Beruflich Dokumente

Kultur Dokumente

Effect of Sensitization On Microhardness and Corrosion Resistance of Austenitic Stainless Steel

Hochgeladen von

IJOCAASOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Effect of Sensitization On Microhardness and Corrosion Resistance of Austenitic Stainless Steel

Hochgeladen von

IJOCAASCopyright:

Verfügbare Formate

International Journal of Computation and Applied Sciences IJOCAAS, Volume2, Issue 2, April 2017, ISSN: 2399-450

Effect of sensitization on microhardness and corrosion

resistance of austenitic stainless steel

Shukur F. Hasan& Sami I J. Alrubaiey

different metallographic paper SIC and it has been refined by

polishing paper assistance of cloth Damon and refine oil to

Abstract-This study presents the results of research for micro polish the surface of samples. The samples have been clean

hardness and corrosion behavior of ASTM 304 stainless steel by

and dried. Etching has obtained for the purpose of showing the

investigating and performing the pitting corrosion 1N H2SO4 as a

function of heating temperature (500, 600, 700, 800, 900) C.

microscopic structure using chemical solution, consisting of

Different amounts of carbides precipitated in the austenitic 50 ml HNO3 and 50 ml HCL. Finally was washed with water

stainless steel. These precipitates are one of problems with samples and alcohol and then dried by dryer.

austenitic stainless steel due to the formation of extreme pitting

corrosion. The current pitting corrosion density for heated 2.2 Chemical Compositions

stainless steel at 900 C is greater than that of non-heated

specimen by about 34% in 1N H2SO4. The pitting potential of The chemical compositions of stainless steel 304 were carried

heated stainless steel at 900 C is more negative than that of non- out by using oxford instruments product of foundry Master

heated specimen by a value of 284 mV. This means that the Xpert Company.

increase in heating temperature led to the increase of pitting

intensity. 2.3 Heat treatment

Keywords:Corrosion resistance,austenitic stainless steel,

sensitization, hardness, Cr-carbides

Heat treatment was done at rang of temperature in order to

make it sensitive to produce chromium carbides in the

I. INTRODUCTION structure. The samples were placed inside the furnace for

AISI 304 stainless steels are used in a wide range of heated to several different temperatures from (500, 600, 700

applications like chemical, petrochemical, medical and kitchen and, 800, 900) oC respectively. Use thermal furnace

equipment because of their good mechanical properties and (CARBOLITE FURNACE). The installation was for an hour

excellent corrosion resistance [1, 2]. Most of these of time then were cooled slow cooling inside the furnace to

applications are done at higher temperature, which leads to room temperature.

formation of sensitization phenomena, and the sensitization

generally takes place in the range of temperature (500-900) C. 2.4 Corrosion Test

These phenomena are considered as a susceptible reason for

pitting corrosion [3, 4]. At the sensitization range, the Cyclic Polarization test was performed using Tafel

dissolved carbon in the microstructure would pull the extrapolation method to investigate pitting corrosion

chromium to forms several chromium carbides, depending on properties of sensitized specimens. Sulfuric acid solution was

the annealing temperature along the grain boundaries. At the prepared. This acid diluted to 1N aqueous solution of

same time, a depletion zone of chromium would take place H2SO4.Equation was used to calculate corrosion rate as

inside the microstructure. These two phenomena (carbide follows: [9].

precipitation and Cr-depletion zone) are considered as the

main reason for formation of pitting corrosion [5, 6]. A CR (mpy) =0.13 Icorr. . e/D.(1)

various of phases may accelerate in the different classes of Where:

stainless steels, particularly AISI 304. Some of these phases, Icorr : Corrosion current density A/cm2.

similar to the Cr7C3, Cr23C6, might be the basic to all classes; e: Equivalent weight (for steel =25.5). g.equivalent

however, some of them are most certainly not [7, 8]. The D: Density of metal (for steel =7.9 gm/ cm3) [10]

corrosion resistance of AISI 304 is analyzed to study the effect

of temperature by using Tafel extrapolation method. It

2.5 Digital Planimeter

becomes clear that the best methods to study the

susceptibilities to this form of corrosion are the Tafel To measure the hysteres loop area of cyclic polarization curve.

extrapolation method. It represented the energy for pitting corrosion occurrence in

samples of stainless steel. By using a digital planimeter model

(BLCOM-KP-90N-NO.H12556),

II.EXPERIMENTAL METHODS

2.6 Microhardness Test

2.1 Sample preparation

Microhardness values were calculated as for receive sample,

The samples were prepared by cutting into square shape with

sensitive samples and after corrosion. The test force was (9.8

1.5 mm and thickness of 2 mm followed by grinding with

N + 1 Kg) for (20 sec). The average of 3 readings of the

International Journal of Computation and Applied Sciences IJOCAAS, Volume2, Issue 2, April 2017, ISSN: 2399-450

indentation length was taken. The Vickers microhardness boundaries are increased with increasing of the annealing

(HV) was calculated according to the following equation [11]: temperature. This condition can be attributed to the formation

of coherent precipitation of Cr23C6, Cr7C3, Cr2.9C as indicated

HV = 1.8544 p/ d2... (1-2) in XRD.

Where,

P = Applied load, kgf.

d = The mean diagonal of the indentation, mm

III. RESULTS AND DISCUSSION

3.1 Chemical composition

Table (1) represent the chemical composition of samples

which were used in this investigation, and by comparing these

percentages with standard we can conclude that the sample is

austenitic stainless steel type 304.

TABLE 1

CHEMICAL COMPOSITION OF SAMPLE

Fig. 1Microstructures after heat treatment at 400X

3.3 Corrosion behavior results

Table (3) represents the parameter that we got from the

polarization curve. The correlation between microstructural

and pitting corrosion resistance proved that unsensitized

structure had low susceptibility to pitting corrosion. It can be

3.2 Effect of Heat Treatment on Microstructure of 304

seen that the heating temperature has a great effect on the

Stainless Steels

corrosion of AISI 304 stainless steel in 1 N H2SO4. As heating

Figure (1) shows the microstructure of 304 stainless steel in temperature increases, the corrosion current density increases

the as received condition. From this figure, it can be seen that also. As increase in sensitization temperatures the nucleation

the microstructure has fine and homogenous grains of of pitting corrosion increase. When sensitization temperature

austenitic stainless steel. There are no carbides on the grain increase the surface introduced more pitting corrosion in the

boundary. body of grain and in the grain boundary. Show that the surface

interdusing intergranular corrosion when sensitized

The effect of temperatures of annealing on the microstructure

of stainless steel showed that as temperature increases, the temperature increase .The hysteresis loop area of 304 stainless

microstructure becomes non-homogeneous due to chromium steel specimen sensitized at 900 C decreased to 9.3simulated

by cm2,which represents the energy required to the emergence

carbides precipitation at grain boundaries. The small numbers

of coarse chromium carbide precipitations were observed at of pitting corrosion which is less than the required energy to

the grain boundaries. It is appeared as dark areas in the optical emergence of pitting corrosion the as received, sensitized

specimen.

microstructure. The more carbides get at high annealing

temperature (900 C) as shown in fig. (1). The areas of grain

boundary have different colors. The dark area indicated to

carbides. These areas became darker as the temperature of

annealing was increased. These indicated to more precipitation

carbides. The density and size of precipitation at the grain

International Journal of Computation and Applied Sciences IJOCAAS, Volume2, Issue 2, April 2017, ISSN: 2399-450

Potential [mV]

Potential [mV]

As received AT 800C

As receiv

received ed

Current [mA/cm] Current [mA/cm]

Potential [mV]

Potential [mV]

AT 500C AT 900C

receiv receiv

ed ed

Current [mA/cm] Current [mA/cm]

Fig. 2 Corrosion behavior of austenitic stainless steel sensitized at different

Potential [mV]

condition in 1N H2SO4

AT 600C

receiv C ONDITION As At At At At At

ed PARAMETER reseived 500C 600C 700C 800C 900C

Io mA/cm2 2.6*10-3 9.5*10-3 2.5*10-2 1.3*10-1 1.4*10-1 7.5*10-1

o

E mV -381 -400 -418 -452 -500 -506

Icorr.mA/cm2 2*10-2 3.5*10-1 5.8*10-1 2*100 5*100 9.5*100

E corr. mV -411 -425 -431 -478 -503 -520

Ipit mA/cm2 9*10-1 6*100 1.3*101 6.7*101 9.6*101 2.6*102

E pit mV 1010 978 946 886 811 726

Area under 26.7 20.1 17.9 15.9 15.1 9.3

the curve

Current [mA/cm]

corrosion 0.0083 0.1468 0.2433 0.8390 2.097 3.985

rate (mpy)

Potential [mV]

AT 700C 3.4 Microhardness Results

receiv

Figure (1.3) exhibits the microhardness results for austenitic

ed stainless steel AISI 304 samples sensitized with various heat

treatment conditions, that shown in blue coloure.And, the

microhardness results for samples after corrosion test are

shown in red coloure. The microhardness of as-received

specimen has an average value of 164.3Hv. The average

microhardness was increaseto171.4Hv, 176.3Hv and 184.6Hv

for sensitized specimen at 500 C, 600 C, and 700 C,

recpectively. The increase on microhardness can beascribes

Current [mA/cm] the formation of carbide chromium in boundary of sensitized

specimen at this teamperature. The precipitated of chromium

International Journal of Computation and Applied Sciences IJOCAAS, Volume2, Issue 2, April 2017, ISSN: 2399-450

carbide imped movement of dislocation and reduce the flaw Reference

within crystals lattice.

Moreover, the movement of flaw is often indicate as the [1] J. R. Davis, "Heat-Resistant Materials", ASM Specialty Handbook,

ASM International, 1997.

predominant carriers of plasticity and materials ductility [2] W. Ozgowicz, A. Kurc, and M. Kciuk, "Effect of deformation-induced

hugely be based on the easiness of crystal lattice flaw could be martensite on the microstructure, mechanical properties and corrosion

propagate. However,the average microhardness was riseseto resistance of XCrNi18-8 stainless steel", International Scientific

186.02Hv and 187.4Hv for sensitized specimen at 800 C Journal, vol.43, pp. 42-53, 2010.

[3] A. Philip, P. E.Schweitzer,"Metallic Materials: Physical, Mechanical,

and900C, recpectively. This increase in micro hardness could and Corrosion Properties", Marcel Dekker, Inc, 2003.

be attributing to increase the amount of carbides and [4] ASM Specialty Handbook": Steels 2- Volume Set Description Your

chromium depletion in zone. Single Resource for Stainless, Sep.21-25, 2009.

The average microhardness results for as received samples [5] R. K. Singh, R. Kumer, "Study of corrosion and corrosion protection of

stainless steel in phosphate fertilizer industry", American Journal of

decrease after corrosion. Its value is 161.1Hvdue to the Mining and Metallurgy, vol. 2, No. 2, pp. 27-31, 2014.

occurrence of pitting corrosion. The average microhardness [6] P. de lima-Neto, J. P. Farias, L.Flavo, G. Herculano, C. Helio, W. S.

for sensitized specimen after corrosion test decrease to Araujo, J.Jorence and N.Pebere, "Determenation of the sensitization

167.8Hv,170.9Hv,179.5Hv,183.22Hv and 183.9Hv at 500 C, zone extension in welded AISI 304 stainless steel using non-destructive

electrochemical techniques", Corrosion Science, vol. 50, No. 4, pp.

600 C,700 C, 800 C and 900 C, recpectively. This decrease 1149-1155, 2008

caused by intergranular and pitting corrosion and for [7] D. Llewellyn and R.Hud ,"Steels Metallurgy and

chromium depletion zones that became weak. Applications",Butterworth-Heinemann, 1998.

[8] N. Srisuwan,"Investigation of chromium carbide precipitation and

corrosion behavior on stainless steel AISI 304 for welding process

190 184.6 186.02 187.4 development", The 2nd RMUTP International Conference, pp.102- 107,

180 176.3 2010.

171.4

170 164.3 [9] Fontana and Green," Corrosion Engineering", McGraw-Hill, 1978.

160 [10] A. Etor, "Electrochemical measurement of crevice corrosion of type

Hardness [Hv]

aisi304 stainless steel", PhD. Thesis, University of Saskatchewan,

150 November, 2009.

140 [11] ASM International, Volume 8, Stainless Steel Grades Mechanical

130 Properties, 2004.

25 500

600 700

800 900

sample conditions [c]

Fig. 3 Microhardness chart results

IV.CONCLUSIONS

1. Temperature affects the nature of the corrosion in stainless

steel 304 in terms of original positions devoid of it and the

formation of chromium depletion zones. The chromium

depletion zones are being corroded. When sensitization

temperature rises (500-900) C, Cr carbides will be

precipitated at grain boundary, therefore pitting corrosion

increases as the temperature increases.

2. The pitting corrosion can be occurred by two mechanisms

as follows:

A) As a result of the interaction of carbon with chromium

at the grain boundaries and depletion of Cr that takes

place depending on the carbides formations.

B) Due to the carbides precipitation on the grain boundary,

a galvanic effect will be occurred between carbides and

matrix due to the difference in the electromotive force

that leads to pitting corrosion.

3. The energy to pitting initiation which is measured by the

area of the loop indicated that the pitting corrosion needs

less energy to occur as temperature increases from 500 to

900 C.

4. Hardness increased as sensitization temperature increased

from 500 to 900 C and increased also after corrosion

during this range of temperatures.

Das könnte Ihnen auch gefallen

- Amorphous and Nano Alloys Electroless Depositions: Technology, Composition, Structure and TheoryVon EverandAmorphous and Nano Alloys Electroless Depositions: Technology, Composition, Structure and TheoryNoch keine Bewertungen

- Electron and Positron Spectroscopies in Materials Science and Engineering: Materials Science and TechnologyVon EverandElectron and Positron Spectroscopies in Materials Science and Engineering: Materials Science and TechnologyOtto BuckNoch keine Bewertungen

- Oxide Dispersion Strengthened SteelsDokument31 SeitenOxide Dispersion Strengthened SteelsJuliana FortunatoNoch keine Bewertungen

- Sources of Oxygen Contamination in SAW - EagerDokument5 SeitenSources of Oxygen Contamination in SAW - EagerAndres CasteloNoch keine Bewertungen

- Effect of Boron Content On Hot Ductility and Hot Cracking TIG 316L SSDokument10 SeitenEffect of Boron Content On Hot Ductility and Hot Cracking TIG 316L SSafnene1Noch keine Bewertungen

- Transmission Electron Microscopy Skills:Diffraction Lecture 9Dokument25 SeitenTransmission Electron Microscopy Skills:Diffraction Lecture 9LIAKMANNoch keine Bewertungen

- Corrosion Resistance of Cerium-Doped Zinc Calcium Phosphate Chemical Conversion Coatings On AZ31 Magnesium AlloyDokument15 SeitenCorrosion Resistance of Cerium-Doped Zinc Calcium Phosphate Chemical Conversion Coatings On AZ31 Magnesium AlloyMichael Merino CrispinNoch keine Bewertungen

- Anti PasccDokument4 SeitenAnti PasccMohd Idris MohiuddinNoch keine Bewertungen

- Effect of Heat Treatment On Microstructures and Mechanical Prop of Spring SteelDokument7 SeitenEffect of Heat Treatment On Microstructures and Mechanical Prop of Spring SteelMahmood KhanNoch keine Bewertungen

- Etching Stainless Steels For Delta FerriteDokument2 SeitenEtching Stainless Steels For Delta FerriteAPINoch keine Bewertungen

- Phase Diagram Study of Alloys in Iron Carbon Chromium Mo-NiDokument13 SeitenPhase Diagram Study of Alloys in Iron Carbon Chromium Mo-NiRavichandran JayaprakashNoch keine Bewertungen

- Joining KovarDokument11 SeitenJoining Kovarharan2000Noch keine Bewertungen

- Ferrite Morphology and Variations inDokument9 SeitenFerrite Morphology and Variations inAndrea CalderaNoch keine Bewertungen

- Creep Test ProcedureDokument22 SeitenCreep Test ProcedureJames Ugo100% (1)

- Evolution of Quench Factor Analysis - A ReviewDokument22 SeitenEvolution of Quench Factor Analysis - A Reviewluigi_mazzucco100% (1)

- Slag Metal ReactionsDokument7 SeitenSlag Metal ReactionsEr Dikshant Malhotra100% (1)

- Evolution of Microstructural BandingDokument8 SeitenEvolution of Microstructural BandingvishalNoch keine Bewertungen

- Stress Corrosion Crack Growth Behavior of Cold Worked Austenitic Stainless Steel in High Temperature WaterDokument7 SeitenStress Corrosion Crack Growth Behavior of Cold Worked Austenitic Stainless Steel in High Temperature Wateramd mhmNoch keine Bewertungen

- Corrosion Behavior of Carbon Steel in Oxygenated Sodium Sulphate Solution Under Different Operating ConditionsDokument11 SeitenCorrosion Behavior of Carbon Steel in Oxygenated Sodium Sulphate Solution Under Different Operating ConditionsSEP-PublisherNoch keine Bewertungen

- Astm E407Dokument22 SeitenAstm E407Carlos Pinto PradillaNoch keine Bewertungen

- Detecting Transformation From Delta Ferrite To Sigma Phase in SsDokument9 SeitenDetecting Transformation From Delta Ferrite To Sigma Phase in SsAndrea CalderaNoch keine Bewertungen

- Mechanical Properties of Advanced Nuclear Reactor MaterialsDokument24 SeitenMechanical Properties of Advanced Nuclear Reactor MaterialsAmit SinghNoch keine Bewertungen

- AL 6XN SourceBookDokument56 SeitenAL 6XN SourceBookdrbeyerNoch keine Bewertungen

- Ebsd (Electron Backscattered Diffraction)Dokument45 SeitenEbsd (Electron Backscattered Diffraction)mm11_nedNoch keine Bewertungen

- WJ 1985 10 s281 PDFDokument15 SeitenWJ 1985 10 s281 PDFbabaaromeNoch keine Bewertungen

- Problems 13.1: Difficulties Associated With The Partially Melted ZoneDokument2 SeitenProblems 13.1: Difficulties Associated With The Partially Melted ZoneSayyidah FarhanaNoch keine Bewertungen

- Fireside Corrosion of Alloys For Combustion Power PlantsDokument11 SeitenFireside Corrosion of Alloys For Combustion Power Plantsdealer82Noch keine Bewertungen

- Atmospheric Corrosion of Materials PDFDokument24 SeitenAtmospheric Corrosion of Materials PDFMarcos LeiteNoch keine Bewertungen

- Pourbaix Diagrams For The Ternary System of Iron-Chromium-NickelDokument11 SeitenPourbaix Diagrams For The Ternary System of Iron-Chromium-NickelOscar Herrera AmézquitaNoch keine Bewertungen

- Corrosion Inhibition by Various Plant Products at Mild Steel Surfaces in Acidic and Basic MediaDokument4 SeitenCorrosion Inhibition by Various Plant Products at Mild Steel Surfaces in Acidic and Basic MediaEditor IJTSRDNoch keine Bewertungen

- Corrosion Kinetics BasheerDokument9 SeitenCorrosion Kinetics Basheerchenabeel0% (1)

- Engineering Alloys (Non Ferrous)Dokument52 SeitenEngineering Alloys (Non Ferrous)Sukhwinder Singh GillNoch keine Bewertungen

- AP621 Lect02 DiffractionDokument117 SeitenAP621 Lect02 DiffractionHassanNoch keine Bewertungen

- ME 292 - Metallic Materials SessionalDokument39 SeitenME 292 - Metallic Materials SessionalMuhammedNayeemNoch keine Bewertungen

- Sliding Wear Performance of Reinforced A413 Alloy at Elevated Temperatures PDFDokument8 SeitenSliding Wear Performance of Reinforced A413 Alloy at Elevated Temperatures PDFirajfarjiNoch keine Bewertungen

- Common Causes of Premature Failure of MN SteelDokument3 SeitenCommon Causes of Premature Failure of MN Steeldrackensohn100% (1)

- Corrosion Effects of MgCl2 and NaClDokument91 SeitenCorrosion Effects of MgCl2 and NaClandrebrezolin100% (1)

- Leidenfrost EffectDokument10 SeitenLeidenfrost EffectSnowswimmerNoch keine Bewertungen

- Reduction of Ferric Oxides in The Red Mud by The Aluminıothermic ProcessDokument5 SeitenReduction of Ferric Oxides in The Red Mud by The Aluminıothermic Processlaurentiu_filipescuNoch keine Bewertungen

- OsidationDokument49 SeitenOsidationSadhasivam VeluNoch keine Bewertungen

- MM435 - CDP-4 - Nernst Equation+Ref ElectrodesDokument23 SeitenMM435 - CDP-4 - Nernst Equation+Ref ElectrodesAbdul Ahad ShamsNoch keine Bewertungen

- Constitutive Model For Full-Range Elasto-Plastic Behavior of Structural Steels With Yield Plateau Formulation (Hu, Et Al. 2016)Dokument12 SeitenConstitutive Model For Full-Range Elasto-Plastic Behavior of Structural Steels With Yield Plateau Formulation (Hu, Et Al. 2016)Jose ManuelNoch keine Bewertungen

- Surfaceb Finish Meterology TutorialDokument162 SeitenSurfaceb Finish Meterology TutorialChristian Barnard100% (1)

- Physical Metallurgy-18 Heat Treatment of SteelDokument7 SeitenPhysical Metallurgy-18 Heat Treatment of SteelDSGNoch keine Bewertungen

- Foundations of Materials Science and Engineering 5th Edition Smith Solutions ManualDokument79 SeitenFoundations of Materials Science and Engineering 5th Edition Smith Solutions Manualdextrermachete4amgqgNoch keine Bewertungen

- Sequential Leaching For The Production of Alumina From A Nigerian ClayDokument7 SeitenSequential Leaching For The Production of Alumina From A Nigerian ClayPuturrú De Fuá100% (1)

- Yield Criteria PDFDokument11 SeitenYield Criteria PDFTarza Bayez100% (1)

- Fundamentos de Metalurgia Física - VerhoevenDokument60 SeitenFundamentos de Metalurgia Física - VerhoevenLeoncio Santos Tress100% (1)

- An Assesment of The High Temperature Oxidation Behaviour of Fe-Cr Steels in Water Vapour and SteamDokument15 SeitenAn Assesment of The High Temperature Oxidation Behaviour of Fe-Cr Steels in Water Vapour and SteammogirevansNoch keine Bewertungen

- 1 - Lecture Notes For 1st Cycle Test 07022016Dokument17 Seiten1 - Lecture Notes For 1st Cycle Test 07022016SaiPraneethNoch keine Bewertungen

- Making and Using C-Ring Stress-Corrosion Test Specimens: Standard Practice ForDokument7 SeitenMaking and Using C-Ring Stress-Corrosion Test Specimens: Standard Practice Forvuqar0979Noch keine Bewertungen

- NULIFE-07-21 - Guideline For The Development of High Quality SCC Growth DataDokument26 SeitenNULIFE-07-21 - Guideline For The Development of High Quality SCC Growth DataOtso CronvallNoch keine Bewertungen

- Analytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryVon EverandAnalytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryNoch keine Bewertungen

- Metal matrix composites: Processing and InterfacesVon EverandMetal matrix composites: Processing and InterfacesR EverettNoch keine Bewertungen

- Swes v08 I1 PP 3 6Dokument4 SeitenSwes v08 I1 PP 3 6ashav patelNoch keine Bewertungen

- Towards Carburizing Treatment Applied On Low Alloy Steel 16CN6Dokument5 SeitenTowards Carburizing Treatment Applied On Low Alloy Steel 16CN6موسىNoch keine Bewertungen

- Effect of Heat TreatmentDokument5 SeitenEffect of Heat TreatmentsupNoch keine Bewertungen

- Horing 2010 - Characterization of Reverted Austenite During Prolonged Ageing of Maraging - ORIGINALDokument5 SeitenHoring 2010 - Characterization of Reverted Austenite During Prolonged Ageing of Maraging - ORIGINALIAragaoNoch keine Bewertungen

- NDT Characterization of Decarburization of Steel After Long-Time AnnealingDokument9 SeitenNDT Characterization of Decarburization of Steel After Long-Time AnnealingSHUBHNoch keine Bewertungen

- Photovoltaic Degradation of Methylene Blue Dye Using CuO Nanoparticles by SOL-GEL MethodDokument4 SeitenPhotovoltaic Degradation of Methylene Blue Dye Using CuO Nanoparticles by SOL-GEL MethodIJOCAASNoch keine Bewertungen

- Optimal Value of Cyclic Prefix and Effective Area For Single Polarization O-OfDMDokument4 SeitenOptimal Value of Cyclic Prefix and Effective Area For Single Polarization O-OfDMIJOCAASNoch keine Bewertungen

- Model Nano-Doped PolymersDokument4 SeitenModel Nano-Doped PolymersIJOCAASNoch keine Bewertungen

- Obtaining and Analyzing The Characteristics Curves of A Solar CellDokument5 SeitenObtaining and Analyzing The Characteristics Curves of A Solar CellIJOCAASNoch keine Bewertungen

- Model of System Recovery in Periodic Disaster and ReproductionDokument5 SeitenModel of System Recovery in Periodic Disaster and ReproductionIJOCAASNoch keine Bewertungen

- Photovoltaic Thermal PV-T Systems A ReviewDokument6 SeitenPhotovoltaic Thermal PV-T Systems A ReviewIJOCAASNoch keine Bewertungen

- Face Recognition Using Local Graph Structure and Support Vector Machine (LGS-SVM)Dokument5 SeitenFace Recognition Using Local Graph Structure and Support Vector Machine (LGS-SVM)IJOCAASNoch keine Bewertungen

- Calibration of Convex Lenses With 2nd Order Radial Distortion ModelDokument4 SeitenCalibration of Convex Lenses With 2nd Order Radial Distortion ModelIJOCAASNoch keine Bewertungen

- Car Accident Notification Based On Mobile ComputingDokument5 SeitenCar Accident Notification Based On Mobile ComputingIJOCAASNoch keine Bewertungen

- Tipped Fiber Bragg Grating Sensor For Concentration MeasurementsDokument5 SeitenTipped Fiber Bragg Grating Sensor For Concentration MeasurementsIJOCAASNoch keine Bewertungen

- A Review of Chronic Diseases Map and Data Trends AnalysisDokument13 SeitenA Review of Chronic Diseases Map and Data Trends AnalysisIJOCAASNoch keine Bewertungen

- The Characteristic of Li-Fi Technology Comparing With Wi-FiDokument6 SeitenThe Characteristic of Li-Fi Technology Comparing With Wi-FiIJOCAASNoch keine Bewertungen

- Smart Photovoltaic SystemDokument5 SeitenSmart Photovoltaic SystemIJOCAASNoch keine Bewertungen

- Automatic Attendance Registration System Based Mobile Cloud ComputingDokument7 SeitenAutomatic Attendance Registration System Based Mobile Cloud ComputingIJOCAAS100% (1)

- Photo Catalytic Degradation of Methylene Blue by Using CuO NanoparticlesDokument4 SeitenPhoto Catalytic Degradation of Methylene Blue by Using CuO NanoparticlesIJOCAASNoch keine Bewertungen

- Static Synchronous Compensator (SATACOM) Performance For Grid - Connected Wind TurbinesDokument6 SeitenStatic Synchronous Compensator (SATACOM) Performance For Grid - Connected Wind TurbinesIJOCAASNoch keine Bewertungen

- Nanofiltration Means (Reduced in Pollution, Water Consumption, and Win Money)Dokument5 SeitenNanofiltration Means (Reduced in Pollution, Water Consumption, and Win Money)IJOCAASNoch keine Bewertungen

- The Impact of Dust Accumulation On The PV Panels OutcomesDokument5 SeitenThe Impact of Dust Accumulation On The PV Panels OutcomesIJOCAASNoch keine Bewertungen

- Experimental and Numerical Study of Enhancement Heat Transfer in Tube Heat ExchangersDokument8 SeitenExperimental and Numerical Study of Enhancement Heat Transfer in Tube Heat ExchangersIJOCAASNoch keine Bewertungen

- Deposition of Colloidal Titanium and Copper Nanoparticles by Pulsed Laser Ablation On Si Solar Cell To Increase The EfficiencyDokument5 SeitenDeposition of Colloidal Titanium and Copper Nanoparticles by Pulsed Laser Ablation On Si Solar Cell To Increase The EfficiencyIJOCAASNoch keine Bewertungen

- Design of Hybrid Photovoltaic-Diesel System For Al-Sadder City in Baghdad-IraqDokument6 SeitenDesign of Hybrid Photovoltaic-Diesel System For Al-Sadder City in Baghdad-IraqIJOCAASNoch keine Bewertungen

- Forecasting Hydrogen Sulfide Level Based Neural ComputationDokument6 SeitenForecasting Hydrogen Sulfide Level Based Neural ComputationJabar H. YousifNoch keine Bewertungen

- IJOCAAS 01 01 001 Aug2016Dokument6 SeitenIJOCAAS 01 01 001 Aug2016Anonymous DSw62vBSWqNoch keine Bewertungen

- Solar Radiation, Temperature and Humidity Measurements in Sohar-OmanDokument6 SeitenSolar Radiation, Temperature and Humidity Measurements in Sohar-OmanIJOCAASNoch keine Bewertungen

- Human Comfort Indicators in The City of Baghdad-IraqDokument9 SeitenHuman Comfort Indicators in The City of Baghdad-IraqIJOCAASNoch keine Bewertungen

- Technical Test 03Dokument13 SeitenTechnical Test 03KartikNoch keine Bewertungen

- Standard Dimensions Grooved and Shouldered Joints AMERICAN - The Right WayDokument2 SeitenStandard Dimensions Grooved and Shouldered Joints AMERICAN - The Right WaySopon SrirattanapiboonNoch keine Bewertungen

- Frequency Polygons pdf3Dokument7 SeitenFrequency Polygons pdf3Nevine El shendidyNoch keine Bewertungen

- EE 8602 - Protection and Switchgear Unit I - MCQ BankDokument11 SeitenEE 8602 - Protection and Switchgear Unit I - MCQ Bankpoonam yadavNoch keine Bewertungen

- Num Sheet 1Dokument1 SeiteNum Sheet 1Abinash MohantyNoch keine Bewertungen

- FoundationDokument98 SeitenFoundationManognya KotaNoch keine Bewertungen

- Hooke's LawDokument1 SeiteHooke's LawAnan BarghouthyNoch keine Bewertungen

- Slip Ring Motor CheckDokument3 SeitenSlip Ring Motor CheckRolando LoayzaNoch keine Bewertungen

- Course Outline Principles of MarketingDokument3 SeitenCourse Outline Principles of MarketingKhate Tria De LeonNoch keine Bewertungen

- The Role of Needs Analysis in Adult ESL Programme Design: Geoffrey BrindleyDokument16 SeitenThe Role of Needs Analysis in Adult ESL Programme Design: Geoffrey Brindleydeise krieser100% (2)

- Bio 104 Lab Manual 2010Dokument236 SeitenBio 104 Lab Manual 2010Querrynithen100% (1)

- Libro INGLÉS BÁSICO IDokument85 SeitenLibro INGLÉS BÁSICO IRandalHoyos100% (1)

- 01 IntroductionDokument15 Seiten01 IntroductionAli FarhatNoch keine Bewertungen

- Curriculum Improvement v2Dokument47 SeitenCurriculum Improvement v2Nica Lagrimas100% (1)

- Business Statistics: Fourth Canadian EditionDokument41 SeitenBusiness Statistics: Fourth Canadian EditionTaron AhsanNoch keine Bewertungen

- Apps Android StudioDokument12 SeitenApps Android StudioDaniel AlcocerNoch keine Bewertungen

- Watershed Conservation of Benguet VisDokument2 SeitenWatershed Conservation of Benguet VisInnah Agito-RamosNoch keine Bewertungen

- The Invisible SunDokument7 SeitenThe Invisible SunJay Alfred100% (1)

- Kimura K.K. (KKK) : Can This Customer Be Saved? - Group D13Dokument6 SeitenKimura K.K. (KKK) : Can This Customer Be Saved? - Group D13Mayuresh GaikarNoch keine Bewertungen

- SR# Call Type A-Party B-Party Date & Time Duration Cell ID ImeiDokument12 SeitenSR# Call Type A-Party B-Party Date & Time Duration Cell ID ImeiSaifullah BalochNoch keine Bewertungen

- Evolution DBQDokument4 SeitenEvolution DBQCharles JordanNoch keine Bewertungen

- GARCH (1,1) Models: Ruprecht-Karls-Universit at HeidelbergDokument42 SeitenGARCH (1,1) Models: Ruprecht-Karls-Universit at HeidelbergRanjan KumarNoch keine Bewertungen

- 2014 Abidetal. TheoreticalPerspectiveofCorporateGovernance BulletinofBusinessDokument11 Seiten2014 Abidetal. TheoreticalPerspectiveofCorporateGovernance BulletinofBusinessOne PlusNoch keine Bewertungen

- DICKSON KT800/802/803/804/856: Getting StartedDokument6 SeitenDICKSON KT800/802/803/804/856: Getting StartedkmpoulosNoch keine Bewertungen

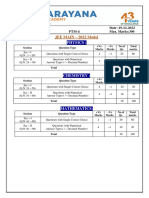

- Xii - STD - Iit - B1 - QP (19-12-2022) - 221221 - 102558Dokument13 SeitenXii - STD - Iit - B1 - QP (19-12-2022) - 221221 - 102558Stephen SatwikNoch keine Bewertungen

- 09-11-2016 University Exam PaperDokument34 Seiten09-11-2016 University Exam PaperSirisha AsadiNoch keine Bewertungen

- Tutorial: MSBA7003 Quantitative Analysis MethodsDokument29 SeitenTutorial: MSBA7003 Quantitative Analysis MethodsAmanda WangNoch keine Bewertungen

- Report Painter GR55Dokument17 SeitenReport Painter GR55Islam EldeebNoch keine Bewertungen

- Lic Nach MandateDokument1 SeiteLic Nach Mandatefibiro9231Noch keine Bewertungen

- 【SIEMENS】Cios Spin-FlyerDokument8 Seiten【SIEMENS】Cios Spin-FlyerAshleyNoch keine Bewertungen