Beruflich Dokumente

Kultur Dokumente

Check Valve DS

Hochgeladen von

sinamicsCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Check Valve DS

Hochgeladen von

sinamicsCopyright:

Verfügbare Formate

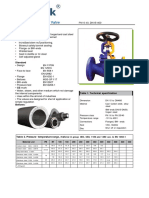

Data Sheet 810493-05

Issue Date: 01/14

DN 25 PN 40

Non-Return Valve

RK 86, 86A for Flanges PN 10/16/25/40, DN 15-200

ASME Class 125/150/300

Description

Wafer-type non-return (check) valve for sandwiching between flanges. Valve with spring for installation in any position. Without

spring only for vertical lines with upward flow. Self-centering valve body. Application for liquids, gases and vapours (observe

classification according to PED).

Pressure/Temperature Rating

DN 15-100 mm ( 4")

RK 86 DIN, EN, ASME B16.5, Class 300 Design

Standard design fitted with M8 antistatic connection

[C] 200 10 20 100 200 300 350 400 500 550

DN 15 100 51 51 46.4 43.9 38.9 metal-to-metal (standard)

[bar] g 51 51 46.4 43.9 38.9 36.9 metal-to-metal with Nimonic-springs

DN 125 200 51 51 46.4 43.9 38.9 metal-to-metal (standard)

[bar] g 51 51 46.4 43.9 38.9 36.9 34.5 metal-to-metal with Nimonic-springs

RK 86 A DIN, EN, ASME B16.5, Class 300 Design

[C] 200 10 20 100 200 300 350 400 500 550

DN 15 200 49.6 49.6 49.6 42.3 35.8 31.6 metal-to-metal (standard)

[bar] g 49.6 49.6 49.6 42.3 35.8 31.6 30.4 29.3 27.3 24.0 metal-to-metal with Nimonic-springs

Valve seat sealing tmin [C] tmax [C] Application Leakage rate

DN 125-200 mm (5 8") metal-to-metal RK 86, DN 15-100 10 350 Liquids, gases, steam DIN 3230-3, BN 2, BO 3

Standard design fitted with M8 antistatic connection metal-to-metal RK 86, DN 125-200 10 400 Liquids, gases, steam DIN 3230-3, BN 2, BO 3

metal-to-metal RK 86A, DN 15-200 200 550 Liquids, gases, steam DIN 3230-3, BN 2, BO 3

PTFE 190 250 Aggressive fluids DIN 3230-3, BN 2, BO 3

EPDM 40 150 Water, condensate, steam DIN 3230-3, BN 1, BO 1

FPM 25 200 Mineral oils, gases, air DIN 3230-3, BN 1, BO 1

For additional information on chemical resistance go to www.gestra.de and click on Technical Support

and then on Chemical Resistance.

End Connections

DIN 1) ASME BS 10 3) JIS 4)

EN 1092-1 B 16.1 Class 125 FF B2238

Table D, E, F, H, J

PN 10 / 16 / 25/40 2) B 16.5 Class 150 / 300 RF 10K

1) DN 125200 mm (58"): On request form D or E acc. to EN 1092. 2) DN 15100 mm (4") also suitable for PN 6.

3) For installation between flanges DN 15 mm ("), BS 10, table H and J, please use RK 86/86A, DN 20 mm (").

4) As standard for installation between Fl. JIS 10K (except DN 80 mm). When ordering please indicate nominal size (reworking required).

Dimensions

L Nominal [mm] 15 20 25 32 40 50 65 80 100 125 150 200

sizes [inch] 1 1 1 2 2 3 4 5 6 8

Dimensions L 5) 16 19 22 28 31.5 40 46 50 60 90 106 140

Z min [mm] Zmin 44 53 64 73 83 96 110 128 151

Zmax 67 76 82 93 104 118 136 158 186

PN 10/16 194 220 275

PN 25 194 226 286

D PN 40 194 226 293

Class 125/150 194 220 275

Class 300 216 251 308

Weight [kg] 0.27 0.38 0.52 0.8 1.12 1.78 2.43 3.37 5.34 11 14 25

Zmax 5) Short overall length according to EN 558-1, series 49 (; DIN 3202, part 3, series K4)

Materials

DN 15 100 ( 4") DIN / EN ASTM Category

Body, seat and RK 86 1.4317 A 743-CA 6-NM Chromium steel

guide ribs RK 86 A 1.4408 A 351CF8M Stainless steel

Valve disc, spring retainer Stainless steel

1.4571

Spring Stainless steel

DN 125 200 (5 8") DIN / EN ASTM Category

D

RK 86 1.0619 A 216 WCB Cast steel (carbon steel)

Body hard faced seat 1.4502

RK 86 A 1.4408 A351CF8M Stainless steel

Valve cone RK 86 1.4006 A 182F6 Chromium steel

Guide RK 86 1.4107 Chromium steel

Guide RK 86 A 1.4408 Stainless steel

L Valve cone RK 86 A 1.4404 A 182F316 Stainless steel

Spring RK 86 and 86A 1.4571 Stainless steel

*) For the use in hygienic installations, foodstuff industry, pharmaceutical industry and similar applications please order RK 86 A

in pickled design.

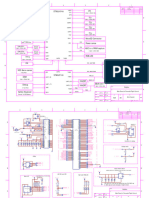

Non-Return Valve Pressure Drop Chart

Vw = V

RK 86, 86A for Flanges The curves given in the chart are valid for water at 20 C. To

read the pressure drop for other fluids the equivalent water

1000

PN 10/16/25/40, DN 15-200 volume flowrate V w must be calculated and used in the graph.

Vw = Equivalent water volume flow

in l/s or m/h

ASME Class 125/150/300 The values indicated in the chart are applicable for spring- = Density of fluid

assisted valves with horizontal flow and to valves without (operating condition) in kg/m

spring installed in vertical pipes with upward flow.

V = Volume of fluid

Opening pressures (operating condition) in l/s or m/h

Differential pressures at zero volume flow

DN Opening pressures in mbar [Imp.

Direction of flow gal/min.] [m3/h] [l/s]

without 3000 700 200

with springs DN

springs

2000

r r q o 100 200

15 2.5 10 7.5 5 1000 60 150

20 2.5 10 7.5 5 125

600 40

25 2.5 10 7.5 5 100 30

400 100

32 3.5 12 8.5 5 20

300 80

40 4.0 13 9 5 65

9.5 5 200

50 4.5 14 10 50

65 5.0 15 10 5

100 6 40

80 5.5 16 10.5 5

100 6.5 18 11.5 5 60 4 32

10 3

125 12.5 35 22.5 10 40 25

30 2

150 14.0 38 24.0 10

200 13.5 37 23.5 10 20 20

1

1 mbar = 0.0145 psi = 100 mm w.g. = 0.4 in w.g. 10 0,6 15

On request at extra charge, special springs for opening 6 0,4

pressures: 4 0,3

1

Between 5 and 1000 mbar for DN 15 50 mm ( 2"), 3 0,2

between 5 and 700 mbar for DN 65 and 80 mm (2, 3"), 2

between 5 and 500 mbar for DN 100200 mm (4 8").

Volumenstrom Vw

0,1

Volume flow Vw

1

0,06

Enquiry Specification 0,2

0,6 0,04

GESTRA DISCO Non-return valve type RK 86 / RK 86A for 0,1 0,03

flanges PN 10/16/25/40. 0,4

0,02

[bar]

Wafer design with extremely short overall length to EN 558- 0,002 0,005 0,01 0,02 0,03 0,05 0,1 0,2 0,3 0,5

1, series 49. [psi]

Suitable for fitting between pipe flanges to DIN/EN, BS and 0,03 0,05 0,1 0,2 0,5 1 2 5 7

ASME. Self-centering valve body (DN 15 DN 100). The Druckverlust p

valve disc rests on two of the four guide ribs, independently Pressure drop p

of the flange standard. Broad sealing surfaces. Installation

in any position. Connection for electrostatic discharge line Required minimum volume flow VW for equipment without spring installed in

as standard. Stronger springs for other opening pressures vertical pipes with upward flow.

are also available on request. Metal-to-metal or soft (EPDM,

Required minimum volume flow VW for equipment with standard spring and

FPM) seats. Design in accordance with PED 97/23/EC, with horizontal flow.

CE marking. Specification of nominal pressure, size, body

materials etc. in accordance with EN 19.

Please note:

The selected non return valve must ensure that the

minimum volume flowrate keeps the valve disk in the open

position (see Pressure Drop Chart / stable range). Valve When ordering please state: PED (Pressure Equipment Directive)

construction is very robust, but they are not recommended

for use on compressors or where pulsating flow exists. If in Fluid, flowrate, service pressure and temperature, standard The equipment complies with the requirements of the Pres-

doubt please consult us and we will carry out the pressure of pipe flange. sure Equipment Directive 97/23/CE. Applicable with fluids of

drop calculation and select a suitable valve. The following test certificates can be issued on request, group 1 and 2. With CE marking (apart from equipment that

at extra cost: is excluded from the scope of the PED according to section

3.3). For more information refer to our PED Declaration of

In accordance with EN 10204-2.1, -2.2, 3.1 and 3.2. Conformity.

All inspection requirements have to be stated with the order.

After supply of the equipment certificates can no longer be

established. Charges and extent of the above mentioned

ATEX (Atmosphre Explosible)

certificates as well as the different tests confirmed therein The equipment does not have its own potential source of

are listed in our price list Test and Inspection Charges for ignition and is therefore excluded from the scope of the

Standard Equipment. ATEX Directive 94/9/EC. Applicable in Ex zones 0, 1, 2, 20,

21, 22 (1999/92/EC). The equipment does not bear an Ex

For other tests and inspections than those listed above,

marking. For more information refer to our ATEX Declaration

Supply in accordance with our general terms of business. please consult us.

of Manufacturer.

GESTRA AG

P. O. Box 10 54 60, D-28054 Bremen

Mnchener Str. 77, D-28215 Bremen

Tel. 0049 (0) 421 35 03 - 0, Fax 0049 (0) 421 35 03-393

E-Mail gestra.ag@flowserve.com, Web www.gestra.de

810493-05/01-2014cm (804144-07) GESTRA AG Bremen Printed in Germany

Das könnte Ihnen auch gefallen

- RK 86, 86A For Sandwiching Between Flanges PN 10/16/25/40, DN 15-200 ASME Class 125/150/300, NPS 1/2-8Dokument2 SeitenRK 86, 86A For Sandwiching Between Flanges PN 10/16/25/40, DN 15-200 ASME Class 125/150/300, NPS 1/2-8DanielNoch keine Bewertungen

- DBL 810388 04 RK16A enDokument2 SeitenDBL 810388 04 RK16A enVignesh NadimuthuNoch keine Bewertungen

- Wafer 150Dokument1 SeiteWafer 150torobelkaNoch keine Bewertungen

- DBL 810493 07 RK86-RK86A-RKE86-RKE86A enDokument3 SeitenDBL 810493 07 RK86-RK86A-RKE86-RKE86A enŁukasz OlszewskiNoch keine Bewertungen

- Valve-Gestra NRV VPENC000050Dokument2 SeitenValve-Gestra NRV VPENC000050bokachoda786Noch keine Bewertungen

- DBL 810708 01 BK15 en PDFDokument2 SeitenDBL 810708 01 BK15 en PDFMedian Ari WidodoNoch keine Bewertungen

- C 2018-07-10 ME H. Pelders S M. Ummelen ME PCL R. Menon/hpe 1 of 2Dokument2 SeitenC 2018-07-10 ME H. Pelders S M. Ummelen ME PCL R. Menon/hpe 1 of 2mokie305Noch keine Bewertungen

- 321H Buttweld FittingsDokument5 Seiten321H Buttweld FittingsPetromat Oil and Gas Equipment Pvt. Ltd.Noch keine Bewertungen

- PP Lined Pipe PDFDokument27 SeitenPP Lined Pipe PDFNILADRI BHATTACHARYYANoch keine Bewertungen

- PDS01.09.001 - Wouter Witzel - EVMLDokument5 SeitenPDS01.09.001 - Wouter Witzel - EVMLSiniša MorasNoch keine Bewertungen

- DIN Version: T 8015 EN Series 240 Type 3241-1 and Type 3241-7 Pneumatic Control Valves Type 3241 Globe ValveDokument8 SeitenDIN Version: T 8015 EN Series 240 Type 3241-1 and Type 3241-7 Pneumatic Control Valves Type 3241 Globe ValveLoander David GeronimoNoch keine Bewertungen

- BS5163 Cast Irton Gate Valve ISO Top PDFDokument2 SeitenBS5163 Cast Irton Gate Valve ISO Top PDFhung0% (1)

- PDS01.06.001 - Wouter Witzel - EVTLSDokument7 SeitenPDS01.06.001 - Wouter Witzel - EVTLSVilius BukysNoch keine Bewertungen

- Spirax BSA TDokument4 SeitenSpirax BSA TNang DapiNoch keine Bewertungen

- SAMSON Globe 3241Dokument12 SeitenSAMSON Globe 3241Shaheen HydrosNoch keine Bewertungen

- Valvula de Retencion A Clapeta Oscilante Din pn16 dn50 300Dokument2 SeitenValvula de Retencion A Clapeta Oscilante Din pn16 dn50 300JOHNNY CALERONoch keine Bewertungen

- Klinger Ball Valve KHCDokument4 SeitenKlinger Ball Valve KHCFood andfoodNoch keine Bewertungen

- 1 Valvula Globo Con Fuelle Didtek Acero Carbono PDFDokument1 Seite1 Valvula Globo Con Fuelle Didtek Acero Carbono PDFjoaquin torrano veraNoch keine Bewertungen

- BOQ For Pipe Fittings For Flash Steam & Condensate PDFDokument2 SeitenBOQ For Pipe Fittings For Flash Steam & Condensate PDFsppatilNoch keine Bewertungen

- VAL Team: Humidity Separators SF251/S PN 16 and PN 40Dokument2 SeitenVAL Team: Humidity Separators SF251/S PN 16 and PN 40peyman mahinsaNoch keine Bewertungen

- 77Vds 04 18Dokument7 Seiten77Vds 04 18Allen RichardNoch keine Bewertungen

- Thermodynamic Steam Traps DK PN 40, PN 63/class 600: Features of The DK SeriesDokument2 SeitenThermodynamic Steam Traps DK PN 40, PN 63/class 600: Features of The DK Serieshamid vahedil larijaniNoch keine Bewertungen

- DIN Version: T 8015 EN Series 240 Type 3241-1 and Type 3241-7 Pneumatic Control Valves Type 3241 Globe ValveDokument8 SeitenDIN Version: T 8015 EN Series 240 Type 3241-1 and Type 3241-7 Pneumatic Control Valves Type 3241 Globe ValveMohamed RaafatNoch keine Bewertungen

- TLV SJ3FXDokument2 SeitenTLV SJ3FXÁlvaro Martínez FernándezNoch keine Bewertungen

- Asme B31.8Dokument14 SeitenAsme B31.8omar equihua100% (1)

- ASME B31.8 Riser CalcDokument12 SeitenASME B31.8 Riser CalcSalz EngineeringNoch keine Bewertungen

- PDS01.11.001 - Wouter Witzel - EVFLDokument7 SeitenPDS01.11.001 - Wouter Witzel - EVFLVilius BukysNoch keine Bewertungen

- Ep33411 b11Dokument9 SeitenEp33411 b11salamrefighNoch keine Bewertungen

- ASME B31.8 Riser CalcDokument23 SeitenASME B31.8 Riser Calcisrar khan100% (2)

- Double OffsetDokument10 SeitenDouble Offsetkrbabu1969Noch keine Bewertungen

- Swing Check Valve - Flanged: Technical FeaturesDokument1 SeiteSwing Check Valve - Flanged: Technical FeaturesAhmed El MorsyNoch keine Bewertungen

- V5-Gan-Gp16 Series: Resilient Seated Gate Valve, Non Rising Stem (Hand Wheel)Dokument2 SeitenV5-Gan-Gp16 Series: Resilient Seated Gate Valve, Non Rising Stem (Hand Wheel)Em Es WeNoch keine Bewertungen

- GAV36FDokument2 SeitenGAV36FFeryNoch keine Bewertungen

- Ghibson ButterflyDoubleEccentric BrochureDokument9 SeitenGhibson ButterflyDoubleEccentric Brochurejhon jairo arangoNoch keine Bewertungen

- Dynaxe - W201: Product Data SheetDokument3 SeitenDynaxe - W201: Product Data SheetKristinNoch keine Bewertungen

- Temp. Control ValveDokument7 SeitenTemp. Control Valvesaurabh kumarNoch keine Bewertungen

- Glass GRPDokument4 SeitenGlass GRPPetrNoch keine Bewertungen

- ASME B31 8 Riser CalcDokument12 SeitenASME B31 8 Riser CalcEmmanuel LawrenceNoch keine Bewertungen

- 1) Wouter Witzel EVTLSDokument7 Seiten1) Wouter Witzel EVTLSAizat RomainoNoch keine Bewertungen

- ANSI Version: T 8012 EN Type 3241-1 and Type 3241-7 Pneumatic Control Valves Type 3241 Globe ValveDokument12 SeitenANSI Version: T 8012 EN Type 3241-1 and Type 3241-7 Pneumatic Control Valves Type 3241 Globe ValveMohamed RaafatNoch keine Bewertungen

- Swagelok Flange AdaptersDokument6 SeitenSwagelok Flange AdapterstotcsabNoch keine Bewertungen

- Spirax Sarco Fig 33Dokument2 SeitenSpirax Sarco Fig 33Jacobus CalvelageNoch keine Bewertungen

- Dynaxe - L201: Product Data SheetDokument3 SeitenDynaxe - L201: Product Data SheetKristinNoch keine Bewertungen

- Wika Diaphragm Seal, Flange Connection Model 990.27Dokument4 SeitenWika Diaphragm Seal, Flange Connection Model 990.27Syed Imtiaz HussainNoch keine Bewertungen

- Fig 520 High Lift Safety Valve: Features & BenefitsDokument3 SeitenFig 520 High Lift Safety Valve: Features & Benefitst_rajith1179Noch keine Bewertungen

- Lit RD10 ENDokument6 SeitenLit RD10 ENlesonspkNoch keine Bewertungen

- Alfa Laval Alfacond 400 - enDokument2 SeitenAlfa Laval Alfacond 400 - enAjayNoch keine Bewertungen

- Datasheet - Wouter Witzel - EVBLSDokument3 SeitenDatasheet - Wouter Witzel - EVBLSKristinNoch keine Bewertungen

- PDS01.05.001 - Wouter Witzel - EVBLSDokument3 SeitenPDS01.05.001 - Wouter Witzel - EVBLSVilius BukysNoch keine Bewertungen

- FCD VLENTB0200 Mark200TB AQ PDFDokument36 SeitenFCD VLENTB0200 Mark200TB AQ PDFmetal_dung2Noch keine Bewertungen

- Technical Bulletin: ArgusDokument11 SeitenTechnical Bulletin: ArgusTerry wei shengNoch keine Bewertungen

- 400E EngineeringDokument8 Seiten400E EngineeringDenis Oliveira CostaNoch keine Bewertungen

- KSB Globe ValvesDokument2 SeitenKSB Globe ValvesvttneverloseNoch keine Bewertungen

- TLV Tc1 Self Acting Temperature Regulator FlangedDokument2 SeitenTLV Tc1 Self Acting Temperature Regulator FlangedSDP02Noch keine Bewertungen

- Stauff Clamps DNV Till Nov 2022Dokument3 SeitenStauff Clamps DNV Till Nov 2022Muhammad Zhakri Muhammad KamalNoch keine Bewertungen

- EN 13480 (UE Standard) - A16Dokument8 SeitenEN 13480 (UE Standard) - A16keduse100% (1)

- DFS (GS 06p01y01-E-E - 008)Dokument30 SeitenDFS (GS 06p01y01-E-E - 008)tetioNoch keine Bewertungen

- SY Rubber Disc Check ValveDokument2 SeitenSY Rubber Disc Check ValvePhú Song LongNoch keine Bewertungen

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- All-in-One Manual of Industrial Piping Practice and MaintenanceVon EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceBewertung: 5 von 5 Sternen5/5 (1)

- Actuator MANDokument30 SeitenActuator MANsinamicsNoch keine Bewertungen

- TI110CENDokument8 SeitenTI110CENsinamicsNoch keine Bewertungen

- TI028CENDokument12 SeitenTI028CENsinamicsNoch keine Bewertungen

- 3 Way Valve - DSDokument1 Seite3 Way Valve - DSsinamicsNoch keine Bewertungen

- Endress Hauser LC301 ManualDokument24 SeitenEndress Hauser LC301 Manualtopaz45Noch keine Bewertungen

- TI085CENDokument16 SeitenTI085CENsinamicsNoch keine Bewertungen

- BA200PENDokument32 SeitenBA200PENsinamicsNoch keine Bewertungen

- KTR Mounting Inst. 200-201Dokument6 SeitenKTR Mounting Inst. 200-201sinamicsNoch keine Bewertungen

- Assembly Line 1 Palletizer Electrical SchematicsDokument13 SeitenAssembly Line 1 Palletizer Electrical SchematicssinamicsNoch keine Bewertungen

- 38352cable ListDokument9 Seiten38352cable ListsinamicsNoch keine Bewertungen

- (ESS) Sample ProjectDokument239 Seiten(ESS) Sample ProjectsinamicsNoch keine Bewertungen

- M W Plan PDFDokument1 SeiteM W Plan PDFsinamicsNoch keine Bewertungen

- Konsole PDFDokument1 SeiteKonsole PDFsinamicsNoch keine Bewertungen

- Konsole PDFDokument1 SeiteKonsole PDFsinamicsNoch keine Bewertungen

- Lift3 Oben PDFDokument2 SeitenLift3 Oben PDFsinamicsNoch keine Bewertungen

- Executive SummeryDokument1 SeiteExecutive SummeryShahed HossainNoch keine Bewertungen

- Ncell VAS RFP Main BodyDokument18 SeitenNcell VAS RFP Main BodyJitendra MishraNoch keine Bewertungen

- User Instructions: Installation Operation MaintenanceDokument60 SeitenUser Instructions: Installation Operation MaintenanceYaku YokuNoch keine Bewertungen

- 10 Bibliografia Adjunta Iso - 6888 - 3Dokument6 Seiten10 Bibliografia Adjunta Iso - 6888 - 3Jen UculmanhaNoch keine Bewertungen

- Tefra Corporate BrochureDokument20 SeitenTefra Corporate BrochurepmpintoisqNoch keine Bewertungen

- CUSM BK SF31C8B0 00 Socialminer-User-GuideDokument92 SeitenCUSM BK SF31C8B0 00 Socialminer-User-GuideAnonymous IU9mn1Noch keine Bewertungen

- Domain Name SystemDokument8 SeitenDomain Name SystemSrishti AroraNoch keine Bewertungen

- DIYDachshundDokument15 SeitenDIYDachshundClaudia LopezNoch keine Bewertungen

- 648 Commander Wrapper UserGuideDokument146 Seiten648 Commander Wrapper UserGuideMelissa TomeNoch keine Bewertungen

- How To Implement ISO 20121Dokument9 SeitenHow To Implement ISO 20121Rajesh SapNoch keine Bewertungen

- YanmarDokument56 SeitenYanmarvaleriawolff100% (5)

- Operations Management Key Terms FlashcardsDokument5 SeitenOperations Management Key Terms Flashcardsddathaw100% (1)

- Door and Frame - Technical Manual PDFDokument384 SeitenDoor and Frame - Technical Manual PDFRichard Oon100% (1)

- Construction InspectionDokument1.153 SeitenConstruction Inspectionjazmontz0% (1)

- Page No Section 1 - Project Management 2Dokument27 SeitenPage No Section 1 - Project Management 2Doina ShalaruNoch keine Bewertungen

- Expulsion Fuse Links For Use in High Voltage (Liston Fusible)Dokument36 SeitenExpulsion Fuse Links For Use in High Voltage (Liston Fusible)Leon OrtegaNoch keine Bewertungen

- Incident Detection and Response To Suspicious Root Access PlaybookDokument10 SeitenIncident Detection and Response To Suspicious Root Access PlaybookirokoNoch keine Bewertungen

- ERouting OSPF PT Practice SBADokument4 SeitenERouting OSPF PT Practice SBAwilsonmadridNoch keine Bewertungen

- 664 Publist 2014 DecemberDokument15 Seiten664 Publist 2014 DecemberJ Salvador Calderón BarrancosNoch keine Bewertungen

- Tacoma: Here's The Tacoma TRD Pro 4x4 Double Cab V6 6-Speed Automatic Short BedDokument7 SeitenTacoma: Here's The Tacoma TRD Pro 4x4 Double Cab V6 6-Speed Automatic Short Bedk2057282Noch keine Bewertungen

- Biréli LagrèneDokument17 SeitenBiréli LagrèneMarcos Faustino0% (1)

- An Update On Electric Vehicle Chanrging Equipment Installation RequirementsDokument2 SeitenAn Update On Electric Vehicle Chanrging Equipment Installation RequirementsarekgliNoch keine Bewertungen

- Ds Transmitter U952TDokument2 SeitenDs Transmitter U952TZafar YabNoch keine Bewertungen

- Durandal MB H743schDokument2 SeitenDurandal MB H743schashley0% (1)

- Champion Compressors Modbus RTU Manual: Aircon L1 Compressor Controller Enercon Sequencer Controller & AccessoriesDokument45 SeitenChampion Compressors Modbus RTU Manual: Aircon L1 Compressor Controller Enercon Sequencer Controller & Accessoriessudirmanpriyo100% (2)

- Manual de Perforadoras JacklegDokument34 SeitenManual de Perforadoras JacklegFernando Pretell LozanoNoch keine Bewertungen

- 4NM Winker Light - Jul 2012Dokument1 Seite4NM Winker Light - Jul 2012Tripod1970Noch keine Bewertungen

- Rig Power LLCDokument12 SeitenRig Power LLCRichard EVNoch keine Bewertungen

- Company Profile KsiDokument10 SeitenCompany Profile KsiarieprachmanNoch keine Bewertungen

- Progressive Web AppsDokument15 SeitenProgressive Web AppsSamuel PutraNoch keine Bewertungen