Beruflich Dokumente

Kultur Dokumente

J Bearings

Hochgeladen von

Faisca_R0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

127 Ansichten5 SeitenJournal bearing oil ring design

Originaltitel

j Bearings

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenJournal bearing oil ring design

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

127 Ansichten5 SeitenJ Bearings

Hochgeladen von

Faisca_RJournal bearing oil ring design

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 5

Lubricating

Journal Bearings

with Oil Rings

=

Asimple, low-cost

device called an oil

ring can provide

primary or backup

lubrication for

journal bearings.

But operating limits

are more critical

than with

conventional

lubrication methods.

RICHARD C. ELWELL

Consulting Engineer

Schenectady, NY

E.R.BOOSER

Consulting Engineer

Scotia, NY

Most smooth-bore journal bearings

are lubricated by systems that

supply them with a generous

amount of oil. Bearings using these

systems are said to be fully flooded.

Pressurized systems generally work

well, but if a pump oF motor fails,

fr a filter clogs, the oil supply can

drop toa point where the journal method is not new, but until now, in the bearing upper half. which

contacts (wipes) the bearing sur- the design guidelines have been keeps the ring from wandering

face. If wiping is extensive, the vague. along the shaft. The lower portion

bearing may need to be replaced. ‘of Uhe ring dips into the lubricant

Oil rings provide a lubrication How it works: reservoir. As the shaft turns, drag

method that works asa reliable ‘The oil ring is usually made of rotates the ring, which in turn lifts

backup to pressurized systems. In die-cast zinc or brass, and are less oil upto the bearing.

fact, when journal speeds are low to than twice the diameter of the jour- At low speeds, a few rpm, ring

‘moderate, oil rings can be the pri- nal. The ring simply hangs over the and shaft surface speeds are the

mary means of oil supply. ‘The shaft or journal and rides in a slot same, As speed increases, an oil

MACHINE DESIGN/OECEMBER?.1909 111

film forms betaoan ring and shat

which allows them to slip against

‘each other. When this happens, the

ring slows to about one-tenth shaft

speed.

Oil delivery rate reaches « max

imum at a surface speed of about 30

fps, Then, the delivery rate begins

1 fall off because centrifugal force

and air currents generated by’ tive

Spinning shaft throw oil frou Ue

ring. This is one of the most im:

portant limitations in the use of

Ting-oiled bearings. At speeds over

45 fps, when the bearing needs the

most oil, delivery ean be reduced to

a dangerously low rate

For operating speeds other than

the slowest, the bearing surface

does not receive as much oil as re-

quired for full fuid-film lubri-

cation. That is, the bearing oper

ates “starved,” or with the surface

of the journal closer to the bearing

babbitt than it would be with @

pressurized oil supply. Starved

operation is typical for disk and

‘wick-fed bearings, and is accept

‘able for many applications, such as

large motors, pumps, and blowers

‘Commercially-available oil-ring

bearings come with oil-level sights,

fill ports, and pillow blocks for

mounting. Water-eooled pillow

Docks are also available, and they

have higher load and speed ratings

than uncooled designs. Shafts from

1 to 12-in, diameter can use a

standardized design. These bear-

ings tend to be long, usually about

‘twice their diameter.

Sizing recommendations

Most oil-ring bearings are de.

signed for specific applications and

to fit a limited space. Ifa standard.

ined design cannot be used, a cus:

tom bearing can be designed rather

easily. Typical proportions for

common applications such as

Pumps or electric motors are:

© Length/diameter ratio ranges

from 0.7 to 1-1. This is based on the

‘benring’s net working length.

‘© Oil-ring bore to bearing-bore

ratio ranges from 1.5 to 19.

© Bearing/journal clearance ra

tio spans 0,002 to 0.00275 in, fin.

Selecting an oil grade re

quires a balance between operating

speed and viscosity, For example, a

high viscosity (1S0 44 68 or SAE 30)

promotes @ high oil-delivery rate

fand good load capacity at speeds

12 MACHINEDESIGN/occeMaER 1960

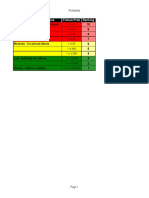

Maximum jouralelamate (in)

‘Shaft speed (x 1,000 pn)

below about 1,500 rpm. Lower vis: oll delivery when a cold machine is

cosity oll (180 VG 32 oF SAK TO) re- Started

duces temperature rise in higher Staying below 45 fps is rec

speed bearings and eases cold- ommended in the shaft speed vs

Starting problems. For general use, journal diameter graph, and may

150 ¥G 82. usually in the form of be the most crucial design prin

light turbine oil, e'a good choice. ciple. This liait can be exceeded

Also, this ol is often used in power- but only when other bearing char

Plani pumps, motors, and fans be acteristics, such as oil-delivery rate

cause iis readily available. fire better than marginal. Soectol

‘il selection alen should ncconnt designe should also be ventied by

for special circumstances, such as testing before production.

corrosion-producing condensation If testing is not performed, sys

in the sump during long shut- tem reliability depends on controi-

downs. In arcticlike conditions, it ling oil temperature. Oil couled by

tay be necessary to install heaters forced air or water allows higher

in the bearing sump to prevent ex- speeds and loads. But if ol cooling

cessive ring drag snd insufficient is interrupted, even temporarily,

USING THE OIL-RING EQUATIONS

‘A din. diameter alone bearing with a -ineffctive length, must operate at

1,800 rpm. A O46, 0:30-in wide ol ving with a 85-in. bores to supply toe

Dearing with 180 VG 12 ight Curie oi. Diametral clearance in 0.002 inn, and

‘ol rserve temperature ia 122°F- Ifthe al vincnities are w= 2.46% 10" reyn

finds ~ 0031 n'a what are the rings operating characteristic?

From Equation 2 ring speed at initial elipia

on 040)

em eae x 10) RE” HM

Solving Bqution {,shaftopend at the tart flip ia

ert)

= 20mm

Fill-film operation ny begins at a shaft speed af 2.9(200) = §80 rpm. Equa.

tion 3 predicts a ring speed af

y= 8290080" 1800 01 65 om

From Equation , the transition to high-speed delivery characteristicn occur

“Then, the corresponding journal speed, found by solving Equation 3 is

the journal will pi

against the bearing.

Loading a ring-lubed bearing

safely means not exceeding 150 ps

for a downward load and 50 psi for

upward loads. Allowable up-ioad

ing is reduced due to the bearing

‘rea lost in the upper half from the

fing slots. Water cooling. allows in

creasing a load by about 50%.

Bearing load per unit area is

found with P= W/Ld, where W =

bearing load, 1b, L = load length,

in and d ~ shaft diameter, in.

‘These general limits can be ex

ceeded if actual bearing capacity is

calculated with a more detailed

fanalysis. Using an estimated bear

ing oil ow, Uke analysis works

hackward to calculate the extent of

the ol film between the journal and

bearing. Knowing film area and

thickness allows the shaft ec

centricity within the bearing to be

calculated. Hence, it is poanble to

draw a theoretical load capacity

curve of load vs. minimum film

thickness.

‘The shortcoming in these calcu:

lations is the accuracy of the esti

mated oil delivered to the bearing.

One common estimate is that 50":

of this actually enters the bearing

ably wipe

‘Testing is usually done for critical

Oil ring speeds are calculated

for three significant operating con

wo

From Equation 5, il delivery by the ring atthe transition speed is

@

Equation 6 shows that when ring speed exceeds the transition speed, delivery

rate

= ur( (25)

Minimum bearing oil fow, from Equation 7, is

Qe, ~ 0.089 (1800) 4 (8) 4 (0.002) = 6.7 nim

eecause minimum oil requirements are exceeded by ring delivery rate, the

design is acceptable. Other performance characteristics can be calculated from

handbooks or a previous MACHINE DESIGN article, “New Technique Simplifies

Journal Benring Design”, Apr, 23, 1987. [foil ow had been ineufficient, ring oF

‘searing dimeneions could be changed, A second ring might also be added.

“To examine a number of possible bearing and ring designs, the calculations

can be easly written into a progeam or

‘uctlarly useful for organizing the equations and their results.

97 rpm

0.018 (0.38) 0.081" [65 (999) = 11

= 10582

ditions, Ring speed is proportional

to shaft speed only. at low values

Over this no-shp range, ring speed

Nand shaft speed n are related by

i uw

where d = journal diameter, in

and D ~ oil ing inner diameter, in

‘This relationship is valid up to

the ring slip speed N., when viscous

oil drag on the lower are of the ring

exceeds the friction drive by the ro.

tating journal. Slipping begins at

N= 0008 Me ®

where W, = ring weight, Ib, and a

wil vievonity, reyno.

A partial-film drive develops

inYmin

in?

solver. Spreadsheets are par

above Ny and extends to the in

ception of a fullilm drive speed

range. Here, viscous drive and drag.

forces balance. Full-film ring

speed, N; commonly begins at

2.9N, and is

aa)" a

where » = oil kinematic viscosity.

1m."/s. Oil rings in most small ma.

chines operate in this full-film

drive region, Large, slower speed

applications, such as steel-mill

drive motors or ship lineshatt bear

ings, involve nonslip or partial-film

rings.

Oil delivery rate is calculated

for high and low speeds, The

‘method changes at a ring transition

ili-ring and snatt

Surface speed are

the same foriow

rotatonal speeds

‘Above Ne. an ol

‘tim Denéatn tne

"ing causes 10

‘lip. Abowe Na

the oil fim

‘completely

Separates the

‘ing and shart.

speed N;, above which an incre

iating portion of ail picked up by:

the ring is thrown’ off without

reaching the bearing. Transition

speed.

™

vate w

Below the transition speed, oil

delivery rate is

@= oosiDn vide si

where w = ring width on the jour-

nal. in, Above the transition speed

the delivery rate is

ean (a) 6

As journal surface speed ap

proaches the 45-fps limit, oil deliv

‘ery falls off quickly enough to en

danger reliable operation.

From experiments, minimum oil

delivery required from a ring is of:

ten about 10/7 of that needed to

fully fill the bearing-journal clear

ance. For many operating condi

MACHINE DESIGN/OEcewarR? 1888-113

approximately |] Allow sped,

an a moore

a = 09nd LC ” trough onto

I delivery fram one fi rmowtbeerng

Geel upevona ing itcomiared roquremonts After

Sip begins oiaemery

More than just round Serco omy

Sseverat additions: tothe Isic wrinspeed

ving design can improve Ise oper owe No conta

ation, On large low speed bearings force and shat

Sireunferenialgroarce in the nig spunerin me

Savire scale ta ie Bosna removes

rapt the supporting ei film be momner

tween the ring and shaft journal, Goivery rate toss

‘This extends the no-slip and par ———— than mnmum

tual-film ring operation to slightly Shatt speed, n(rom) ‘aperating conditons.

higher speeds, thereby increasing

ring speed and oil delivery

However, on most other designs, vide no significant improvement in ring is necessary. In fact. when the

1 grooved ring bore is not recom: oil delivery ring must be split and hinged tor

mended because it may wear the The most con ring mate: assembly over the journal, brass is

shaft locally. Shaft grooves rials are die-cast zinc and brass. preferred

iddle of the bearing Zine is easily fabricated and has Die-cast rings usually have a

reduce an good sliding compatibility with trapezoidal cross section, partls tor

acity. Also, steel. Also, its specific gravity is easier fabrication, but also te

when ring speed is in the full-film nearly the same as that of steel. duce ring-to-slut contact area ai

region, the ring-bore grooves pro- Brass is selected when a heavier friction, Split brass rings are us

ally made with « T-shaped once

Section so that they can be opened

GROOVED BEARINGS GO “nator

‘Although ring roundness 4s

WITH THE FLOW portant for proper oil delivers. ex

periments show that out-of-plane

Distribution grooves in the bearing allow more efficient use of limited il ow. | distortion, or warping, is more crit

One common grome, ealled« race track «continuous from the ring slot to the | ical to proper operation. In une ex

‘bearing bottom, and back to the slot. The design presents groove edges to the periment, a 16.5-1n. ring was ben

shaft at angles that pump oil like a viscous pump. The looped grome can bepo- | into an ellipse (1-in. out of rounds

sutioned asymmetrically to the slot ww produce oil flow in one direction. The yet delivered about the same

amount of oil as when found. In

vestigators report that even near

perfect rings experience a variety cf

tncillatory motions at speeds that

coincide with reduced oil delivers

‘On some high-speed bearings

ring scrapers have been tested. 10

capture some of the oil that re

circulates back to sump. But scrap.

fers are usually not used because

they slow the ring, making ite oper

ion undependable

One successful approach to

areater oil delivery. however, 16 4

Small baffle placed below the rng

lunderside as it rolls aif the shaft

half «split bearing. Its edges shouldbe careully faired or tapered intothe | ‘This reclaimns sorue oil blown ont of

bearing load 2one to induce cl ow out ofthe groove and into the film. Axial | the window by shaft windage.

toores through the load zone should be woided because they Bled aff pres: | ‘Surface finish on the journal is

sure fom the load-carrying fim. more important than with other

‘An ai vent near the top or end of any of these gress required to prevent | Deeg pre tne iy ot

su oat econ ap uf fae win apes mr erated ou me | PATow, era stared. Alfie

‘ot flow well ingrooves. Alo, fa babbitedthrit surfaces built into the end | DEa"tDRs operate starved. Alun

‘Linnie ural bearing, aching ever ented radial gromesinto the | {he wal SPvin Goh wali, for

sree aed areal Nneing meokioies overs lower epeeds.»jairnal operating a

* improves: the 45-fps limit should have a fin:

ish of 16 uin. or better. Operating

114 MACHINE DESIGN DEcENABLH 985

Break edges

A.rapezoidal oiiring should have 10

10 15°side rele Typical dimensions

‘are, for aring bore Dot 5.625 in. a

= Sein. and = ‘in, For = 7.5

fan. and = ein.

‘above the limit, especially if there is ships or dragline excavators, re- small. Leaks are most likely to oc

significant shaft bending, requires quire extra attention. If the shaft cur at housing joints and where the

polishing and perhaps even lapping tilts more than a few degrees from housing is mounted to the machine.

the journal toa 4-uin. finish. Test- horizontal, the ring may stick. Also, At times, even cooling air can be

ing should then be done to verify if sump oil sloshes about during troublesome because it may blow

the design machine motion, oil can leak out oil droplets and mist out of the

the end seals. housing end seals. An easy-to-read

‘Special situations Leaks of any kind are serious be- il-level indicator, however, helps

Mobile applications, such as on cause the oil reservoir is generally spot a sump going dry. .

Das könnte Ihnen auch gefallen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- 1 PDFDokument1 Seite1 PDFFaisca_RNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- CMMI QuestionnaireDokument1 SeiteCMMI QuestionnaireFaisca_RNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- 2 PDFDokument1 Seite2 PDFFaisca_RNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Capability Maturity Model IntegrationDokument13 SeitenCapability Maturity Model IntegrationFaisca_RNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Fire Case (Liquid Filled Vessel) - AllDokument1 SeiteFire Case (Liquid Filled Vessel) - AllFaisca_RNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Assign PDFDokument1 SeiteAssign PDFFaisca_RNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Clamp Calc ExampleDokument1 SeiteClamp Calc ExampleFaisca_RNoch keine Bewertungen

- New1 PDFDokument1 SeiteNew1 PDFFaisca_RNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Left OneDokument1 SeiteLeft OneFaisca_RNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- PROBABILITY of Failure Failure Prob Ranking: Very High: Failure Is Almost InevitableDokument1 SeitePROBABILITY of Failure Failure Prob Ranking: Very High: Failure Is Almost InevitableFaisca_RNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Workd FneibhevDokument1 SeiteWorkd FneibhevFaisca_RNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Welded Tee SIFDokument1 SeiteWelded Tee SIFFaisca_RNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Frig PrincipleDokument1 SeiteFrig PrincipleFaisca_RNoch keine Bewertungen

- SsssDokument1 SeiteSsssFaisca_RNoch keine Bewertungen

- Ef34 F42f3f2vv34v434ervwg24v42g4Dokument1 SeiteEf34 F42f3f2vv34v434ervwg24v42g4Faisca_RNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- BF SweeopoletDokument1 SeiteBF SweeopoletFaisca_RNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- AileronDokument1 SeiteAileronFaisca_RNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)