Beruflich Dokumente

Kultur Dokumente

Nickel Base Alloys

Hochgeladen von

ElMacheteDelHuesoCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Nickel Base Alloys

Hochgeladen von

ElMacheteDelHuesoCopyright:

Verfügbare Formate

Section D - Nickel Base consumables

As a whole, nickel-base consumables have a very wide range of applications. They can be roughly divided

into those with compositions matching specific parent materials, usually for corrosion resistance, and

those with compositions unique to weld metal specifications some of which have specialised uses and

others more general purpose applications.

Electrode characteristics vary according to the intended application and the constraints dictated by

particular alloys. Most types have basic flux coverings, those with the suffix KS being suitable for positional

welding of fixed pipework. Rutile flux systems are compatible with some of the high molybdenum

corrosion-resistant alloys. A low level of impurities is desirable in all cases to minimise sensitivity to hot

cracking and microfissuring.

The most important general purpose group are the 'Inconel' types, very loosely based on heat-resistant

alloy 600 with 15%Cr-75%Ni-8%Fe. Compared with alloy 600, all these weld metals have significant

additions of manganese and niobium which give resistance to hot cracking and raise hot strength. Nimrod

182/182KS have the highest manganese to maximise resistance to hot cracking, whereas in Nimrod

AB/AKS manganese is partially replaced by molybdenum which has the additional effect of improving

creep resistance. In many applications these two types can be used interchangeably, particularly in

dissimilar metal welds between nickel base and most steels or other ferrous alloys. Useful service

properties range from cryogenic up to elevated temperatures of 1000C plus. Related to these is the more

specialised heat resisting type Nimrod 132KS used primarily for welding 600 and similar materials in cast

or wrought form.

Nimrod 625/625KS electrodes and 62-50 wires are designed to match alloy 625 which was originally

developed for heat-resisting applications. However, parent material and consumables of this alloy have

gained more widespread use for many applications exploiting its excellent pitting and crevice corrosion

resistance and high strength at all service temperatures.

Electrode types Nimrod C276, C276KS, C22KS and Nimax B2L and complimentary solid wires match the

current specifications for corrosion-resistant parent alloys C276, C22 and B2 respectively. Also related to

this group is the higher alloy Nimrod 59KS, matching alloy 59. Their uses include overmatching welds for

various superaustenitic stainless steels.

The precursor to alloy C276 was alloy C which is represented by rutile electrodes Nimrod C and the high

efficiency type Nimax C. Their general corrosion resistance is useful for overlays and high work-hardening

rate and thermal fatigue resistance for build-up and repair of hot-work dies.

Welding 5%Ni and 9%Ni steels for cryogenic service requires a combination of strength and toughness that

cannot be obtained reliably using weld metal of similar composition. In practice dissimilar nickel base

weld metal is used. Nimrod NCM6 is a high efficiency electrode particularly intended for this purpose, but

others may be suitable alternatives depending on design requirements.

Nickel, nickel-copper (Monel ) and cupronickel consumables are well established for use in high integrity

fabrication welds between their respective parent alloys. For surfacing steels or dissimilar welds it should

be noted that tolerance to iron dilution decreases with increasing copper content and the pure nickel type

is therefore used as a buffer layer.

Inconel and Monel are trademarks of Special Metals.

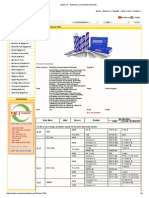

Column for gas processing plant 20.70.Nb MIG wire

Data Specifications

Alloy Process Product

Sheet AWS BS EN / BS EN ISO

Nimrod 182KS ENiCrFe-3 E Ni6182

MMA Nimrod 182 ENiCrFe-3 E Ni6182

D-10 182

Nimax 182 ENiCrFe-3 E Ni6182

TIG/MIG/SAW 20.70.Nb ERNiCr-3 SNi6082

Nimrod AKS ENiCrFe-2 E Ni6092

MMA

D-11 AB Nimrod AB ENiCrFe-2/4 E Ni6093

TIG/MIG/SAW 20.70.Nb ERNiCr-3 SNi6082

D-12 132 MMA Nimrod 132KS ENiCrFe-1 E Ni6062

Nimrod 625 ENiCrMo-3 E Ni6625

MMA

D-20 625 Nimrod 625KS ENiCrMo-3 E Ni6625

TIG/MIG/SAW 62-50 ERNiCrMo-3 SNi6625

Nimrod C276 ENiCrMo-4 E Ni6276

MMA

D-30 C276 Nimrod C276KS ENiCrMo-4 E Ni6276

TIG/MIG/SAW HAS C276 ERNiCrMo-4 SNi6276

MMA Nimrod 59KS ENiCrMo-13 E Ni6059

D-31 59

TIG/MIG HAS 59 ERNiCrMo-13 SNi6059

MMA Nimrod C22KS ENiCrMo-10 E Ni6022

D-32 C22

TIG/MIG HAS C22 ERNiCrMo-10 SNi6022

MMA Nimrod 617KS ENiCrCoMo-1 E Ni6617

D-40 617

TIG 61-70 ERNiCrCoMo-1 SNi6617

D-41 690 MMA Nimrod 690KS ENiCrFe-7 E Ni6152

MMA Nimrod 200Ti ENi-1 E Ni2061

D-50 Nickel

TIG/MIG Nickel 2Ti ERNi-1 SNi2061

MMA Nimrod 190 ENiCu-7 E Ni4060

D-60 Monel

TIG/MIG/SAW 65NiCu ERNiCu-7 SNi4060

MMA Cupromet N30 ECuNi --

D-70 Cupronickel TIG/MIG 70CuNi ERCuNi BS: C18

TIG 90CuNi -- BS C16

MMA Nimax B2L ENiMo-7 E Ni1066

D-80 B2

TIG HAS B2 ERNiMo-7 SNi1066

D-87 Dissimilar MMA EPRI P87 -- --

Nimrod C (ENiCrMo-5) DIN: E23-UM-200CKT

E-45 C MMA

Nimax C (ENiCrMo-5) DIN: E23-UM-200CKT

Walking beam furnace Nimrod 182 used

Das könnte Ihnen auch gefallen

- Materials Data for Cyclic Loading: Low-Alloy SteelsVon EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsBewertung: 5 von 5 Sternen5/5 (2)

- Svařovací Dráty A Tyčky Oddíl SDokument31 SeitenSvařovací Dráty A Tyčky Oddíl SWael MansourNoch keine Bewertungen

- 182Dokument1 Seite182ElMacheteDelHuesoNoch keine Bewertungen

- Repair and MaintenanceDokument4 SeitenRepair and MaintenanceElMacheteDelHuesoNoch keine Bewertungen

- item8-LNT NiCro60.20Dokument1 Seiteitem8-LNT NiCro60.20VVan TanNoch keine Bewertungen

- FSH TigDokument105 SeitenFSH TigChee WeiNoch keine Bewertungen

- item11-LNT NiCroMo 59.23Dokument1 Seiteitem11-LNT NiCroMo 59.23VVan TanNoch keine Bewertungen

- Metrode Instructions For 625 Wires D20Dokument5 SeitenMetrode Instructions For 625 Wires D20haran2000Noch keine Bewertungen

- High Quality Products For Welding and CladdingDokument25 SeitenHigh Quality Products For Welding and Claddingsanketpavi21100% (1)

- Alloy 625 ConsumablesDokument4 SeitenAlloy 625 ConsumablesRodrigo CarneiroNoch keine Bewertungen

- Method Statement For Welding-Rev.01Dokument6 SeitenMethod Statement For Welding-Rev.01weydongshengNoch keine Bewertungen

- Ni Resist and Ductile Ni Resist Alloys 11018Dokument40 SeitenNi Resist and Ductile Ni Resist Alloys 11018Prasad Aher100% (1)

- VOKSEL Power CablesDokument33 SeitenVOKSEL Power CablesAbyssus TntNoch keine Bewertungen

- Giunzione e ManutenzioneDokument29 SeitenGiunzione e Manutenzionerenhat parulian sitorusNoch keine Bewertungen

- Special Metals - Product CatalogDokument65 SeitenSpecial Metals - Product Catalogilham_metallurgy6744Noch keine Bewertungen

- Weldwell Catalogue PDFDokument8 SeitenWeldwell Catalogue PDFmitesh0% (1)

- Wespa 2014-EDokument46 SeitenWespa 2014-ESergio Gonzalez GuzmanNoch keine Bewertungen

- CMI WeldingChartsDokument1 SeiteCMI WeldingChartsnitinNoch keine Bewertungen

- CMI WeldingChartsDokument1 SeiteCMI WeldingChartsnitinNoch keine Bewertungen

- Stainless SteelsDokument4 SeitenStainless SteelsElMacheteDelHuesoNoch keine Bewertungen

- Mn-Mo Gas Shileded (E90T1-D3, E100T5-D2) PDFDokument1 SeiteMn-Mo Gas Shileded (E90T1-D3, E100T5-D2) PDFborovniskiNoch keine Bewertungen

- Section 12 - Welding Consumables - NickelDokument26 SeitenSection 12 - Welding Consumables - NickelFriedrich SchwimNoch keine Bewertungen

- Nickel Alloy Based Filler MetalDokument1 SeiteNickel Alloy Based Filler MetaljoehodohNoch keine Bewertungen

- Untitled 1 PDFDokument35 SeitenUntitled 1 PDFRAVI KANT BARANWALNoch keine Bewertungen

- Duplex-Alloy-2205-Stress ValuesDokument5 SeitenDuplex-Alloy-2205-Stress ValuesShiniNoch keine Bewertungen

- Nickel and HT Alloys For Petrochemical Applications PDFDokument39 SeitenNickel and HT Alloys For Petrochemical Applications PDFganeshNoch keine Bewertungen

- Equivalent Grades, Seamless Pipes, Tubes, Welded Pipes, Electric Resistance, Welded Tubes, Carbon Steel, Heat ExchangerDokument3 SeitenEquivalent Grades, Seamless Pipes, Tubes, Welded Pipes, Electric Resistance, Welded Tubes, Carbon Steel, Heat ExchangerMediAnsyahNoch keine Bewertungen

- Valve MaterialsDokument1 SeiteValve MaterialsMarcel BolovedeaNoch keine Bewertungen

- Duplex UNS 32205Dokument1 SeiteDuplex UNS 32205Ercan YilmazNoch keine Bewertungen

- Weldwell Catalogue 2015Dokument8 SeitenWeldwell Catalogue 2015jaganelrNoch keine Bewertungen

- U Utp A 786 Gmaw 01Dokument1 SeiteU Utp A 786 Gmaw 01RPNoch keine Bewertungen

- A-23 WB36 Rev 03 15NiCuMoNb5 MicrostructureDokument4 SeitenA-23 WB36 Rev 03 15NiCuMoNb5 Microstructuremavis16Noch keine Bewertungen

- MaterialsDokument2 SeitenMaterialsLLNoch keine Bewertungen

- ShamrockDokument12 SeitenShamrockFerdinand LizadaNoch keine Bewertungen

- EN19 Alloy Steel - EN19 Forging - EN19 Flat - Saaj Steel CorporationDokument5 SeitenEN19 Alloy Steel - EN19 Forging - EN19 Flat - Saaj Steel CorporationNaiduNoch keine Bewertungen

- Barrettetig Catalogo Oerlikon 35035Dokument44 SeitenBarrettetig Catalogo Oerlikon 35035mp303Noch keine Bewertungen

- Metrode Dissimilar Consumable SelectorDokument7 SeitenMetrode Dissimilar Consumable SelectorClaudia MmsNoch keine Bewertungen

- TDG 7467 001 Rev 00Dokument17 SeitenTDG 7467 001 Rev 00Dilip PatilNoch keine Bewertungen

- All Types of MaterialsDokument8 SeitenAll Types of MaterialsAniket KabadeNoch keine Bewertungen

- Low Alloy13Dokument5 SeitenLow Alloy13Branko FerenčakNoch keine Bewertungen

- Hot-Rolled Seamless Tubes For Mechanical ApplicationsDokument8 SeitenHot-Rolled Seamless Tubes For Mechanical ApplicationsErhan BeylihanNoch keine Bewertungen

- CAPILLA - Welding Consumables For Welding of Creep and Heat ResistantDokument40 SeitenCAPILLA - Welding Consumables For Welding of Creep and Heat ResistantdantegimenezNoch keine Bewertungen

- 20NiCrMo2-2 Alloy Steel DIN 1.6523 AISI 8620 SteelDokument5 Seiten20NiCrMo2-2 Alloy Steel DIN 1.6523 AISI 8620 SteelzhenyupanNoch keine Bewertungen

- Welding Wire CatalogDokument10 SeitenWelding Wire CatalogElvis MaljanovicNoch keine Bewertungen

- LINCOLN Nicromo 60-16Dokument2 SeitenLINCOLN Nicromo 60-16AbdülHak ÖZkaraNoch keine Bewertungen

- 3dprint AM 625: Material TypeDokument1 Seite3dprint AM 625: Material TypeKara WhiteNoch keine Bewertungen

- WeldingDokument9 SeitenWeldingAkshay VenugopalNoch keine Bewertungen

- Weldability of Materials - Nickel and Nickel AlloysDokument5 SeitenWeldability of Materials - Nickel and Nickel AlloysmanimaranNoch keine Bewertungen

- Aladin SDokument4 SeitenAladin SJeffrey BeanNoch keine Bewertungen

- Stainless Steel Welding by Weld RealityDokument50 SeitenStainless Steel Welding by Weld RealitylightwinterdayNoch keine Bewertungen

- JIS G4103 Grade SNCM439: Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearDokument4 SeitenJIS G4103 Grade SNCM439: Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearsaputraNoch keine Bewertungen

- Nimonic AlloyDokument2 SeitenNimonic AlloyOZAIRTRADELINKNoch keine Bewertungen

- Covered Electrodes For Stainless Steel: Avesta Electrodes Product ProgrammeDokument4 SeitenCovered Electrodes For Stainless Steel: Avesta Electrodes Product Programmekamals55Noch keine Bewertungen

- JIS G4103 Grade SNCM220: Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearDokument4 SeitenJIS G4103 Grade SNCM220: Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearsaputraNoch keine Bewertungen

- CERTILAS EN Edition2023 318Dokument1 SeiteCERTILAS EN Edition2023 318Alireza KhodabandehNoch keine Bewertungen

- MIP Bohler Welding Austria 364Dokument1 SeiteMIP Bohler Welding Austria 364c131508Noch keine Bewertungen

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesVon EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNoch keine Bewertungen

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantVon EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Za G. IvkovićaDokument1 SeiteZa G. IvkovićaElMacheteDelHuesoNoch keine Bewertungen

- Hpes 34Dokument31 SeitenHpes 34ElMacheteDelHuesoNoch keine Bewertungen

- Radiography BookDokument40 SeitenRadiography BookBijo Mathew100% (1)

- Č Itanje RadiogramaDokument2 SeitenČ Itanje RadiogramaElMacheteDelHuesoNoch keine Bewertungen

- Za G. Ivkovića-R1Dokument1 SeiteZa G. Ivkovića-R1ElMacheteDelHuesoNoch keine Bewertungen

- HBP-QMS-WI 15-14 - Control and Issue of Welding Consumables Rev 01Dokument6 SeitenHBP-QMS-WI 15-14 - Control and Issue of Welding Consumables Rev 01ElMacheteDelHuesoNoch keine Bewertungen

- EJ Handbook.A5Dokument261 SeitenEJ Handbook.A5ElMacheteDelHuesoNoch keine Bewertungen

- Sulfide Stress Cracking - NACE MR0175-2002, MR0175/ISO 15156Dokument9 SeitenSulfide Stress Cracking - NACE MR0175-2002, MR0175/ISO 15156Anonymous B7pghhNoch keine Bewertungen

- Sandvik Pipe - Tube - Bar - Hollow Bar: Stock Program in StainlessDokument26 SeitenSandvik Pipe - Tube - Bar - Hollow Bar: Stock Program in Stainlessalbejo_r9Noch keine Bewertungen

- FPWHT p1 h5 Soft L r1Dokument2 SeitenFPWHT p1 h5 Soft L r1ElMacheteDelHuesoNoch keine Bewertungen

- B-61 25Cr Zeron 100 Superduplex Rev 08Dokument5 SeitenB-61 25Cr Zeron 100 Superduplex Rev 08Luis Gustavo AndradeNoch keine Bewertungen

- Industrial Materials For The Future R&D Strategies:: A Case Study of Boiler Materials For The Pulp and Paper IndustryDokument58 SeitenIndustrial Materials For The Future R&D Strategies:: A Case Study of Boiler Materials For The Pulp and Paper IndustryElMacheteDelHuesoNoch keine Bewertungen

- Ferralium LeafletDokument21 SeitenFerralium LeafletChristian Contreras ArdilesNoch keine Bewertungen

- Enq Cov 2620900154 TotDokument31 SeitenEnq Cov 2620900154 TotElMacheteDelHuesoNoch keine Bewertungen

- AVESTA POLARIT - Stainless Steels - Their Properties and Their Suitability For WeldingDokument11 SeitenAVESTA POLARIT - Stainless Steels - Their Properties and Their Suitability For Weldingmirza_adil99Noch keine Bewertungen

- CM900Dokument1 SeiteCM900ElMacheteDelHuesoNoch keine Bewertungen

- E 8018 B2Dokument1 SeiteE 8018 B2ElMacheteDelHuesoNoch keine Bewertungen

- HR3 1Dokument1 SeiteHR3 1ElMacheteDelHuesoNoch keine Bewertungen

- LE HD4 IEC-GOST (EN) A 1VCP000260-0904xDokument2 SeitenLE HD4 IEC-GOST (EN) A 1VCP000260-0904xElMacheteDelHuesoNoch keine Bewertungen

- MIG 80SB2: ClassificationDokument1 SeiteMIG 80SB2: ClassificationElMacheteDelHuesoNoch keine Bewertungen

- ECO Model PDFDokument1 SeiteECO Model PDFElMacheteDelHuesoNoch keine Bewertungen

- Baldev 5Dokument62 SeitenBaldev 5ElMacheteDelHuesoNoch keine Bewertungen

- 79695L 002Dokument156 Seiten79695L 002ElMacheteDelHuesoNoch keine Bewertungen

- 479Dokument7 Seiten479ElMacheteDelHuesoNoch keine Bewertungen

- Greda WHTPDokument1 SeiteGreda WHTPElMacheteDelHuesoNoch keine Bewertungen

- Stellite 6 FinalDokument2 SeitenStellite 6 FinalGumersindo MelambesNoch keine Bewertungen

- 05 ADokument3 Seiten05 APWHt.es : Tratamiento térmico de la soldaduraNoch keine Bewertungen

- Cromax 42CrMo4Dokument3 SeitenCromax 42CrMo4ElMacheteDelHuesoNoch keine Bewertungen

- BohlerThyssen PDFDokument386 SeitenBohlerThyssen PDFElMacheteDelHuesoNoch keine Bewertungen

- Chapter 3 TurbomachineDokument60 SeitenChapter 3 TurbomachineMohd Soufian100% (1)

- Energizer 522: Product DatasheetDokument1 SeiteEnergizer 522: Product DatasheetAli AbdullahNoch keine Bewertungen

- A Working Guide To Shell-and-Tube Heat ExchangersDokument642 SeitenA Working Guide To Shell-and-Tube Heat ExchangersSiva baalan80% (5)

- Semester II Shivaji University Kolhapur S. E. Electrical II Power ElectronicsDokument2 SeitenSemester II Shivaji University Kolhapur S. E. Electrical II Power ElectronicsAnonymous q6cOT5XgXANoch keine Bewertungen

- SQT 200 - 250 Maintenace OperationDokument179 SeitenSQT 200 - 250 Maintenace Operationosteanu100% (4)

- Bangladesh Power Development Board Electricity Bill: LT CONSUMER (Single Register)Dokument1 SeiteBangladesh Power Development Board Electricity Bill: LT CONSUMER (Single Register)adfaxfafaea0% (1)

- Viskoziteee PDFDokument8 SeitenViskoziteee PDFKamil AytekinNoch keine Bewertungen

- A Simple Heliodon System For Horizontal Placed ModelsDokument8 SeitenA Simple Heliodon System For Horizontal Placed ModelsJournal of Contemporary Urban AffairsNoch keine Bewertungen

- Title: Boom Cylinder Model Number: E32 Serial Number: A94H11001 & Above, AC2N11001 & AboveDokument3 SeitenTitle: Boom Cylinder Model Number: E32 Serial Number: A94H11001 & Above, AC2N11001 & AboveMateo Londoño UrreaNoch keine Bewertungen

- 1 Copert MainDokument18 Seiten1 Copert MaindpmgumtiNoch keine Bewertungen

- Primo SD Data SheetDokument1 SeitePrimo SD Data SheetEric Vergel de DiosNoch keine Bewertungen

- ENGINEERING PHYSICS Problem Set 1 - MidtermDokument2 SeitenENGINEERING PHYSICS Problem Set 1 - MidtermShieNoch keine Bewertungen

- Ieee C57.135 (2001)Dokument50 SeitenIeee C57.135 (2001)Daniel PaniaguaNoch keine Bewertungen

- Carbon Footprint Calculator OfflineDokument6 SeitenCarbon Footprint Calculator Offlineinder2655Noch keine Bewertungen

- Transfer Station PDFDokument2 SeitenTransfer Station PDFgernNoch keine Bewertungen

- PhoneAire PTTDokument2 SeitenPhoneAire PTTEgresados Udg BcsNoch keine Bewertungen

- Engine Kontrol 1Dokument35 SeitenEngine Kontrol 1imat ruhimatNoch keine Bewertungen

- Influence MN S Properties Cast IronDokument14 SeitenInfluence MN S Properties Cast Ironvivek1312Noch keine Bewertungen

- VP01-VP10 d900Dokument6 SeitenVP01-VP10 d900Constantin294Noch keine Bewertungen

- Volvo Error Codes CCMDokument5 SeitenVolvo Error Codes CCMsengottaiyan67% (9)

- Biodiesel Separation and Purification A ReviewDokument7 SeitenBiodiesel Separation and Purification A ReviewKarla SotoNoch keine Bewertungen

- Chapter 5-Drillstem TestDokument156 SeitenChapter 5-Drillstem TestShalihan MustafaNoch keine Bewertungen

- Weld Quality PDFDokument31 SeitenWeld Quality PDFNaceur TurkiNoch keine Bewertungen

- 303-01 - 2.3L EcoBoost - Removal and Installation - Intake ManifoldDokument14 Seiten303-01 - 2.3L EcoBoost - Removal and Installation - Intake ManifoldCARLOS LIMADANoch keine Bewertungen

- Hopper Building: Tikaria Expansion Project-ACC Pre-Commissioning ChecklistDokument2 SeitenHopper Building: Tikaria Expansion Project-ACC Pre-Commissioning ChecklistRajuNoch keine Bewertungen

- Ms6001b Operation DescriptionDokument53 SeitenMs6001b Operation Descriptionprasad503486% (7)

- EX-2 Fuel Pump Timing Setting and AdjustmentDokument2 SeitenEX-2 Fuel Pump Timing Setting and AdjustmentAayush Agrawal100% (1)

- Acti9 Ic40 - A9P42606Dokument3 SeitenActi9 Ic40 - A9P42606south adventureNoch keine Bewertungen

- Instruction Manual Model 175 Autoranging MultimeterDokument67 SeitenInstruction Manual Model 175 Autoranging Multimetervmilano1Noch keine Bewertungen