Beruflich Dokumente

Kultur Dokumente

6825 29541 1 PB

Hochgeladen von

NKOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

6825 29541 1 PB

Hochgeladen von

NKCopyright:

Verfügbare Formate

Volume 9, Issue 2, Spring2015

Banana Fiber: Scope and Value Added Product Development

C. Vigneswaran, V. Pavithra, V. Gayathri, and K. Mythili

Department of Fashion Technology

PSG college of Technology

India

ABSTRACT

Banana fiber is a natural bast fiber which has wide range of uses in handicraft product

developments such as mat, rope and twines, but only 10% of its pseudo stem is being used

for making products and remaining is waste or used as fertilizer. As it has a property like

weatherproof, UV protection (because of lignin content), moisture absorption, anti-oxidant

and bio degradable etc., it can be used to make variety of products that help farmers

economically and have wide scope to create new market. Recent studies have indicated

banana fiber possesses a lot of advantageous physical and chemical properties which can

be used a very good raw material for the textile and packaging industry.

Keywords: banana fiber, bio degradable, value addition, weather proof, packaging

material

1. INTRODUCTION the pseudostem is thrown as agricultural

Banana plant (scientific name: Musa waste to a great extent. These pseudostems

acuminate) not only gives the delicious fruit can be effectively utilized in production of

but it also provides textile fiber, the banana the banana fibers as, annually; about 1.5

fiber. It grows easily as it sets out young million tons of dry banana fibers can be

shoots and is most commonly found in hot produced from the outer sheath of

tropical climates. All varieties of banana pseudostem. Biomass (pseudostem) waste, a

plants have fibers in abundance. These fibers rich source of natural fibers the pseudostem

are obtained after the fruit is harvested and can be profitably utilized for numerous

fall in the group of bast fibers. After the fruit applications and preparation of various

production, the trunk of the banana plant i.e. products.

Article Designation: Scholarly 1 JTATM

Volume 9, Issue 2, Spring 2015

layer including the epidermis, contain the

bundles of fiber dispersed in a soft tissue

matrix. The middle layer consists of water

transporting fiber vascular tissue and the

inner layer consists of soft, cellular tissue.

The quantity of fiber in each sheath depends

upon its width and its location in the stem, as

does its quality. In addition to fruit

production, huge quantity of biomass

(pseudostem, leaves, suckers etc.) is

generated [1,2].

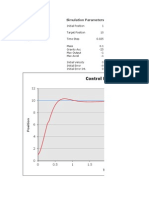

Figure 1. Growth % of Banana in the

world

2. BIO FIBERS

Lignocellulosic are used for various

applications, depending on their composition

and physical properties. Recently, natural

cellulose fibers suitable for textile and other

industrial applications have been produced

from corn husks and corn stalk. Use of Figure 2. Pseudostem cross sectional view

lignocellulosic to produce ethanol and other

sugars can possible by fermentation. Presently, this biomass is discarded as

Biomasses can also be converted into carbon, waste. In past, some researchers have

hydrogen and oxygen to produce various successfully demonstrated use of banana

chemicals, enzymes and proteins. It is pseudostem and leaves for extraction of

reasonable to expect that agricultural fibers on a small scale. In India, the fibers are

byproducts will be a major source of being used for preparing handicrafts, ropes

industrial products and chemicals in the near etc., which otherwise can be used for making

future. However, there are a few limitations fabrics, home furnishings and good quality

associated with agro-based fibers that should papers. The major problem of non-adoption

be considered when designing products using of fiber extraction technology is low recovery

bio-fibers. The primary limitation is the of fibers leading to high transport cost. This

relatively higher moisture absorption of plant has long been a good source for high

natural fibers, making it difficult for the quality textiles in many parts of the world,

hydrophobic fibers and hydrophilic polymers especially in Japan and Nepal. [3-5]

to bond together.

All varieties of banana trees abound in 3. BANANA PRODUCTS

fibers. In fact almost each and every part of The stem of the banana plant is usually

the banana plant gives fibers of various thrown away once the plantain is harvested.

strength, color and beauty and staple length The stem forms a major waste material in the

which can be used for various purposes. Out large4 scale and this disposal has become a

of the 14-18 sheaths available in a stem, the huge problem. So form this they started to

outermost 4-6 sheaths yield course fiber, the extract fiber mechanically and used to make

outer 6-8 sheath soft lustrous fiber and the various products. Most of the Banana fibers

rest middle sheath excluding the innermost 4- produced today is used for ropes and cordage.

6 sheaths yield very soft fibers. In each The resistance of the fiber to the sea-water

sheath, there are 3 distinct layers, the outer and its natural buoyancy has created a ready

Article Designation: Scholarly 2 JTATM

Volume 9, Issue 2, Spring 2015

market for it in the manufacture of shipping

cables. It is also widely used for making

power transmission ropes and cordage, wall

drilling cables, fishing nets, lines and other

types of cordage. Although banana plants and

fibers are available in tropical regions in

abundance, their application potential has not

been exploited fully. At present, other

companies make the limited application of

banana fiber, for example, in making ropes,

mats, and some other fields such as the

composite materials. In recent years, more Figure 3. Banana Fiber package

and more plant fibers were considered to be

"environmentally friendly" fiber sources, and

many countries are emphasizing the utilizing

of these fibers. The best thing about these

fabrics is that they are biodegradable, finally

broken down into water and carbon dioxide

by microorganisms in the soil. Innovation

sees no limit and consumers can expect

something big coming up in the textile

industry like fabrics and textiles woven from

fine quality banana fiber. Several studies

carried out on blending revealed that the Figure 4. Banana Fiber mat

studies were carried out on cotton with

various natural and synthetic fibers with a

view to impart value addition. In the present

investigation banana fibers were blended

with cotton and jute fibers to make banana

blended fabrics and further evaluation of the

fabric properties are also carried out. With the

increasing environmental awareness and

growing importance of eco-friendly fabrics,

banana fiber has also been recognized for all

its good qualities and now its application is

increasing in other fields too such as apparel

garments and home furnishings. Figure 5. Banana Sheet

However, in Japan, it is being used for

The fiber portion of the pseudostem

making traditional dresses like kimono, and

left over after extraction of starch was

kamishimo since the Edo period (1600-

utilized for the preparation of paper pulp.

1868). Due to its being lightweight and

Banana fibers are reported to have been spun

comfortable to wear, it is still preferred by

on the jute spinning machinery and used in

people there as summer wear. Banana fiber is

making ropes and sacks. Hand extracted

also used to make fine cushion covers,

fibers have been used to produce handbags

Neckties, bags, table cloths, curtains etc.

and other fancy articles was done first in

Rugs made from banana silk yarn fibers are

Bombay. However, to do any material we

also very popular world over.

have to first know about fiber yield, structure

and properties of banana fibers.

Subsequently, Bhama evaluated yield,

structure and properties of banana fibers

Article Designation: Scholarly 3 JTATM

Volume 9, Issue 2, Spring 2015

gathered from a few commercially cultivated breaking [10, 11]. Several products have

varieties and observed that variations exist in been made from banana fibers in the

both structure and properties of fibers from Philippines. Paper board, tissue paper etc.,

different regions along the length and across can be prepared out of banana pseudostem.

the thickness of the pseudostem. They also Banana fibers can be used as natural

reported differences in tensile and structural absorbent, bio remediation agent for

properties among fibers belonging to bacteria in natural water purifier, for

different varieties and showed that the matrix mushroom production, they are also used in

in which the cells are embedded in the fiber making of handicrafts, quality paper cards,

had a role in deciding the tensile strength of tea bags, string thread, high quality fabric

the fiber. Visvesvaraya Industrial Research material, paper for currency notes and good

and Development Centre Mumbai have rope for tying purpose. The banana fibers

carried out a techno economic research study were reported to be elegant and highly

on extraction and utilization of banana stem versatile. As they did not easily crumple,

fiber. According to them, handmade paper these fibers have been used in the

industry can effectively and competitively manufacture of dress materials. The fineness

use banana fiber as its raw material. It has of texture was found to depend on the quality

been stated that banana fibers possess lot of of fibers used. The material had beautiful

advantageous physical and chemical sheen and so has been used to prepare

properties which promotes its use in textile wedding gowns and barongs. When used in

applications. Enzyme application increases layers and flourlike, the fiber made beautiful

tensile energy, extensibility and improves the dresses. Banana fiber dyed from its natural

surface characteristics of the cotton-banana beige to bright colors was used to make chic

union fabric. Detailed study was undertaken blouses and outfits with plenty of ruffles and

to explore the sewability of cotton-banana laces. Napkins and placemats have also been

blended fabrics and it is concluded that they made. The fiber of Cavendish variety has

give higher/better seam pucker but higher been used as a potential source for specialty

bending rigidity than 100% cotton. A wide pulp manufacture. Pulped through sulphate

range of products including bags, basket, process, it has been used as a raw material for

wall hangings, floor mats, home furnishings, the manufacture of good quality wrapping

etc. can be made in banana fiber. The fiber papers. Banana fibers spun with other fibers

extracted by mechanical process is of make excellent ropes suitable for agricultural

superior quality and is extensively used for purposes. Banana fiber being a natural

making high quality special pare and sorbent has high potential in absorbing

decorative papers. Banana fiber is being used spilled oils in refineries. With fairly low

in making socks in European countries. [6-9]. amount of ash and lignin and high amount of

Tenacity of 33 cultivars of banana holocellulose, pseudostem and petioles are

grown in Philippines was reported to range suitable for pulping in paper industry. Banana

from 22.4-44.8 g/tex. Saba cultivar showed and banana pseudostem contains

maximum strength of 22.4g/tex. These values pathogenesis proteins possessing

were lower in comparison with those of antimicrobial properties.

abaca, which were 55.3 g/tex. The percentage In Costa Rica, Industrial production of

elongation of single fiber in tensile testing is paper from banana pseudostem is going on

found to be more than that of the hybrid and a whole range of products labeled Earth

composite. which includes paper, cardboard, notepads,

Therefore, the single composite letter paper, envelopes, post card, packaging

withstands more strain before failure in material and notebooks have been launched.

tensile testing than the hybrid fiber The banana fiber paper is reported to be of

composite. The fiber was extracted by hand high strength and it is used to make tea bags

stripping by using a stripping device applying and currency notes. In Germany, work is in

low pressure to prevent the fibers from

Article Designation: Scholarly 4 JTATM

Volume 9, Issue 2, Spring 2015

progress to develop banana fiber lining for 4. BANANA PACKAGING

car interiors [12-14]. The research examined the green

packaging development from banana fiber

Many applications of banana pseudostem for instant food products. The purposes were

have been enlisted as follows: to construct, approve and develop the sketch

As an eco-friendly substitute in textile design, to develop banana fiber package

industry in place of the environmentally prototypes that protect food products inside,

hazardous synthetic fibers. to eliminate packaging environment

To provide livelihood to the rural poor problems, prevent natural resource and save

through generation of employment in the energy in package processing, and to design

fiber producing and processing industry. packaging for instant banana food products

Being completely biodegradable and such as packages such as stand-up pouch,

naturally occurring, the banana fiber paper box, paper cup, and zip lock paper bag.

products are expected to be in great The research was found that Satisfaction of

demand in the international markets as every factor was good level and every

they pose no toxic effects to man and packaging patterns conformed to the identity

environment. design in structural and graphical packaging.

To make value added products, which As a result of studying structural packaging

would enhance the profitability of factors, it indicated factors that had excellent

banana farming. satisfaction level in every packaging pattern,

To minimize deforestation due to various were packaging with aesthetic and elegant

wood/cellulose processing industries, ones, identity packaging, and souvenir

thus protecting our ecology and packaging.

environment. The development of green packaging

Boxes made from these boards can be from banana fiber for instant food products.

used for transport of fruits and other Variables studied in this issue, packaging

materials. design of green packaging from banana fiber

Thicker varieties of banana paper can be for instant food products of the envelope

used for making files, covers and packing (Stand-up pouch), box (Paper Box), paper

materials [15,16] cups (Paper Cup), paper bags (Zip Lock

Paper Bag). In this research, banana fiber

The present study reports used to produce packaging to select the

development of softening processes for the quality of the physical, chemical and

inherently coarse banana fibers making it consumer product safety. Packaging is

more suitable for spinning operations, recycling-based that is eco-friendly disposal.

spinning of the softened fibers into yarns, [18]

after blending them with suitable natural After completion of product

fibers and testing the physical and development, to find out the results a

mechanical properties of the yarns. The questioner was prepared and the results are

Yarns were further converted to fabrics and found, it was found for each style. Data were

again assessed for their physical and analyzed opinions by the statistical package

mechanical properties. The fabrics were for the social science program and using

further passed through various finishing mean, percentage and standard deviation

processes and then tested for all the 4.50 to 5.00 - very good

mechanical and physical properties. The 3.50 to 4.49 - good

fabrics were further taken for dyeing with 2.50 to 3.49 - medium

two classes of dyes and then assessed for the 1.50 to 2.49 - less

various fastness properties [17] 1 to 1.49 least

Article Designation: Scholarly 5 JTATM

Volume 9, Issue 2, Spring 2015

Packaging from banana fiber for instant food CONCLUSION

products as envelope style, the result Banana is cultivated in about 2, 30,000

obtained was 4.10 (mean), 0.48 (S.D) good hectares of land and the fiber yield is around

8.7 lakh toned. Though banana fiber

Packaging from banana fiber for instant food extraction is not done on any large scale at

products as box style, the result obtained was present, banana fibers are reported to have

4.14(mean), 0.48 (S.D) good been spun on the jute spinning machinery and

used hand bags and other fancy articles.

Packaging from banana fiber for instant food Agro-based bio-fibers have the composition,

products as paper cup style, the result properties and structure that make them

obtained was 4.17 (mean), 0.39 (S.D) good suitable for uses such as composite, textile,

pulp and paper manufacture. In addition, bio-

Packaging from banana fiber for instant food fibers can also be used to produce fuel,

products as zip lock style, the result obtained chemicals, enzymes and food. Byproducts

was 4.27 (mean), 0.40 (S.D) good. produced from the cultivation of corn, wheat,

rice, sorghum, barley, sugarcane, pineapple,

Enzymes are specific in action. banana and coconut are the major sources of

Contrary to inorganic catalysts such as acids, agro-based bio-fibers. Likewise banana fiber

bases, metals, and metal oxides, enzymes are based production processes, structure,

very specific. In other words, each enzyme properties and suitability of these bio-fibers

can breakdown or synthesized one particular are to be identified for various industrial

compound. In some cases, they limited their applications.

actions to specific both in the compound with

which they react. Most proteases, for 5. REFERENCES

instance, can breakdown several types of 1. Narendra Reddy and Yiqi Yang,

protein, but in each protein molecule only Biofibers from agricultural byproducts

certain bonds will be cleaned depending on for industrial application, Trends in

the which enzyme is used. Enzymatic Biotechnology, 23(1), 2005, 22-27.

reaction are nontoxic and readily broken 2. Sakthivel M, Ramesh S, Mechanical

down biofinishing, also called bio properties of natural fiber (banana, coir,

polishing, is a finishing process applied to sisal) polymer composites, Science Park,

cellulose textiles that produces permanent 1(1), ISSN 2321-8045, 2013.

effects by the use of enzymes. Bio finishing 3. Das P K, Nag D, Debanath S and Nayak

removes protruding fiber and slubs from L K, Machinery for extraction and

fabrics, significantly reduces pilling, softens traditional spinning of plant fibers,

fabric hand and provides a smooth fabric Indian Journal of Traditional

appearance, especially for knitwear and as a Knowledge, 9(2), 2010, 328-332.

pretreatment for printing. In denim 4. Venkatasubramanian H, Chainthanyan

processing, Bio finishing can reduce or C, Raghuraman S, Panneerselvam M,

eliminate abrasive stone and the aggressive Evaluation of mechanical properties of

chlorine chemistry. Biofinishing is not only abaca glass banana fiber reinforced

useful for cotton but also for regenerated hybrid composites, International Journal

cellulose fabrics, especially for lyocel and of Innovative Research in Science,

microfiber articles. By incorporating Engineering and Technology, 3(1), 2014,

enzymes into detergents to remove 8169-8178.

protruding surface fibers, improved color 5. Debabandya Mohapatra, Sabyasachi

retention is achieved after multiple Mishra and Namrata Sutar, Banana and

launderings [19, 20]. Its By-Products Utilisation, Journal of

Scientific & Industrial Research, 69,

2010, 323-329.

Article Designation: Scholarly 6 JTATM

Volume 9, Issue 2, Spring 2015

6. Debabandya Mohapatra, Sabyasachi 14. Nicemol Jacob, K.N. Niladevi, G.S.

Mishra And Namrata Sutar, Banana And Anisha, P. Prema, Hydrolysis of Pectin:

Its By-Products Utilisation, Journal of An Enzymatic Approach and Its

Scientific and Industrial Research, 69(5), application In Banana fiber Processing,

2010, 323-329. Microbiological Research, 163(5), 2008,

7. Preethi P and Balakrishna Murthy, 538-544.

Physical and chemical properties of 15. Vigneswaran C, Anbumani N,

banana fiber extracted from commercial Ananthasubramanian M, Biovision in

banana cultivars grown in Tamilnadu textile wet processing industry-

State, Agro technology, 11, 2013. Technological Challenges, Journal of

8. Kulkarni G, Mechanical properties of Textile, Apparel Technology and

banana fibers, Journal of Material Management, 7(1), 2011, 1-10.

Science, 18 (1983), 22902296. 16. Manish kumar, Deepak kumar,

9. Bussara Soiraya, Chompunuch Comparative study of pulping of banana

Duangkamol, Autcha Siripun, stem, International Journal of Fiber and

Praparnporn Theeramongko The Textile Research, 1(1), 2011, 1-5.

development of green packaging from 17. Baig M V, Baig B L, Baigand M I,

banana fiber for instant food products, Majenda Y, Sacharification of banana

International Conference, 3-4, 2012. agro waste by cellulolytic enzymes,

10. Rita Araujo, Margarida Casal and Artut African Journal of Biotechnology, 3(9),

Cavanco Paulo, Applications of 2004, 447-450.

enzymes for textile fibers processing, 18. Raghavendra S, Lingaraju S,

Biocatalysis and Biotransformation, Balachandra Shetty P, Mukunda P G,

26(5), 2008, 332 -349. Mechanical properties of short banana

11. S.M. Sapuan, N. Harun and K.A. Abbas, fiber reinforced natural rubber

Design and Fabrication Of A composites, International Journal of

Multipurpose Table Using A Composite Innovative Research in Science,

Of Epoxy And Banana Pseudostem Engineering and Technology, 2013,

Fibers, Journal of Tropical Agriculture, 1652-1655.

45, 2007, 67-69. 19. Rajesh Ghosh, Reena G, Rama Krishna

12. Boruah K, Microstructural study of fibers A, Lakshmipathi R, Effect of fiber

extracted from wild banana plant by X- volume fraction on the tensile strength of

ray line broadening analysis, Indian banana fiber reinforced vinyl ester resin

Journal of Fiber and Textile Research. composites, International Journal of

23(2), 1998, 7680. Advanced Engineering Sciences and

13. Karen L. B. Gast, Proposal for Use Of Technologies, 4(1), 2010, 89-91.

Pseudostem From Banana Tree -Musa 20. Sevgi Hour, Kerim Cetinkaya,

Cavendish Containers And Packaging Of Production of banana/glass fiber

Fruits & Vegetables, 2001. biocomposites profile and its bending

strength, Journal of Material Sciences,

2012, 43-49.

Article Designation: Scholarly 7 JTATM

Volume 9, Issue 2, Spring 2015

Das könnte Ihnen auch gefallen

- Banana Fibers Such As FlaxDokument2 SeitenBanana Fibers Such As Flaxmuthamil05Noch keine Bewertungen

- MAKALAH TEKSTIL 1 Softfile BingDokument10 SeitenMAKALAH TEKSTIL 1 Softfile BingHuswatun HasanaNoch keine Bewertungen

- Energy Conservation Drives For Efficient Extraction and Utilization of Banana FibreDokument15 SeitenEnergy Conservation Drives For Efficient Extraction and Utilization of Banana FibregjhesraelNoch keine Bewertungen

- Drying of Banana Pseudo-Stem Fibers: Evaluation of Kinetic Models, Effective Diffusivity, Thermodynamic Properties, and Structural CharacterizationDokument3 SeitenDrying of Banana Pseudo-Stem Fibers: Evaluation of Kinetic Models, Effective Diffusivity, Thermodynamic Properties, and Structural CharacterizationSaritha SakthivelNoch keine Bewertungen

- Ojsadmin, Art-8Dokument4 SeitenOjsadmin, Art-8mikaela.pagatpatanNoch keine Bewertungen

- APA Style Citations2009Dokument37 SeitenAPA Style Citations2009Wazed AliNoch keine Bewertungen

- Extraction of Banana FiberDokument2 SeitenExtraction of Banana Fibermuthamil05Noch keine Bewertungen

- Rescap R1Dokument9 SeitenRescap R1SofiáNoch keine Bewertungen

- BANANA FIBREDokument18 SeitenBANANA FIBRERaghaNoch keine Bewertungen

- MethodologyDokument3 SeitenMethodologyKaye Ashley TandasNoch keine Bewertungen

- Banana Fiber Extraction MethodsDokument15 SeitenBanana Fiber Extraction MethodsRoem EsmernaNoch keine Bewertungen

- Unconventional Fibre PlantsDokument18 SeitenUnconventional Fibre PlantsRajendra Singh MeenaNoch keine Bewertungen

- Research PapaerDokument6 SeitenResearch PapaerChris TengNoch keine Bewertungen

- Banana Fibre - A Potential Source of Sustainable Textiles: K. Sangamithirai and N. VasugiDokument4 SeitenBanana Fibre - A Potential Source of Sustainable Textiles: K. Sangamithirai and N. VasugiShailendra RajanNoch keine Bewertungen

- Banana Fiber: Environmental Friendly Fabric: Uraiwan PitimaneeyakulDokument5 SeitenBanana Fiber: Environmental Friendly Fabric: Uraiwan Pitimaneeyakularif septaNoch keine Bewertungen

- A10160681S419Dokument3 SeitenA10160681S419Shahabas ShabuNoch keine Bewertungen

- Kapok Fiber InfoDokument3 SeitenKapok Fiber InfoErfan TanhaeiNoch keine Bewertungen

- Banana Fiber: A Natural and Eco-Friendly TextileDokument7 SeitenBanana Fiber: A Natural and Eco-Friendly TextileDevashish Bakshi100% (1)

- Tropical Natural Fibres and Their Properties: 2.1 BackgroundDokument25 SeitenTropical Natural Fibres and Their Properties: 2.1 BackgroundbatazivoNoch keine Bewertungen

- CAPSTONE For Grade 12Dokument16 SeitenCAPSTONE For Grade 12Rona RuizNoch keine Bewertungen

- Inter Disciplinary Minor: Creative TextilesDokument19 SeitenInter Disciplinary Minor: Creative TextilesPratik RajNoch keine Bewertungen

- Chapter IIDokument11 SeitenChapter IIBenjamin PariñasNoch keine Bewertungen

- Banana Fiber Environmental Friendly Fabric A Way To Health and WealthDokument15 SeitenBanana Fiber Environmental Friendly Fabric A Way To Health and WealthIJRASETPublicationsNoch keine Bewertungen

- Tahir Et Al, 2011Dokument22 SeitenTahir Et Al, 2011Diego Arcos100% (1)

- Banana Fiber: Extraction to WeavingDokument11 SeitenBanana Fiber: Extraction to WeavingkavineshpraneetaNoch keine Bewertungen

- 04 Banana FiberDokument8 Seiten04 Banana FiberfaithjudithmalabayabasNoch keine Bewertungen

- Bamboo FabricDokument12 SeitenBamboo FabricSweta Saha100% (1)

- Review About Bast Fiber and RettingDokument22 SeitenReview About Bast Fiber and RettingzubairNoch keine Bewertungen

- 956 Article Text 2459 1 10 20210615Dokument4 Seiten956 Article Text 2459 1 10 20210615VNoch keine Bewertungen

- Comparitive Study of Fabrics Produced From Bamboo and ModalDokument24 SeitenComparitive Study of Fabrics Produced From Bamboo and Modalshashank drNoch keine Bewertungen

- Study The Effect of Acids and Bases On The Tensile Strength of A FibreDokument15 SeitenStudy The Effect of Acids and Bases On The Tensile Strength of A FibreHiaderKhokhawala75% (67)

- Review of Banana Fiber Uses and Rope MakingDokument11 SeitenReview of Banana Fiber Uses and Rope Makingsingson singson0% (1)

- Banana Fiber: A Review: Neenu Poonia, Nisha Arya, and PoojaDokument1 SeiteBanana Fiber: A Review: Neenu Poonia, Nisha Arya, and PoojaWeimar ManiosNoch keine Bewertungen

- 13-Agb-Dr S K DeyDokument9 Seiten13-Agb-Dr S K DeyNurr Hayaatii YahyaNoch keine Bewertungen

- The Effectiveness of Banana in Making Paper Bag CHAPTER IIDokument4 SeitenThe Effectiveness of Banana in Making Paper Bag CHAPTER IIrazelfaith tois bautistaNoch keine Bewertungen

- Banana Fiber as Source of RopeDokument11 SeitenBanana Fiber as Source of RopeArjay Niño Agub LagguiNoch keine Bewertungen

- Production of Pulp 6Dokument17 SeitenProduction of Pulp 6Fábio CalliariNoch keine Bewertungen

- Banana plant paper manufacturing processDokument6 SeitenBanana plant paper manufacturing processXhanto FiliaNoch keine Bewertungen

- Charles Darwin Group 2 Pineapple Leaves and Banana Stems As Eco Waste Fabrics Casapao Fionna Lee A.Dokument32 SeitenCharles Darwin Group 2 Pineapple Leaves and Banana Stems As Eco Waste Fabrics Casapao Fionna Lee A.Yuika ʚíɞNoch keine Bewertungen

- Advanced Technologies For Textile and Fashion IndustryDokument5 SeitenAdvanced Technologies For Textile and Fashion Industryfamilia -gentileNoch keine Bewertungen

- Pineapple Fibre Thread As A Green and Innovative Instrument For Textile RestorationDokument6 SeitenPineapple Fibre Thread As A Green and Innovative Instrument For Textile RestorationkelseyNoch keine Bewertungen

- FibresDokument57 SeitenFibresvandana photostateNoch keine Bewertungen

- Sisal FiberDokument13 SeitenSisal FiberanadiNoch keine Bewertungen

- Production of Pulp 6 PDFDokument17 SeitenProduction of Pulp 6 PDFMahalakshmi H MNoch keine Bewertungen

- Fiber CropsDokument3 SeitenFiber Cropsmalath bash100% (1)

- 07 Chapter 2Dokument103 Seiten07 Chapter 2Mukesh Manwani100% (1)

- A Comprehensive Study On Jute Fiber PDFDokument51 SeitenA Comprehensive Study On Jute Fiber PDFRenato GuimaraesNoch keine Bewertungen

- Characteristics of Biomass Particle Board Using Commercial Adhesive and Cassava Root Paste As Partial BinderDokument22 SeitenCharacteristics of Biomass Particle Board Using Commercial Adhesive and Cassava Root Paste As Partial BinderALBIN LOYOLANoch keine Bewertungen

- Eco-Friendly Degumming of Natural Fibers For Textile Applications - A Comprehensive ReviewDokument11 SeitenEco-Friendly Degumming of Natural Fibers For Textile Applications - A Comprehensive ReviewWanna MsAbstractNoch keine Bewertungen

- To Find The Effect of Acids and Alkalies On Tensile Strength of Cotton, Silk and Wool Fibers.Dokument18 SeitenTo Find The Effect of Acids and Alkalies On Tensile Strength of Cotton, Silk and Wool Fibers.Yogesh SinghNoch keine Bewertungen

- Banana Fibre Extraction MethodsDokument13 SeitenBanana Fibre Extraction MethodsPranav100% (1)

- Topic 1:: Types of Textile Fibers - List of Textile Fibers by Its SourcesDokument9 SeitenTopic 1:: Types of Textile Fibers - List of Textile Fibers by Its SourcesKAWSER RAFINoch keine Bewertungen

- Viability of Pineapple Leaves As An Alternative Natural Fiber GeotextileDokument5 SeitenViability of Pineapple Leaves As An Alternative Natural Fiber GeotextileKyle SarmientoNoch keine Bewertungen

- Visual Diary GEODokument14 SeitenVisual Diary GEONAMITHA LOHIDAKSHANNoch keine Bewertungen

- Eco PaperDokument11 SeitenEco PaperBenjamin Pariñas100% (1)

- Fashion Material Management and QualityDokument24 SeitenFashion Material Management and Qualitypooja jaiswalNoch keine Bewertungen

- Significant of StudyDokument3 SeitenSignificant of StudyAmenodin PandacaNoch keine Bewertungen

- Characterization and Processing of Balete Vine 1Dokument12 SeitenCharacterization and Processing of Balete Vine 1Annalie LobianoNoch keine Bewertungen

- 1.nodes: Node Design Conditions/Parameters Drawings / ReferencesDokument3 Seiten1.nodes: Node Design Conditions/Parameters Drawings / ReferencesNKNoch keine Bewertungen

- PID Control ParametersDokument14 SeitenPID Control ParametersarnisiNoch keine Bewertungen

- RepressurizationDokument2 SeitenRepressurizationanithaNoch keine Bewertungen

- RepressurizationDokument2 SeitenRepressurizationanithaNoch keine Bewertungen

- Pid Loop SimulatorDokument9 SeitenPid Loop SimulatorNKNoch keine Bewertungen

- 11-8840 BLOWDOWN White Paper - FINAL PDFDokument13 Seiten11-8840 BLOWDOWN White Paper - FINAL PDFphantanthanhNoch keine Bewertungen

- CGDF FlowlineDokument2 SeitenCGDF FlowlineNKNoch keine Bewertungen

- Assessment Rubrics - Modelling Course - Project - May 2021 Semester S. NoDokument2 SeitenAssessment Rubrics - Modelling Course - Project - May 2021 Semester S. NoNKNoch keine Bewertungen

- Date Assumed To Be Infected Day From Symptoms Sleep On That NightDokument4 SeitenDate Assumed To Be Infected Day From Symptoms Sleep On That NightNKNoch keine Bewertungen

- Provisions ListDokument2 SeitenProvisions ListNKNoch keine Bewertungen

- HolduptimeDokument3 SeitenHolduptimeNKNoch keine Bewertungen

- Number SH Pe Addition Within 30: Use The Number Shapes To Work Out The Answers To Each AdditionDokument5 SeitenNumber SH Pe Addition Within 30: Use The Number Shapes To Work Out The Answers To Each AdditionNKNoch keine Bewertungen

- Holdup TimeDokument3 SeitenHoldup TimeNKNoch keine Bewertungen

- Flowline To CGDF: Size 14" Wall Thickness 12.7 MMDokument2 SeitenFlowline To CGDF: Size 14" Wall Thickness 12.7 MMNKNoch keine Bewertungen

- Estimate & Measure Object Lengths in CubesDokument1 SeiteEstimate & Measure Object Lengths in CubesNKNoch keine Bewertungen

- 505 Digital Control For Steam Turbines: Product Manual 26839V2 (Revision C, 3/2018)Dokument139 Seiten505 Digital Control For Steam Turbines: Product Manual 26839V2 (Revision C, 3/2018)Mourya DevuNoch keine Bewertungen

- Summary of Account: Invoice/Statement of Account Service Tax REG. NO:B16-1808-31031789Dokument4 SeitenSummary of Account: Invoice/Statement of Account Service Tax REG. NO:B16-1808-31031789NKNoch keine Bewertungen

- PID Control ParametersDokument14 SeitenPID Control ParametersarnisiNoch keine Bewertungen

- Summary of Account: Invoice/Statement of Account Service Tax REG. NO:B16-1808-31031789Dokument4 SeitenSummary of Account: Invoice/Statement of Account Service Tax REG. NO:B16-1808-31031789NKNoch keine Bewertungen

- Summary of Account: Invoice/Statement of Account Service Tax REG. NO:B16-1808-31031789Dokument4 SeitenSummary of Account: Invoice/Statement of Account Service Tax REG. NO:B16-1808-31031789NKNoch keine Bewertungen

- Summary of Account: Invoice/Statement of Account Service Tax REG. NO:B16-1808-31031789Dokument4 SeitenSummary of Account: Invoice/Statement of Account Service Tax REG. NO:B16-1808-31031789NKNoch keine Bewertungen

- PID Loop Tuning SpreadSheetDokument14 SeitenPID Loop Tuning SpreadSheetNKNoch keine Bewertungen

- Summary of Account: Invoice/Statement of Account Service Tax REG. NO:B16-1808-31031789Dokument4 SeitenSummary of Account: Invoice/Statement of Account Service Tax REG. NO:B16-1808-31031789NKNoch keine Bewertungen

- Calculating Dew Points from Gas CompositionDokument1 SeiteCalculating Dew Points from Gas CompositionNKNoch keine Bewertungen

- Analysis of A Flooded Heat Exchanger: LaboratoryDokument4 SeitenAnalysis of A Flooded Heat Exchanger: LaboratoryNKNoch keine Bewertungen

- Analysis of A Flooded Heat Exchanger: LaboratoryDokument4 SeitenAnalysis of A Flooded Heat Exchanger: LaboratoryNKNoch keine Bewertungen

- Topside - Cold Blowdown ChartDokument1 SeiteTopside - Cold Blowdown ChartNKNoch keine Bewertungen

- Blowdown Calculation Inventory-TopsideDokument16 SeitenBlowdown Calculation Inventory-TopsideNK100% (1)

- Subsea Flowline-Cold Blowdown ChartDokument3 SeitenSubsea Flowline-Cold Blowdown ChartNKNoch keine Bewertungen

- Blowdown Calculation Inventory - Subsea FlowlineDokument13 SeitenBlowdown Calculation Inventory - Subsea FlowlineNK0% (1)

- Kami Export - Physical and Chemical Changes WorksheetDokument2 SeitenKami Export - Physical and Chemical Changes WorksheetTheo MillsNoch keine Bewertungen

- Mixing Eductors Mixing EductorsDokument1 SeiteMixing Eductors Mixing Eductorsdetreomycyna100% (1)

- Competitive Solutions For Joining TechnologyDokument19 SeitenCompetitive Solutions For Joining Technologyjy12bhuNoch keine Bewertungen

- GroupIV WSDokument14 SeitenGroupIV WSMaryam RaiNoch keine Bewertungen

- Color Reactions Intact Protein (Gluten) Basic HydrolysisDokument6 SeitenColor Reactions Intact Protein (Gluten) Basic HydrolysisJennifer CamaNoch keine Bewertungen

- Ecoliser-100Kg: Features Specifications CustomizationDokument1 SeiteEcoliser-100Kg: Features Specifications CustomizationjohnNoch keine Bewertungen

- Piht0f402 Icmts Icad600tsDokument2 SeitenPiht0f402 Icmts Icad600tsamruta21Noch keine Bewertungen

- Training For Handling Hazardous MaterialsDokument24 SeitenTraining For Handling Hazardous Materialssyreiljude100% (3)

- The Effect of Different Fertilizers On Plant GrowthDokument2 SeitenThe Effect of Different Fertilizers On Plant GrowthVeerath தமிழன்0% (2)

- Peroxide Value Test ProcedureDokument2 SeitenPeroxide Value Test ProcedureWynona BasilioNoch keine Bewertungen

- IrelDokument29 SeitenIrelvarghis_k_thomasNoch keine Bewertungen

- Orthovoltage Vs MegavoltageDokument7 SeitenOrthovoltage Vs MegavoltageEmmanuel Cuevas MisNoch keine Bewertungen

- Ruchi Soya Project ReportDokument45 SeitenRuchi Soya Project ReportAnkita Toshniwal75% (4)

- Material Data Sheet: Urban@plastum - CZ WWW - Plastum.czDokument1 SeiteMaterial Data Sheet: Urban@plastum - CZ WWW - Plastum.czDavis GNoch keine Bewertungen

- Sieve Analysis and Density Test For AggregatesDokument11 SeitenSieve Analysis and Density Test For AggregatesgeorgeantoniosNoch keine Bewertungen

- E 155 - 00 - Rte1nq - PDFDokument4 SeitenE 155 - 00 - Rte1nq - PDFLeón SuárezNoch keine Bewertungen

- Extract Human DNA from Cheek Cells in 40 StepsDokument1 SeiteExtract Human DNA from Cheek Cells in 40 StepsJosaphat M. AnteNoch keine Bewertungen

- Reliance Water Controls Hoseguard Bib Tap WRAS 1999 HTAP218001 520-041-0003Dokument2 SeitenReliance Water Controls Hoseguard Bib Tap WRAS 1999 HTAP218001 520-041-0003AdvancedWaterCompanyNoch keine Bewertungen

- To Study The Quantity of Casein Present in Different Samples of MilkDokument12 SeitenTo Study The Quantity of Casein Present in Different Samples of MilkVartika MehrotraNoch keine Bewertungen

- BIO130 Sec2 - Lec1and2 - 1pptDokument38 SeitenBIO130 Sec2 - Lec1and2 - 1pptlemonpartymanNoch keine Bewertungen

- NDA Chemistry MCQs For PracticeDokument9 SeitenNDA Chemistry MCQs For Practicekumar HarshNoch keine Bewertungen

- Chapter 1 Intro To CellDokument6 SeitenChapter 1 Intro To CellrexartoozNoch keine Bewertungen

- Introduction To Cell BiologyDokument43 SeitenIntroduction To Cell BiologyEllemrac GageloniaNoch keine Bewertungen

- BSC2011 Animals Exam 2 ReviewDokument72 SeitenBSC2011 Animals Exam 2 ReviewDan TranNoch keine Bewertungen

- CHM131 MAC 2019 exam: Density, isotopes, balancing equationsDokument4 SeitenCHM131 MAC 2019 exam: Density, isotopes, balancing equationsijah rosmiNoch keine Bewertungen

- Draft PLG 4201 QaDokument2 SeitenDraft PLG 4201 QaJeremia Mb PakpahanNoch keine Bewertungen

- Aisi S7Dokument2 SeitenAisi S7123vigenNoch keine Bewertungen

- Corian in Healthcare enDokument8 SeitenCorian in Healthcare engoomeshwar9003Noch keine Bewertungen

- Lecture 5 - Industrial HygieneDokument50 SeitenLecture 5 - Industrial HygieneDivyashini MohanNoch keine Bewertungen