Beruflich Dokumente

Kultur Dokumente

Fora450 PDF

Hochgeladen von

Yosmer David BolañoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fora450 PDF

Hochgeladen von

Yosmer David BolañoCopyright:

Verfügbare Formate

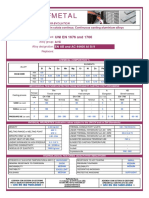

Industeel

FORA 450

A 450 HB wear resistant steel

FORA 450 is a martensitic water quenched steel, with a FORA 450 is easy to process, it has a good weldability

typical hardness of 450 HB constituting a real answer to and a good aptitude to bending, considering its high

abrasive wear. Its toughness, high hardness and yield mechanical properties.

strength confer it a very good resistance to plastic

deformations and to both sliding and impact wear. This steel is particularly suitable for applications in

quarries, construction industry, mines, cement plants, iron

FORA 450 exhibits a wear resistance typically equal to and steel industry, etc

4 times and yield strength 3 times higher than those of a

S355. Use of FORA 450 induces a strong improvement in FORA 450 is a grade specially adapted of truck bodies

term of lifetime and lightening of equipment through a manufacturing.

thickness reduction.

Standard

FORA 450 INDUSTEEL Specification

Chemical analysis - % weight C. Equivalent

C Mn P S Cr Ni Mo B M n C r + M o + V N i+ C u

C eq = C + + +

6 5 15

.20 1.5 .02 .003 1.0 .7 .2 .003

Thickness range - mm () C.Eq

Guaranteed maximum values 4/15 (.16/.59) .50

15,01/50 (.59/2) .59

Mechanical properties

Hardness Y.S. 0.2 UTS El 5.65s KCVL

% -40C (-40F)

450 HB 1200 MPa 1400 MPa 10 30 J

47.5 HRC 174 KSI 203 KSI 10 22 ft.lbs

Typical values

Guaranteed hardness in delivery condition : 410 / 500 HB (44 /51.5 HRC)

FORA 450 -10.06.2011 issue - page 1

Wear resistant properties Processing

Cutting

Low energy impact - Dry media

FORA 450 can be cut by all classical thermal processes

15 (oxygen, plasma, and laser).

FORA 450 Plates 4 to 10 mm thick do not require any preheating, as

Lifetime 10 far as processing is done at a temperature higher than

FORA 400

10C (plate temperature). If steel temperature is below

10C (50F), a preheating is necessary to avoid cracking.

5 S355

Thickness

4-40mm

Hardness Cutting (.16-1.6)

temperature

...

..

g...

Cu e

, Zn

Kaoite

lin

psu s

m

Gy ou

ke.

Fe , x i t

Minerals

e

lo m

zit

,A

e

u

Co

r

Ba 10C (50F) No pre-heating

art

Au

lc a

Do

Qu

Ca

< 10C (.) Preheating 100-150C (212-302F)

Water jet cuting can also be used

Medium energy impact - Wet media

Machining

15

Drilling and milling should be performed with super-

FORA 450

Lifetime

carburized cobalt high-speed steel type HSSCO, using

10 FORA 400 wherever possible an oil lubricant. However, classical

high-speed steels can be used. The typical cutting

5 parameters are :

S355

Hardness

...

..

g...

Cu e

, Zn

Kaoite

lin

psu s

m

Gyreou

ke.

Fe, xit

e

Minerals

lo m

zit

,A

u

Co

= 5mm 10mm 20mm 30mm

Ba

art

Au

lc a

Do

(.20) (.40) (.80) (1.18)

Qu

Ca

Drilling

Cutting m/min 6-8 6-8 6-8 6-8

speed ft/min 20 - 26 20 - 26 20 - 26 20 - 26

Rotational rev/min 380 - 500 190 - 250 90 - 120 60 - 80

speed

High energy impact

Feed mm/rev 0.07 0.1 0.2 0.3

15 FORA 450

Lifetime

= 10mm 20mm 30mm

Tapping

10 FORA 400 (.40) (0.80) (1.18)

m/min 1-3 1-3 13

Cutting speed ft/min 3.3 - 10 3.3 - 10 3.3 - 10

5 S355 Rotational speed rev/min 30 - 95 15 - 45 10 - 30

Hardness

...

..

g...

Cu e

, Zn

Kaoite

lin

psu s

m

Gyreou

ke.

Fe , x i t

Minerals

e

lo m

zit

,A

u

Co

Ba

art

Au

lc a

Do

Depth Cutting speed Feed

Qu

Ca

Milling mm () (m/min) (mm/tooth)

Wear tests data HSSCO 1 (.04) 100-120 (3.9-4.7) 0.08

AR 12.0.5.5 (T15) 4 (.16) 80-110 (3.1-4.3) 0.12

1 to 5 70 to 200

F40M .04 to .20 2.7 to 7.9 .15 to .35

FORA 450 - 10.06.2011 issue - page 2

Bending Welding consumable

Due to its good refining (low sulfur and phosphorus All products in accordance with following standards are

content), FORA 450 is easy to cold bending provided that acceptable :

Submerged

following conditions are respected : Flux core wire

Stick Electrodes MIG-MAG arc welding

gas protected

Dressing (or grinding) of the ridges caused by Wire-flux

AFNOR

gas-cutting to limit hardened zones, NF A 81-322

Sufficiently powerful equipment, NF A81-340

EY50 1NiMo Bxxx1xTBH

FP/x xx/xx xB xSA31

Respect of minimum forming radius. 47 05 04

ASW

A5-28

A5-5-81 E 70xx A5-29 E 7xT5-x A5-23 F7P4-Exxx-A2

For plates below 20 mm (0.8) thickness, forming ER 70 S-x

conditions are summarized in following table ; beyond DIN

20 mm (0.8"), consult us. DIN 1913 E51 55 BX

Perpendicular to Parallel to

th = thickness the rolling direction the rolling direction The following standards are met by following products on

the market :

Bending internal radius Stick electrode MIG-MAG FCAW SAW Wire SAW Flux

Ri (mini) 4 x th 4 x th

BHLER Fox Ev 50 EM K7 AM S3

Die opening V (mini) 14 x th 14 x th COMMERCY CY2051 SG 6 CY 10 SP 1000

ESAB OK 48.04 OK 12.51 OK 15.00 OK 12.32 OK 10.62

Whitin these allowable

bending parameters, the v KLCKNER FIRMA 5520 R VDG 15/60 EWB1-MF VDG-S3

Th

LINCOLN CONARC 49C LNM 27 MC 710 H L60 880M

force required to form a MESSER GRICON 515S UP S2 Ni LW 330

plate is function of the Ri METRODE MET-MILD MP51 ER 70-S6

bent length, the metal OERLIKON TENACITO 38R FLUXOFIL 31 SOUDOR SD3 OP 121TT

thickness, die opening, die SAF SAFDRY NF58 NIC 70S SAFDUAL 200 AS 36 AS 589

THYSSEN B120 K52 S2 UV 421TT

form (V or U), punch form

UTP 613 KB

etc

For truck bodies, this list is valid for classical welded structures without

Bending angle = 90

any special stress applied. However, it is recommended to check with

The following table shows the each supplier of welding consumable.

bending forces, for the minimum die opening (V=14 th),

required for V bending plates for for 1m bent. Pre-Post heating conditions

Combined thickness

Bending force th In the th. range 4 to 10mm(.15 to .39), as far as welding

Thickness required per

mm () meterof bend * sequences are optimized to avoid introduction of high wel-

Ton/m ding stress, no preheating shoud be applied for FORA 450.

5 (.20) 65 L

Case of combined thickness : FORA 450 can be

10 (.40) 125

welded without any crack risk and without preheating up

* 10%

to a combined plate thickness of 50 mm (2").

FORA 450 steel is unsuitable for hot forming at a

temperature higher than 200C (392F). th1 th2

comb.th = th1 + th2

th'2 th'3

Welding

Thanks to its chemical analysis with a low carbon

content, FORA 450 shows very good welding aptitude. It

can be welded in easy conditions in total safety.

th'1

Weld preparation Comb.th = 2xth'1 + th'2+th'3

Weld surfaces must be dry, clean and superficially ground

in order to eliminate any rust, scale, grease or paint For higher thicknesses, the following conditions are

traces as well as any gas-cutting ridges. recommended :

Energy 30. 40 50 60 70 80 90 100 110 mm

Welding process (kJ/cm) 1.18 1.57 1.96 2.36 2.75 3.14 3.54 3.93 4.33

Any conventional fusion welding method can be used, 15

GMAW

such as submerged arc welding (SAW), manual metal arc 30

welding (SMAW), flux core wire arc welding (FCAW), SMAW

10

MIG, MAG (GMAW) and TIG (GTAW). 20

Depending on thickness, heat input should be controlled SAW

20

within a range 5 to 15 KJ/cm. 30

Heat input should be limited to 10-30 kJ/cm with Without pre-heating With slight pre-heating With pre-post heating

maximum interpass temperature between preheating TPlate >5C/40F 85C / 175F 130C / 265F

temperature and 200/220C (390-430F) maxi.

FORA 450 - 10.06.2011 issue - page 3

Sizes - Tolerances

FORA 450 is available in a large dimensional programme :

Thickness Coils Quarto Typical lengths

Flatness

mm/m mm ft

width width Tol./th width width Tol./th

mm inch (*) 6 000 19.68

mm inches (mm) mm inches (mm)

8 000 26.24

4-6 3/16 -.24 1200 47 0.25 1200-2000 47-79 0.6 5

10 000 32.80

6-9 .24 - .35 1200-2500 47-98.4 0.6 5 12 000 39.37

9-12 .35 - .47 1200-3100 47-122 0.6 5

12-25 .47 - .98 1200-3800 47-149.6 0.6 5

25-50 .98 - 1.97 1200-3680 47-144 0.7 5

* .20 in every 40

Plates outside this dimensional programme can be available after agreement.

Please ask us.

Applications

Truck bodies

Quarries, Construction, Earth moving

For any information Skimmers, crushers, screens, bunkers, bulldozers...

Industeel France Cement plants

Le Creusot Plant

56 rue Clemenceau Buckets, crushers, bunkers...

F-71202 Le Creusot Cedex

Mines, coal mines

Tel +33 3 85 80 58 32 (Sales)

+33 3 85 80 57 29 (Mkt)

Excavator, winding and discharging machines,

Fax +33 3 85 80 55 00 conveyors...

Iron and steel industry

Industeel Belgium Bunkers, various casing, guide and shifting plates...

266 rue de Chatelet

B-6030 Marchienne au Pont

Tel +32 71 44 18 26 (Sales)

Fax +32 71 44 19 50

www.industeel.info

www.arcelormittal.com

Nota

Technical data and information are to the best of our knowledge at the time of printing. However, they may be

subject to some slight variations due to our ongoing research programme on wear resistant grades. Therefore,

we suggest that information be verified at time of enquiry or order.

Furthermore, in service, real conditions are specific for each application. The data presented here are only for the

purpose of description, and considered as guarantees when written formal approval has been

delivered by our company.

FORA 450 -10.06.2011 issue - page 4

Das könnte Ihnen auch gefallen

- Analytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryVon EverandAnalytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryNoch keine Bewertungen

- High Tensile: Voestalpine High Performance Metals (Australia) Pty LTDDokument5 SeitenHigh Tensile: Voestalpine High Performance Metals (Australia) Pty LTDSinan YıldızNoch keine Bewertungen

- Ador Welding Cromoten D For c5 & f5 WeldingDokument1 SeiteAdor Welding Cromoten D For c5 & f5 WeldingShar MathewNoch keine Bewertungen

- Aisi E50100, E52100: 154/amoyDokument6 SeitenAisi E50100, E52100: 154/amoyahmad hafizNoch keine Bewertungen

- 1 Ceramic Fiber BoardsDokument2 Seiten1 Ceramic Fiber BoardsMahesh MishraNoch keine Bewertungen

- Invalved Valve Trim Materials Standard Trim ConfigurationsDokument1 SeiteInvalved Valve Trim Materials Standard Trim ConfigurationsmanishkapriNoch keine Bewertungen

- Fora 400Dokument4 SeitenFora 400PeterWayNoch keine Bewertungen

- Trim Number Chart API ValveDokument2 SeitenTrim Number Chart API ValveVelu .cNoch keine Bewertungen

- Properties of Ss410Dokument5 SeitenProperties of Ss410gregkilatonNoch keine Bewertungen

- 02 Hard and Soft Zones in Hot Formed Parts Jan 15 2013Dokument37 Seiten02 Hard and Soft Zones in Hot Formed Parts Jan 15 2013luan weiNoch keine Bewertungen

- En 44100Dokument2 SeitenEn 44100hiren_mistry55Noch keine Bewertungen

- BS en 1706 - En44100 PDFDokument2 SeitenBS en 1706 - En44100 PDFDhamodaran RNoch keine Bewertungen

- TMCP Steel Plate: Structural Steel For BuildingsDokument8 SeitenTMCP Steel Plate: Structural Steel For BuildingsJOAO ELOINoch keine Bewertungen

- Kme STOL76 C19010 enDokument1 SeiteKme STOL76 C19010 enMattia Terri TerrandoNoch keine Bewertungen

- Adi 4 (2021 - 03 - 22 20 - 48 - 50 Utc)Dokument2 SeitenAdi 4 (2021 - 03 - 22 20 - 48 - 50 Utc)Milton Pereira JúniorNoch keine Bewertungen

- Stainless Steel Grade AISI 430/430FDokument2 SeitenStainless Steel Grade AISI 430/430Fabhijit.ghotane100% (1)

- Cat LoaDokument56 SeitenCat LoaHugo C.P.Noch keine Bewertungen

- The Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedDokument1 SeiteThe Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedRavindra ErabattiNoch keine Bewertungen

- Böhler Fox CN 13/4 Supra: Classifi CationsDokument1 SeiteBöhler Fox CN 13/4 Supra: Classifi CationsBranko FerenčakNoch keine Bewertungen

- Formalloy 500 Dsheet - FINAL - 091712Dokument2 SeitenFormalloy 500 Dsheet - FINAL - 091712Agustin ChavezNoch keine Bewertungen

- High Speed Steel Round BarDokument4 SeitenHigh Speed Steel Round BarMANJEET KUMARNoch keine Bewertungen

- Betachrome 17cr Welding ElectrodeDokument1 SeiteBetachrome 17cr Welding ElectrodeSatyendra SinghNoch keine Bewertungen

- Fora 450Dokument4 SeitenFora 450PeterWayNoch keine Bewertungen

- Tata Steel - AR400 & 450Dokument2 SeitenTata Steel - AR400 & 450Gabriel CamargoNoch keine Bewertungen

- Precipitation Hardening Stainless Steel: Voestalpine High Performance Metals (Australia) Pty LTDDokument3 SeitenPrecipitation Hardening Stainless Steel: Voestalpine High Performance Metals (Australia) Pty LTDAtlantic Heat Treat ShopNoch keine Bewertungen

- 1415712636wpdm - Stainless Steel Grade AISI 409Dokument2 Seiten1415712636wpdm - Stainless Steel Grade AISI 409Anurag SarkarNoch keine Bewertungen

- PSP 108 Alloy409Dokument2 SeitenPSP 108 Alloy409Alexis A. Illarramendi G.Noch keine Bewertungen

- 410 Tech DataDokument1 Seite410 Tech DataAbraham FernandezNoch keine Bewertungen

- 410 Spec SheetDokument4 Seiten410 Spec SheetDavid CabreraNoch keine Bewertungen

- AISI 440 Martensit PDFDokument4 SeitenAISI 440 Martensit PDFJimmyVargasNoch keine Bewertungen

- Interlloy Grade 1045 Carbon Steel BarDokument3 SeitenInterlloy Grade 1045 Carbon Steel BarPRASHANT KANTENoch keine Bewertungen

- Carbo 4370 Mpr-E307Dokument1 SeiteCarbo 4370 Mpr-E307ali torabiNoch keine Bewertungen

- Chap 11Dokument27 SeitenChap 11Qwe QNoch keine Bewertungen

- FPO22001 ASME Filer Metal Data SheetDokument5 SeitenFPO22001 ASME Filer Metal Data Sheetyousab creator2Noch keine Bewertungen

- Physical Properties Classification: The Siam Refractory Industry Co., LTDDokument23 SeitenPhysical Properties Classification: The Siam Refractory Industry Co., LTDManekGorisNoch keine Bewertungen

- D2 1.2379 SKD11 Flat BarDokument4 SeitenD2 1.2379 SKD11 Flat BarMANJEET KUMARNoch keine Bewertungen

- sdg4 - 9 - STAINLESS STEELDokument3 Seitensdg4 - 9 - STAINLESS STEELJian Ming WongNoch keine Bewertungen

- Alloy 410s Spec SheetDokument2 SeitenAlloy 410s Spec SheetALONSO GOMEZNoch keine Bewertungen

- Thermanit 17-06 (Boehler)Dokument1 SeiteThermanit 17-06 (Boehler)queno1Noch keine Bewertungen

- Raffmetal: UNI EN 1676 and 1706Dokument2 SeitenRaffmetal: UNI EN 1676 and 1706Hareth MRAIDINoch keine Bewertungen

- Alloy 276 Spec SheetDokument3 SeitenAlloy 276 Spec SheetJAYA BHARATHA REDDYNoch keine Bewertungen

- 17-7 PH Stainless SteelDokument2 Seiten17-7 PH Stainless Steelzain malikNoch keine Bewertungen

- High Tensile Steel: Voestalpine High Performance Metals (Australia) Pty LTDDokument3 SeitenHigh Tensile Steel: Voestalpine High Performance Metals (Australia) Pty LTDJoko tri SantosoNoch keine Bewertungen

- 15B21H, 15B21RHDokument4 Seiten15B21H, 15B21RHGil CabreraNoch keine Bewertungen

- L1 7723 en BOEHLER FOX FF 2SF7A05E 3383108 ENDokument1 SeiteL1 7723 en BOEHLER FOX FF 2SF7A05E 3383108 ENkamals55Noch keine Bewertungen

- Wall Colmonoy Surfacing Alloys Selector ChartDokument3 SeitenWall Colmonoy Surfacing Alloys Selector ChartAjimKe'enNoch keine Bewertungen

- Böhler Fox CM 5 KB: Classifi CationsDokument1 SeiteBöhler Fox CM 5 KB: Classifi CationsBranko FerenčakNoch keine Bewertungen

- Mds SM13CRM 110 en PDFDokument6 SeitenMds SM13CRM 110 en PDFPedroSoucasauxNoch keine Bewertungen

- Supercito (E 42 5 B 32 h5)Dokument1 SeiteSupercito (E 42 5 B 32 h5)brunizzaNoch keine Bewertungen

- 055 PDFDokument1 Seite055 PDFantonio111aNoch keine Bewertungen

- Wire Data Sheet - Elgiloy PDFDokument1 SeiteWire Data Sheet - Elgiloy PDFvprakshaindiaNoch keine Bewertungen

- Issues To Address... : Chapter 11 - 1Dokument20 SeitenIssues To Address... : Chapter 11 - 1Rowen PratherNoch keine Bewertungen

- Alloy 6063 Rev2012Dokument2 SeitenAlloy 6063 Rev2012Hilbert FloresNoch keine Bewertungen

- c544 Phosphor BronzeDokument2 Seitenc544 Phosphor BronzesleonNoch keine Bewertungen

- Bohler Fox N Ev 50-1Dokument1 SeiteBohler Fox N Ev 50-1Kara WhiteNoch keine Bewertungen

- Bronze c54400 SpecificationsDokument3 SeitenBronze c54400 SpecificationsRam Parimalam100% (1)

- Electrode Booklet F Web 101Dokument1 SeiteElectrode Booklet F Web 101satnamNoch keine Bewertungen

- 94B15, 94B15HDokument2 Seiten94B15, 94B15HGil CabreraNoch keine Bewertungen

- 17 4 PHDokument2 Seiten17 4 PHParag NaikNoch keine Bewertungen

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDokument2 SeitenDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelHugo RodriguezNoch keine Bewertungen

- Branson Plastic JoiningDokument8 SeitenBranson Plastic Joiningapbeese3178Noch keine Bewertungen

- Rehau - PPR Pipe and FittingDokument12 SeitenRehau - PPR Pipe and FittingharefiezNoch keine Bewertungen

- Astm A 928 Dss Pipe EfwDokument6 SeitenAstm A 928 Dss Pipe Efwarifin rizalNoch keine Bewertungen

- 7th Congr Mat TestDokument6 Seiten7th Congr Mat TestAlireza KhodabandehNoch keine Bewertungen

- Spiro General Brochure enDokument28 SeitenSpiro General Brochure enLuis NovaisNoch keine Bewertungen

- Estimation (Steel Work)Dokument21 SeitenEstimation (Steel Work)Poorti JainNoch keine Bewertungen

- OILCO Loading Arm Catalog No 408Dokument16 SeitenOILCO Loading Arm Catalog No 408ccostykNoch keine Bewertungen

- Proposed Damansara Shah Alam Elevated Expressway (Dash)Dokument8 SeitenProposed Damansara Shah Alam Elevated Expressway (Dash)Nurulhidayah Abdul JalilNoch keine Bewertungen

- Chapter-1: Welding RobotsDokument22 SeitenChapter-1: Welding RobotsPranayNoch keine Bewertungen

- Done - SSAB - 64 TechSupport Static Strength in Joints of Strenx Grades en PDFDokument5 SeitenDone - SSAB - 64 TechSupport Static Strength in Joints of Strenx Grades en PDFMONoch keine Bewertungen

- Strain Gauge ReportDokument34 SeitenStrain Gauge ReportJay PatelNoch keine Bewertungen

- MS of Earth Mat Installation - 12-10-2018-SVH-RSDokument25 SeitenMS of Earth Mat Installation - 12-10-2018-SVH-RSPankaj Upadhyay100% (1)

- Technical English in MechanicalDokument60 SeitenTechnical English in MechanicalTuran ÇetinNoch keine Bewertungen

- A656 GR 80 Brochure 06-26-08Dokument2 SeitenA656 GR 80 Brochure 06-26-08OsmanNoch keine Bewertungen

- Draft For Public Comment: Latest Date For Receipt of Comments: 30 April 2013Dokument237 SeitenDraft For Public Comment: Latest Date For Receipt of Comments: 30 April 2013mordidomi0% (1)

- 0 - Curriculum Vitae - Zakarya Hiba-2014Dokument8 Seiten0 - Curriculum Vitae - Zakarya Hiba-2014Ahmed IraqiabdelnabyNoch keine Bewertungen

- Automatic Object Oriented Coding Facility For Product Life Cycle Management of Discrete ProductsDokument26 SeitenAutomatic Object Oriented Coding Facility For Product Life Cycle Management of Discrete ProductsUsman AhmadNoch keine Bewertungen

- Material Data Sheets For Piping: 1 ForewordDokument50 SeitenMaterial Data Sheets For Piping: 1 ForewordMuhammad Ramadhan Ismukada SyahrifNoch keine Bewertungen

- High-Strength and Ultra-High-Strength Thermomechanically Rolled Fine-Grained SteelsDokument16 SeitenHigh-Strength and Ultra-High-Strength Thermomechanically Rolled Fine-Grained SteelsInaamNoch keine Bewertungen

- Keedex Price Book - 2015Dokument12 SeitenKeedex Price Book - 2015Security Lock DistributorsNoch keine Bewertungen

- 2nd Summative TestDokument8 Seiten2nd Summative TestSally Java Senayo100% (3)

- Astm 02Dokument623 SeitenAstm 02Bilel RebaiNoch keine Bewertungen

- Install of Mech Equip ProcesosDokument15 SeitenInstall of Mech Equip ProcesosMiguel A. CondeNoch keine Bewertungen

- EN 287-1-2011-Otkl (Grupi Celici)Dokument1 SeiteEN 287-1-2011-Otkl (Grupi Celici)Vasko MandilNoch keine Bewertungen

- RT Film IntepretationDokument44 SeitenRT Film Intepretationawong_911374100% (3)

- Tig Torç Kataloğu PDFDokument40 SeitenTig Torç Kataloğu PDFwenigmaNoch keine Bewertungen

- WeldingDokument27 SeitenWeldingsuman kumarNoch keine Bewertungen

- Shell DEP 44.24.32.30-Gen.Dokument29 SeitenShell DEP 44.24.32.30-Gen.Manoj ChitreNoch keine Bewertungen

- Flow Chart of Pouch, Cylinder and Coin Cell by MTI's Battery EquipmentDokument6 SeitenFlow Chart of Pouch, Cylinder and Coin Cell by MTI's Battery EquipmenthcaNoch keine Bewertungen

- EN 13445-2 +A2 (2012) Unfired Pressure Vessels, Part 2 MaterialsDokument86 SeitenEN 13445-2 +A2 (2012) Unfired Pressure Vessels, Part 2 Materials김창배Noch keine Bewertungen