Beruflich Dokumente

Kultur Dokumente

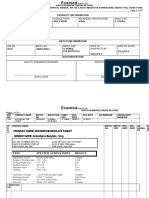

SOP For Changeovers Carried Out in Manufacturing and Packing Area

Hochgeladen von

reflectprakash3610Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SOP For Changeovers Carried Out in Manufacturing and Packing Area

Hochgeladen von

reflectprakash3610Copyright:

Verfügbare Formate

SOP for Changeovers Carried Out in Manufacturing and Packing Area

1.0 OBJECTIVE:

To lay down the Procedure for Changeovers carried out in Manufacturing and Packing area.

2.0 SCOPE:

This SOP shall be applicable to the Batch to Batch and Product to Product Changeovers carried out for

area and equipments in manufacturing & Packing area at Production department.

3.0 RESPONSIBILITY:

3.1 Execution :Operator

3.2 Checking :Production Pharmacist & Above

4.0 ACCOUNTABILITY:

HOD-Production / Assigned Designee

5.0 PROCEDURE:

5.1 BATCH TO BATCH CHANGEOVERS

5.1.1 Batch to batch change over is change over from one batch of a product to another batch (next

batch) of the same product in granulation, Compression, Coating & packing section.

5.1.2 For individual equipment, first ensure that the process of that batch on that particular equipment

or area is complete, and the product is removed or has proceeded further for the next stage.

5.1.3 Remove the entire residual product like Granules, Fines, Tablets, and Strips etc. from the

equipment and the area.

5.1.4 Remove the status label of the previous batch.

5.1.5 Clean the equipment with the dry clean lint free cloth, nylon brush and use vacuum as per the

requirement.

5.1.6 Clean the accessory equipments like dust extractors and dehumidifiers in the area as per their

respective SCPs.

5.1.7 Affix the status label for the next batch. Get the area and the equipment certified by Q.A. person

and record it on the batch document of the new batch to be processed.

5.1.8 Start the processing of the new batch.

5.2 PRODUCT TO PRODUCT CHANGEOVERS

5.2.1 Product change over is changeover of the area and the equipments after processing of one

Product and before starting the processing of another product. This is essential to avoid

the contamination of previous product into the new product to be processed in Manufacturing and

Packing sections.

5.2.2 STATUS LABELLING FOR AREA & EQUIPMENTS

5.2.2.1 Remove the product label / in process label from the equipment and area.

5.2.2.2 Affix To Be Cleaned Label to equipment and to the area.

5.2.2.3 Remove the previous processed product from the area for storage or further processing.

5.2.2.4 Remove the entire residual product like granules, fines, tablets, strips, etc from the equipment

and the area.

5.2.2.5 Clean the equipments and the area as per their respective Standard Cleaning Procedures.

5.2.2.6 Clean the return filters of AHUs.

5.2.2.7 Raise the intimation for swab analysis to Quality Control Department.

5.2.2.8 The Q.A person shall take the swab of the equipments from the specified area as per the

standard operating procedure, by using the specified solvents and swab samples should not be

hold exceeding the hold time period.

5.2.2.9 The area cleanliness shall be certified by Q.A. person by visual inspection of the area.

5.2.2.10 The results of Swab Test shall be informed to production department on the pink copy of the

Technical Information Sheet. After receiving clearance form Q.A, affix Cleaned status label to the

area & equipment.

5.2.2.11 In case of compression m/c if the m/c is not used within one shift, apply thin layer of food

grade oil to the turret to prevent rusting, and affixed To be Cleaned label. Before taking the m/c for

compression take the swab. The results of Swab Test shall be informed to production department on

the pink copy of the Technical Information Sheet.

5.2.2.12 After the receipt of the clearance from Q.A. assembling of the equipment can be started.

5.2.2.13 Affix the status label and start the operation.

5.2.2.14 Mentioned the status of the equipment / process in the remarks column of Equipment Log

Book.

5.3 SHIFT END CLEANING:

5.3.1 Before the end of the shift the machine is to be stopped & ensure the cleaning of the machine &

accessories by wiping with dry lit free cloth.

5.3.2 Ensure cleaning of in process area & disinfectant solution poured in the respective drains.

5.3.3 All the in process containers will be properly closed & affixed with the Under process label

mentioning the status.

5.3.4 The same should be entered in the Equipment log book.

NOTE

At the start of the shift ensure the cleaning of in process equipments, if the batch is continued for

more than one shift.

If same product is continued for more than 3 days then cleaning of equipments & area as per

respective SCP & take line clearance from Q.A. Department.

Complete cleaning of the area & equipments after three batches (For Batch to Batch) & after every

batch (For Product to Product). Take Clearance of Q. A. department before work start.

Mentioned the type of cleaning as:

Type A : Product to Product change over.

Type B : Batch to Batch change over.

Type C : Shift end cleaning.

6.0 ABBREVIATIONS:

6.1 SOP: Standard Operating Procedure

6.2 Q.A.: Quality Assurance

6.3 HOD: Head of The Department

Das könnte Ihnen auch gefallen

- SOP For Operation of Carton Coding MachineDokument3 SeitenSOP For Operation of Carton Coding MachineJayant Kumar JhaNoch keine Bewertungen

- 44-O&C Blister Packing MachineDokument7 Seiten44-O&C Blister Packing MachineananthNoch keine Bewertungen

- Handling of Sieves and ScreensDokument4 SeitenHandling of Sieves and Screensreflectprakash3610Noch keine Bewertungen

- SOP For Handling and Storage of Raw & Packing Material - Pharmaceutical Guidelines PDFDokument2 SeitenSOP For Handling and Storage of Raw & Packing Material - Pharmaceutical Guidelines PDFdahiphale1100% (1)

- Annual Product Review Developing An SOPDokument26 SeitenAnnual Product Review Developing An SOPanants2567% (3)

- Line Clearance ProcedureDokument3 SeitenLine Clearance ProcedurePrince Moni67% (3)

- 5-Operation & Cleaning of Ropp Sealing MachineDokument3 Seiten5-Operation & Cleaning of Ropp Sealing MachineananthNoch keine Bewertungen

- Finished ProductDokument4 SeitenFinished ProductDilip ChaudharyNoch keine Bewertungen

- 38-SOP-Layout of Work Place and PremisesDokument4 Seiten38-SOP-Layout of Work Place and Premisesarun100% (1)

- Line Clearance Procedure at Pharma ManufacturingDokument3 SeitenLine Clearance Procedure at Pharma ManufacturingRainMan75Noch keine Bewertungen

- SOP For Collection and Storage of Retained Samples of Raw Material Pharmaceutical GuidelinesDokument2 SeitenSOP For Collection and Storage of Retained Samples of Raw Material Pharmaceutical GuidelinesMosub Al.Dirdiry100% (1)

- What Is BMR (Batch Manufacturing Record)Dokument2 SeitenWhat Is BMR (Batch Manufacturing Record)Prince Moni100% (1)

- SOP Personnel HygieneDokument4 SeitenSOP Personnel HygieneBejoy Karim100% (3)

- Factory Clothing RulesDokument3 SeitenFactory Clothing Rulespiyusharora1964Noch keine Bewertungen

- OQ Protocol Capsulating MachineDokument11 SeitenOQ Protocol Capsulating MachineNadine LilleNoch keine Bewertungen

- SOP for GLP Compliance in Quality Control LabsDokument2 SeitenSOP for GLP Compliance in Quality Control LabsPrince MoniNoch keine Bewertungen

- List of SOP's For Quality Assurance DepartmentDokument1 SeiteList of SOP's For Quality Assurance DepartmentPrince Moni100% (1)

- SOP On Cleaning and Sanitization in PharmaceuticalljhiuDokument13 SeitenSOP On Cleaning and Sanitization in PharmaceuticalljhiuMahadi Hasan Khan0% (1)

- Batch Manufacturing Record: Wellborne Pharmachem & BiologicalsDokument23 SeitenBatch Manufacturing Record: Wellborne Pharmachem & BiologicalsMohammed Zubair100% (1)

- Batch ReleaseDokument12 SeitenBatch Releasemarkandey gupta50% (2)

- BMR PraperationDokument9 SeitenBMR PraperationwondwossengNoch keine Bewertungen

- SOP of Rejection of Packaging MaterialDokument3 SeitenSOP of Rejection of Packaging MaterialYousif67% (3)

- Sop - F-P StorageDokument3 SeitenSop - F-P Storagekundanrana0% (1)

- Batch Manufacturing Record Requisition FormDokument1 SeiteBatch Manufacturing Record Requisition FormSolomon GamanuelNoch keine Bewertungen

- Sop of Cleaning and Operation of Dispensing BoothDokument3 SeitenSop of Cleaning and Operation of Dispensing BoothRainMan75100% (2)

- SOP Storage & Handling of Finished ProductDokument1 SeiteSOP Storage & Handling of Finished ProductUjwal C Kamble0% (1)

- Storage and Handling of Finished ProductsDokument2 SeitenStorage and Handling of Finished Productsreflectprakash3610100% (1)

- Master Formula and Manufacturing RecordsDokument7 SeitenMaster Formula and Manufacturing RecordsTrilochan Ayurveda100% (1)

- Operation & Cleaning Procedure for Octagonal BlenderDokument7 SeitenOperation & Cleaning Procedure for Octagonal BlenderNgoc Sang HuynhNoch keine Bewertungen

- URS Lab Scale Counter Pressure Autoclave (Rev 1b)Dokument12 SeitenURS Lab Scale Counter Pressure Autoclave (Rev 1b)puneetogupta100% (2)

- Guide To Master Formulae Final 2012Dokument119 SeitenGuide To Master Formulae Final 2012MohamedRefaatMohamedNoch keine Bewertungen

- Parenteral Process Validation (1) DarusazDokument30 SeitenParenteral Process Validation (1) Darusazeshwar_orgNoch keine Bewertungen

- Annual Products ReviewDokument5 SeitenAnnual Products Reviewmainart50% (2)

- Sop of GowningDokument3 SeitenSop of GowningPrince Moni50% (2)

- Process Validation Protocol (500 MG Tablet)Dokument6 SeitenProcess Validation Protocol (500 MG Tablet)Mohammed Zubair100% (1)

- Dispensing of Raw Materials Version 02 (GMF 095)Dokument4 SeitenDispensing of Raw Materials Version 02 (GMF 095)ShagorShagor100% (1)

- Actpro Al Drysyrup 3b001Dokument48 SeitenActpro Al Drysyrup 3b001joerichladNoch keine Bewertungen

- Area Qualification ProtocolDokument19 SeitenArea Qualification ProtocolBRIJENDRA KUMAR SINGH100% (1)

- Sop For Operating Dry GranulatorDokument3 SeitenSop For Operating Dry GranulatorsaimaNoch keine Bewertungen

- Validate Furosemide Tablet ProcessDokument26 SeitenValidate Furosemide Tablet ProcessPatricia Joyce Malabanan SunglaoNoch keine Bewertungen

- Subject:: 1) Installation QualificationDokument2 SeitenSubject:: 1) Installation QualificationDonig FermanianNoch keine Bewertungen

- Metro Fabrics Raw Material Receiving ProcedureDokument2 SeitenMetro Fabrics Raw Material Receiving ProcedureHaseem Ali100% (1)

- Capsule Filling Machine MalibaDokument35 SeitenCapsule Filling Machine Malibawissem100% (2)

- SOP For DespatchDokument7 SeitenSOP For DespatchKishan Maurya0% (1)

- Destruction SopDokument11 SeitenDestruction SopPrince Moni0% (1)

- Cleaning Validation Protocol For PharmaceuticalsDokument5 SeitenCleaning Validation Protocol For PharmaceuticalsManivannan Kathirvel100% (2)

- Cleaning Validation Protocol TEMPLATEDokument9 SeitenCleaning Validation Protocol TEMPLATEnatavceNoch keine Bewertungen

- 13 SOP Cleaning For Dispensing AreaDokument3 Seiten13 SOP Cleaning For Dispensing Areaanoushia alviNoch keine Bewertungen

- Batch Manufacturing Record Capsule FormatDokument2 SeitenBatch Manufacturing Record Capsule FormatAkik Sasmal100% (1)

- SOP For Handling of Market ComplaintDokument32 SeitenSOP For Handling of Market Complaintsubbu_281Noch keine Bewertungen

- SOP For Cleaning of StirrerDokument2 SeitenSOP For Cleaning of StirrerPrince Moni100% (1)

- Blister Machine PQ PDFDokument10 SeitenBlister Machine PQ PDFNiranjan Pradhan100% (1)

- Quality Assurance Incoming Raw Materials Inspection PlanDokument2 SeitenQuality Assurance Incoming Raw Materials Inspection PlanAlvin NodaNoch keine Bewertungen

- SOP For Cleaning of Sticker Labeling MachineDokument2 SeitenSOP For Cleaning of Sticker Labeling MachineYousifNoch keine Bewertungen

- Reconciliation SOP NEWDokument4 SeitenReconciliation SOP NEWPrince MoniNoch keine Bewertungen

- SOP On Transferring Finished Products To Finished Goods StoresDokument3 SeitenSOP On Transferring Finished Products To Finished Goods StoresRainMan7550% (2)

- SOP For Change OverDokument6 SeitenSOP For Change OverJayesh Meharwal100% (3)

- SOP Granulation, CoatingDokument6 SeitenSOP Granulation, CoatingDSP PVCNoch keine Bewertungen

- SOP of Cleaning of Equipment and Accessories in Production: 1.0 ObjectiveDokument2 SeitenSOP of Cleaning of Equipment and Accessories in Production: 1.0 ObjectiveYousif100% (1)

- Cleaning of Equipment & Accessories in Production AreaDokument2 SeitenCleaning of Equipment & Accessories in Production AreaRakesh RauniyarNoch keine Bewertungen

- NPOP STD PDFDokument238 SeitenNPOP STD PDFPOOJA BKNoch keine Bewertungen

- PBI E-BookDokument122 SeitenPBI E-BookAshutosh ChauhanNoch keine Bewertungen

- Vatakulantka Rasa TabletDokument7 SeitenVatakulantka Rasa Tabletreflectprakash3610Noch keine Bewertungen

- DNC NotesDokument1 SeiteDNC Notesreflectprakash3610Noch keine Bewertungen

- Organic Food Processing and Handling: 1. Specific RequirementsDokument11 SeitenOrganic Food Processing and Handling: 1. Specific RequirementsdemiNoch keine Bewertungen

- Marketing SDH FormatDokument14 SeitenMarketing SDH Formatreflectprakash3610Noch keine Bewertungen

- Sap PPDokument3 SeitenSap PPreflectprakash3610Noch keine Bewertungen

- BIS Stan 29 06 2016Dokument34 SeitenBIS Stan 29 06 2016reflectprakash3610Noch keine Bewertungen

- Excel Shortcuts Cheat SheetDokument22 SeitenExcel Shortcuts Cheat SheetVikash ChetiwalNoch keine Bewertungen

- The Aspiration for the Good Life - Bhadra-cari-praṇidhānamDokument8 SeitenThe Aspiration for the Good Life - Bhadra-cari-praṇidhānamreflectprakash3610Noch keine Bewertungen

- Quality Manual TemplateDokument37 SeitenQuality Manual TemplateSteve UNoch keine Bewertungen

- Classical Tests to Evaluate Ayurvedic Herbal Ash (Bhasma) QualityDokument1 SeiteClassical Tests to Evaluate Ayurvedic Herbal Ash (Bhasma) Qualityreflectprakash3610Noch keine Bewertungen

- Draft GMP For Ayurveda Ravindra PrakashDokument28 SeitenDraft GMP For Ayurveda Ravindra Prakashreflectprakash3610Noch keine Bewertungen

- 8 Steps To Attitude Change Shiv KheraDokument1 Seite8 Steps To Attitude Change Shiv Kherareflectprakash3610Noch keine Bewertungen

- Storage and Handling of Finished ProductsDokument2 SeitenStorage and Handling of Finished Productsreflectprakash3610100% (1)

- ANTI-INFLAMMATORY CAPSULEDokument2 SeitenANTI-INFLAMMATORY CAPSULEreflectprakash3610Noch keine Bewertungen

- Final Liver SyrupDokument1 SeiteFinal Liver Syrupreflectprakash3610Noch keine Bewertungen

- Common keyboard shortcuts for Google SheetsDokument3 SeitenCommon keyboard shortcuts for Google Sheetsreflectprakash3610Noch keine Bewertungen

- Price List 2017 20Dokument16 SeitenPrice List 2017 20reflectprakash3610Noch keine Bewertungen

- Segregation Based On Hazard Classes1Dokument1 SeiteSegregation Based On Hazard Classes1reflectprakash3610Noch keine Bewertungen

- Potable Water Specification Shree Dhanwantri HerbalsDokument2 SeitenPotable Water Specification Shree Dhanwantri Herbalsreflectprakash3610Noch keine Bewertungen

- QC Tests For Tablet Dosage FormsDokument8 SeitenQC Tests For Tablet Dosage FormsSai Krishna ManchikantiNoch keine Bewertungen

- Raw Water Raw Water Raw Water Raw WaterDokument2 SeitenRaw Water Raw Water Raw Water Raw Waterreflectprakash3610Noch keine Bewertungen

- Solutions LabDokument2 SeitenSolutions Labreflectprakash3610Noch keine Bewertungen

- Table For Cleaning SolutionsDokument1 SeiteTable For Cleaning Solutionsreflectprakash3610Noch keine Bewertungen

- FSMS SOP-01 Control of DocumentsDokument6 SeitenFSMS SOP-01 Control of Documentsreflectprakash3610100% (1)

- Coding of Pipes 20170611Dokument3 SeitenCoding of Pipes 20170611reflectprakash3610Noch keine Bewertungen

- Steam Steam Steam SteamDokument2 SeitenSteam Steam Steam Steamreflectprakash3610Noch keine Bewertungen

- Coding - of - Pipes - 20170611 - Purified WaterDokument3 SeitenCoding - of - Pipes - 20170611 - Purified Waterreflectprakash3610Noch keine Bewertungen

- A Seminar On Bharat Pumps & Compressors LTD: Presented by Amit Singh Roll - No. 1110440006Dokument17 SeitenA Seminar On Bharat Pumps & Compressors LTD: Presented by Amit Singh Roll - No. 1110440006madhurauto100% (3)

- Ti809 07Dokument136 SeitenTi809 07SusandiHarahapNoch keine Bewertungen

- MN 304 - Production Economics - 6Dokument59 SeitenMN 304 - Production Economics - 6Nipuna Thushara WijesekaraNoch keine Bewertungen

- A. A B C D E F G H I: Bracket Base Springs (2) Clamps (4) Housing (2) Handle Casting Bearings (2) ShafDokument4 SeitenA. A B C D E F G H I: Bracket Base Springs (2) Clamps (4) Housing (2) Handle Casting Bearings (2) ShafRadinne Fakhri Al Wafa100% (1)

- Energy Analysis of The Steel Making IndustryDokument7 SeitenEnergy Analysis of The Steel Making Industrymrshami7754Noch keine Bewertungen

- Acrylic rod & tube manufacturing tolerances guideDokument1 SeiteAcrylic rod & tube manufacturing tolerances guidemhNoch keine Bewertungen

- NIFT Students Explore Marketing Activities of MerchandisingDokument49 SeitenNIFT Students Explore Marketing Activities of MerchandisingzahidNoch keine Bewertungen

- Consumables To Match Cast & Wrought Alloy 800: Astm Bs en & DinDokument3 SeitenConsumables To Match Cast & Wrought Alloy 800: Astm Bs en & Dinankitniranjan1390Noch keine Bewertungen

- Adani Supply ChainDokument52 SeitenAdani Supply ChainSaikat GhoshNoch keine Bewertungen

- Polysafe Standard PUR PS PDFDokument1 SeitePolysafe Standard PUR PS PDFFloorkitNoch keine Bewertungen

- China ExhibitorsDokument8 SeitenChina ExhibitorsYaIpha NaOremNoch keine Bewertungen

- ISO 9001 Quality Management System DocumentsDokument33 SeitenISO 9001 Quality Management System DocumentsSanjay Rajpal100% (1)

- Prepared by Debby Bloom-Hill Cma, CFMDokument55 SeitenPrepared by Debby Bloom-Hill Cma, CFMAlondra SerranoNoch keine Bewertungen

- A Study On Consumer Behaviour About Remanufactured Electronic Gadgets in Indian MarketDokument10 SeitenA Study On Consumer Behaviour About Remanufactured Electronic Gadgets in Indian MarketarcherselevatorsNoch keine Bewertungen

- Top of FormDokument131 SeitenTop of FormPawan SinghNoch keine Bewertungen

- Apply Quality StandardDokument81 SeitenApply Quality StandardJunNoch keine Bewertungen

- 1 - 2015 Enimex Ball ValvesDokument55 Seiten1 - 2015 Enimex Ball ValvesNoytsias KostantinosNoch keine Bewertungen

- (2.01) Complete! ChaexDokument15 Seiten(2.01) Complete! ChaexJason MaldonadoNoch keine Bewertungen

- Cir 041 - Information of Member MillsDokument6 SeitenCir 041 - Information of Member MillsAzhar RanaNoch keine Bewertungen

- Expert-Reconditioning Reduces CostsDokument97 SeitenExpert-Reconditioning Reduces CostsBryanNevadoNoch keine Bewertungen

- The Basic Issues Involved in Design and Operating DecisionsDokument19 SeitenThe Basic Issues Involved in Design and Operating DecisionsqamarulislamNoch keine Bewertungen

- Volume 3A GTSDokument154 SeitenVolume 3A GTSpavankumar001Noch keine Bewertungen

- Karla Melissa Martinez Medina. Vanessa Margarita Duran Aguilera. Leticia Serrano Wong. Dariela Zuñiga TreviñoDokument12 SeitenKarla Melissa Martinez Medina. Vanessa Margarita Duran Aguilera. Leticia Serrano Wong. Dariela Zuñiga TreviñoKarla Martinez100% (1)

- Lego StudentDokument7 SeitenLego StudentPookguy100% (1)

- Stainless Steel 304 PipesDokument6 SeitenStainless Steel 304 PipesVikas ShahNoch keine Bewertungen

- 2005 PSS Road MeshDokument4 Seiten2005 PSS Road MeshJim Arturo Rivera VidalNoch keine Bewertungen

- Finalvalue Usb FanDokument9 SeitenFinalvalue Usb FanDianne De FranciaNoch keine Bewertungen

- Supply Chain Management - Wal-Mart CaseDokument18 SeitenSupply Chain Management - Wal-Mart CaseBinay Pradhan50% (4)

- An Introduction To International Economics: Dominick Salvatore John Wiley & Sons, IncDokument51 SeitenAn Introduction To International Economics: Dominick Salvatore John Wiley & Sons, IncTuyết TrinhNoch keine Bewertungen

- Orthodontic WiresDokument10 SeitenOrthodontic Wiresanon_191534692Noch keine Bewertungen

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsVon EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNoch keine Bewertungen

- Guidelines for Implementing Process Safety ManagementVon EverandGuidelines for Implementing Process Safety ManagementNoch keine Bewertungen

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisVon EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisBewertung: 5 von 5 Sternen5/5 (1)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsVon EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsBewertung: 4 von 5 Sternen4/5 (11)

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeVon EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNoch keine Bewertungen

- A Complete Guide to Safety Officer Interview Questions and AnswersVon EverandA Complete Guide to Safety Officer Interview Questions and AnswersBewertung: 4 von 5 Sternen4/5 (1)

- Guidelines for Auditing Process Safety Management SystemsVon EverandGuidelines for Auditing Process Safety Management SystemsNoch keine Bewertungen

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesVon EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesBewertung: 5 von 5 Sternen5/5 (1)

- Introduction to Petroleum Process SafetyVon EverandIntroduction to Petroleum Process SafetyBewertung: 3 von 5 Sternen3/5 (2)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationVon EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNoch keine Bewertungen

- Inherently Safer Chemical Processes: A Life Cycle ApproachVon EverandInherently Safer Chemical Processes: A Life Cycle ApproachBewertung: 5 von 5 Sternen5/5 (1)

- Rules of Thumb for Maintenance and Reliability EngineersVon EverandRules of Thumb for Maintenance and Reliability EngineersBewertung: 4.5 von 5 Sternen4.5/5 (12)

- Incidents That Define Process SafetyVon EverandIncidents That Define Process SafetyNoch keine Bewertungen

- Safety Fundamentals and Best Practices in Construction IndustryVon EverandSafety Fundamentals and Best Practices in Construction IndustryNoch keine Bewertungen

- Radium Girls: Women and Industrial Health Reform, 1910-1935Von EverandRadium Girls: Women and Industrial Health Reform, 1910-1935Bewertung: 4.5 von 5 Sternen4.5/5 (4)

- Chemical Process Safety: Learning from Case HistoriesVon EverandChemical Process Safety: Learning from Case HistoriesBewertung: 4 von 5 Sternen4/5 (14)

- LNG Risk Based Safety: Modeling and Consequence AnalysisVon EverandLNG Risk Based Safety: Modeling and Consequence AnalysisNoch keine Bewertungen

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemVon EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNoch keine Bewertungen

- Nobody Cares: The Story of the World from SafetymanVon EverandNobody Cares: The Story of the World from SafetymanNoch keine Bewertungen

- Exercise, Sport, and Bioanalytical Chemistry: Principles and PracticeVon EverandExercise, Sport, and Bioanalytical Chemistry: Principles and PracticeNoch keine Bewertungen

- 3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionVon Everand3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionArnaud PerrotNoch keine Bewertungen

- One Health: Integrated Approach to 21st Century Challenges to HealthVon EverandOne Health: Integrated Approach to 21st Century Challenges to HealthJoana C. PrataNoch keine Bewertungen

- Autophagy in Health and DiseaseVon EverandAutophagy in Health and DiseaseBeverly RothermelNoch keine Bewertungen

- The Single Cure: Human Life Extension to 300+ YearsVon EverandThe Single Cure: Human Life Extension to 300+ YearsNoch keine Bewertungen

- The Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceVon EverandThe Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceBewertung: 5 von 5 Sternen5/5 (1)

- Safety and Intelligent Transport Systems Development in the People’s Republic of ChinaVon EverandSafety and Intelligent Transport Systems Development in the People’s Republic of ChinaNoch keine Bewertungen

- Fire in the Night: The Piper Alpha DisasterVon EverandFire in the Night: The Piper Alpha DisasterBewertung: 4.5 von 5 Sternen4.5/5 (5)