Beruflich Dokumente

Kultur Dokumente

Readme Cooldt Manual PDF

Hochgeladen von

Yutt WattOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Readme Cooldt Manual PDF

Hochgeladen von

Yutt WattCopyright:

Verfügbare Formate

Cooldt cool-down time calculator for multi-layers pipe

Cooldt calculate the cooling duration of a multi-layers pipe in a cold environment. The duration to reach the Final fluid

temperature or cool-down time (CDT) is calculated by solving the heat equation in cylindrical coordinates with a flux

conservative formulation.

Cold environment at Tambient

Layer 1

Warm

Layer 2

fluid

wall =hambient ( T wall T ambient ) Layer 3

Figure 1: Example of a multi-layers pipe

A typical plot of initial, final temperature profiles and the temperature decay at the fluid / solid interface is shown below.

Figure 2: Initial, final temperature profiles and temperature decay at the fluid / solid interface

Cooldt 2, January 2014 1/9 http://cooldt.sourceforge.net/

1 Features

Flux Conservative Formulation of Transient Heat Transfer

Automatic meshing and time step calculation (0.1% accuracy)

LibreOffice and Excel interfaces

Excel Add-in with Visual Basic interface

Gnuplot compatible output

32 and 64 bits versions

2 Requirements

Gnu/Linux or Windows (or any operating system if you compile Cooldt from source)

Recommended: LibreOffice or Excel

Optional: Gnuplot

3 Install Cooldt

Download Gnu/Linux 64 bits or Windows 32/64 bits binaries version and extract the archive.

To install the Excel Add-in, follow instructions from the link below.

http://office.microsoft.com/en-us/excel-help/load-or-unload-add-in-programs-HP010096834.aspx

For the 32 bits version of Excel select cooldt.xll and for the 64 bits version of Excel select cooldt-w64.xll. No administrative

privilege are required to install it.

4 Run Cooldt

4.1 LibreOffice or Excel

Open CooldtSheet.xls or CooldtSheet.ods, enter your data then click the Launch cooldt button.

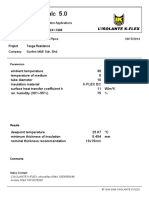

Figure 3: Spreadsheet input

The cooldt executable and the spreadsheet must be in the same folder and the decimal separator must be the point (.)

On Windows, Cooldt can not run on an UNC path (i.e. a path starting with \\). Map your UNC path, or run Cooldt from a local

drive to solve this problem

4.2 Excel Add-in

The Excel Add-in provides a native Excel function to calculate cool-down time. It is very useful to calculate an insulation

thickness for a given cool-down time with the Excel solver. Avoid goal seek, it does not work very well with non-linear

functions. To use the CoolDownTime function, click on the fx button on the formula bar, select the Cooldt 2 category, select the

CoolDownTime function then enter your data. Examples of usage are presented on the CooldtSheet file.

Cooldt 2, January 2014 2/9 http://cooldt.sourceforge.net/

4.3 Command line interface

Type cooldt example.dat to calculate the cool-down time of the example.dat data file. Results will be saved to the

example.txt file.

Figure 4: Command line interface

Replace cooldt by cooldt-w64 if you are using the 64 bits version of Windows.

The data file is a text file with numbers separated by spaces or tabs. The file format is presented in the table below:

InitialTemp.(C) AmbientTemp.(C) FinalTargetTemp.(C) AmbientHeatTransfer(W/m2/K)

Pipe.ID(m) FluidConductivity.(W/m/K) FluidDensity(kg/m3) FluidHeatCapacity(J/kg/K)

Layer.1.OD(m) Layer.1.Conductivity.(W/m/K) Layer.1.Density(kg/m3) Layer.1.HeatCapacity(J/kg/K)

Layer.n.OD(m) Layer.n.Conductivity.(W/m/K) Layer.n.Density(kg/m3) Layer.n.HeatCapacity(J/kg/K)

Several files can be processed in one command, e.g. type cooldt file-1.dat file-2.dat file-3.dat to process

three files.

4.4 With Gnuplot (http://gnuplot.sourceforge.net/)

To generate png and svg plots from a Cooldt output file, use the gnuplot-script.gp script file with the Gnuplot command:

gnuplot -e "OutputFile='example.txt';" gnuplot-script.gp

4.5 Excel Visual Basic Interface

Cooldt can be called from Visual Basic. The declaration of the cooldt function and two examples of usage are given in the

CooldtVB file.

5 Build from Source

5.1 Gnu/Linux

Requirements:

Windows 32 bits build: MinGW gcc and g++ http://www.mingw.org/

Windows 64 bits build: MinGW-w64 gcc and g++ http://mingw-w64.sourceforge.net/

Gnu/Linux build: gcc http://gcc.gnu.org/

Build commands:

Gnu/Linux build: make -f Makefile

Windows 32 bits build: make -f Makefile PLATFORM=WIN32

Windows 64 bits build: make -f Makefile PLATFORM=WIN64

Cooldt 2, January 2014 3/9 http://cooldt.sourceforge.net/

If you have Code::Blocks installed, open the project file Cooldt.cbp and select one of these targets:

Linux build: Gnu/Linux

Windows 32 bits build: CrossWIN32

Windows 64 bits build: CrossWIN64

All Cooldt 2 binary releases have been built on Gnu/Linux with gcc, i586-mingw32msvc-gcc, i586-mingw32msvc-g++,

x86_64-w64-mingw32-gcc and x86_64-w64-mingw32-g++ version 4.6.3.

5.2 MS Windows

Requirements:

Windows 32 bits build: MinGW gcc and g++ http://www.mingw.org/

Windows 64 bits build: MinGW-w64 gcc and g++ http://mingw-w64.sourceforge.net/

I recommend:

To use the tdm installer for MinGW-w64 http://tdm-gcc.tdragon.net/

To install MinGW and/or MinGW-w64 in paths without spaces (i.e. not in C:\Program Files)

It is possible to install both MinGW and MinGW-w64 e.g. in C:\mingw32 and C:\mingw64 respectively. If so:

It is useless to install mingw32-make with MinGW-w64 (it is included with MinGW 32 bits)

Because both C:\mingw32\bin and C:\mingw64\bin are defined in %PATH%, use non ambiguous compilers names like

mingw32-gcc.exe and x86_64-w64-mingw32-gcc.exe

Build commands:

Windows 32 bits build: mingw32-make -f MakefileWindows.mak PLATFORM=WIN32

Windows 64 bits build: mingw32-make -f MakefileWindows.mak PLATFORM=WIN64

If you have Code::Blocks installed, open the project file Cooldt.cbp and select one of these targets:

Windows 32 bits build: WIN32

Windows 64 bits build: WIN64

6 Cooldt cool-down time calculator License

Copyright 2010, 2013, 2014, Benjamin DEGLO DE BESSES. All rights reserved.

Redistribution and use in source and binary forms, with or without modification, are permitted provided that the following

conditions are met:

1. Redistributions of source code must retain the above copyright notice, this list of conditions and the following

disclaimer.

2. Redistributions in binary form must reproduce the above copyright notice, this list of conditions and the following

disclaimer in the documentation and/or other materials provided with the distribution.

THIS SOFTWARE IS PROVIDED BY Benjamin DEGLO DE BESSES "AS IS" AND ANY EXPRESS OR IMPLIED

WARRANTIES, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE ARE DISCLAIMED. IN NO EVENT SHALL Benjamin DEGLO DE BESSES OR

CONTRIBUTORS BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL, EXEMPLARY, OR

CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO, PROCUREMENT OF SUBSTITUTE GOODS OR

SERVICES; LOSS OF USE, DATA, OR PROFITS; OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND ON ANY

THEORY OF LIABILITY, WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT (INCLUDING NEGLIGENCE OR

OTHERWISE) ARISING IN ANY WAY OUT OF THE USE OF THIS SOFTWARE, EVEN IF ADVISED OF THE

POSSIBILITY OF SUCH DAMAGE.

Cooldt includes XLW A Wrapper for the Excel API http://xlw.sourceforge.net

Cooldt 2, January 2014 4/9 http://cooldt.sourceforge.net/

7 Cooldt formulation

The heat equation in cylindrical coordinates is

( 2 r C p T ) T

t

=

r

2k r

r ( ) (1)

The flux per unitary length is given by

T

=2 k r (2)

r

See [1] for details.

7.1 Pipe discretization

The pipe is dividing in N cells delimited by N points indexed from 0 to N.

r(i-1/2) r(i) r(i+1/2)

r=0

i=0 i=2 i-1 i i+1 i = N-1 i=N

Figure 5: Pipe discretization with a cell centred nodes approach

Interfaces conductivities are given by the steady state solution

k i k i+1 ln (r i +1 /r i )

k i +1/ 2= (3)

k i ln (r i +1 / r i +1/ 2 )+ k i+ 1 ln (r i +1 /2 /r i )

Obviously

k i1 / 2=k i 1 / 21 (4)

At the pipe center (i = 0)

k +1/ 2=k 0 (5)

7.2 Flux Conservative Formulation

For one cell, flux at i - and i + interfaces are

T ip+1T i1

p +1

p+1

/2 =2 r i1/ 2 k i1/ 2

i1 (6)

r ir i1

And:

p+1 T i+p +11 T ip+1

i +1/ 2 =2 r i +1/ 2 k i+1 / 2 (7)

r i +1r i

Thus the flux conservative formulation is

T i ip+1 p+1

2 r i i Cpi = 1 / 2 i +1/ 2 (8)

t r i +1/ 2r i1 /2

See [2] and [4] for details.

Cooldt 2, January 2014 5/9 http://cooldt.sourceforge.net/

With

p 1 p

T i =T i T i (9)

The equation (8) can be rearranged and Si the surface of the cell i appears

Si

Ti

(r r2

)

i +1/ 2

2

i1 /2 i Cpi p+1

=i1 p+1

/ 2 i +1/ 2

(10)

t

7.2.1 At the Pipe Center (i = 0)

The equation (8) become

S0

Ti T p +1T 0p+1

r 2

1/ 2 0 Cp0 =2 r 1 / 2 k 1 / 2 1 (11)

t r1

If

0=0 (12)

And

0=S 0 0 Cp 0 (13)

And

2 r 1 / 2 k 1 / 2

0= (14)

r1

The equation (11) is equivalent to

0 p1

T 0 T 0p = 0 T 1p1T 0p 1 (15)

t

Consequently

B0 C0 D0

T T

[ 0 + t 0 ] t 0 +

[ t 0 ] t 1 = p p

0 (T 1 T 0 )

(16)

7.2.2 In Fluid and Pipe Layers (1 i N-1)

The equation (8) become

Si

p +1

T ip T ip+1T i1p+ 1

T T ip+1+1T ip+1 (17)

( r 2i +1/ 2r 2i1 /2 ) i Cpi i =2 r i 1 / 2 k i 1/ 2 +2 r i +1/ 2 k i+1 / 2

t r i r i1 r i +1r i

If

i =S i i Cpi (18)

And

2 r i 1 / 2 k i 1/ 2

i= = i1 (19)

r i r i 1

And

2 r i1/ 2 k i1/ 2

i = (20)

r i 1r i

Cooldt 2, January 2014 6/9 http://cooldt.sourceforge.net/

The equation (17) is equivalent to

i

T p1T ip =i T ip1T i1

p1 p1

i T i1 T ip1 (21)

t i

Consequently

Ai Bi Ci Di

T T T

[ t i ] ti 1 +

[ i + t( i + i) ] t i +

[ t i ] ti +1 = p p p p

i (T i1T i )+ i (T i +1T i )

(22)

7.2.3 At the Outer Boundary (i = N)

The equation (8) become

SN

T N T p+1T Np +1

2

( r r

N ) 2

N 1 /2 N Cp N =2 r N 1 /2 k N 1/ 2 N 1 p+1

+wall (23)

t r i r i1

With

p+1

+wall =2 r N hambient ( T Np+ 1T ambient ) (24)

If

N =S N N Cp N (25)

And

2 r N 1/ 2 k N 1 /2

N = = N 1 (26)

r N r N 1

And

N =2 r N hambient (27)

The equation (23) is equivalent to

N p+1 p p+1 p +1 p+1

(T N T N )= N (T N T N 1 ) N (T N T ambient ) (28)

t

Consequently

AN BN DN

T T

[ t N ] Nt 1 +

[ N + t( N + N )] t N = p p p

N (T N 1 T N )+ N (T ambient T N )

(29)

7.2.4 System of Equations

The following system of equation is build with equations (16), (22) and (29)

[ ] [ ][ ]

B0 C 0 0 0 T0

D0

A 1 B1 C 1 0 T1

D1

0 1

Ai Bi Ci = Di

t Ti (30)

0

0 AN 1 B N 1 C N 1 D

T N 1 N 1

0 0 AN BN D

TN N

T i

t

This non-symmetric tri-diagonal diagonally-dominant system is solved with a Thomas algorithm (see [3] for details).

Cooldt 2, January 2014 7/9 http://cooldt.sourceforge.net/

7.3 Steady State

All fluid cell are at the initial temperature

T i =T initial for i < number of fluid cells (31)

The virtual1 temperature at the fluid/solid interface is supposed to be the initial temperature

[ # i ] T i [ i ] T i1=[ # ] T initial with i = number of fluid cells (32)

With

2 ri k i

# = with i = number of fluid cells (33)

r i r i 1/ 2

The temperature gradient in solid layers is given by

[i ] T i1[ i i ] T i [ i ] T i1=0 for i > number of fluid cells (34)

And for the last node

[N ] T N 1[ N N ] T N = N T ambient if i = N (35)

A non-symmetric tri-diagonal system is build with (32), (34) and (35) then solved with a Thomas algorithm (see [3] for details) to

generate the initial temperature profile.

The steady state numerical solution match the analytic solution by design.

7.4 Implicit Time Integration

7.4.1 Backward Euler Method (cooldt v 0.5)

Ti

T ip1=T ip t (36)

t

7.4.2 Exponential Decay Method

The cool-down process is close2 to an exponential decay to the ambient temperature. As a consequence it is possible to calculate

Ti

decay constants i for each cells from the calculated values. Thus:

t

Ti

T ip + t T ambient

t

i= (37)

T i

t

Then next temperatures are calculated with:

p+1 p

T i =T ambient +(T i T ambient ) exp ( t / i) (38)

1 There is no node at the fluid/solid interface

2 Exact solutions of heat conduction in cylindrical coordinates are based on Bessel's function.

Cooldt 2, January 2014 8/9 http://cooldt.sourceforge.net/

7.4.3 Comparison of Methods

The figure below presents the comparison of the cool-down time calculated with these two methods.

10.3

10.2

Cool down time (h)

10.1 cooldt v0.5 cooldt v0.6, Time

step = 1000 s

10.0

9.9

9.8

9.7

5 50 500

Time step (s)

Figure 6: Cool-down time vs. Time step

The exponential decay method offer a very good accuracy with large time steps compared to the Euler backward method. The

exponential decay method is more than 100 times faster than the Euler backward method.

7.5 Accuracy Control

The accuracy control algorithm is shortly describe below:

a) Produce a first estimation of the calculated cool-down time (CDT) with 2 cells for the first layer (fluid), 1 cell for solid

layers and a large time step (1000 s)

b) Try to improve each parameter (i.e. double cell number or divide time step by 10) individually

c) Find the parameter which produce the bigger change (i.e. best improvement) of CDT, then keep only the parameter

change corresponding to the best improvement of CDT

d) While the relative change of CDT has not converged, go to step b

7.6 References

[1]. Bernard Eyglunent, Manuel De Thermique - Thorie Et Pratique, 2me dition, Hermes Science Publications

[2]. Suhas V, Patankar , Numerical Heat Transfer and Fluid Flow - Series in computational methods in mechanics and

thermal sciences , Hemisphere Publishing Corporation

[3]. http://en.wikipedia.org/wiki/Tridiagonal_matrix_algorithm

[4]. http://en.wikipedia.org/wiki/Finite_volume_method

Cooldt 2, January 2014 9/9 http://cooldt.sourceforge.net/

Das könnte Ihnen auch gefallen

- Three 2D DisksDokument32 SeitenThree 2D DisksjonathanyflorenciaNoch keine Bewertungen

- Udf Wall TempDokument7 SeitenUdf Wall TempAmal ..Noch keine Bewertungen

- Exercises 19 TotDokument65 SeitenExercises 19 TotSikander AzamNoch keine Bewertungen

- Pes1ug20ec217 Isa04 2022 23 Ue20ec324 PDFDokument16 SeitenPes1ug20ec217 Isa04 2022 23 Ue20ec324 PDFVaishnavi B VNoch keine Bewertungen

- Numme Lab: Finite ElementsDokument5 SeitenNumme Lab: Finite ElementstalletbaptisteNoch keine Bewertungen

- Tutorial 2. Modeling Periodic Flow and Heat TransferDokument26 SeitenTutorial 2. Modeling Periodic Flow and Heat Transferwaleed yehiaNoch keine Bewertungen

- Turbulent Flow in Compact Heat ExchangerDokument15 SeitenTurbulent Flow in Compact Heat ExchangerwasemNoch keine Bewertungen

- Udf TempDokument8 SeitenUdf TempSatish GuptaNoch keine Bewertungen

- ECEP 443 Lab#1: Layout & Analysis of CMOS InverterDokument9 SeitenECEP 443 Lab#1: Layout & Analysis of CMOS InverterAldrin taduranNoch keine Bewertungen

- Elmer TutorialsDokument81 SeitenElmer TutorialsPutri Nur CahyantiNoch keine Bewertungen

- A1 1D 2D CHCondDokument8 SeitenA1 1D 2D CHCondPratyushAgarwalNoch keine Bewertungen

- Exercise For Tutorial "A2 - Conjugate Heat Transfer": Contents of ReportDokument16 SeitenExercise For Tutorial "A2 - Conjugate Heat Transfer": Contents of ReportRiken MangukiyaNoch keine Bewertungen

- Code Saturne TutorialDokument33 SeitenCode Saturne TutorialargaborNoch keine Bewertungen

- Caffa3d MBDokument16 SeitenCaffa3d MBJeremy Dudley100% (1)

- BertTutorial TomographyDokument28 SeitenBertTutorial Tomographymartinez_vladim3914Noch keine Bewertungen

- Elmer GUI Tutorials: CSC - IT Center For Science December 19, 2018Dokument96 SeitenElmer GUI Tutorials: CSC - IT Center For Science December 19, 2018Amr HitchNoch keine Bewertungen

- ANSYS FLUENT Conjugate Heat Transfer TutorialDokument30 SeitenANSYS FLUENT Conjugate Heat Transfer Tutorialteguh hady aNoch keine Bewertungen

- Fluent Tutorial 02 Modeling Periodic Flow and Heat TransferDokument26 SeitenFluent Tutorial 02 Modeling Periodic Flow and Heat Transferparvaz747Noch keine Bewertungen

- MECH3427-Assignment QuestionsDokument15 SeitenMECH3427-Assignment QuestionsMandy ShiuNoch keine Bewertungen

- Modeling Periodic Flow and Heat Transfer TutorialDokument26 SeitenModeling Periodic Flow and Heat Transfer TutorialIshani GuptaNoch keine Bewertungen

- Tanner EDA VLSI Project Lab 1Dokument9 SeitenTanner EDA VLSI Project Lab 1MohamedNoch keine Bewertungen

- Compact Heat Exchanger WWW - Profluent.irDokument14 SeitenCompact Heat Exchanger WWW - Profluent.irHaunted HunterNoch keine Bewertungen

- Elmer GUIDokument168 SeitenElmer GUIRonnaruchitNoch keine Bewertungen

- Lecture 21Dokument7 SeitenLecture 21litoduterNoch keine Bewertungen

- Thermal Analysis of Electronic Equipment - Quick GuideDokument84 SeitenThermal Analysis of Electronic Equipment - Quick Guideprashant_salima6377Noch keine Bewertungen

- Temperature Dependent Viscosity TutorialDokument9 SeitenTemperature Dependent Viscosity TutorialAdrian García MoyanoNoch keine Bewertungen

- Hello WorldDokument5 SeitenHello Worldsachin1985tNoch keine Bewertungen

- Watts & Strogatz Small World Model: Barış EkdiDokument11 SeitenWatts & Strogatz Small World Model: Barış EkdibekdiNoch keine Bewertungen

- NVIDIA CUDA Computational Finance Geeks3DDokument39 SeitenNVIDIA CUDA Computational Finance Geeks3DJin BinNoch keine Bewertungen

- Elmer TutorialsDokument96 SeitenElmer TutorialsMartin CaicedoNoch keine Bewertungen

- C11: The New C Standard by Thomas Plum: ConcurrencyDokument14 SeitenC11: The New C Standard by Thomas Plum: ConcurrencycompangelNoch keine Bewertungen

- Cdo NcoDokument33 SeitenCdo NcoCristiano PrestreloNoch keine Bewertungen

- Tutorial 2. Modeling Periodic Flow and Heat TransferDokument32 SeitenTutorial 2. Modeling Periodic Flow and Heat TransfermeciebNoch keine Bewertungen

- Iot Lab ManualeditedDokument29 SeitenIot Lab ManualeditedprashantNoch keine Bewertungen

- Lab BookDokument70 SeitenLab Bookअमरेश झाNoch keine Bewertungen

- Design and Analysis of Cooling Fins: Deepak Gupta, Wankhade S.RDokument4 SeitenDesign and Analysis of Cooling Fins: Deepak Gupta, Wankhade S.RAntonio SilvaNoch keine Bewertungen

- Ultra-Light Decoder For Turbo Product Codes: IEEE Communications Letters December 2017Dokument5 SeitenUltra-Light Decoder For Turbo Product Codes: IEEE Communications Letters December 2017dixson1965Noch keine Bewertungen

- Users GuideDokument34 SeitenUsers GuideZaratustra NietzcheNoch keine Bewertungen

- Tutorial: Solving A Conjugate Heat Transfer Problem Using Ansys FluentDokument30 SeitenTutorial: Solving A Conjugate Heat Transfer Problem Using Ansys FluentThiagarajanNoch keine Bewertungen

- Chip Design Methods Pros and ConsDokument9 SeitenChip Design Methods Pros and Conslavender4994Noch keine Bewertungen

- Compact Thermal ModelingDokument6 SeitenCompact Thermal ModelingteomondoNoch keine Bewertungen

- Murphy TDXM 10702748 Temperature Scanner PyrometerDokument2 SeitenMurphy TDXM 10702748 Temperature Scanner PyrometerVikram JitNoch keine Bewertungen

- Design and Implementation of H/W Efficient Multiplier: Reversible Logic Gate ApproachDokument5 SeitenDesign and Implementation of H/W Efficient Multiplier: Reversible Logic Gate ApproachAnas RazzaqNoch keine Bewertungen

- 01EX8 Tempdistrbn FinDokument6 Seiten01EX8 Tempdistrbn FinSivakumar ANoch keine Bewertungen

- Elmer TutorialsDokument148 SeitenElmer Tutorialsuser123Noch keine Bewertungen

- Experiment No-8: OBJECT: - To Design IIR Filter Using TMS320C6713 Digital Signal Processing Starter KitDokument7 SeitenExperiment No-8: OBJECT: - To Design IIR Filter Using TMS320C6713 Digital Signal Processing Starter KitMayank SardanaNoch keine Bewertungen

- Chapter 2 Learning To Use The Hardware and SoftwareDokument86 SeitenChapter 2 Learning To Use The Hardware and SoftwareosbihatNoch keine Bewertungen

- UdfDokument6 SeitenUdfmujikagNoch keine Bewertungen

- Computer Arithemetic ProjectDokument12 SeitenComputer Arithemetic ProjectJason MillerNoch keine Bewertungen

- Resolution de Gray-Scott Sur Plusieurs CPU Et GPUDokument3 SeitenResolution de Gray-Scott Sur Plusieurs CPU Et GPUMatteoNoch keine Bewertungen

- Ohmic Heating Modeling with UDS and UDMDokument28 SeitenOhmic Heating Modeling with UDS and UDMDeepankumar AthiyannanNoch keine Bewertungen

- CFDSTUDY Documentation Tutorial Turbulent Mixing T-JunctionDokument39 SeitenCFDSTUDY Documentation Tutorial Turbulent Mixing T-JunctionNa JangoNoch keine Bewertungen

- Tut 05 BerlDokument14 SeitenTut 05 BerlrpatelNoch keine Bewertungen

- Spreading Codes in Cdma Detection: Eastern Mediterranean University July 2003Dokument24 SeitenSpreading Codes in Cdma Detection: Eastern Mediterranean University July 2003Alex BadeaNoch keine Bewertungen

- Engineering School of Sustainable Infrastructure and Environment EOC 6934Dokument3 SeitenEngineering School of Sustainable Infrastructure and Environment EOC 6934Mashal KhanNoch keine Bewertungen

- OneWire Ds18b020 Termometre UygulamasımikrocDokument4 SeitenOneWire Ds18b020 Termometre Uygulamasımikrocabdulkadir dönerNoch keine Bewertungen

- Exp 1 Mannual TransformerDokument10 SeitenExp 1 Mannual TransformerÅnshùmãn ShùklåNoch keine Bewertungen

- Thermo-hydrodynamic Lubrication in Hydrodynamic BearingsVon EverandThermo-hydrodynamic Lubrication in Hydrodynamic BearingsNoch keine Bewertungen

- PLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.Von EverandPLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.Noch keine Bewertungen

- CAPREO Freehub: 9-SpeedDokument1 SeiteCAPREO Freehub: 9-SpeedYutt WattNoch keine Bewertungen

- COLMAC Iom-Arevaporators-Eng00014424Dokument38 SeitenCOLMAC Iom-Arevaporators-Eng00014424Yutt WattNoch keine Bewertungen

- WSRC - Ms.934) 37: .Ois'Rrtbut1Onof: Lr.4:S Docu - ,,jeittkt.. Ui/Tlih4Rrel.Dokument12 SeitenWSRC - Ms.934) 37: .Ois'Rrtbut1Onof: Lr.4:S Docu - ,,jeittkt.. Ui/Tlih4Rrel.Yutt WattNoch keine Bewertungen

- K Flex Calculation Based On Ambient Temperature 30 C RH 75 H 11 FinalDokument1 SeiteK Flex Calculation Based On Ambient Temperature 30 C RH 75 H 11 FinalYutt WattNoch keine Bewertungen

- Tech Note Dehumidification and The Psychrometric Chart Technical Bulletin DA103Dokument4 SeitenTech Note Dehumidification and The Psychrometric Chart Technical Bulletin DA103Marcelo RibeiroNoch keine Bewertungen

- KUKEN closed-type-KKDokument5 SeitenKUKEN closed-type-KKYutt WattNoch keine Bewertungen

- HVAC & Cooling Towers PDFDokument74 SeitenHVAC & Cooling Towers PDFSanket Phatangare0% (1)

- SelectRT Coils 2023-02-07Dokument2 SeitenSelectRT Coils 2023-02-07Yutt WattNoch keine Bewertungen

- GHF0501037 RT15 55RH TD7Dokument2 SeitenGHF0501037 RT15 55RH TD7Yutt WattNoch keine Bewertungen

- h4 Presure Vessels and Water Storage TanksDokument69 Seitenh4 Presure Vessels and Water Storage TanksRakesh Ranjan100% (1)

- CHAPTER 7 Vapor-Liquid Flash SeparatorDokument15 SeitenCHAPTER 7 Vapor-Liquid Flash SeparatorahmadsaysNoch keine Bewertungen

- AC Load by CoolPackDokument1 SeiteAC Load by CoolPackYutt WattNoch keine Bewertungen

- Balmor Al Tanks: Epoxy Coated Steel TanksDokument12 SeitenBalmor Al Tanks: Epoxy Coated Steel TanksYutt WattNoch keine Bewertungen

- EFUSION O&M ManualDokument8 SeitenEFUSION O&M ManualYutt WattNoch keine Bewertungen

- Testing and Safety of Ammonia Refrigeration SystemsDokument3 SeitenTesting and Safety of Ammonia Refrigeration SystemsCorrosion FactoryNoch keine Bewertungen

- Large Unit Cooler Evaporator: Technical GuideDokument64 SeitenLarge Unit Cooler Evaporator: Technical GuideYutt WattNoch keine Bewertungen

- GHF0501037 RT15 55RH TD7Dokument2 SeitenGHF0501037 RT15 55RH TD7Yutt WattNoch keine Bewertungen

- Dreyer Analysis 1988Dokument349 SeitenDreyer Analysis 1988Yutt WattNoch keine Bewertungen

- KPS 2142 ManualDokument44 SeitenKPS 2142 ManualYutt WattNoch keine Bewertungen

- MeterDokument81 SeitenMeterYutt WattNoch keine Bewertungen

- IIR Short Course Presentation PDFDokument129 SeitenIIR Short Course Presentation PDFAmir QayyumNoch keine Bewertungen

- GHF0501037 RT15 55RH TD7Dokument2 SeitenGHF0501037 RT15 55RH TD7Yutt WattNoch keine Bewertungen

- Belt Sizes: InfeedDokument1 SeiteBelt Sizes: InfeedYutt WattNoch keine Bewertungen

- Spreadsheet Calculations of Thermodynamic Properties PDFDokument14 SeitenSpreadsheet Calculations of Thermodynamic Properties PDFLija BinuNoch keine Bewertungen

- Wtbc70 Roll in Blast ChillerDokument2 SeitenWtbc70 Roll in Blast ChillerYutt WattNoch keine Bewertungen

- 3867 - Spiral Freezer 1500-2000Dokument2 Seiten3867 - Spiral Freezer 1500-2000Yutt WattNoch keine Bewertungen

- KPS180SFLSB - Gram Process Kps Blast Chillers and Freezers Operating InstructionsDokument33 SeitenKPS180SFLSB - Gram Process Kps Blast Chillers and Freezers Operating InstructionsYutt WattNoch keine Bewertungen

- GHF0501037 RT15 55RH TD7Dokument2 SeitenGHF0501037 RT15 55RH TD7Yutt WattNoch keine Bewertungen

- 5667 - Gram Plate Freezer InstallationDokument7 Seiten5667 - Gram Plate Freezer InstallationVictor MuñozNoch keine Bewertungen

- GHF0501037 RT15 55RH TD7Dokument2 SeitenGHF0501037 RT15 55RH TD7Yutt WattNoch keine Bewertungen

- Generation of Computers: Camarines Sur National High School Icf 7 Learning Activity Sheet Quarter 1, Week 4Dokument9 SeitenGeneration of Computers: Camarines Sur National High School Icf 7 Learning Activity Sheet Quarter 1, Week 4Houstine ErisareNoch keine Bewertungen

- Introduction To Scratch ProgrammingDokument9 SeitenIntroduction To Scratch ProgrammingabdullahiNoch keine Bewertungen

- Goldmansachs 1Dokument2 SeitenGoldmansachs 1Nidhish SrivastavaNoch keine Bewertungen

- ADSS Server Digital Signature SupportDokument1 SeiteADSS Server Digital Signature SupportannastacyNoch keine Bewertungen

- OOMD Question Bank 2022Dokument7 SeitenOOMD Question Bank 2022Nikita NawleNoch keine Bewertungen

- The Guide To Moble Game Monetization StrategiesDokument18 SeitenThe Guide To Moble Game Monetization StrategiesBuckyNoch keine Bewertungen

- TBMC12Dokument10 SeitenTBMC12Joel E ValenciaNoch keine Bewertungen

- Sushma Gunji's Resume for Creative and Challenging PositionDokument2 SeitenSushma Gunji's Resume for Creative and Challenging PositionJamdigadu JaffaNoch keine Bewertungen

- AeromodelDokument10 SeitenAeromodelAymen NasrNoch keine Bewertungen

- Tneb Power Engineers HandbookDokument2 SeitenTneb Power Engineers Handbooksalman50% (4)

- HexaDokument128 SeitenHexaSandeep GajwelNoch keine Bewertungen

- FBL1N - Vendor HistoryDokument13 SeitenFBL1N - Vendor HistorytserafimNoch keine Bewertungen

- Figure 4-35. Modelsim Altera Starter Edition: Hello World!Dokument5 SeitenFigure 4-35. Modelsim Altera Starter Edition: Hello World!ali alilouNoch keine Bewertungen

- Bangood CS85 AlarmeDokument19 SeitenBangood CS85 Alarmecarvalhomeister0% (2)

- Email Etiquette RulesDokument3 SeitenEmail Etiquette RuleseutiuhiaNoch keine Bewertungen

- Course CIT711Dokument14 SeitenCourse CIT711usoroukNoch keine Bewertungen

- How To Use A PS3 Controller On A PC - 11 Steps (With Pictures)Dokument6 SeitenHow To Use A PS3 Controller On A PC - 11 Steps (With Pictures)Alex I.aNoch keine Bewertungen

- Cyber Forensics Principles: Jayaram P CdacDokument54 SeitenCyber Forensics Principles: Jayaram P CdacMartin HumphreyNoch keine Bewertungen

- SAP Cloud For Customer - SAP Analytics Cloud IntegrationDokument16 SeitenSAP Cloud For Customer - SAP Analytics Cloud Integrationparatchana channiwetNoch keine Bewertungen

- Select Last - Name, Salary: Lab - 02 - 01.sql. Run Your QueryDokument4 SeitenSelect Last - Name, Salary: Lab - 02 - 01.sql. Run Your Queryhermanos osorioNoch keine Bewertungen

- WhirlpoolDokument2 SeitenWhirlpoolJeffrey DavisNoch keine Bewertungen

- An Advanced AES Algorithm Using Swap and 400 Bit Data Block With Flexible S-Box in Cloud ComputingDokument6 SeitenAn Advanced AES Algorithm Using Swap and 400 Bit Data Block With Flexible S-Box in Cloud ComputingusuimisakiNoch keine Bewertungen

- Databases Questions and AnswersDokument5 SeitenDatabases Questions and Answersosama abushamaNoch keine Bewertungen

- Es Model ExamDokument3 SeitenEs Model ExamAarun ArasanNoch keine Bewertungen

- Netware 3.12 InstallDokument20 SeitenNetware 3.12 InstallRio RamajiNoch keine Bewertungen

- Poly Works S DK Reference GuideDokument44 SeitenPoly Works S DK Reference GuidetiborNoch keine Bewertungen

- Multiplexing Troubleshooting: Service Bulletin Number: 4021378 Released Date: 25-Apr-2011 Multiplexing TroubleshootingDokument8 SeitenMultiplexing Troubleshooting: Service Bulletin Number: 4021378 Released Date: 25-Apr-2011 Multiplexing TroubleshootingAvs Electron100% (1)

- Role-based Access Control for E-healthcare WorkflowDokument95 SeitenRole-based Access Control for E-healthcare Workflowsamee530100% (1)

- Handy Unix Commands For A DBADokument3 SeitenHandy Unix Commands For A DBAmdrajivNoch keine Bewertungen

- Jde GTFree MODataDokument4 SeitenJde GTFree MODataRaveRaveNoch keine Bewertungen