absorptive Compacted Bituminous Mixtures mass or volume).

D3665 Practice for Random Sampling of Construction Ma- 3.1.4 test portion, na quantity of the material of sufficient

terials size extracted from the larger field sample by a procedure

D5361 Practice for Sampling Compacted Bituminous Mix- designed to ensure accurate representation of the field sample,

tures for Laboratory Testing and thus of the unit sampled.

D5444 Test Method for Mechanical Size Analysis of Ex- 3.1.5 unit, na batch or finite subdivision of a lot of bulk

tracted Aggregate material (for example, a truck load or a specific area covered).

4. Significance and Use

1

This practice is under the jurisdiction of ASTM Committee D04 on Road and 4.1 General:

Paving Materials and are the direct responsibility of Subcommittee D04.30 on 4.1.1 Sampling is equally as important as the testing, and

Methods of Sampling.

Current edition approved Feb. 1, 2012. Published February 2012. Originally the sampler shall take every precaution to obtain samples that

approved in 1948. Last previous edition approved in 2011 as D979 11. DOI: will yield an acceptable estimate of the nature and conditions

10.1520/D0979_D0979M-12.

2

of the materials which they represent.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.1.2 Samples for the development of preliminary data are

Standards volume information, refer to the standards Document Summary page on obtained by the party responsible for the development of the

the ASTM website. data. Samples for control of the product at the source of

Copyright ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International

Provided by IHS under license with ASTM

1Licensee=University of Hong Kong/5910986001

No reproduction or networking permitted without license from IHS Not for Resale, 08/29/2012 19:48:56 MDT

D979/D979M 12

manufacture or storage, or at the site of use, are obtained by the combined increments should form a field sample whose

manufacturer, contractor, or other parties responsible for ac- quantity equals or exceeds the minimum recommended in

complishing the work. Samples for tests to be used in accep- 5.3.2.

tance or rejection decisions by the purchaser are obtained by 5.2.5 Sampling from a Funnel Device Feeding a Conveyor

the purchaser or his authorized representative. for Mixture Delivery to StorageSelect the units to be

4.1.3 This standard shall not be used for the sampling of sampled from the funnel device by a random method based on

compacted bituminous paving mixtures. D5361 shall be used. the bins maximum storage capacity. Obtain at least three

approximately equal increments of material for each sample by

5. Procedure passing a bucket or pan or other suitable container across the

5.1 InspectionThe material shall be inspected to deter- full flow of materials as it drops from the funnel device onto

mine discernible variations. The seller shall provide equipment the conveyor. The combined portions should form a field

needed for safe and appropriate inspection and sampling. sample whose quantity equals or exceeds the minimum recom-

5.2 SamplingThe procedures for selecting locations or mended in 5.3.2.

times for sampling are described in Practice D3665. 5.2.6 Sampling from Bituminous Cold Mix Stockpiles

5.2.1 Sampling from a Conveyor BeltStop the conveyor Cold mixes that are in a stockpile for some time may develop

belt. Randomly select at least three areas of approximately a crust on the surface of the pile. This crust should be removed

equal size on the belt for sampling. In each of the locations to to a depth of 100 mm, over an area of one square meter, to

be sampled, insert templates, the shape of which conform to the expose the unweathered mix. Stir the exposed stockpile and

shape of the belt. From the selected areas obtain approximately obtain three approximately equal samples selected at random

equal increments of material which will form a sample whose from the unit being sampled, and combine to form a field

quantity equals or exceeds the minimum recommended in sample whose quantity equals or exceeds the minimum recom-

5.3.2. Carefully scoop all material between templates into a mended in 5.3.2.

suitable container. 5.2.6.1 When three or more samples are to be taken, sample

5.2.2 Sampling from Truck TransportsBy a random in accordance with 5.2.3.1.

method, select the units to be sampled from the production of 5.3 Number and Quantities of Field Samples:

materials delivered. Obtain at least three approximately equal 5.3.1 The number of field samples (obtained by one of the

increments. Avoid sampling the extreme top surface. Select at methods described in 5.2) required depends on the criticality

random from the unit being sampled and combine to form a of, and variation in, the properties to be measured. Designate

field sample whose quantity equals or exceeds the minimum each unit from which a field sample is to be obtained prior to

recommended in 5.3.2. The sample may be obtained by sampling. The number of field samples from the production

collecting the increments with a scoop or shovel. should be sufficient to give the desired confidence in test

5.2.3 Sampling from the Roadway Prior to Compaction results.

When only one sample is to be taken, obtain at least three

NOTE 1Guidance for determining the number of samples required to

approximately equal increments, selected at random from the

obtain the desired level of confidence in test results may be found in

unit being sampled, and combine to form a field sample whose Method D2234/D2234M, Practice E105, Practice E122, and Practice

quantity equals or exceeds the minimum recommended in E141.

5.3.2. NOTE 2The unit to be represented by a single field sample should not

5.2.3.1 When three or more samples are to be taken in order be so large as to mask the effects of significant variability within the unit.

to evaluate a lot of material, utilize a random method to Nor should a unit be so small as to be affected by the inherent variability

determine the locations to be sampled. Select a sample, between small portions of any bulk material.

consisting of approximately three equal increments, from each NOTE 3A unit of bulk material composed of graded aggregate or

location, assuring the quantity of each sample exceeds the aggregate mixtures might consist of a full truckload. If it were possible,

the entire load might be tested as a practical matter. A field sample is

minimum recommended in 5.3.2. composed of three or more increments chosen at random from the material

5.2.3.2 Take all increments or samples from the roadway for as it is loaded or unloaded from the truck. Research has shown that such

the full depth of the material, taking care to exclude any a procedure permits an acceptable estimate to be made of the average

underlying material. When necessary, place templates on the gradation that might be measured from 15 or 20 increments from the

existing roadway to exclude any underlying material. Clearly truck.

mark the specified area from which each increment or sample NOTE 4Significant variability within a lot of material, where it might

is to be removed. Templates which are placed before the exist, should be indicated by statistical measures, such as the standard

deviation between units selected at random from within the lot.

mixture is spread will be a definite aid securing increments of

approximately equal mass. 5.3.2 The quantities of the material in the sample depend on

5.2.4 Sampling from a Skip Conveyor Delivering Mixture to the type and number of tests to which the material is to be

Bin StorageSelect the units to be sampled from the skip subjected, and sufficient material must be obtained to provide

conveyor by a random method based on the bins storage for the proper execution of these tests. Standard control and

capacity. Stop the skip conveyor immediately following pug acceptance tests are covered by ASTM Standards and specify

mill discharge. Dig a furrow 150 mm [6 in.] in depth extending the portion of the field sample required for each specific test.

from the top to the bottom of the pile. Obtain three approxi- Table 1 provides a guide of the minimum amounts of bitumi-

mately equal increments from the top, middle, and bottom of nous mixture that will be needed for routine testing for test

the furrow depositing each increment in a container. The methods D6307, D5444, D2041, D2726, D6925, D6926,

--`,,,`,````,,,,,,,,`,`````,,,`-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

2Licensee=University of Hong Kong/5910986001

No reproduction or networking permitted without license from IHS Not for Resale, 08/29/2012 19:48:56 MDT

D979/D979M 12

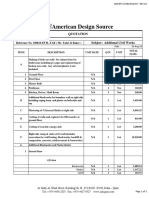

TABLE 1 Guide for Estimating Quantity of Sample information that may be useful could include, but not neces-

Maximum Size Uncompacted Mixture sarily be limited to, the following:

of AggregatesA

6.2.1 Job for which the material is to be used, giving project

Approximate Mass Approximate Volume number, highway route number, county, and other pertinent

min, kg [lb] L [Gal]

geographical information,

2.36-mm [No. 8] 10 [22] 8 [2]

4.75-mm [No. 4] 10 [22] 8 [2] 6.2.2 Source of sample, including for plant-mixed samples

9.5-mm [38-in.] 16 [35] 12 [3] the name of owner or operator of plant, location of plant, type

12.5-mm [12-in.] 20 [45] 15 [4] of plant, size of batch, and identification of bitumen and

19.0-mm [34-in.] 20 [45] 15 [4]

25.0-mm [1-in.] 24 [52] 18 [5] mineral aggregates used in the mixture,

37.5-mm [112-in.] 30 [66] 22 [6] 6.2.3 Point at which sampled, for samples taken from

50-mm [2-in.] 35 [75] 22 [6]

roadway, both by station number and location transversely in

A

The maximum size of aggregate is the largest sieve size listed in the pavement; also whether sampled from completed pavement,

applicable specification upon which any material is permitted to be retained.

windrow, etc.,

D6927. If there are to be additional tests, the sample size must 6.2.4 Quantity represented,

be increased. If there are fewer tests to be performed, adjust the 6.2.5 By whom sampled and title,

size of the sample accordingly. Extract test portions from the 6.2.6 Date of most recent mixing, if road-mixed,

field sample by quartering or splitting in a similar manner to 6.2.7 Date sampled,

Practice C702 or as required by other applicable test methods. 6.2.8 By whom submitted and address,

6. Shipping Samples 6.2.9 Purpose for which sample was taken, and

6.2.10 To whom report is to be made.

6.1 Transport samples in containers so constructed as to

preclude loss or contamination of any part of the sample, or

damage to the contents from mishandling during shipment. 7. Keywords

6.2 Samples shall have individual identification attached 7.1 asphalt paving mixture; bituminous paving mixture;

giving the information required by the sample user. Typical sampling

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

--`,,,`,````,,,,,,,,`,`````,,,`-`-`,,`,,`,`,,`---

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the ASTM website (www.astm.org/

COPYRIGHT/).

Copyright ASTM International

Provided by IHS under license with ASTM

3Licensee=University of Hong Kong/5910986001

No reproduction or networking permitted without license from IHS Not for Resale, 08/29/2012 19:48:56 MDT

Das könnte Ihnen auch gefallen

- Sampling Bituminous Paving Mixtures: Standard Practice ForDokument4 SeitenSampling Bituminous Paving Mixtures: Standard Practice ForAnonymous x7VY8VF7Noch keine Bewertungen

- Astm C702 C702M 11Dokument12 SeitenAstm C702 C702M 11Jhaiiler ZlatanNoch keine Bewertungen

- Preparation and Determination of The Relative Density of Asphalt Mix Specimens by Means of The Superpave Gyratory CompactorDokument5 SeitenPreparation and Determination of The Relative Density of Asphalt Mix Specimens by Means of The Superpave Gyratory CompactorSurya Mahapatra100% (2)

- ASTM D 560-96 Standard Test Methods For Freezing and Thawing Compacted Soil-Cement MixturesDokument6 SeitenASTM D 560-96 Standard Test Methods For Freezing and Thawing Compacted Soil-Cement MixturesPablo Antonio Valcárcel Vargas100% (1)

- Uncompacted Void Content of Fine Aggregate (As Influenced by Particle Shape, Surface Texture, and Grading)Dokument5 SeitenUncompacted Void Content of Fine Aggregate (As Influenced by Particle Shape, Surface Texture, and Grading)Oscar LopezNoch keine Bewertungen

- Astm D140-15Dokument6 SeitenAstm D140-15SusanaTorresGonzálezNoch keine Bewertungen

- ASTM D2995-99 (R04) Estimating Application Rate of Bituminous Distributors PDFDokument4 SeitenASTM D2995-99 (R04) Estimating Application Rate of Bituminous Distributors PDFPatagon Eduardo50% (2)

- M 140-03 Emulsified Asphalt PDFDokument4 SeitenM 140-03 Emulsified Asphalt PDFWalticoZegarraHerrera100% (2)

- Astm D1140 PDFDokument4 SeitenAstm D1140 PDFcatalina_tudosa0% (1)

- Minimum Requirements For Agencies Testing and Inspecting Road and Paving MaterialsDokument7 SeitenMinimum Requirements For Agencies Testing and Inspecting Road and Paving Materialsاحمد علي احمدNoch keine Bewertungen

- C535 - 16 - Standard Test Method For Resistance To Degradatio of Large-Size Coarse Aggregate ByAbrasion Impact in The Los Angeles MachineDokument3 SeitenC535 - 16 - Standard Test Method For Resistance To Degradatio of Large-Size Coarse Aggregate ByAbrasion Impact in The Los Angeles MachineTomás Venegas Pardo100% (1)

- Graded Aggregate Material For Bases or Subbases For Highways or AirportsDokument3 SeitenGraded Aggregate Material For Bases or Subbases For Highways or AirportsNyimas Febrika100% (1)

- D1557 PDFDokument8 SeitenD1557 PDFgadNoch keine Bewertungen

- D4867 PDFDokument5 SeitenD4867 PDFAdderly Ortega100% (1)

- ASTM D6927 - 15 Standard Test Method For Marshall Stability and Flow of Asphalt MixturesDokument2 SeitenASTM D6927 - 15 Standard Test Method For Marshall Stability and Flow of Asphalt MixturesAzlan Abd43% (7)

- ASTM D1461 (1994) - Moisture or Volatile Distillates in Bituminous Paving MixturesDokument5 SeitenASTM D1461 (1994) - Moisture or Volatile Distillates in Bituminous Paving Mixturesnoto SugiartoNoch keine Bewertungen

- R67-16 Muestreo Mezcla Asfaltica Despues Compactacion (Nucleos)Dokument5 SeitenR67-16 Muestreo Mezcla Asfaltica Despues Compactacion (Nucleos)dannychacon270% (1)

- Estimating Application Rate and Residual Application Rate of Bituminous DistributorsDokument4 SeitenEstimating Application Rate and Residual Application Rate of Bituminous DistributorsShaker Qaidi100% (2)

- D 4867 - D 4867M - 04Dokument5 SeitenD 4867 - D 4867M - 04Luisinho Alvarez ChávezNoch keine Bewertungen

- Bulk Specific Gravity and Density of Non-Absorptive Compacted Asphalt MixturesDokument4 SeitenBulk Specific Gravity and Density of Non-Absorptive Compacted Asphalt MixturesKev SantiagoNoch keine Bewertungen

- Aashto T340-10Dokument14 SeitenAashto T340-10ROBERTO MIRANDANoch keine Bewertungen

- ASTM D979 Standard Practice For Sampling Bituminous Paving MixturesDokument3 SeitenASTM D979 Standard Practice For Sampling Bituminous Paving MixturesKen KaHo Yu100% (1)

- Astm D2041-D2041M - 11Dokument4 SeitenAstm D2041-D2041M - 11Black Goku100% (1)

- ASTM D4402 - D4402M-15 (Reapproved 2022)Dokument4 SeitenASTM D4402 - D4402M-15 (Reapproved 2022)anant1123550% (2)

- Automated Extraction of Asphalt Binder From Asphalt MixturesDokument6 SeitenAutomated Extraction of Asphalt Binder From Asphalt MixturesJose Luis Contreras RamaycunaNoch keine Bewertungen

- Astm D1558Dokument3 SeitenAstm D1558johan lopez100% (1)

- Determination of Cracking Tolerance Index of Asphalt Mixture Using The Indirect Tensile Cracking Test at Intermediate TemperatureDokument6 SeitenDetermination of Cracking Tolerance Index of Asphalt Mixture Using The Indirect Tensile Cracking Test at Intermediate TemperatureJulissa Larios100% (3)

- Aashto R 47Dokument9 SeitenAashto R 47chris_996Noch keine Bewertungen

- ASTM D6938-08aDokument11 SeitenASTM D6938-08ainspmtto100% (1)

- Bituminous Mix Design ApproachesDokument72 SeitenBituminous Mix Design ApproachesSamarth Garg100% (1)

- Astm D3665 12Dokument2 SeitenAstm D3665 12Lupita Ramirez25% (4)

- Astm D7830 - D7830M-2013 - 8750Dokument3 SeitenAstm D7830 - D7830M-2013 - 8750Wael SeoulNoch keine Bewertungen

- D8079 16Dokument4 SeitenD8079 16refgvxvsdfNoch keine Bewertungen

- ASTM D 2042 - 09 - Standard Test Method For Solubility of Asphalt Materials in TrichloroethyleneDokument3 SeitenASTM D 2042 - 09 - Standard Test Method For Solubility of Asphalt Materials in Trichloroethylenehenry rojas100% (2)

- Aashto T27-T11Dokument14 SeitenAashto T27-T11Rifki Aulia50% (4)

- Aashto T 250 PDFDokument13 SeitenAashto T 250 PDFHsaam HsaamNoch keine Bewertungen

- Bulk Specific Gravity and Density of Non-Absorptive Compacted Asphalt MixturesDokument4 SeitenBulk Specific Gravity and Density of Non-Absorptive Compacted Asphalt MixturesAshraf Tomizeh100% (1)

- Superpave Mix Design GuideDokument8 SeitenSuperpave Mix Design Guideadane mekonnenNoch keine Bewertungen

- Random Sampling of Construction Materials: Standard Practice ForDokument13 SeitenRandom Sampling of Construction Materials: Standard Practice ForaraNoch keine Bewertungen

- ASTM D 1632-96 Standard Practice For Making and Curing Soil-Cement Compression and Flexure Test Specimens in The LaboratoryDokument6 SeitenASTM D 1632-96 Standard Practice For Making and Curing Soil-Cement Compression and Flexure Test Specimens in The LaboratoryPablo Antonio Valcárcel Vargas100% (1)

- Astm D6926-10Dokument6 SeitenAstm D6926-10kinlaycheng100% (2)

- Aashto T166 275Dokument11 SeitenAashto T166 275Alejandro Pinto100% (1)

- Astm C1077Dokument9 SeitenAstm C1077chankawai28Noch keine Bewertungen

- Softening Point of Bitumen (Ring-and-Ball Apparatus) : Standard Test Method ForDokument5 SeitenSoftening Point of Bitumen (Ring-and-Ball Apparatus) : Standard Test Method ForJanardhana Reddi100% (1)

- Astm D 6926 Marshall Specimen Prepration PDFDokument6 SeitenAstm D 6926 Marshall Specimen Prepration PDFrajeshji_000Noch keine Bewertungen

- Performance-Graded Asphalt Binder Using Multiple Stress Creep Recovery (MSCR) TestDokument8 SeitenPerformance-Graded Asphalt Binder Using Multiple Stress Creep Recovery (MSCR) Testmohammed karasnehNoch keine Bewertungen

- D4221 1518350-1Dokument4 SeitenD4221 1518350-1Joseph Marriott AndersonNoch keine Bewertungen

- Potential Application of ASTM C 1701 For Evaluating Surface Infiltration of Permeable Interlocking Concrete PavementsDokument8 SeitenPotential Application of ASTM C 1701 For Evaluating Surface Infiltration of Permeable Interlocking Concrete PavementsHalit YILMAZNoch keine Bewertungen

- Astm D6236-11Dokument7 SeitenAstm D6236-11LydiaNoch keine Bewertungen

- ASTM D 2419 - 95Dokument9 SeitenASTM D 2419 - 95Jordan RiveraNoch keine Bewertungen

- Astm C 31-2021Dokument7 SeitenAstm C 31-2021Mohammed Ali100% (3)

- D7113 tcxp6531 DensityDokument3 SeitenD7113 tcxp6531 DensityDasarathaNoch keine Bewertungen

- Astm D7263 PDFDokument7 SeitenAstm D7263 PDFMuhammad AsifNoch keine Bewertungen

- Sampling Bituminous Paving Mixtures: Standard Practice ForDokument3 SeitenSampling Bituminous Paving Mixtures: Standard Practice Foraastha mehtaNoch keine Bewertungen

- Sampling Bituminous Paving Mixtures: Standard Practice ForDokument3 SeitenSampling Bituminous Paving Mixtures: Standard Practice ForAhmedJardakNoch keine Bewertungen

- Astm d2950Dokument4 SeitenAstm d2950asdrecv100% (1)

- Bulk Density ("Unit Weight") and Voids in Aggregate: Standard Test Method ForDokument5 SeitenBulk Density ("Unit Weight") and Voids in Aggregate: Standard Test Method ForElvis Saman CaceresNoch keine Bewertungen

- Astm D7460-10Dokument14 SeitenAstm D7460-10ROBERTO MIRANDANoch keine Bewertungen

- D6931 12 Standard Test Method For Indirect Tensile (IDT) Strength of Bituminous Mixtures1-TerceraDokument5 SeitenD6931 12 Standard Test Method For Indirect Tensile (IDT) Strength of Bituminous Mixtures1-TerceraLupita Ramirez100% (1)

- Astm C 704 PDFDokument11 SeitenAstm C 704 PDFJeganeswaranNoch keine Bewertungen

- Improvement Upgrading of Coco Fiber Processing FacilityDokument103 SeitenImprovement Upgrading of Coco Fiber Processing FacilityErwinBasconNoch keine Bewertungen

- Project TS Al Baker P2Dokument3 SeitenProject TS Al Baker P2ErwinBasconNoch keine Bewertungen

- Mohd Khalifa Al Jalahma - CercisDokument2 SeitenMohd Khalifa Al Jalahma - CercisErwinBasconNoch keine Bewertungen

- Talal Bakar - LANDSCAPE CIVIL WORK Option 1 TERRAZZO TILES PDFDokument2 SeitenTalal Bakar - LANDSCAPE CIVIL WORK Option 1 TERRAZZO TILES PDFErwinBasconNoch keine Bewertungen

- Install laundry center guideDokument20 SeitenInstall laundry center guideErwinBasconNoch keine Bewertungen

- Standing, Walking and Running For GodDokument1 SeiteStanding, Walking and Running For GodErwinBasconNoch keine Bewertungen

- Muaither Stairs DetailingDokument1 SeiteMuaither Stairs DetailingErwinBasconNoch keine Bewertungen

- High-Efficiency Laundry Centers: FFLE4033Q T / WDokument3 SeitenHigh-Efficiency Laundry Centers: FFLE4033Q T / WErwinBasconNoch keine Bewertungen

- American Design Source: QuotationDokument2 SeitenAmerican Design Source: QuotationErwinBasconNoch keine Bewertungen

- Talal Bakar - LANDSCAPE CIVIL WORK Option 2 PORCELAIN TILES PDFDokument2 SeitenTalal Bakar - LANDSCAPE CIVIL WORK Option 2 PORCELAIN TILES PDFErwinBasconNoch keine Bewertungen

- Private Villa B+G+1+P+PoolDokument2 SeitenPrivate Villa B+G+1+P+PoolErwinBascon100% (1)

- CEG ReportDokument14 SeitenCEG ReportErwinBasconNoch keine Bewertungen

- Khalid Khalifa Al Jalahma Service StairsDokument1 SeiteKhalid Khalifa Al Jalahma Service StairsErwinBasconNoch keine Bewertungen

- 1709EIFS - Jassim Al MarzouqiDokument5 Seiten1709EIFS - Jassim Al MarzouqiErwinBasconNoch keine Bewertungen

- Heba CorniceDokument1 SeiteHeba CorniceErwinBasconNoch keine Bewertungen

- Forefront Parex Usa EifsDokument9 SeitenForefront Parex Usa EifsErwinBasconNoch keine Bewertungen

- 2002 DAR AO 1 2002 Comprehensive Rules On Land Use ConversionDokument42 Seiten2002 DAR AO 1 2002 Comprehensive Rules On Land Use ConversionJee JeeNoch keine Bewertungen

- Packing List PhotosDokument11 SeitenPacking List PhotosErwinBasconNoch keine Bewertungen

- Dpwh-Cost Estimate GuidelinesDokument20 SeitenDpwh-Cost Estimate Guidelinesnagtipunan85% (94)

- Simple Project Schedule SampleDokument1 SeiteSimple Project Schedule SampleErwinBasconNoch keine Bewertungen

- Sermons From The Barr The Grace in Which We Stand (Rom. 51-11)Dokument8 SeitenSermons From The Barr The Grace in Which We Stand (Rom. 51-11)ErwinBasconNoch keine Bewertungen

- Khalid Khalifa Proj SchedDokument1 SeiteKhalid Khalifa Proj SchedErwinBasconNoch keine Bewertungen

- Xii Neet Chemistry Mcqs PDFDokument30 SeitenXii Neet Chemistry Mcqs PDFMarcus Rashford100% (3)

- ML AiDokument2 SeitenML AiSUYASH SHARTHINoch keine Bewertungen

- Retaining Wall-Masonry Design and Calculation SpreadsheetDokument6 SeitenRetaining Wall-Masonry Design and Calculation SpreadsheetfarrukhNoch keine Bewertungen

- Railway Airport Docks and HarbourDokument21 SeitenRailway Airport Docks and HarbourvalarmathibalanNoch keine Bewertungen

- Asian Paints Tile Grout Cement BasedDokument2 SeitenAsian Paints Tile Grout Cement Basedgirish sundarNoch keine Bewertungen

- A Fossil Hunting Guide To The Tertiary Formations of Qatar, Middle-EastDokument82 SeitenA Fossil Hunting Guide To The Tertiary Formations of Qatar, Middle-EastJacques LeBlanc100% (18)

- Metal Framing SystemDokument56 SeitenMetal Framing SystemNal MénNoch keine Bewertungen

- Sap ThufingteDokument10 SeitenSap ThufingtehangsinfNoch keine Bewertungen

- Acuity Assessment in Obstetrical TriageDokument9 SeitenAcuity Assessment in Obstetrical TriageFikriNoch keine Bewertungen

- Reflection 2: WHAT DOES It Mean To Be A Pacific Islander Today and in The Future To Me?Dokument5 SeitenReflection 2: WHAT DOES It Mean To Be A Pacific Islander Today and in The Future To Me?Trishika NamrataNoch keine Bewertungen

- ProtectionDokument160 SeitenProtectionSuthep NgamlertleeNoch keine Bewertungen

- CG Module 1 NotesDokument64 SeitenCG Module 1 Notesmanjot singhNoch keine Bewertungen

- Datasheet PDFDokument6 SeitenDatasheet PDFAhmed ElShoraNoch keine Bewertungen

- Ricoh 4055 PDFDokument1.280 SeitenRicoh 4055 PDFPham Nguyen Hoang Minh100% (1)

- Conjoint Analysis Basic PrincipleDokument16 SeitenConjoint Analysis Basic PrinciplePAglu JohnNoch keine Bewertungen

- ADIET Digital Image Processing Question BankDokument7 SeitenADIET Digital Image Processing Question BankAdarshNoch keine Bewertungen

- Monster of The Week Tome of Mysteries PlaybooksDokument10 SeitenMonster of The Week Tome of Mysteries PlaybooksHyperLanceite XNoch keine Bewertungen

- Application of Fertility Capability Classification System in Rice Growing Soils of Damodar Command Area, West Bengal, IndiaDokument9 SeitenApplication of Fertility Capability Classification System in Rice Growing Soils of Damodar Command Area, West Bengal, IndiaDr. Ranjan BeraNoch keine Bewertungen

- Clean Milk ProductionDokument19 SeitenClean Milk ProductionMohammad Ashraf Paul100% (3)

- European GMP Annex 1 - 2008 Edition - 'Pmeasuring'Dokument3 SeitenEuropean GMP Annex 1 - 2008 Edition - 'Pmeasuring'Khairul AnwarNoch keine Bewertungen

- Artifact and Thingamy by David MitchellDokument8 SeitenArtifact and Thingamy by David MitchellPedro PriorNoch keine Bewertungen

- Casio AP-80R Service ManualDokument41 SeitenCasio AP-80R Service ManualEngkiong Go100% (1)

- Fake News Poems by Martin Ott Book PreviewDokument21 SeitenFake News Poems by Martin Ott Book PreviewBlazeVOX [books]Noch keine Bewertungen

- Swami Rama's demonstration of voluntary control over autonomic functionsDokument17 SeitenSwami Rama's demonstration of voluntary control over autonomic functionsyunjana100% (1)

- HSC 405 Grant ProposalDokument23 SeitenHSC 405 Grant Proposalapi-355220460100% (2)

- De Thi HSG Tinh Binh PhuocDokument9 SeitenDe Thi HSG Tinh Binh PhuocDat Do TienNoch keine Bewertungen

- Hypophosphatemic Rickets: Etiology, Clinical Features and TreatmentDokument6 SeitenHypophosphatemic Rickets: Etiology, Clinical Features and TreatmentDeysi Blanco CohuoNoch keine Bewertungen

- Panasonic 2012 PDP Troubleshooting Guide ST50 ST Series (TM)Dokument39 SeitenPanasonic 2012 PDP Troubleshooting Guide ST50 ST Series (TM)Gordon Elder100% (5)

- Elevator Traction Machine CatalogDokument24 SeitenElevator Traction Machine CatalogRafif100% (1)

- Aircraft Design Project 2Dokument80 SeitenAircraft Design Project 2Technology Informer90% (21)