Beruflich Dokumente

Kultur Dokumente

I-09 Coating Coverage, Costs & Calculations v5

Hochgeladen von

Anonymous VRspXsmCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

I-09 Coating Coverage, Costs & Calculations v5

Hochgeladen von

Anonymous VRspXsmCopyright:

Verfügbare Formate

COATING COVERAGE,

I-09

COSTS & CALCULATIONS

PURPOSE

This section provides information on the key factors effecting coating coverage and costs. Consideration is also given to

stretching a coating with thinner, and comparing costs per litre.

INTRODUCTION

The purchaser of protective coatings is responsible for selecting the most economic coating available which is suitable to achieve

the required protection. The coatings field is complex and knowledge of coating calculation techniques and interpretation of data

is required in order to make the appropriate choice.

VOLUME SOLIDS

Most liquid coatings contain a solids portion and a volatile portion. The solids portion consists of the binder, normally oil or resin,

together with colouring and functional pigments, extenders and additives. The volatile portion is the solvent or thinner that merely

liquefies the solids sufficiently to carry them onto the surface being coated. The solvent then evaporates, leaving behind the dried

film of solids, which provides protection and decoration. The coating user is most concerned with this remaining film volume or

thickness because it is this, which provides the desired hiding, gloss, weather resistance, colour etc.

When selecting a coating the key is how much area will the solids cover per litre after the volatiles have evaporated?

SOLIDS CONTENT BY VOLUME OF SURFACE COATINGS

Solids content is a theoretical calculation based on certain assumptions concerning the densities of the raw materials used in

paints. In practice, the solids content obtained can vary greatly from its theoretical value because of change in the following:

Densities

Temperature effects

Small differences in the physical condition of the paint

The methods and conditions of application

In addition, film contraction, solvent-retention and volatility of low molecular weight polymers can all contribute error. The

determination of volume solids by AS/NZS 1580.301.2, is difficult to calculate and large variations have been observed in practice.

For these reasons the volume solids values given in this manual are determined by a method which corresponds to ASTM method

D2697 and ISO 3233 with a slight modification for use at practical film thickness and with usual curing and hardening

requirements.

The calculations obtained are generally higher than the theoretical calculated volume solids, but the method approximates the

spreading rates obtained under ideal conditions. Volume solids should not be used to gauge practical spreading rate as so many

other variables have to be taken into account. For this purpose please use the data provided later in this section.

STRETCHING A COATING WITH THINNER IS A MYTH

Adding solvent or thinner to the liquid coating adds nothing to the hiding or spreading rate of the coating solids as the extra solvent

evaporates. Instead, extra solvent merely increases the coating cost by the price of the thinner and increases application costs by

the additional labour time required to mix the thinner into the coating. In the case of baking systems, the cost is increased by the

greater amount of oven heating required to remove the thinner.

Adequate volume solids, not thinners, are the key to proper coverage by a coating.

Version 5, June 2016 1 of 4

COATING COVERAGE,

I-09

COSTS & CALCULATIONS

COMPARING LITRE COSTS

Often buyers tend to select a coating strictly on a cost per litre basis without considering the volume solids of the paint. The user of

a coating should be interested in the cost of finishing a given unit area and not the price per litre.

In the long run the coating user receives value only from that portion of the litre that remains as dried coating film after the volatile

solvent or thinner has been released. Volume solids are the key factor in determining coating economies and not weight solids.

THEORETICAL SPREADING RATE

The theoretical spreading rate is a calculation of the amount of coating on average applied to a surface, assuming no losses or

penetration into the substrate. It can be calculated as follows:

Volume Solids (%) X 10

Theoretical Spreading Rate (m2/L) =

Dry Film Thickness (in microns)

Example (i): A primer has a volume solids of 55% and needs to be applied at a dry film thickness of 75 microns. What is the

theoretical spreading rate?

Theoretical Spreading Rate (m2/L) 55 X 10

= 75

= 7.33m2/L

Example (ii): If 10% thinner was required to thin the coating to application viscosity and a dry film thickness of 75 microns is

still required. The calculation would be as follows:

Theoretical Spreading Rate (m2/L) 55 X 10 100%

X

= 75 (100% + 10%)

= 6.67m2/L

PRACTICAL SPREADING RATE

Except under closely controlled conditions, Theoretical Spreading Rates are hardly ever achieved, therefore in estimating coating

requirements and costs, allowance must be made for losses which occur during application due to such factors as surface

roughness, application method and application conditions. An empirical relationship which may be used to calculate Practical

Spreading Rate as follows:

Practical Spreading Rate = Theoretical Spreading Rate X Coverage Efficiency

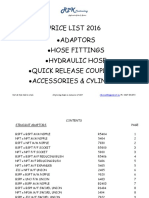

The guide (table) below shows the approximate coverage efficiencies expected for various surfaces and application conditions.

Application Method

Surface Coating Efficiency

Airless Airless Airless Spray/Windy

Brush/Roller

Spray/Interior Spray/Exterior Conditions

New Smooth Steel 0.87 0.78 0.68 0.49

Blast Cleaned Steel 0.83 0.74 0.65 0.46

Power Tool Cleaned Steel 0.79 0.70 0.61 0.44

Blasted Steel lightly pitted 0.79 0.70 0.61 0.44

Blasted Steel heavily pitted 0.74 0.70 0.58 0.41

Rough Concrete or Masonry 0.61 0.66 0.47 0.34

Example (i): An application had a coating with a theoretical spreading rate pf 4.0m2/L and intended to airless spray lightly

pitted steel, with only light winds. Calculate the practical spreading rate:

Practical Spreading Rate (m2/L) = 4.0 X 0.61

= 2.44m2/L

Version 5, June 2016 2 of 4

COATING COVERAGE,

I-09

COSTS & CALCULATIONS

CONVERSION OF SPREADING RATES TO USAGE RATES

It is sometime necessary to convert from spreading rates expressed in m2/L to a usage rate in L/m2. This is gives the amount of

paint required to coat a square metre of surface:

1

Usage Rate (L/m2) =

Spreading Rate (m2/L)

Example (i): A coating has a spreading rate of 2.5m2/L. What is the usage rate in L/m2?

Usage Rate (L/m2) = 1

2.5

= 0.4L/m2

DRY AND WET FILM THICKNESS

It is often necessary to convert between a wet film thickness and a dry film thickness. This calculation assumes that a perfect film

is laid and that after evaporation of the solvents there is no air or solvent trapped in the film. This calculation is not accurate for

inorganic zincs that have a porous silicate matrix:

Wet Film Thickness X Volume Solids (%)

Dry Film Thickness (microns) =

100

Example (i): A coating has a wet film thickness of 100 microns and volume solids of 60%. What would you expect the dry

film thickness to be?

Dry Film Thickness (microns) 100 X 60

= 100

= 60 microns (DFT)

Wet Film Thickness (microns) Dry Film Thickness X 100

= Volume Solids (%)

Example (ii): A coating has a dry film thickness of 100 microns and volume solids of 80%. What would you expect the wet

film thickness to be?

Wet Film Thickness (microns) 100 X 100

= 80

= 125 microns (WFT)

MATERIAL COST PER SQUARE METRE

To determine the material cost per square metre we must know the coverage rate at the film thickness specified:

Cost per litre ($/L)

Material Cost ($/m2) =

Spreading Rate (m2/L)

Example: A primer has a spreading rate of 6.0 m2/L at 75 microns dry film thickness. The cost of the coating is $9.00/L.

What is the material cost of the coating, assuming no losses?

$9.00/L

Material Cost ($/m2) =

6.0m2/L

= $1.50/m2

Version 5, June 2016 3 of 4

COATING COVERAGE,

I-09

COSTS & CALCULATIONS

ESTIMATING PAINT QUANTITIES FOR BOATS

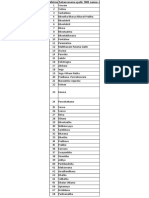

The following table outlines the calculations for paint quantities for boats, an example is provided.

Boat Area & Quantity Calculation

Spars & Masts length X mean circumference = square metres

Deck Areas length overall X beam X 0.75 = square metres

Topsides (length overall + beam) X 2 X average freeboard = square metres

Underwater Areas length at waterline X (beam + draught) = square metres

Example: Calculation of required paint quantity for a boat hull.

An underwater area of a steel vessel 15 metres long at the waterline, draught of 1.5 metres and beam of 4 metres.

The coating to be applied has a theoretical spreading rate of 7m2/Litre and the following application conditions apply:

Application method = Spray

Substrate = Blasted steel lightly pitted

Location = Exterior no wind

Area to be coated = length at waterline X (beam + draught)

= 15 X (4 + 15)

= 82.5 m2

Practical Spreading Rate = Theoretical Spreading Rate X Coverage Efficiency

= 7 X (0.61)

= 4.27m2/Litre

Paint quantity required for underwater area = 82.5m2/4.27m2 /Litre

= 19.32 Litres

Practical quantity = 20 Litres.

Valspar is committed to quality in the design, Valspars laboratory facilities are accredited for

production and delivery of its products and technical competence with the National

services. Valspars Australian manufacturing Association of Tests Authorities, Australia (NATA)

facilities quality management systems are and comply with the requirements of ISO/IEC

certified to ISO9001. 17025. Accreditation No.104 (Footscray), 166

(Blacktown), 1154 (Glendenning) and 931

(Kilburn).

For the most up to date information contact Valspar Customer Service Hotline or visit the Wattyl Website.

Australia New Zealand

CUSTOMER SERVICE HOTLINE 132 101 0800 735 551

WEBSITE www.wattypc.com www.wattylpc.com

Trademarks are the property of Valspar Paint (Australia) Pty Ltd.

1. This information, provided by Valspar Paint (Australia) Pty Ltd (hereinafter referred to as Valspar), is important to ensure that the listed product(s) perform according

to the stated application and uses and must be followed to meet Valspars warranties express and implied. Valspar advises that you (a) review the Technical Data

Sheets (TDS) and Material Safety Data Sheets (MSDS) before you use or handle the product; (b) ensure that the product be used only in accordance with the information

provided by Valspar and the product(s) be transported, stored and handled in accordance with the information on the MSDS and relevant TDS; and (c) thoroughly test the

product, using the recommended application method on a sample of intended substrate, before using the product. 2. The information in this TDS was prepared using

information gathered during product development. While Valspar endeavours to update this information and maintain the accuracy and currency of its contents, Valspar

does not warrant that the information provided is current when the product is used or is wholly comprehensive. 3. For all product and non-product related information,

Valspar recommends that you conduct such additional investigations as may be necessary to satisfy yourself of the accuracy, currency and comprehensiveness of the

information on which you rely in using and handling the product. If you require further information please contact your nearest Valspar office before using the product(s).

4. To the full extent permitted by law, Valspars liability for breach of a condition or warranty implied into the contract for sale between Valspar and you by law is limited

at Valspars election to: (a) the replacement of the product; or (b) payment of the cost of replacing the product. If coating rectification is required Valspar Technical

Services shall be contacted prior to commencement. VALSPAR PAINT (AUSTRALIA) PTY LTD (ABN 40 000 035 914)

Version 5, June 2016 4 of 4

Das könnte Ihnen auch gefallen

- Forging Die Design For Gear BlankDokument4 SeitenForging Die Design For Gear BlankAnonymous kw8Yrp0R5rNoch keine Bewertungen

- Machining Time Required For Taper Grinding and Its Cost Analysis in G17-22U Grinding MachineDokument5 SeitenMachining Time Required For Taper Grinding and Its Cost Analysis in G17-22U Grinding MachineAnonymous VRspXsmNoch keine Bewertungen

- An Integrated Framework For Die and Mold Cost Estimation Using Design Features and Tooling ParametersDokument12 SeitenAn Integrated Framework For Die and Mold Cost Estimation Using Design Features and Tooling ParametersAnonymous VRspXsmNoch keine Bewertungen

- Forging Die Design For Gear BlankDokument4 SeitenForging Die Design For Gear BlankAnonymous kw8Yrp0R5rNoch keine Bewertungen

- MM Reference Guide 2016Dokument72 SeitenMM Reference Guide 2016InaamNoch keine Bewertungen

- KMT Orifice-Cutting Speeds DataDokument1 SeiteKMT Orifice-Cutting Speeds DataAnonymous VRspXsmNoch keine Bewertungen

- Fulfill Instructions Quotation Analysis FormDokument5 SeitenFulfill Instructions Quotation Analysis FormAnonymous VRspXsmNoch keine Bewertungen

- Fulfill Instructions Quotation Analysis FormDokument5 SeitenFulfill Instructions Quotation Analysis FormAnonymous VRspXsmNoch keine Bewertungen

- KMT Orifice-Cutting Speeds Data PDFDokument2 SeitenKMT Orifice-Cutting Speeds Data PDFAnonymous VRspXsmNoch keine Bewertungen

- Welding Cost Estimation For 12 Joints in 8 NPS SCH 80 PDFDokument1 SeiteWelding Cost Estimation For 12 Joints in 8 NPS SCH 80 PDFAnonymous VRspXsmNoch keine Bewertungen

- Machining Time Required For Taper Grinding and Its Cost Analysis in G17-22U Grinding MachineDokument5 SeitenMachining Time Required For Taper Grinding and Its Cost Analysis in G17-22U Grinding MachineAnonymous VRspXsmNoch keine Bewertungen

- Section 2 Tooling Fo Die Casting OptDokument22 SeitenSection 2 Tooling Fo Die Casting OptAnonymous VRspXsmNoch keine Bewertungen

- Fulfill Instructions Quotation Analysis FormDokument2 SeitenFulfill Instructions Quotation Analysis FormAnonymous VRspXsm100% (1)

- Section 2 Tooling Fo Die Casting OptDokument22 SeitenSection 2 Tooling Fo Die Casting OptAnonymous VRspXsmNoch keine Bewertungen

- Fulfill Instructions Quotation Analysis FormDokument5 SeitenFulfill Instructions Quotation Analysis FormAnonymous VRspXsmNoch keine Bewertungen

- Cutting Data Ramax HH EngDokument6 SeitenCutting Data Ramax HH EngAnonymous VRspXsmNoch keine Bewertungen

- Book 1Dokument2 SeitenBook 1Anonymous VRspXsmNoch keine Bewertungen

- Girl Baby NameDokument40 SeitenGirl Baby NameAnonymous VRspXsmNoch keine Bewertungen

- Principle of Powder Metallurgy PDFDokument10 SeitenPrinciple of Powder Metallurgy PDFAnonymous VRspXsmNoch keine Bewertungen

- Cutting Data Ramax HH EngDokument6 SeitenCutting Data Ramax HH EngAnonymous VRspXsmNoch keine Bewertungen

- Cutting Data Ramax HH EngDokument7 SeitenCutting Data Ramax HH EngAnonymous VRspXsmNoch keine Bewertungen

- DimensionsDokument22 SeitenDimensionsanmol6237Noch keine Bewertungen

- EML2322L-Tolerances Vs ProcessDokument7 SeitenEML2322L-Tolerances Vs ProcessAnonymous VRspXsmNoch keine Bewertungen

- Ring Gear Blank Case BriefDokument6 SeitenRing Gear Blank Case BriefAnonymous VRspXsmNoch keine Bewertungen

- Cutting Data Ramax HH EngDokument6 SeitenCutting Data Ramax HH EngAnonymous VRspXsmNoch keine Bewertungen

- CastingDokument18 SeitenCastingAnonymous VRspXsmNoch keine Bewertungen

- 7 Shpaper PlanerDokument29 Seiten7 Shpaper PlanerfamilyumaNoch keine Bewertungen

- LangeDokument13 SeitenLangeAnonymous VRspXsmNoch keine Bewertungen

- r2k Contracting Price List 2016Dokument129 Seitenr2k Contracting Price List 2016Anonymous VRspXsmNoch keine Bewertungen

- Sprint Capacity Planner 27 NovDokument11 SeitenSprint Capacity Planner 27 NovAnonymous VRspXsmNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Edexcel - IAS - Organic Chemistry - 1Dokument27 SeitenEdexcel - IAS - Organic Chemistry - 1mostafa barakatNoch keine Bewertungen

- Astm D-3840 - 01Dokument9 SeitenAstm D-3840 - 01Bipin SasikumarNoch keine Bewertungen

- Amercoat 400AL PDFDokument4 SeitenAmercoat 400AL PDFLalit Bom MallaNoch keine Bewertungen

- MasterPel 777 v3Dokument3 SeitenMasterPel 777 v3Mohamed KhanNoch keine Bewertungen

- An Auditorium Case Study: Veer Savarkar Auditorium, Shivaji ParkDokument15 SeitenAn Auditorium Case Study: Veer Savarkar Auditorium, Shivaji Parkram shreevastavNoch keine Bewertungen

- 1B DamanDokument12 Seiten1B Damananon_981731217Noch keine Bewertungen

- Production of FormaldehydeDokument92 SeitenProduction of FormaldehydegozdebstnciNoch keine Bewertungen

- Econoline Sandblasting Catalog PDFDokument20 SeitenEconoline Sandblasting Catalog PDFRay ZerNoch keine Bewertungen

- CHAPTER 5 HydrotreatingDokument41 SeitenCHAPTER 5 HydrotreatingNurfarhana JelenNoch keine Bewertungen

- Non - Halogen Flame RetardantsDokument8 SeitenNon - Halogen Flame RetardantsJimmy WongNoch keine Bewertungen

- Effect of Sunlight Ultraviolet Exposure On The Corrosion of Fusion Bonded Epoxy (FBE) Coated Steel Rebars in ConcreteDokument40 SeitenEffect of Sunlight Ultraviolet Exposure On The Corrosion of Fusion Bonded Epoxy (FBE) Coated Steel Rebars in ConcretenagarajuNoch keine Bewertungen

- Wedge Wire Screens & Tubes PROGRESSDokument8 SeitenWedge Wire Screens & Tubes PROGRESSPhu, Le HuuNoch keine Bewertungen

- USP 401 Fats and OilsDokument13 SeitenUSP 401 Fats and OilsChandrajeet U. SagarNoch keine Bewertungen

- Final Year ProjectDokument50 SeitenFinal Year ProjectDanish KaiserNoch keine Bewertungen

- Hexadrain Brickslot OverviewDokument2 SeitenHexadrain Brickslot Overviewloren4_rengifo3044Noch keine Bewertungen

- Joint Free Slabs On Grade An Innovative Approach WorkingDokument6 SeitenJoint Free Slabs On Grade An Innovative Approach Workingmehdi_hoseineeNoch keine Bewertungen

- Magway University, Men Chummery (158'-0" X 30'-0") 2-Storyde R.C.C Building, SUB-Structure Bill of Quantity Particulars Quantity Unit Rate Per AmountDokument1 SeiteMagway University, Men Chummery (158'-0" X 30'-0") 2-Storyde R.C.C Building, SUB-Structure Bill of Quantity Particulars Quantity Unit Rate Per Amountnang homNoch keine Bewertungen

- Croda Lubricants: Innovation You Can Build OnDokument6 SeitenCroda Lubricants: Innovation You Can Build OnYesica RozoNoch keine Bewertungen

- Table A-1 Basic Allowable Stresses in Tension For MetalsDokument28 SeitenTable A-1 Basic Allowable Stresses in Tension For MetalsMohamed ElsayedNoch keine Bewertungen

- Comprehensive Review of Graphene Nano FluidsDokument22 SeitenComprehensive Review of Graphene Nano Fluidschitta sandeep dattuNoch keine Bewertungen

- Catalogue Fan Coil Unit DDBDokument36 SeitenCatalogue Fan Coil Unit DDBLuqmanAssaffatG80% (5)

- Heat Shrink Sleeves Install Manual 2005 PDFDokument3 SeitenHeat Shrink Sleeves Install Manual 2005 PDFkalai0% (1)

- Metric DIN 939 Double End Studs (1.25xD) : Visit Our For Product AvailabilityDokument4 SeitenMetric DIN 939 Double End Studs (1.25xD) : Visit Our For Product Availabilitysudarshan pugaliaNoch keine Bewertungen

- Catalogue Pressure GaugeDokument2 SeitenCatalogue Pressure GaugeSupriyaRongNoch keine Bewertungen

- Causes and Prevention of Cracks in BuildingDokument47 SeitenCauses and Prevention of Cracks in BuildingvishalgoreNoch keine Bewertungen

- Belt Conveyor DesignDokument21 SeitenBelt Conveyor DesignAjith100% (1)

- Silica and Silanes-II: Muhammad FarooqDokument30 SeitenSilica and Silanes-II: Muhammad FarooqRana AnasNoch keine Bewertungen

- British Gypsum WB DriLyner DabDokument6 SeitenBritish Gypsum WB DriLyner DabManu FraguelaNoch keine Bewertungen

- Chapter - 3.3 Precipitation TitrationDokument25 SeitenChapter - 3.3 Precipitation TitrationDessu AshagrieNoch keine Bewertungen

- Expt 3 Bioplastic From Plant Starch Lab Data SheetDokument9 SeitenExpt 3 Bioplastic From Plant Starch Lab Data SheetjanaNoch keine Bewertungen