Beruflich Dokumente

Kultur Dokumente

CL PDF

Hochgeladen von

Oscar VillaseñorOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

CL PDF

Hochgeladen von

Oscar VillaseñorCopyright:

Verfügbare Formate

TRANSMISSION/TRANSAXLE

SECTION CL CLUTCH

B

CL

E

CONTENTS

SERVICE INFORMATION ............................ 2 OPERATING CYLINDER .................................. 10 F

Component ..............................................................10

PRECAUTIONS ................................................... 2 Removal and Installation .........................................11

Precaution for Supplemental Restraint System Disassembly and Assembly .....................................11 G

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN- Inspection ................................................................11

SIONER" ................................................................... 2

Precaution ................................................................. 2 CLUTCH PIPING ............................................... 12

Component ..............................................................12 H

PREPARATION ................................................... 3 Removal and Installation .........................................12

Special Service Tool ................................................. 3

Commercial Service Tool .......................................... 3 CLUTCH RELEASE MECHANISM ................... 13 I

Component ..............................................................13

NOISE, VIBRATION AND HARSHNESS Removal and Installation .........................................13

(NVH) TROUBLESHOOTING ............................. 4 Inspection ................................................................14

NVH Troubleshooting Chart ...................................... 4 J

CLUTCH DISC, CLUTCH COVER AND FLY-

INSPECTION AND ADJUSTMENT ..................... 5 WHEEL .............................................................. 16

Inspection and Adjustment ........................................ 5 Component ..............................................................16 K

Removal and Installation .........................................16

CLUTCH PEDAL ................................................. 7 Inspection and Adjustment ......................................17

Component ................................................................ 7

Removal and Installation ........................................... 7 L

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................. 19

CLUTCH MASTER CYLINDER ........................... 8

Clutch Control System .............................................19

Component ................................................................ 8 M

Clutch Master Cylinder (with clutch damper) ...........19

Removal and Installation ........................................... 8

Clutch Operating Cylinder .......................................19

Disassembly and Assembly ...................................... 8

Clutch Disc ..............................................................19

Inspection .................................................................. 9

Clutch Cover ............................................................19 N

Revision: September 2009 CL-1 2010 D22 LCV

PRECAUTIONS

< SERVICE INFORMATION >

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000005781255

The Supplemental Restraint System such as AIR BAG and SEAT BELT PRE-TENSIONER, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing

serious injury.

When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution INFOID:0000000005473191

Recommended fluid is brake fluid DOT 3.

Never reuse drained brake fluid.

Be careful not to splash brake fluid on painted areas.

When removing and installing clutch piping, use Tool.

Use new brake fluid to clean or wash all parts of master cylin-

der, operating cylinder and clutch damper.

Never use mineral oils such as gasoline or kerosene. It will

ruin the rubber parts of the hydraulic system.

WARNING:

After cleaning the clutch disc, wipe it with a dust collector. Do

not use compressed air. SBR686C

Revision: September 2009 CL-2 2010 D22 LCV

PREPARATION

< SERVICE INFORMATION >

PREPARATION

A

Special Service Tool INFOID:0000000005473192

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here. B

Tool number

(Kent-Moore No.) Description

Tool name

CL

ST20600000 Installing clutch cover and clutch disc

(J-26366) a: 16 mm (0.630 in) dia.

Clutch aligning bar b: 22.8 mm (0.898 in) dia.

c: 55 mm (2.17 in) D

E

NT405

ST20050240 Adjusting unevenness of diaphragm spring of

( ) clutch cover

Diaphragm spring adjusting wrench F

ZZA0508D

Commercial Service Tool INFOID:0000000005473193

H

Tool name Description I

1. Flare nut crowfoot Removing and installing clutch piping

2. Torque wrench a: 10 mm (0.39 in)

J

K

NT360

Bearing puller Removing release bearing

L

NT077

Bearing drift Installing release bearing N

a: 52 mm (2.05 in) dia.

b: 45 mm (1.77 in) dia.

O

NT474

P

Revision: September 2009 CL-3 2010 D22 LCV

Symptom

(Possible cause)

gage

SUSPECTED PARTS

Clutch slips

Reference page

Clutch noisy

Revision: September 2009

Clutch pedal spongy

Clutch grabs/chatters

Clutch does not disen-

< SERVICE INFORMATION >

CLUTCH PEDAL (Inspection and Adjustment) CL-5

1

1

NVH Troubleshooting Chart

CLUTCH LINE (Air in line) CL-5

2

MASTER CYLINDER PISTON CUP (Damaged) CL-9

3

2

OPERATING CYLINDER PISTON CUP (Damaged) CL-11

4

2

ENGINE MOUNTING (Loose) EM-51 (KA24DE), EM-176 (YD25DDTi)

CL-4

RELEASE BEARING (Worn, dirty or damaged) CL-14

1

CLUTCH DISC (Out of true)

5

CLUTCH DISC (Runout is excessive)

5

CLUTCH DISC (Lining broken)

5

CLUTCH DISC (Dirty or burned)

5

CL-17

CLUTCH DISC (Oily)

5

2

CLUTCH DISC (Worn out)

2

CLUTCH DISC (Hardened)

2

cause of the problem. Check each part in order. If necessary, repair or replace these parts.

CLUTCH DISC (Lack of spline grease)

5

DIAPHRAGM SPRING (Damaged)

6

3

CL-17

DIAPHRAGM SPRING (Out of tip alignment)

2

6

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

PRESSURE PLATE (Distortion) CL-17

7

4

5 FLYWHEEL (Distortion) CL-17

2010 D22 LCV

Use the chart below to help you find the cause of the problem. The numbers indicate the priority of the likely

INFOID:0000000005473194

INSPECTION AND ADJUSTMENT

< SERVICE INFORMATION >

INSPECTION AND ADJUSTMENT

A

Inspection and Adjustment INFOID:0000000005473195

CLUTCH PEDAL INSPECTION AND ADJUSTMENT B

1. Check to see if the clutch pedal clevis pin (1) floats freely in the

bore of the clutch pedal (2). It should not be bound by the clevis

(3) or clutch pedal. CL

a. If the clevis pin is not free, check that the pedal stopper bolt (A)

is not applying pressure to the clutch pedal causing the clevis

pin to bind. To adjust, loosen the pedal stopper bolt lock nut (B) D

and turn the pedal stopper bolt.

b. Tighten the lock nut.

c. Verify that the clutch pedal clevis pin floats freely in the bore of E

the clutch pedal. It should not be bound by the clevis or clutch

pedal.

d. If the clevis pin is still not free, remove the clevis pin and check F

for deformation or damage. Replace the pin if necessary. Leave

the pin removed for step 2.

2. Check the clutch pedal stroke for free range of movement.

G

a. With the clutch pedal clevis pin removed, manually move the

pedal up and down to determine if it moves freely.

b. If any sticking is noted, replace the related parts (clutch pedal,

H

pedal bracket, assist spring, bushing, etc.). Reassemble the

pedal and re-verify that the clevis pin floats freely in the bore of

the pedal.

3. Check the clutch hydraulic system components (clutch master

AWDIA0513GB

I

cylinder, clutch operating cylinder, Clutch withdrawal lever, clutch release bearing, etc.) for sticking or

binding.

a. If any sticking or binding is noted, repair or replace the related parts as necessary. J

b. If any hydraulic system repair was necessary, bleed the clutch hydraulic system by following the bleeding

procedure.

K

BLEEDING PROCEDURE

CAUTION:

Carefully monitor the fluid level at the clutch master cylinder during the bleeding operation.

Do not splash brake fluid on painted areas; it may cause paint damage. If brake fluid is splashed on L

painted areas, wash it away with water immediately.

NOTE:

Do not use a vacuum assist or any other type of power bleeder on this system. Use of a vacuum assist or M

power bleeder will not purge all of the air from the system.

1. Top off the clutch master cylinder reservoir with the recommended brake fluid "DOT 3".

2. Connect a transparent vinyl tube to the air bleeder valve on the N

clutch operating cylinder as shown.

3. Slowly depress the clutch pedal to its full stroke and release it

completely. Repeat this operation several times at 2 to 3 sec- O

onds intervals.

4. With the clutch pedal fully depressed, open the air bleeder valve

to release the air.

P

5. Close the air bleeder valve.

6. Release the clutch pedal and wait at least 5 seconds.

7. Repeat steps 3 through 6 above until no more air bubbles are in SCL203-A

the brake fluid coming out of the vinyl tube attached to the air

bleeder valve.

8. Close the air bleeder valve and tighten to specification.

Revision: September 2009 CL-5 2010 D22 LCV

INSPECTION AND ADJUSTMENT

< SERVICE INFORMATION >

Air bleeder valve : Refer to CL-10, "Component".

Revision: September 2009 CL-6 2010 D22 LCV

CLUTCH PEDAL

< SERVICE INFORMATION >

CLUTCH PEDAL

A

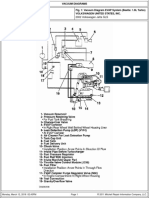

Component INFOID:0000000005473196

CL

I

AWDIA0515GB

1. Clutch pedal bracket 2. Fulcrum pin 3. Lock nut J

4. Pedal stopper bolt 5. Clevis pin 6. Pedal stopper rubber

7. Clutch pedal 8. Snap pin 9. Bushing

10. Assist spring A. Refer to CL-8, "Component". K

: Apply lithium-based grease including molybdenum disulphide.

Removal and Installation INFOID:0000000005473197 L

REMOVAL

1. Remove the clutch master cylinder nuts from inside the engine compartment. M

2. Remove the lower instrument panel LH. Refer to IP-10, "Removal and Installation".

3. Remove the snap pin and clevis pin from the clutch pedal.

4. Remove the clutch pedal bracket bolts and then remove the clutch pedal assembly. N

INSTALLATION

Installation is in the reverse order of removal. O

After installation, inspect and adjust the clutch pedal. Refer to CL-5, "Inspection and Adjustment".

Revision: September 2009 CL-7 2010 D22 LCV

CLUTCH MASTER CYLINDER

< SERVICE INFORMATION >

CLUTCH MASTER CYLINDER

Component INFOID:0000000005473198

AWDIA0514GB

1. Reservoir cap 2. Reservoir 3. Seal

4. Cylinder body 5. Push rod 6. Stopper

7. Stopper ring 8. Seat 9. Lock nut

10. Clevis 11. Piston assembly 12. Piston cup

13. Return spring 14. Spring pin

r: Apply rubber lubricant. S: Apply silicone grease.

Removal and Installation INFOID:0000000005473199

CAUTION:

Do not spill brake fluid onto painted surfaces. If it spills, wipe it up immediately and wash the affected

area with water.

REMOVAL

1. Remove the snap pin and clevis pin from the clevis, and separate it from the clutch pedal.

2. Drain the brake fluid from the clutch hydraulic system.

3. Remove the clutch tube from the clutch master cylinder using suitable tool.

4. Remove the clutch master cylinder nuts, and remove the clutch master cylinder from the vehicle.

INSTALLATION

Installation is in the reverse order of removal.

After installation, inspect and adjust the clutch pedal as necessary and bleed the clutch hydraulic system.

Refer to CL-5, "Inspection and Adjustment".

Disassembly and Assembly INFOID:0000000005473200

DISASSEMBLY

1. Remove the spring pin using suitable tool.

2. Remove the reservoir and seal from the cylinder body.

3. Remove the clevis and lock nut, if necessary.

4. Remove the seat, stopper ring, stopper and push rod.

CAUTION:

Carefully remove the push rod to prevent it from popping out and becoming damaged.

NOTE:

Revision: September 2009 CL-8 2010 D22 LCV

CLUTCH MASTER CYLINDER

< SERVICE INFORMATION >

Remove stopper ring using suitable tool while pushing push rod into cylinder body.

5. Remove the piston assembly and return spring. A

ASSEMBLY

Assembly is in the reverse order of disassembly.

When installing stopper ring, tap in lightly while pushing push rod into cylinder body. B

CAUTION:

Firmly hold the push rod into cylinder body to prevent it from popping out and becoming damaged.

CL

Inspection INFOID:0000000005473201

Check the following items, and replace if necessary.

Rubbing surface of cylinder and piston, for uneven wear, rust or damage D

Piston with piston cup, for wear or damage

Return spring, push rod, stopper and seat for wear or damage

Reservoir, for deformation or damage E

Revision: September 2009 CL-9 2010 D22 LCV

OPERATING CYLINDER

< SERVICE INFORMATION >

OPERATING CYLINDER

Component INFOID:0000000005473202

KA24DE MODELS

AWDIA0516GB

1. Clutch hose 2. Copper washer 3. Cylinder body

4. Piston spring 5. Piston cup 6. Piston assembly

7. Dust cover 8. Push rod 9. Air bleeder valve

R: Apply rubber grease. r: Apply rubber lubricant. S: Apply silicone grease.

YD25DDTi MODELS

AWDIA0517GB

1. Clutch hose (4WD) 2. Cylinder body 3. Piston spring

4. Piston cup 5. Piston assembly 6. Dust cover

7. Push rod 8. Air bleeder valve 9. Copper washer

Revision: September 2009 CL-10 2010 D22 LCV

OPERATING CYLINDER

< SERVICE INFORMATION >

10. Clutch hose (2WD)

A

R: Apply rubber grease. r: Apply rubber lubricant. S: Apply silicone grease.

Removal and Installation INFOID:0000000005473203

B

CAUTION:

Do not spill brake fluid on painted surfaces. If it spills, wipe up immediately and wash the affected area

with water.

CL

REMOVAL

1. Drain the brake fluid from the clutch hydraulic system.

2. Remove the clutch hose and copper washer from the operating cylinder. D

CAUTION:

Do not reuse copper washer.

3. Remove the operating cylinder bolts, and remove the operating cylinder. E

INSTALLATION

Installation is in the reverse order of removal.

CAUTION: F

Make sure the clutch hose is not bent or twisted.

After installation, bleed the clutch hydraulic system. Refer to CL-5, "Inspection and Adjustment".

G

Disassembly and Assembly INFOID:0000000005473204

DISASSEMBLY

H

Remove the dust cover, push rod, piston assembly and piston spring from the cylinder body.

ASSEMBLY

1. Apply rubber lubricant to the cylinder body inner surface and rubber grease to the piston cup and piston. I

2. Insert the piston assembly and piston spring into the cylinder body.

3. Apply rubber grease to the dust cover and install the push rod and dust cover.

J

Inspection INFOID:0000000005473205

Check the following items, and replace if necessary.

Rubbing surface of cylinder and piston, for uneven wear, rust or damage K

Piston assembly (piston with piston cup), for wear or damage

Piston spring, for wear or damage

Push rod, for wear or damage L

Dust cover, for cracks, deformation or damage

Revision: September 2009 CL-11 2010 D22 LCV

CLUTCH PIPING

< SERVICE INFORMATION >

CLUTCH PIPING

Component INFOID:0000000005473206

AWDIA0520GB

1. Clutch pedal 2. Clutch master cylinder 3. Clutch pipe

4. Connector (if equipped) 5. Clip 6. Clutch hose

7. Operating Cylinder

Removal and Installation INFOID:0000000005473207

Carefully observe the following during clutch tube removal and installation.

CAUTION:

Do not spill brake fluid onto painted surfaces. If it spills, wipe up immediately and wash the affected

area with water.

Do not reuse the copper washer.

Do not damage the clutch hose, clutch tube or fittings.

Make sure the clutch hose is not bent or twisted.

After installation, bleed the air from the clutch hydraulic system. Refer to CL-5, "Inspection and Adjustment".

Revision: September 2009 CL-12 2010 D22 LCV

CLUTCH RELEASE MECHANISM

< SERVICE INFORMATION >

CLUTCH RELEASE MECHANISM

A

Component INFOID:0000000005473208

CL

G

WCIA0441E

1. Holder spring 2. Release bearing sleeve 3. Release bearing

4. Withdrawal lever 5. Dust cover 6. Retainer spring

H

Removal and Installation INFOID:0000000005473209

I

REMOVAL

1. Remove the transmission. Refer to MT-12, "Removal and Installation" (KA24DE) or MT-52, "Removal and

Installation" (YD25DDTi). J

2. Remove the release bearing sleeve assembly, holder spring, and withdrawal lever from inside the clutch

housing.

3. Remove the dust cover. K

4. Remove the retainer spring from the withdrawal lever.

5. Remove the release bearing from the release bearing sleeve

using suitable tool. L

CL145

O

INSTALLATION

Installation is in the reverse order of removal.

P

Revision: September 2009 CL-13 2010 D22 LCV

CLUTCH RELEASE MECHANISM

< SERVICE INFORMATION >

When installing release bearing to release bearing sleeve, use

suitable drift.

WCL025

Install retainer spring and holder spring as shown.

SCL217

Clean old grease and abrasive materials off the grease application areas and apply grease to the specified

points as shown.

WCL043

Apply approximately 1mm (0.04 in) thick coat of grease to withdrawal lever and holder spring frictional sur-

faces.

Apply a coat of grease to ball pin contact surface of the withdrawal lever and inner slots of the release bear-

ing. The grease surface should be level with the surrounding area.

Apply a thin coat of clutch sleeve grease to the release bearing frictional surface. After grease application,

install release bearing and wipe off excess grease forced out during bearing installation.

CAUTION:

Do not bring any grease into contact with the clutch disc facing, pressure plate surface, or flywheel

surface.

Before installing transmission to the vehicle, check that each sliding surface slides smoothly by

operating the withdrawal lever.

Inspection INFOID:0000000005473210

Check the following items, and replace if necessary.

Revision: September 2009 CL-14 2010 D22 LCV

CLUTCH RELEASE MECHANISM

< SERVICE INFORMATION >

Release bearing, for faulty rotation, damage and proper alignment

Release bearing sleeve, for wear, rust or damage A

Withdrawal lever, for wear, rust or damage

Dust seal, for deformation or cracks

B

CL

SCL733

Revision: September 2009 CL-15 2010 D22 LCV

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

< SERVICE INFORMATION >

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

Component INFOID:0000000005473211

AWDIA0518GB

1. Flywheel 2. Clutch disc 3. Clutch cover

A. Refer to CL-16, "Removal and Installation".

: Apply lithium-based grease including molybdenum disulphide.

Removal and Installation INFOID:0000000005473212

CAUTION:

Do not clean the clutch disc with solvent.

When installing, do not get grease from the main drive shaft onto the clutch disc friction surface.

REMOVAL

1. Remove the manual transmission from the vehicle. Refer to MT-12, "Removal and Installation"

(FS5W71C) or MT-52, "Removal and Installation" (FS5R30A).

2. Remove the clutch cover bolts using power tool and remove the clutch cover and clutch disc.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Do not allow grease to contaminate the clutch facing.

When installing clutch disc and clutch cover, install the Tool and

pre-tighten the bolts. Then tighten the clutch cover bolts according

to the following.

Tool number : ST20630000 (J-26366)

WCIA0172E

KA24DE

Revision: September 2009 CL-16 2010 D22 LCV

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

< SERVICE INFORMATION >

- Tighten the clutch cover bolts to the specified torque in two steps in

numerical order as shown. A

Step 1 : 10 - 20 Nm (1.0 - 2.0 kg-m, 8 - 14 ft-lb)

Step 2 : 22 - 29 Nm (2.2 - 3.0 kg-m, 16 - 22 ft-lb) B

CL

AWDIA0519ZZ

D

YD25DDTi

- Tighten the clutch cover bolts to the specified torque in two steps in

numerical order as shown. E

Step 1 (A) : 10 - 20 Nm (1.0 - 2.0 kg-m, 8 - 14 ft-lb)

Step 2 (B) : 22 - 29 Nm (2.2 - 3.0 kg-m, 16 - 22 ft-lb) F

K

AWDIA0521ZZ

Inspection and Adjustment INFOID:0000000005473213

L

CLUTCH DISC

Check the following items, and replace if necessary.

Clutch disc, for burns, discoloration, oil or grease leakage M

Clutch disc, for wear of facing

Facing wear : Refer to CL-19, "Clutch Disc".

N

ACL063

Revision: September 2009 CL-17 2010 D22 LCV

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

< SERVICE INFORMATION >

Clutch disc, for runout of facing and backlash of spline.

Runout and backlash : Refer to CL-19, "Clutch Disc".

ACL064

CLUTCH COVER

Check clutch cover, installed on vehicle, for uneven diaphragm

spring toe height. If unevenness exceeds the limit, adjust the dia-

phragm spring toe height using Tool.

Uneven limit of diaphragm : Refer to CL-19, "Clutch

spring toe height Cover".

Tool number : ST20050240 ( )

SCL466

FLYWHEEL

CAUTION:

Do not allow any magnetic materials to contact the ring gear teeth.

Inspect contact surface of flywheel for slight burns or discoloration. Clean flywheel with emery paper.

Check flywheel runout. Refer to EM-55, "Inspection" (KA24DE), or

EM-192, "Inspection After Disassembly" (YD25DDTi).

AEM100

Revision: September 2009 CL-18 2010 D22 LCV

SERVICE DATA AND SPECIFICATIONS (SDS)

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

A

Clutch Control System INFOID:0000000005473214

B

Type of clutch control Hydraulic

Clutch Master Cylinder (with clutch damper) INFOID:0000000005473215

CL

Inner diameter 15.87 mm (5/8 in)

D

Clutch Operating Cylinder INFOID:0000000005473216

Unit: mm (in)

E

Engine KA24DE YD25DDTi

Inner diameter 17.46 (11/16) 19.05 (3/4)

Clutch Disc INFOID:0000000005473217 F

Unit: mm (in)

Engine KA24DE YD25DDTi G

Model 240 250

Facing size 240 x 150 x 3.5 250 x 160 x 3.5

(Outer dia. x inner dia. x thickness) (9.45 x 5.91 x 0.138) (9.84 x 6.30 x 0.138) H

7.75 - 8.25 (0.305 - 0.3248) 8.1 - 8.5 (0.3189 - 0.3346)

Thickness of disc assembly with load

with 4,903 N (500 kg, 1,103 lb) with 7,350 N (750 kg, 1,652 lb)

I

Wear limit of facing surface to rivet head 0.3 (0.012) 0.3 (0.012)

Runout limit of facing 1.0 (0.039) 0.7 (0.028)

Distance of runout check point (from hub center) 115 (4.53) 120 (4.72) J

Maximum backlash of spline (at outer edge of disc) 1.0 (0.039) 1.0 (0.039)

Clutch Cover INFOID:0000000005473218

K

Unit: mm (in)

Engine KA24DE YD25DDTi

L

Model 240 250

2WD 4,903 N (500 kg, 1,103 lb) 7,360 N (751 kg, 1,655 lb)

Set-load

4WD 7,360 N (751 kg, 1,655 lb) M

Diaphragm spring height 38.5 (1.516) 40.5 (1.594)

Uneven limit of diaphragm spring toe height 0.7 (0.028) 0.7 (0.028)

N

Revision: September 2009 CL-19 2010 D22 LCV

Das könnte Ihnen auch gefallen

- Campaña de Bateria de Carro ElectricoDokument3 SeitenCampaña de Bateria de Carro ElectricoOscar VillaseñorNoch keine Bewertungen

- Dongle User Manual V1.3Dokument5 SeitenDongle User Manual V1.3Eduardo Alvarez HuizaNoch keine Bewertungen

- Ma PDFDokument51 SeitenMa PDFOscar VillaseñorNoch keine Bewertungen

- Lan System: SectionDokument44 SeitenLan System: SectionOscar VillaseñorNoch keine Bewertungen

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- GLASSES, WINDOW SYSTEM & MIRRORS SERVICE INFORMATIONDokument42 SeitenGLASSES, WINDOW SYSTEM & MIRRORS SERVICE INFORMATIONOscar VillaseñorNoch keine Bewertungen

- Codigo P076aDokument6 SeitenCodigo P076aOscar VillaseñorNoch keine Bewertungen

- ZED-BULL Installation ExplainDokument7 SeitenZED-BULL Installation ExplainHerciu Andreea RoxanaNoch keine Bewertungen

- 1 8Dokument1 Seite1 8Oscar VillaseñorNoch keine Bewertungen

- Steering System ManualDokument21 SeitenSteering System ManualOscar VillaseñorNoch keine Bewertungen

- Lighting System: SectionDokument42 SeitenLighting System: SectionOscar VillaseñorNoch keine Bewertungen

- Lu PDFDokument28 SeitenLu PDFOscar VillaseñorNoch keine Bewertungen

- Fsu PDFDokument45 SeitenFsu PDFOscar VillaseñorNoch keine Bewertungen

- Instrument Panel Squeak and Rattle DiagnosisDokument14 SeitenInstrument Panel Squeak and Rattle DiagnosisOscar Villaseñor100% (1)

- FL PDFDokument21 SeitenFL PDFOscar VillaseñorNoch keine Bewertungen

- B D A C E F G H I J K L: Transmission/ TransaxleDokument9 SeitenB D A C E F G H I J K L: Transmission/ TransaxleOscar Villaseñor100% (1)

- BL PDFDokument67 SeitenBL PDFOscar VillaseñorNoch keine Bewertungen

- Front Final Drive: SectionDokument32 SeitenFront Final Drive: SectionOscar VillaseñorNoch keine Bewertungen

- Ei PDFDokument32 SeitenEi PDFOscar VillaseñorNoch keine Bewertungen

- Fax PDFDokument27 SeitenFax PDFOscar VillaseñorNoch keine Bewertungen

- BRC PDFDokument74 SeitenBRC PDFOscar VillaseñorNoch keine Bewertungen

- Di PDFDokument53 SeitenDi PDFOscar VillaseñorNoch keine Bewertungen

- Electrical Audio, Visual & Telephone System GuideDokument13 SeitenElectrical Audio, Visual & Telephone System GuideOscar VillaseñorNoch keine Bewertungen

- Ex PDFDokument6 SeitenEx PDFOscar VillaseñorNoch keine Bewertungen

- BR PDFDokument33 SeitenBR PDFOscar VillaseñorNoch keine Bewertungen

- Boletin Codigo 722 y 720 Sensor de VelocidadDokument3 SeitenBoletin Codigo 722 y 720 Sensor de VelocidadOscar VillaseñorNoch keine Bewertungen

- Engine Cooling System: SectionDokument47 SeitenEngine Cooling System: SectionOscar VillaseñorNoch keine Bewertungen

- Acc PDFDokument5 SeitenAcc PDFOscar Villaseñor100% (1)

- Diagram AsDokument3 SeitenDiagram AsOscar VillaseñorNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Theoretical and Experimental Contactless Eddy Current Braking SystemDokument3 SeitenTheoretical and Experimental Contactless Eddy Current Braking SystemInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Falk Lifelign Couplings MetricDokument44 SeitenFalk Lifelign Couplings MetricTeguh Ariefia GunawanNoch keine Bewertungen

- 2023년 N-MAX125 (BALF) (1YBAL411E5) .o 1h2pgtc17p90ngtbam1hjkb6i8Dokument64 Seiten2023년 N-MAX125 (BALF) (1YBAL411E5) .o 1h2pgtc17p90ngtbam1hjkb6i8BikeMaKer BMKNoch keine Bewertungen

- Supplementary Service Manual: 5JN4-AE1Dokument117 SeitenSupplementary Service Manual: 5JN4-AE1IronHorseRiders100% (1)

- P2 Forces and Motion IntermediateDokument16 SeitenP2 Forces and Motion IntermediatedownendscienceNoch keine Bewertungen

- Chapter10 BrakesDokument31 SeitenChapter10 BrakesShreyas IyengarNoch keine Bewertungen

- Parking Brake System: SectionDokument156 SeitenParking Brake System: SectionАндрей НадточийNoch keine Bewertungen

- Dampers Bridges 01 2014 PDFDokument16 SeitenDampers Bridges 01 2014 PDFBarben Group CorpNoch keine Bewertungen

- Catalogo INDEXATOR Rotator EngelskaDokument20 SeitenCatalogo INDEXATOR Rotator EngelskaLars Y. Aray C.Noch keine Bewertungen

- Snake PitDokument15 SeitenSnake Pitnomader56Noch keine Bewertungen

- Boxer BM 150Dokument36 SeitenBoxer BM 150MATEO FRANCISCO REINOSO GOMEZNoch keine Bewertungen

- 8763846-Honda Cr80r Service Repair Manual 1985-1994 Cr80Dokument247 Seiten8763846-Honda Cr80r Service Repair Manual 1985-1994 Cr80paulo50% (4)

- INNSBRUCK User Manual 08212022 1Dokument13 SeitenINNSBRUCK User Manual 08212022 1Caátia Flávia AlmeidaNoch keine Bewertungen

- BMW Datenblatt F 800 R 9 01 08Dokument2 SeitenBMW Datenblatt F 800 R 9 01 08daemonium666Noch keine Bewertungen

- Beringer Brakes Catalogue 2014Dokument88 SeitenBeringer Brakes Catalogue 2014AntonioPalloneNoch keine Bewertungen

- Pintsch Bubenzer SB Brakes CatalogDokument12 SeitenPintsch Bubenzer SB Brakes CatalogEliud AlcarazNoch keine Bewertungen

- Service Booklet: Light TruckDokument33 SeitenService Booklet: Light TruckpcmundotNoch keine Bewertungen

- DTS Unit 5Dokument20 SeitenDTS Unit 5Muthuvel MNoch keine Bewertungen

- Tiger Tractor TC-50 PDFDokument692 SeitenTiger Tractor TC-50 PDFCarlos SolisNoch keine Bewertungen

- Catalog Europa 2014Dokument106 SeitenCatalog Europa 2014ALECUNoch keine Bewertungen

- New Holland CSX7080 PartsDokument1.061 SeitenNew Holland CSX7080 PartsStepan100% (1)

- Alfa Romeo 156 Technical Specifications and Parts CatalogDokument188 SeitenAlfa Romeo 156 Technical Specifications and Parts CatalogcasjcNoch keine Bewertungen

- 206-00 Brake System General - General Procedures - Front Brake Disc Runout CheckDokument4 Seiten206-00 Brake System General - General Procedures - Front Brake Disc Runout CheckCARLOS LIMADANoch keine Bewertungen

- Productos para TráilersDokument204 SeitenProductos para TráilersRymeAutomotiveNoch keine Bewertungen

- KISBEE 50CC-04A BDDokument76 SeitenKISBEE 50CC-04A BDJohan VDWNoch keine Bewertungen

- Bill Honda City AP09BT7726-1 PDFDokument8 SeitenBill Honda City AP09BT7726-1 PDFbeast nightNoch keine Bewertungen

- Wheel Loader Brake SystemDokument23 SeitenWheel Loader Brake Systemsuwardjo100% (1)

- Ceramic Disc BrakeDokument16 SeitenCeramic Disc BrakesachinNoch keine Bewertungen

- SD300H Spec Sheet - 2015.03.09Dokument19 SeitenSD300H Spec Sheet - 2015.03.09Luis Fernando Leal100% (2)

- Discovery 2 MY99 On - Workshop Manual (VDR100090)Dokument1.672 SeitenDiscovery 2 MY99 On - Workshop Manual (VDR100090)Kevin HillebrandNoch keine Bewertungen