Beruflich Dokumente

Kultur Dokumente

Thermocouple Attachment Unit PDF

Hochgeladen von

vjvijay88Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Thermocouple Attachment Unit PDF

Hochgeladen von

vjvijay88Copyright:

Verfügbare Formate

104 - Thermocouple 01-07-2003 15:43 Pagina 1

Stork Thermal and

Inspection Services

Automatic Thermocouple Stork equipment is

manufactured incorporating

ISO 9001:2000 quality controlled

Attachment Unit designs. These designs are

based upon the results of third

party testing for compliance with

100-125V a.c. Stock Reference: 41756 European Safety Directives and

220-240V a.c. Stock Reference 41757 Storks extensive

experience in the field of heat

Eliminate expensive temperature control and recording errors as well as treatment engineering.

thermocouple failures!

Stork's powerful Automatic Thermocouple Attachment Unit (TAU) helps

eliminate the risk of expensive rework by enabling accurate temperature control and

recording and reducing the risk of thermocouples breaking off during the heat

treatment process.

The TAU can also be used to attach thermocouples for many other temperature

monitoring applications that require reliable temperature measurement.

One hand is better than two!

It can be difficult to attach thermocouples with manual attachment units, which

require both hands to operate. Stork's Automatic Thermocouple Attachment

Units require only one hand to operate which can be an important safety feature

when working at elevated levels or inaccessible locations.

Stork's Automatic Ease of Operation and Maintenance Reliable, Safe and Cost Efficient

Thermocouple Attachment Unit Can be operated by one person

Direct attachment of thermocouples Single handed operation in automatic At Stork we deliver

to the work-piece by the 'capacitive mode excellence in the design,

discharge method' has long been Simple to operate manufacture and product

No welding skills required

support of Heat Treatment

established as the preferred industry

Equipment

standard method of attaining Light weight and portable

accurate temperature measurement Recharged simply by connecting to

of the work piece being heat-treated the appropriate a.c. supply Call us today for all your

or monitored. Indicating lights show unit charge heat treatment

requirements.

status and battery status

Stork's Automatic Three power settings can be selected

Thermocouple Attachment Unit in both automatic and manual

utilises this method to attach various operating modes

gauges of thermocouple wire to the Automatic switch off after 3 minutes

work piece. to save battery power

Stork Thermal and

Carrying shoulder strap fitted as Inspection Services

By means of thermocouple standard

contact sensory circuitry, Integral storage compartment for safe Stork locations

Stork's Thermocouple storage of pliers, magnet and worldwide:

Attachment Unit will automatically recharging cable - United Kingdom

discharge through the wire a few - The Netherlands

seconds after the wire comes into Fitness for Purpose - United States

contact with the work piece. Constructed from high-grade - Saudi Arabia

www.stork.com

stainless steel giving excellent - United Arab Emirates

Versatility protection against corrosion even in - Australia

Three power output settings marine offshore applications - Malaysia

Capable of 1000 discharges from a

- New Zealand

enable the unit to attach 12, 18 and

24 gauge (awg) thermocouple wire fully charged integral nickel cadmium info.heattreatment@stork.com

A stainless steel case allows the battery

unit to be used in all Third party tested to ensure Electro-

environmental conditions Magnetic Compatibility (EMC)

including offshore

Battery or mains operated

Available for use with 230V or

110V battery recharging supplies This datasheet contains general

information, no rights can be derived

ds no. 104 v.1 2//03 2000 uk

104 - Thermocouple 01-07-2003 15:43 Pagina 2

Automatic Thermocouple

Attachment Unit

100-125V a.c. Stock Reference: 41756

220-240V a.c. Stock Reference 41757

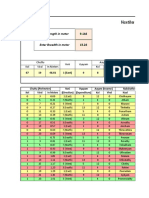

SPECIFICATIONS

Power Consumption 5.0 VA

Battery Voltage 12 Volts

Battery Capacity 2.7 Ah

Thermocouple Diameters 0.5, 1 & 2 mm selectable

Discharge Voltages 50 / 70 / 83 V d.c. nominal

Discharge Energy 12.5 / 25 / 34.5 Joules nominal

Battery Monitor Monitoring LED and Automatic Full Discharge Protection

Number of discharges Approximately 1000 on setting 2 at a rate of 200 discharges

per day with fully charged battery.

Height 210 mm

Width 215 mm

Depth 90 mm

Weight 4.25 kg

SPARE REPLACEMENT PARTS

Part Number Description

ZY-41756/1 100-125 Volts TAU PCB complete

ZY-41757/1 220-240 Volts TAU PCB complete

TH-50RIA40 Thyristor 50RIA100

516-041 16A, 110V, 2P&E plug

530-006 Panel mounting fuse holder 20 mm

530-064 Fuse 20 mm 500 mA (Pack 10)

536-058 Shoulder Strap & Clips

HAR105 Toggle Catches

536-128 Pliers/Magnet Cable Set

538-024 LED Red c/w Ring & Clip

538-025 LED Green c/w Ring & Clip

538-026 LED Yellow c/w Ring & Clip

SWT001 Pushbutton Green

SWT002 Pushbutton Red

HAR150 21 mm Knob black

HAR151 Knob cap 21 mm black

HAR 152 21 mm transparent figure dial

558-027 Battery 12V 3 Ah

CONSUMABLES

43000 100m roll Type K thermocouple wire

516-111 Type K thermocouple plugs

This datasheet contains general

information, no rights can be derived

ds no. 104 v.1 2//03 2000 uk

Das könnte Ihnen auch gefallen

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionVon EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Design, Installation and Maintenance Manual: Industrial Electric Heat Tracing SystemsDokument24 SeitenDesign, Installation and Maintenance Manual: Industrial Electric Heat Tracing SystemsMekaNo1DNoch keine Bewertungen

- TigerTech PredictiveMaintenance 1Dokument2 SeitenTigerTech PredictiveMaintenance 1Música BNoch keine Bewertungen

- Applications: Infrared ThermometerDokument2 SeitenApplications: Infrared Thermometerana jumanaNoch keine Bewertungen

- Rayteck Infrared Thermometers: Monitoring Electrical SystemsDokument4 SeitenRayteck Infrared Thermometers: Monitoring Electrical SystemsHumberto Costa100% (1)

- 174Dokument24 Seiten174Janko ArtukovićNoch keine Bewertungen

- Design, Installation and Maintenance Manual: Industrial Electric Heat Tracing SystemsDokument24 SeitenDesign, Installation and Maintenance Manual: Industrial Electric Heat Tracing SystemssuhasNoch keine Bewertungen

- Design, Installation and Maintenance Manual: Industrial Electric Heat Tracing SystemsDokument24 SeitenDesign, Installation and Maintenance Manual: Industrial Electric Heat Tracing SystemsJohn BeaconNoch keine Bewertungen

- 2 1773452 8 - Heat Shrink CatalogDokument10 Seiten2 1773452 8 - Heat Shrink CatalogAzzeddine BendahakNoch keine Bewertungen

- 14 Fine Tuned Assembly LineDokument4 Seiten14 Fine Tuned Assembly LineSadhish KannanNoch keine Bewertungen

- Product Data Sheet Rosemount 3144p Temperature Transmitter en 73128Dokument48 SeitenProduct Data Sheet Rosemount 3144p Temperature Transmitter en 73128Massaa ProNoch keine Bewertungen

- Ih 025 Volcano: Portable Induction HeaterDokument15 SeitenIh 025 Volcano: Portable Induction HeaterNguyễn ChiếnNoch keine Bewertungen

- Product-Data-Sheet-Rosemount-0085-Pipe-Clamp-SensorDokument24 SeitenProduct-Data-Sheet-Rosemount-0085-Pipe-Clamp-SensorZts MksNoch keine Bewertungen

- 1ZBG000482 - en - A - Integrated Measurement Relay - IMRDokument2 Seiten1ZBG000482 - en - A - Integrated Measurement Relay - IMRCristianoGuimaraesNoch keine Bewertungen

- Thermasense ConferenceDokument5 SeitenThermasense ConferenceAhmad UsmanNoch keine Bewertungen

- Substations Switchgear - Thermal Image ManualDokument2 SeitenSubstations Switchgear - Thermal Image ManualLucia NunezNoch keine Bewertungen

- Hydro Power Synchronous GeneratorsDokument8 SeitenHydro Power Synchronous GeneratorsPritam SinghNoch keine Bewertungen

- Honeywell T6984FDokument8 SeitenHoneywell T6984FPradeep T RNoch keine Bewertungen

- Indian Standard: Built-In Thermal Protection For - !elbctric Motors Rated Up To 660 V Ac - SpecificationDokument14 SeitenIndian Standard: Built-In Thermal Protection For - !elbctric Motors Rated Up To 660 V Ac - Specificationkushal_lonareNoch keine Bewertungen

- Cxh-Ep: Convection Heater For Hazardous LocationsDokument16 SeitenCxh-Ep: Convection Heater For Hazardous Locationskarim karimNoch keine Bewertungen

- Bedien - 32 16 101 003 - JDokument5 SeitenBedien - 32 16 101 003 - JMostafa ShoaibNoch keine Bewertungen

- 1F80-361 1F80-361 1F80-361 1F80-361 1F80-361: Description Description Description Description DescriptionDokument8 Seiten1F80-361 1F80-361 1F80-361 1F80-361 1F80-361: Description Description Description Description DescriptiononeNoch keine Bewertungen

- Design, Installation and Maintenance Manual: Industrial Electric Heat Tracing SystemsDokument24 SeitenDesign, Installation and Maintenance Manual: Industrial Electric Heat Tracing Systemshari95Noch keine Bewertungen

- Pi Adw535 enDokument2 SeitenPi Adw535 enionut pielaruNoch keine Bewertungen

- 11609EN WHY ThermographyDokument2 Seiten11609EN WHY Thermographyg_periwal_pune9635Noch keine Bewertungen

- KXHE120A KXHE120B KXHE122A Air-To-Air Heat Exchangers Operator'S ManualDokument8 SeitenKXHE120A KXHE120B KXHE122A Air-To-Air Heat Exchangers Operator'S Manualignacio andresNoch keine Bewertungen

- XY 168-3C Desktop Soldering StationDokument2 SeitenXY 168-3C Desktop Soldering StationZach JacobNoch keine Bewertungen

- Heat Tracing CableDokument140 SeitenHeat Tracing Cablebhaskar_dandapathakNoch keine Bewertungen

- Fluke Multimeter ComparisonDokument2 SeitenFluke Multimeter ComparisonErick SutantoNoch keine Bewertungen

- SQN 90 Dumper ActuarorDokument9 SeitenSQN 90 Dumper ActuarorRomica CiorneiNoch keine Bewertungen

- The Wiring Rules: Motor ProtectionDokument6 SeitenThe Wiring Rules: Motor ProtectionFuji Electric SMBENoch keine Bewertungen

- Still Will: TestsDokument3 SeitenStill Will: TestsDanilo FortesNoch keine Bewertungen

- Product Information: Motor and Machine ProtectionDokument9 SeitenProduct Information: Motor and Machine ProtectionMarcos Gomez PeresNoch keine Bewertungen

- Thermister RelayDokument14 SeitenThermister Relaysanu1985Noch keine Bewertungen

- Electric Coils For Single Duct TerminalsDokument7 SeitenElectric Coils For Single Duct Terminalsjohnking5555Noch keine Bewertungen

- CETAL Power Control Panels Brochure ENDokument4 SeitenCETAL Power Control Panels Brochure ENHamid MansouriNoch keine Bewertungen

- T874 Q674 Product DataDokument224 SeitenT874 Q674 Product Datarolando ojedaNoch keine Bewertungen

- Bartec Heat Tracing PDFDokument23 SeitenBartec Heat Tracing PDFanisNoch keine Bewertungen

- WKH ManualDokument60 SeitenWKH ManualantmangNoch keine Bewertungen

- IEEE 2014 Paper - Infrared Windows Applied in Switchgear Assemblies - Taking Another LookDokument6 SeitenIEEE 2014 Paper - Infrared Windows Applied in Switchgear Assemblies - Taking Another Lookvenkat chakNoch keine Bewertungen

- Siemens SQN3x SQN4xDokument17 SeitenSiemens SQN3x SQN4xclauNoch keine Bewertungen

- 68 DE EL PORV EngDokument6 Seiten68 DE EL PORV EngDenaibeliNoch keine Bewertungen

- Ethos Up Easytemp: Service Training CourseDokument24 SeitenEthos Up Easytemp: Service Training CourseAntWonxxxNoch keine Bewertungen

- Electric Heaters EHDokument20 SeitenElectric Heaters EHEstevan huertasNoch keine Bewertungen

- Сервисная Инструкция 42uqv (38uyv) 035mDokument104 SeitenСервисная Инструкция 42uqv (38uyv) 035msergeyNoch keine Bewertungen

- Thermal ImagingDokument3 SeitenThermal ImagingarsalNoch keine Bewertungen

- INT10 Anemometer: ® ApplicationDokument2 SeitenINT10 Anemometer: ® ApplicationRUBENNoch keine Bewertungen

- Air Conditioners - Solar Danmark A - SDokument8 SeitenAir Conditioners - Solar Danmark A - SAriana GrandeNoch keine Bewertungen

- Matrix 4000 AcdcDokument42 SeitenMatrix 4000 Acdcsonnguyen2041996Noch keine Bewertungen

- Protecting Axial Fan HVAC Systems Including Cooling TowersDokument4 SeitenProtecting Axial Fan HVAC Systems Including Cooling TowersNhorilaine AbayaNoch keine Bewertungen

- Thermostat White RogersDokument12 SeitenThermostat White RogersKin 2009Noch keine Bewertungen

- Tank HeatingDokument28 SeitenTank Heatingsnikraftar1406Noch keine Bewertungen

- Rec27 100a2 20040598-1Dokument72 SeitenRec27 100a2 20040598-1Sandro RuizNoch keine Bewertungen

- 12 Fire Controllers Sbmh1204011 Wsae v1Dokument1 Seite12 Fire Controllers Sbmh1204011 Wsae v1Silvester SipayungNoch keine Bewertungen

- SQNDokument22 SeitenSQNare_reeNoch keine Bewertungen

- Spot Thermal Detector (Fixed Temperature) : FeaturesDokument2 SeitenSpot Thermal Detector (Fixed Temperature) : FeaturesWil TimpoNoch keine Bewertungen

- Installation and Operation: On Tanks and VesselsDokument24 SeitenInstallation and Operation: On Tanks and VesselsaleksandarlaskovNoch keine Bewertungen

- Operation Instruction ETR 5-80: BA - 0912W5 - ENDokument7 SeitenOperation Instruction ETR 5-80: BA - 0912W5 - ENbango7886Noch keine Bewertungen

- HV Circuit BreakersDokument90 SeitenHV Circuit BreakersModisa TsamaaseNoch keine Bewertungen

- Calculating Short Circuit kVADokument1 SeiteCalculating Short Circuit kVAvjvijay88Noch keine Bewertungen

- Load Flow Analysis of An Eht Network Using Etap ®: June 2016Dokument7 SeitenLoad Flow Analysis of An Eht Network Using Etap ®: June 2016vjvijay88Noch keine Bewertungen

- Atlas HPSEBLv 3Dokument73 SeitenAtlas HPSEBLv 3vjvijay88Noch keine Bewertungen

- 2 June 17Dokument326 Seiten2 June 17vjvijay88Noch keine Bewertungen

- Isp2 PDFDokument3 SeitenIsp2 PDFvjvijay88Noch keine Bewertungen

- 7814Dokument6 Seiten7814vjvijay88Noch keine Bewertungen

- Neptune Revise Pricelist April 17Dokument24 SeitenNeptune Revise Pricelist April 17vjvijay88Noch keine Bewertungen

- Ps 0500Dokument4 SeitenPs 0500vjvijay88100% (1)

- 250 Amf LogicDokument10 Seiten250 Amf LogicChakravarthy Veeru0% (1)

- BPC DrawingDokument12 SeitenBPC Drawingvjvijay88Noch keine Bewertungen

- 2 June 17Dokument326 Seiten2 June 17vjvijay88Noch keine Bewertungen

- English PDFDokument207 SeitenEnglish PDFvjvijay88Noch keine Bewertungen

- Vasthu Shasthra Perimeter CalculatorDokument209 SeitenVasthu Shasthra Perimeter Calculatorvjvijay8864% (67)

- CST H450K User ManualDokument156 SeitenCST H450K User Manualvjvijay88100% (1)

- Gann Square of 9Dokument4 SeitenGann Square of 9vjvijay88Noch keine Bewertungen

- Bank's Office Building at Patna 11 KV HT PanelDokument7 SeitenBank's Office Building at Patna 11 KV HT Panelvjvijay88Noch keine Bewertungen

- PCB Design Course Syllabus PDFDokument3 SeitenPCB Design Course Syllabus PDFvjvijay88Noch keine Bewertungen

- Power Transformer Testing ProceduresDokument13 SeitenPower Transformer Testing ProceduresVENKATESAN R100% (7)

- Highlights of December Edition: Best Performers Mom (%)Dokument36 SeitenHighlights of December Edition: Best Performers Mom (%)vjvijay88Noch keine Bewertungen

- All in One XLDokument3 SeitenAll in One XLvjvijay88Noch keine Bewertungen

- Jfet and MosfetDokument21 SeitenJfet and Mosfetvjvijay88Noch keine Bewertungen

- Cable Sizing Selection Chart: DC Amps Circuit Type Cable Length Correct Cable SizeDokument1 SeiteCable Sizing Selection Chart: DC Amps Circuit Type Cable Length Correct Cable SizeRafid A. Jassem AlashorNoch keine Bewertungen

- AREMA Communications and Signal Style Manual 2021Dokument26 SeitenAREMA Communications and Signal Style Manual 2021Philip El ProfiNoch keine Bewertungen

- F&C Baja Presion EstaticaDokument6 SeitenF&C Baja Presion EstaticaMARCOSNoch keine Bewertungen

- Rugged Transition Joint Probes: StandardDokument5 SeitenRugged Transition Joint Probes: StandardEdwin Oswaldo Rodriguez WagnerNoch keine Bewertungen

- Manual TranstectorDokument6 SeitenManual TranstectorHoku's NickNoch keine Bewertungen

- Hyundai HD78 General Information - 2Dokument12 SeitenHyundai HD78 General Information - 2Bigfair HD78Noch keine Bewertungen

- LGWIR-WE-0871LH 4th WSMW 080,085 N G.Exp VN53, VN64, VN65 PDFDokument334 SeitenLGWIR-WE-0871LH 4th WSMW 080,085 N G.Exp VN53, VN64, VN65 PDForlando100% (1)

- B - Chem SLC Wiring ManualDokument60 SeitenB - Chem SLC Wiring Manualyachtsman57Noch keine Bewertungen

- Aerial Catalog 2 1.2.3Dokument3 SeitenAerial Catalog 2 1.2.3Robert CeaNoch keine Bewertungen

- Linear Actuator La36 Data Sheet EngDokument28 SeitenLinear Actuator La36 Data Sheet EngdavidNoch keine Bewertungen

- TLE 10 Electricity Q1 - M1 For PrintingDokument26 SeitenTLE 10 Electricity Q1 - M1 For PrintingLady Christianne BucsitNoch keine Bewertungen

- 10C0003X0 Anixter Wire&Cable Catalog 2010 Sec14 High Tempurature Cable en USDokument16 Seiten10C0003X0 Anixter Wire&Cable Catalog 2010 Sec14 High Tempurature Cable en USAziz HassanNoch keine Bewertungen

- HOElecDokument32 SeitenHOElecAmarjit ChanaNoch keine Bewertungen

- Nichrome WireDokument4 SeitenNichrome WireDilipSinghNoch keine Bewertungen

- Cable Connector PDFDokument1 SeiteCable Connector PDFAung MhNoch keine Bewertungen

- RE TimersDokument80 SeitenRE Timersimtiyaz100% (1)

- Wire Current RatingsDokument1 SeiteWire Current Ratingszul5107Noch keine Bewertungen

- Crimping Die Assemblies 58492-1 and 58493 - 1Dokument3 SeitenCrimping Die Assemblies 58492-1 and 58493 - 1zavabossNoch keine Bewertungen

- III 1 Electrification 1 28Dokument35 SeitenIII 1 Electrification 1 28SannyBombeoJomoc100% (1)

- Owner's Manual: Installation Operation MaintenanceDokument32 SeitenOwner's Manual: Installation Operation Maintenancevalde_absentisNoch keine Bewertungen

- Tap Joint SplicesDokument5 SeitenTap Joint SplicesMarvin RetutalNoch keine Bewertungen

- VISTA PowerBudgetTool 1059aDokument4 SeitenVISTA PowerBudgetTool 1059athoufiqNoch keine Bewertungen

- EASA AC Redesign Manual V.0214-0815 PDFDokument140 SeitenEASA AC Redesign Manual V.0214-0815 PDFDon FreemanNoch keine Bewertungen

- Delta Dust Collector 50-850Dokument13 SeitenDelta Dust Collector 50-850BobKatNoch keine Bewertungen

- Grounding and Bonding For Electrical Systems - Rev - 1Dokument4 SeitenGrounding and Bonding For Electrical Systems - Rev - 1Hany NassimNoch keine Bewertungen

- AWG To MM - mm2 - Gauge To MM ConversionDokument3 SeitenAWG To MM - mm2 - Gauge To MM ConversionSURESHNoch keine Bewertungen

- Eletrical InstallationDokument14 SeitenEletrical InstallationRenato C. LorillaNoch keine Bewertungen

- Technical Information PDFDokument24 SeitenTechnical Information PDFsouheil boussaidNoch keine Bewertungen

- Principles of Cable Sizing CalculationsDokument5 SeitenPrinciples of Cable Sizing CalculationsDuong BuiNoch keine Bewertungen

- Palladion Thermostat - Ficha de Instalacion - 3691033Dokument25 SeitenPalladion Thermostat - Ficha de Instalacion - 3691033Lutron LutronNoch keine Bewertungen