Beruflich Dokumente

Kultur Dokumente

Calculation of Glass & Mullion

Hochgeladen von

Thành KCCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Calculation of Glass & Mullion

Hochgeladen von

Thành KCCopyright:

Verfügbare Formate

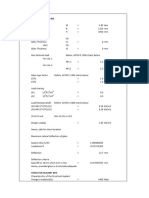

SAMPLE CALCULATION FOR MONOLITHIC OR LAMINATED

Laminated Glass - 6mm thick FT external lite + 1.14 PVB interlayer + 6mm thick FT internal lite

Resistance condition - all sides simply supported

q' = 3.50 kPa ; uniform lateral load

t1 = 8.00 mm ; minimum thickness of outer lite as per ASTM E1300-2

t2 = 8.00 mm ; minimum thickness of inner lite as per ASTM E1300-2

i = 1.14 mm ; thickness of interlayer

tg = 17.14 mm ; total thickness of laminated glass

a = 3330 mm ; glass long dimension between restraints

b = 2300 mm ; glass short dimension between restraints

NFL = 5.10 kPa ; non factored load

GTF = 4.00 ; glass type factor from table 1 of ASTM E1300

LR = 20.40 kPa ; internal lite load resistance (NFL*GTF)

since: LR1 > q' ; therefore glass is adequate strengthwise!

Approximate Center of Glass Deflection

Actual Deflection

E = 71700 MPa ; glass modulus of elasticity

r0 = 0.553 - 3.83*(a/b) + 1.11*(a/b)2 - 0.0969*(a/b)3

= -2.96

r1 = -2.29 + 5.83*(a/b) - 2.17*(a/b)2 + 0.2067*(a/b)3

= 2.23

r2 = 1.485 - 1.908*(a/b) + 0.815*(a/b)2 - 0.0822*(a/b)3

= 0.18

x = ln ln q1*(a*b)2

E*t24

= 1.25

w2 = t2*e(ro+r1*x+r2*x^2)

= 19.32 mm ; center of glass deflection

Allowable deflection

dp = b / 90

= 25.56 mm ; allowable deflection

since: dp > w ; therefore glass is safe for deflection

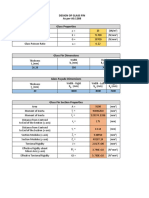

SAMPLE CALCULATION FOR IGU

Insulating Glass Unit - 6mm thick HS external lite + 12mm airspace + 6mm thick FT internal lite

Resistance condition - all sides simply supported

q' = 3.50 kPa ; uniform lateral load

t1 = 8.00 mm ; minimum thickness of outer lite as per ASTM E1300-2

t2 = 12.00 mm ; minimum thickness of inner lite as per ASTM E1300-2

a = 3330 mm ; glass long dimension between restraints

b = 1600 mm ; glass short dimension between restraints

NFL1 = 2.80 kPa ; non factored load for 6mm thick monolithic glass

NFL2 = 2.80 kPa ; non factored load for 6mm thick monolithic glass

GTF1 = 1.90 ; (HS) external lite from table 2 of ASTM E1300

GTF2 = 3.80 ; (FT) internal lite from table 2 of ASTM E1300

LS1 = 4.38 ; load share factor for external lite

LS2 = 1.30 ; load share factor for internal lite

LR1 = 23.28 kPa ; external lite load resistance (NFL1*GTF1*LS1)

LR2 = 13.79 kPa ; internal lite load resistance (NFL2*GTF2*LS2)

since: LR1 > q' ; therefore glass is adequate strengthwise!

Approximate Center of Glass Deflection

For Outer Lite

q1 = q / LS1

= 0.80 kPa ; load carried by outer lite

E = 71700 MPa ; glass modulus of elasticity

r0 = 0.553 - 3.83*(a/b) + 1.11*(a/b)2 - 0.0969*(a/b)3

= -3.48

r1 = -2.29 + 5.83*(a/b) - 2.17*(a/b)2 + 0.2067*(a/b)3

= 2.31

r2 = 1.485 - 1.908*(a/b) + 0.815*(a/b)2 - 0.0822*(a/b)3

= 0.30

x = ln ln q1*(a*b)2

E*t14

= 1.47

w1 = t1*e(ro+r1*x+r2*x^2)

= 14.04 mm ; center of glass deflection

For Inner Lite

q1 = q / LS

= 2.70 kPa ; load carried by outer lite

E = 71700 MPa ; glass modulus of elasticity

r0 = 0.553 - 3.83*(a/b) + 1.11*(a/b)2 - 0.0969*(a/b)3

= -3.48

r1 = -2.29 + 5.83*(a/b) - 2.17*(a/b)2 + 0.2067*(a/b)3

= 2.31

r2 = 1.485 - 1.908*(a/b) + 0.815*(a/b)2 - 0.0822*(a/b)3

= 0.30

x = ln ln q1*(a*b)2

E*t24

= 1.37

w2 = t2*e(ro+r1*x+r2*x^2)

= 15.45 mm ; center of glass deflection

Allowable deflection

dp = b / 90

= 17.78 mm ; allowable deflection

since: dp > w ; therefore glass is safe for deflection

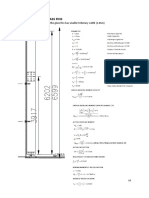

SAMPLE CALCULATION FOR MULLION

PARAMETERS

6063-T6 Aluminium Alloy (Reference to B.S. - 8118 : Part 1: 1991 - Structural use of Aluminum)

Ea = 70000 MPa ; modulus of elasticity

po = 160 MPa ; limiting stress for bending and overall yielding

pa = 175 MPa ; limiting stress for local capacity of the section

pv = 95 MPa ; limiting stress for shear

gm = 1.2 ; material factor

Wind Load

q = 1.95 kPa ; design wind load

Lb = 3640 mm ; unbraced length of mullion

tw = 1140 mm ; tributary width of mullion

WWL = q*tw

= 2.223 kN/m ; nominal wind load of mullion

Section Properties

At = 1324 mm2 ; cross sectional area (gross)

Ixt = 3375368 mm4 : moment of inertia about x-axis

Iyt = 659850 mm4 ; moment of inertia about y-axis

cyt = 77.2 mm ; distance from y-axis to remotest element

Znxt = 43722 mm3 ; elastic section modulus about x-axis

DESIGN FOR WIND LOAD

Check for Bending Moment Resistance

Maximum Design Moment

Mn = ( WWL*Lb )/8

2

= 3.68 kN-m ; nominal moment

MWL = 1.4*Mn

= 5.15 kN-m ; factored moment carried by aluminium due to wind load

Bending Moment Capacity

MRSx = po*Znxt / gm

= 5.83 kN-m ; moment resistance of mullion along x-axis

since: MRSx > MWL , profile is adequate for bending!

Check for Deflection

Note : This is not the exact formula,for a lesser conseravtive result assume partial fixity of mullion.

Actual Deflection

dWL = 3/384*(WWL*Lb / Ea*Ixt)

4

= 12.90 mm ; approximate deflection (continuos mullion)

Allowable Deflection

dP = Lb / 175

= 20.8 mm or 20 mm ; whichever is lesser

since : dp > d WL , profile is adequate for deflection!

e of Aluminum)

ium due to wind load

artial fixity of mullion.

deflection!

Das könnte Ihnen auch gefallen

- Structural Calculation Curtain WallDokument93 SeitenStructural Calculation Curtain Wallashaswamy100% (1)

- Alum SampleDokument2 SeitenAlum Samplewaweng22Noch keine Bewertungen

- Glass Laminate Thicness - No Reduc For Cantilever GlassDokument1 SeiteGlass Laminate Thicness - No Reduc For Cantilever GlassLaurence Sarmiento100% (1)

- Aluminium Mullion AnalysissDokument24 SeitenAluminium Mullion Analysissvtalex100% (4)

- ASTM E1300-09A GLASS DEFLECTION CALCULATIONDokument1 SeiteASTM E1300-09A GLASS DEFLECTION CALCULATIONwaweng22Noch keine Bewertungen

- CW SampleDokument22 SeitenCW SampleLaurence Sarmiento86% (7)

- Glass PanelDokument2 SeitenGlass PanelEIWAA50% (2)

- Structural Glass Design-BS6399Dokument6 SeitenStructural Glass Design-BS6399msiddiq1100% (2)

- Advanced Design of Glass Structures and FinsDokument7 SeitenAdvanced Design of Glass Structures and FinsAmro Ahmad Ali100% (2)

- Load Calculation for Glass Panel DesignDokument1 SeiteLoad Calculation for Glass Panel DesignAnonymous YDwBCtsNoch keine Bewertungen

- Curtain Wall Calculation PDFDokument134 SeitenCurtain Wall Calculation PDFAlaaBadwy100% (1)

- Project Name: Glass BalustradeDokument11 SeitenProject Name: Glass BalustradeNp Pw100% (1)

- Static Calculation CWDokument64 SeitenStatic Calculation CWCatalin Bunescu100% (2)

- Calculation Curtain WallDokument4 SeitenCalculation Curtain WallMcr Kumara100% (1)

- Design Wind Loads For Aluminum Curtain Walls (1975)Dokument21 SeitenDesign Wind Loads For Aluminum Curtain Walls (1975)Alberto GonzalezNoch keine Bewertungen

- Design Calculations For Aluminium Profile-13794Dokument14 SeitenDesign Calculations For Aluminium Profile-13794msiddiq175% (4)

- Structural Calculation of Curtain WallDokument118 SeitenStructural Calculation of Curtain Wallzfrl100% (23)

- Bolted Connection in Glass StructureDokument52 SeitenBolted Connection in Glass StructureCristiana Gruia-Paun100% (2)

- SKYLIGHT REPORT - Rev 01Dokument16 SeitenSKYLIGHT REPORT - Rev 01Muraleedharan100% (1)

- Design of Glass ColumnDokument8 SeitenDesign of Glass ColumnCristiana Gruia-PaunNoch keine Bewertungen

- Glass Laminate Thicknesses and PropertiesDokument1 SeiteGlass Laminate Thicknesses and PropertiesLaurence Sarmiento100% (1)

- Fin Glass 6Dokument6 SeitenFin Glass 6EIWAA100% (1)

- ConnectionDokument2 SeitenConnectionEIWAANoch keine Bewertungen

- Structural Glass Design-UBCDokument6 SeitenStructural Glass Design-UBCmsiddiq1100% (1)

- LGS Facade Wall Design Calculation SampleDokument62 SeitenLGS Facade Wall Design Calculation SampleWaqas HaiderNoch keine Bewertungen

- Steel MullionDokument47 SeitenSteel Mullionزين ال عابدين100% (2)

- GLASS BALUSTRADE DESIGN CALCULATIONSDokument8 SeitenGLASS BALUSTRADE DESIGN CALCULATIONSmsiddiq1100% (2)

- DESIGN CALCULATIONS FOR ALUMINIUM GLAZINGDokument8 SeitenDESIGN CALCULATIONS FOR ALUMINIUM GLAZINGmsiddiq1100% (1)

- Sg12 Frameless Balustrades Structural CalculationsDokument12 SeitenSg12 Frameless Balustrades Structural CalculationsAhmed Mohamed LabibNoch keine Bewertungen

- Check For Glass Fins: The Location Where We Have The Glass Fins Has Smaller Tributary Width (1.44m)Dokument5 SeitenCheck For Glass Fins: The Location Where We Have The Glass Fins Has Smaller Tributary Width (1.44m)Laurence SarmientoNoch keine Bewertungen

- Design of Mullion-BS enDokument16 SeitenDesign of Mullion-BS enPrasad kapure100% (1)

- 1analysis For Curtain Wall GlassDokument2 Seiten1analysis For Curtain Wall GlassEIWAANoch keine Bewertungen

- Project: Lot8 at Macau: SUBJECT: Calculation For The WindowDokument50 SeitenProject: Lot8 at Macau: SUBJECT: Calculation For The WindowHelen ChoiNoch keine Bewertungen

- STRUCTURAL GLASS DESIGN REPORTDokument1 SeiteSTRUCTURAL GLASS DESIGN REPORTsamgivp2869100% (4)

- Glass CalculationDokument2 SeitenGlass Calculationpradeeshpg50% (2)

- Glass Design Strength of 20mm thick Toughened glassDokument13 SeitenGlass Design Strength of 20mm thick Toughened glassARYA0% (1)

- Glass analysis calculations for structural wall projectDokument8 SeitenGlass analysis calculations for structural wall projectARYA100% (1)

- Section Classification BS 8118-1-1991Dokument1 SeiteSection Classification BS 8118-1-1991AthumizNoch keine Bewertungen

- Curtain Walls ReportDokument13 SeitenCurtain Walls ReportAshwini Bramhane100% (3)

- 1-1) Typical Glass Balustrade PanelDokument7 Seiten1-1) Typical Glass Balustrade PaneldanieldumapitNoch keine Bewertungen

- 10th Aug. 2011 Structural Calculation (For Sub.) - 03Dokument29 Seiten10th Aug. 2011 Structural Calculation (For Sub.) - 03Nguyễn Tiến Việt100% (1)

- Design of Curtain Walls For Wind Loads - Details and CalculationsDokument9 SeitenDesign of Curtain Walls For Wind Loads - Details and CalculationsJustin Musopole100% (1)

- Paseo Curtain Wall Strutural CalculationDokument79 SeitenPaseo Curtain Wall Strutural CalculationVictor Dlreyes100% (1)

- Saflex Structural GuideDokument51 SeitenSaflex Structural Guidemercab15Noch keine Bewertungen

- Glass BalustradeDokument7 SeitenGlass BalustradeARYANoch keine Bewertungen

- Bracket CheckDokument3 SeitenBracket Checkwaweng22Noch keine Bewertungen

- Design of Glass Fin for Glass FaçadeDokument4 SeitenDesign of Glass Fin for Glass FaçadeZaido Al HalabiNoch keine Bewertungen

- Glass FinDokument6 SeitenGlass FinSethusweet SethuramanNoch keine Bewertungen

- Strength Design Methods - For Glass StructuresDokument147 SeitenStrength Design Methods - For Glass Structuresasdriana100% (1)

- Louver Report Rev02Dokument12 SeitenLouver Report Rev02MuraleedharanNoch keine Bewertungen

- Fin Glass 6Dokument4 SeitenFin Glass 6EIWAANoch keine Bewertungen

- Facade CalculationDokument60 SeitenFacade CalculationPrabartak Das100% (2)

- Sample Calculation For Igu: Since: Q' Therefore Glass Is Adequate Strengthwise! LRDokument5 SeitenSample Calculation For Igu: Since: Q' Therefore Glass Is Adequate Strengthwise! LRlayaljamal2Noch keine Bewertungen

- Structural Cals For UCWDokument11 SeitenStructural Cals For UCWShubham SoniNoch keine Bewertungen

- DGU Design For Glass DivisionDokument3 SeitenDGU Design For Glass DivisionShafeeq KT100% (1)

- Concrete Industrial Ground Floor Slab Desig1Dokument3 SeitenConcrete Industrial Ground Floor Slab Desig1Mahata PriyabrataNoch keine Bewertungen

- General Data: Bending StessesDokument8 SeitenGeneral Data: Bending Stessesprajakt_pieNoch keine Bewertungen

- Arbor Lanes - Phase 3: Mango Road, Taguig City, Philippines FEBRUARY 18, 2020Dokument2 SeitenArbor Lanes - Phase 3: Mango Road, Taguig City, Philippines FEBRUARY 18, 2020Sharah QuilarioNoch keine Bewertungen

- Laminated tempered glass designDokument3 SeitenLaminated tempered glass designleoNoch keine Bewertungen

- Concrete Slab Formwork - Safety GuideDokument53 SeitenConcrete Slab Formwork - Safety GuideThành KC100% (4)

- HALFEN Punching Shear ReinforcementDokument36 SeitenHALFEN Punching Shear ReinforcementThành KCNoch keine Bewertungen

- Example 16v2Dokument8 SeitenExample 16v2Thành KCNoch keine Bewertungen

- Adapt - Structural Concrete Software System: 1 - PROJECT TITLE: General NameDokument4 SeitenAdapt - Structural Concrete Software System: 1 - PROJECT TITLE: General NameThành KCNoch keine Bewertungen

- GR Ve Grid VV Xem An Hien Doi TuongDokument1 SeiteGR Ve Grid VV Xem An Hien Doi TuongThành KCNoch keine Bewertungen

- Support ReactionsDokument12 SeitenSupport ReactionsThành KCNoch keine Bewertungen

- Tips For Developing Models and SAP2000 and ETABSDokument30 SeitenTips For Developing Models and SAP2000 and ETABSHector RuizNoch keine Bewertungen

- OF-B16M (B21-V6) - KC-200516 ModelDokument1 SeiteOF-B16M (B21-V6) - KC-200516 ModelThành KCNoch keine Bewertungen

- Waffle Slab EconomicsDokument2 SeitenWaffle Slab Economicsmumbler02Noch keine Bewertungen

- Manual For Design and Detailing of RCCDokument340 SeitenManual For Design and Detailing of RCCimranmehfoozNoch keine Bewertungen

- Certification Franc Op HoneDokument1 SeiteCertification Franc Op HoneThành KCNoch keine Bewertungen

- AISC 360-16 LRFD Code Checking of Steel Beam SectionDokument3 SeitenAISC 360-16 LRFD Code Checking of Steel Beam SectionJake CortezNoch keine Bewertungen

- Mohr Coulomb ModelDokument19 SeitenMohr Coulomb ModelSupachai JaingamNoch keine Bewertungen

- Mechanics of MaterialsDokument34 SeitenMechanics of MaterialsCharn69% (16)

- DNV RP F108Dokument24 SeitenDNV RP F108Vicknesh ThanabalNoch keine Bewertungen

- Reinforcement SteelDokument52 SeitenReinforcement Steelnsprasad88Noch keine Bewertungen

- PLAXIS-UDSM-Masonry Model (V20Update1)Dokument22 SeitenPLAXIS-UDSM-Masonry Model (V20Update1)NISHANT ROYNoch keine Bewertungen

- Som Complete Marathon by Abhinav and Dheeraj Sir 13Dokument408 SeitenSom Complete Marathon by Abhinav and Dheeraj Sir 13பிரதீப் சாமிநாதன்Noch keine Bewertungen

- HW 1Dokument2 SeitenHW 1maherkamelNoch keine Bewertungen

- Lecture#4 Strain MeasurementDokument5 SeitenLecture#4 Strain MeasurementRenuga SubramaniamNoch keine Bewertungen

- SAB2223 Mechanics of Materials and Structures: Topic 1 Stress and StrainDokument120 SeitenSAB2223 Mechanics of Materials and Structures: Topic 1 Stress and StrainTsalach100% (1)

- 3 Braking SystemsDokument250 Seiten3 Braking SystemsnigletNoch keine Bewertungen

- 2 3 1 A StressstraincalculationsDokument5 Seiten2 3 1 A Stressstraincalculationsapi-260799820Noch keine Bewertungen

- Modeling of Reinforced Concrete BeamDokument28 SeitenModeling of Reinforced Concrete BeamNGUYEN89% (27)

- Chapter 4: Fluid Kinematics: Eric G. PatersonDokument34 SeitenChapter 4: Fluid Kinematics: Eric G. PatersonZandrik ArismendiNoch keine Bewertungen

- ME 582/ MS 582 Mechanical Behavior of MaterialsDokument3 SeitenME 582/ MS 582 Mechanical Behavior of MaterialsChelseaNoch keine Bewertungen

- RCC properties guideDokument11 SeitenRCC properties guideaminsuhadiNoch keine Bewertungen

- 6 - Mechanical Properties 2Dokument45 Seiten6 - Mechanical Properties 2Ledia EssamNoch keine Bewertungen

- Capítulo 6Dokument83 SeitenCapítulo 6fslsantosNoch keine Bewertungen

- Thompson R. J. and Visser A.T. 1999. Designing and Managing Unpaved Opencast Mine Haul Roads For Optimum PerformanceDokument17 SeitenThompson R. J. and Visser A.T. 1999. Designing and Managing Unpaved Opencast Mine Haul Roads For Optimum PerformanceIr Azizul Bin HawariNoch keine Bewertungen

- TST1501 - S2 - Major Test 1 - 2023Dokument5 SeitenTST1501 - S2 - Major Test 1 - 2023Rachel Du PreezNoch keine Bewertungen

- Load-Deformation Behaviours of Engineering MaterialsDokument25 SeitenLoad-Deformation Behaviours of Engineering MaterialsMarc GoelNoch keine Bewertungen

- Lesson Plan: Elasticity: BackgroundDokument8 SeitenLesson Plan: Elasticity: Backgroundsaira bibiNoch keine Bewertungen

- Quality Control Materials ConstructionDokument74 SeitenQuality Control Materials ConstructionMark James MateoNoch keine Bewertungen

- Fem Nptel Module 1Dokument29 SeitenFem Nptel Module 1Syed Ahmed KabeerNoch keine Bewertungen

- Article - The Effect of Extrusion Temperature On The Development of Deformation Microstructures in 5052 Aluminium Alloy Processed by ECAPDokument11 SeitenArticle - The Effect of Extrusion Temperature On The Development of Deformation Microstructures in 5052 Aluminium Alloy Processed by ECAPAmilton CardosoNoch keine Bewertungen

- Structural Analysis of Car Disk BrakeDokument73 SeitenStructural Analysis of Car Disk BrakeAkesh KakarlaNoch keine Bewertungen

- BENCHMARK 1 Hole Expansion of A High Strength Steel Sheet: 1. OverviewDokument10 SeitenBENCHMARK 1 Hole Expansion of A High Strength Steel Sheet: 1. OverviewSergio PluchinskyNoch keine Bewertungen

- UEME1263 - Topic 2 - Mechanical Properties of MaterialsDokument88 SeitenUEME1263 - Topic 2 - Mechanical Properties of MaterialsKiritoNoch keine Bewertungen

- (Steel Structure Design) AHMED PSHTIWAN & LAWAND DIARIDokument233 Seiten(Steel Structure Design) AHMED PSHTIWAN & LAWAND DIARIAhmad PshtiwanNoch keine Bewertungen

- Introduction To Finite Elements: Shape Functions in 1DDokument29 SeitenIntroduction To Finite Elements: Shape Functions in 1Djawad khalidNoch keine Bewertungen