Beruflich Dokumente

Kultur Dokumente

03 Carvalho Et Al

Hochgeladen von

Irshad AliCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

03 Carvalho Et Al

Hochgeladen von

Irshad AliCopyright:

Verfügbare Formate

Jos Dinis-Carvalho

Associate Professor

Department of Productions and Systems

Engineering School, University of Minho,

Portugal

Process Mapping Improvement:

Lus F. Ferrete

Extending Value Stream Maps with

MSc student

Department of Productions and Systems

Waste Identification Diagrams

Engineering School, University of Minho,

Portugal Value Stream Mapping (VSM) is likely the most common tool to

represent and analyse the value stream of product families. However, it

Rui M. Sousa has several limitations, recognized by professionals and academics,

Assistant Professor

Department of Productions and Systems

namely in terms of identification of certain types of waste (activities

Engineering School University of Minho, without added value). The purpose of this paper is to present a VSM

Portugal extension based on elements coming from a new type of representation

and analysis tool called Waste Identification Diagram (WID), which is

Hyggor S. Medeiros

being developed at the Production and Systems Department of University

PhD student

Department of Productions and Systems of Minho. WID is able to represent, in an effective manner, information

Engineering School, University of Minho, about several aspects, including wastes related with production and

Portugal

people, layout, available capacity and even economic indicators. The

Antnio J. Magalhes inclusion of WID elements within traditional VSM was successfully

MSc student

achieved, resulting in a VSM extension which is more effective than the

Department of Productions and Systems traditional VSM, not only in the information provided but also in terms of

Engineering School, University of Minho, interpretation easiness.

Portugal

Joo P. Ferreira Keywords: Value Stream Mapping; Waste Identification Diagrams;

MSc student Visual Effectiveness; Economic indicators; Lean Manufacturing.

Department of Productions and Systems

Engineering School, University of Minho,

Portugal

1. INTRODUCTION throughput time, etc.

Several tools are available to map processes, e.g.

In general terms, the clear understanding of the business Flowcharts, SIPOC diagrams (Suppliers, Inputs,

and production processes is mandatory for any company Process, Outputs, Customers), BPML diagrams

wishing to diagnose problems and improve (Business Process Modelling Language), VSM (Value

performance. Inherent to that requirement, the process Stream Mapping) and WID (Waste Identification

mapping tools assume thus a quite important role by Diagrams), but VSM is the most popular. However,

providing a representation of processes, which should VSM has some drawbacks (section 2.1) and thus, to

include relevant pieces of information. The process overcome these drawbacks, this work proposes a VSM

mapping technique was initially developed by General extension using some elements of the WID diagram that

Electric to help re-engineering teams to achieve an is being developed at the Production and Systems

effective understanding of the processes, in the context Department of University of Minho. More specifically,

of the companys work out and best practices two variants of the VSM extension will be presented: (i)

strategy. In fact, the incomplete knowledge about the the designated VSM+WID (section 3.1) and (ii) the

processes is quite frequent, hindering, or even VSM+WIDe (section 3.2). The second one includes

preventing, the development and implementation of the representation of the economic impact, measured in

improvement actions. An adequate process mapping monetary units (MU), of crucial aspects as work-in-

should provide companies with important information process (WIP), workforce occupation and transportation

revealing not only their strengths but mainly their effort, while the first one uses the traditional measuring

weaknesses, namely the wastes. In the lean units (quantity, % and Kg*m).

manufacturing context are identified seven types of As contribution to the validation of the developed

waste: (i) overproduction, (ii) transport (materials), (iii) work, the new approach was applied to the production

movement (persons), (iv) defects, (v) inventory, (vi) process of soda concentrate of a Brazilian company

waiting and (vii) over-processing [1]. Other relevant from the beverage sector. A list of criteria is used to

aspects of production processes should also be included assess the potential gains achieved by this extension of

in the processes mapping, e.g. productivity, efficiency, VSM based on WID and WIDe.

The paper is organized is 4 sections. After the

introduction, section 2 presents a brief literature review

Received: September 2015, Accepted: November 2015 about VSM, WID and the fundamentals of the WID-

Correspondence to: Prof. Rui M. Sousa economic (WIDe). Section 3 introduces the two variants

Departamento de Produo e Sistemas, of the VSM extension based on WID and WIDe and,

Campus de Azurm, 4800-058 Guimares, Portugal

rms@dps.uminho.pt

doi:10.5937/fmet1504287D

Faculty of Mechanical Engineering, Belgrade. All rights reserved FME Transactions (2015) 43, 287-294 287

using concrete examples, analyses their effectiveness. innovative characteristic of WID is the use of the

Finally, on section 4 the conclusions are outlined. physical dimensions of its symbols to transmit, in an

immediate an effective way, important information

2. PROCESS MAPPING TOOLS about the production process (e.g. WIP, transportation

effort, setup time and idle time).

This section briefly presents the VSM (section 2.1) and The WID is a network of tri-dimensional blocks and bi-

WID (2.2) as well as the theoretical foundation of WIDe dimensional arrows and there are two types of blocks: the

(section 2.3). Regarding VSM and WID, the respective basic version and the advanced version; the last includes

strengths and weaknesses are reported as they will OEE (Overall Equipment Effectiveness) information. In the

provide part of the context for the proposed extensions basic version (Figure 1), each block represents a process, or

of VSM based on some WID features (section 3). a group of processes, and its dimensions are used to

represent: (i) Takt time (TT) and Cycle time (TC), (ii) Work-

2.1 Value Stream Mapping in-process (WIP) and (iii) Setup time (TS).

The Value Stream Mapping (VSM) was developed

based on the denominated Materials and Information Idle time

Flow Diagram created by Toyota, and is used to map

the value chain of a given product (or family of

TT=120Sec

products), from the suppliers to the client [3]. In general

TC=80Sec

terms, VSM represents the flows of materials and

TS=2min

WS_1

information, allows the quantification of added-

value/no added value ratio and the identification of

some types of wastes (overproduction and inventory) as WIP=50parts

well as improvement opportunities. The VSM

methodology involves four steps: (i) selection of the Figure 1. WID symbol: process block (basic version)

product family (eventually using Pareto analysis), (ii)

drawing the current state VSM, (iii) drawing the future In the advanced version (Figure 2), each block includes

state VSM and (iv) definition and implementation of the OEE information related to availability, performance (or

necessary improvement actions. speed) and quality losses. STT and UTT are the standard takt

Despite the referred characteristics, VSM has some time and useful takt time, respectively.

limitations as reported by several authors [4], [5], [6],

[7], [8], [9] and [10]. More specifically, [10] points out:

(i) inability to map different manufacturing routes, (ii)

absence of economic indicators, (iii) absence of layout

representation and (iv) does not reflect the bill-of-

materials (BOM). According to [11] and [12] the

transportation waste is not quantified and [11]

additionally stated that waiting, over-processing and

motion wastes are difficult to observe, remaining

virtually hidden on the VSM. Lastly, VSM does not

represent the wastes related to people.

A recent work involving a VSM extension can be

found in [13], where it is described an extension of

value stream mapping through waste identification Figure 2. WID symbol: process block (advanced version)

beyond the clients perspective. However, this approach The arrows (Figure 3) represent the transportation of

was specifically created to analyse software materials between processes (blocks) and its width is

development processes being thus applicable only in proportional to the transportation effort ET (e.g. measured in

that context. In [14] it is described a new framework to Kg*m or part*m). A circular graph depicts the workforce

apply VSM to production scenarios involving families occupation (Figure 3).

of products with multiple routes and complex bill-of-

materials. This framework does not improve the waste 4%

identification capabilities of the traditional VSM. 8% OpAV

10% Waiting

40%

2.2 Waste Identification Diagram 10m*part

Transport

8% Motion

The Waste Identification Diagram (WID) is a Rework

representation tool for production units, specifically 30%

Other

developed to overcome some of the VSM limitations,

namely in terms of wastes representation [2]. In fact,

Figure 3. WID symbols: Transportation effort arrow and

WID is able to represent wastes related to materials

workforce occupation circular graph

(inventory, overproduction, transport and defects) as

well as wastes related to people (motion, transport, The data on the circular graph is based on a number

waiting and over-processing). Additionally, an of samples (observations in the shop-floor) conducted at

288 VOL. 43, No 4, 2015 FME Transactions

several moments of the working day and using a pre- that the market consumes monetary units of the

defined path, accordingly to the WID methodology production process in order to fulfil the demand for

described in [2]. manufacturing one unit of product. TTe is given by:

By observing the dimensions of the blocks on the T

examples of Figure 1 and Figure 2, it is immediately TTe = T . (1)

CRM

perceived that workstation 2 (WS_2) has much more WIP

than workstation 1 (WS_1). It is also evident the larger where:

unused capacity of WS_2. Furthermore, the larger frontal TT takt time,

area of WS_2 block indicates a larger throughput time CRM raw materials cost (per product).

(according to Littles law [15]). Thus, even without reading

the values on WID, it is possible to visually obtain important However, notice that each workstation has its own TTe

pieces of information just by looking to the physical depending on the cost of the product (raw materials)

dimensions of the WID blocks. In fact, that also happens after being processed by that workstation, i.e.:

with the transportation arrow (Figure 3) the thicker the TT

TTe,i = . (2)

arrow, the higher the transportation effort. In a lean CRMout ,i

management context, companies should reduce the where:

transportation waste, making this arrow as thinnest as

possible. TT takt time,

Additional features of WID include the ability to CRMout,i raw materials cost (workstation i exit),

represent the layout of the production unit and, as i workstation identification number.

already referred, the inclusion of OEE information [16]. The concept of economic takt time (TTe) presents

OEE is an indicator of the effectiveness of equipment another way of seeing the markets demand, proposing

utilization. In fact, in practice, and due to different types the use of the cost of the raw material as a base for other

of losses, there is no equipment that runs always at its interpretations (e.g. involving workstations and

required rate and makes only good products. So, the transportation) within the production unit. This proposal

identification of the causes of these losses is mandatory is aligned with the Goldratts perspective that differs

to improve the equipments OEE. Accordingly, there from the traditional approaches by considering that, in

have been identified three main losses: availability, economic terms, the inventory corresponds to all the

performance and quality losses; which were further money that systems invests in purchasing things that it

subdivided and denominated as the six big losses to intends to sell it excludes the added value of labour

determine which area should be improved. In the and overhead [19]. Accordingly, for a given

availability loss are involved planned downtimes and workstation i, while TC represents the cycle time in

breakdowns, in performance loss are included minor terms of a product unit, the TCe represents the cycle time

stops and speed losses and quality loss include the in terms of a monetary unit. In other words, TCe,i shows

defects during start-up and steady production. The WID the time necessary to workstation i process one

blocks show these OEE components by dividing the monetary unit and is given by:

blocks using different colours for: planned and

TC ,i

unplanned stops (availability), speed losses TCe,i = . (3)

(performance) and quality losses (Figure 2). CRMout ,i

The most recognized WID limitation is the inability where:

to represent the information flow, which is one of the

advantages of VSM. TC,i cycle time (workstation i),

CRMout,i raw materials cost (workstation i exit),

2.3 Waste Identification Diagram - economic i workstation identification number.

The cost of work-in-process in a workstation i (CWIP,i)

The Waste Identification Diagram economic (WIDe) corresponds to the monetary value of the raw materials

is a WID where some values are represented using waiting to be processed on that workstation, and

monetary units. The WIDe uses an approach based on therefore:

direct costs (raw materials and labour) associated to the CWIP,i = WIPi CRMin,i . (4)

product costing function. The direct cost is basically the

cost directly linked to the cost object and can be easily where:

traced [17], [18].

WIPi work-in-process (workstation i),

From the economic perspective, the WIDe describes

CRMin raw materials cost (workstation i entry),

the information contained in the process blocks,

i workstation identification number.

transportation arrows and workforce occupation circular

graph (Figure 3), as: economic takt time (TTe), economic Note that on WIDe it is important to distinguish

cycle time (TCe), cost of work-in-process (CWIP), cost of between the cost of the product (raw materials) at the

setup (CS), cost of transportation (CT) and cost of workstation entry (CRMin,i) and the cost of the product

workforce waste (CWW). (raw materials) after being processed by that

The TTe is based on the concept of TT but, instead of workstation (CRMout,i).

representing the rate at which the market demands one For workstation i, the setup cost (CS,i) is given by:

unit of product, it represents the rate at which the CS ,i = TS ,i CSU ,i . (5)

market demands one monetary unit. Thus, TTe suggests where:

FME Transactions VOL. 43, No 4, 2015 289

TS,i setup time (workstation i), 3. VSM EXTENSIONS

CSU,i setup unitary cost (workstation i),

i workstation identification number. This section presents the two extensions of VSM

proposed in this work: VSM+WID and VSM+WIDe,

Figure 4 depicts an example of the WIDe block symbol along with the corresponding analysis in terms of

(basic version), with concrete values assigned to the representation capacity.

previously referred data items: economic takt time (TTe),

economic cycle time (TCe), WIP cost (CWIP) and setup 3.1 Extension of VSM with WID

cost (CS).

In order to improve the effectiveness of VSM it is

proposed the integration of some WID features into the

Idle time

VSM diagrams.

As simple example, Figure 6 depicts the mapping of

TTe=2.5s

the production process of soda concentrate in a

TCe=1.6s

Brazilian company (operating 2 shifts with 7 hours

CS=40

WS_1

each), where the WID blocks and transportation effort

arrows are embedded in a VSM diagram.

CWIP=2000 As can be observed in Figure 6, this integration

keeps the essence of VSM, which is the representation

Figure 4. WIDe symbol: block (basic version) of the material and information flows across the entire

process, while incorporating some valuable WID

The transportation cost between two locations i and j features, namely the meaningful interpretation of the

(CT,i,j), represents the monetary value associated to the physical dimensions of WID symbols. In fact, the block

transportation effort (ET,i,j) between these locations and dimensions allow an immediate perception, for each

is obtained from: workstation, of WIP, cycle time, setup time and

CT ,i , j = ET ,i, j CTU ,i, j . (6) throughput time, even without reading the

corresponding values. For example (Figure 6), clearly,

where: the mixing workstation is the process bottleneck

ET,i,j transportation effort (between i and j) (highest cycle time) with the larger WIP (widest block)

CTU,i,j transport. unitary cost (amongst i and j), and throughput time (block with the largest frontal

i,j locations identification numbers. area). Similarly, the weigh workstation has the highest

available capacity (largest idle time) and the highest

Regarding the time periods corresponding to planned transportation effort (thicker arrow) occurs between the

and unplanned stops, idle capacity and speed loss (in warehouse and the mixing workstation.

each workstation), as they are represented per product, Another evident improvement with respect to VSM

their conversion to the economic versions is based on is the inclusion of a circular graph that represents the

the same approach used with TTe,i and TCe,i. information about how the workers occupy their time.

Figure 5 represents an example of the WIDe The comparison of the VSM+WID map with VSM

transportation cost arrow. In this case the transportation and WID, in terms of representation features, can be

effort occurs between locations 1 and 2 and has a cost of observed on Table 1.

4000. Naturally, as with WID, the thicker the arrow,

the higher the transportation cost. Table 1. Comparison of representation capacity

Representation capacity VSM WID VSM+WID

CT,1,2=4000 Information flow Yes No Yes

Production flow Yes Yes Yes

Figure 5. WIDe symbol: Transportation cost arrow Overproduction waste Yes Yes Yes

Inventory waste Yes Yes Yes

The total cost of transportation (CT) is given by the Transportation waste No Yes Yes

sum of the partial transportation costs CT,i,j. The total People related wastes No Yes Yes

cost of the wastes associated to the workforce

OEE information No Yes Yes

occupation (CWW), are given by:

Dimensional meaning No Yes Yes

CWW = PWW CWU n . (7) Multiple routes No Yes No

Layout representation No Yes No

where:

PWW workforce waste percentage, Table 1 shows that the extension of VSM with WID

CWU workforce unitary cost, covers some of the limitations of VSM, namely its

n number of workers. inability to represent transportation waste, waste related

The costs inherent to a given kind of workforce to people utilization and OEE information.

occupation (added-value operation, waiting, transport, Additionally, the VSM+WID inherits the distinctive

motion, rework and other) are calculated using equation characteristic of WID: the designated dimensional

(7), by substituting PWW by the workforce occupation meaning (i.e. the meaning of the physical dimensions

percentage corresponding to that type of occupation. of the block and transportation arrow symbols).

290 VOL. 43, No 4, 2015 FME Transactions

Figure 6. Extension VSM+WID

The product cost of 30 MU/Kg at the entry of the

3.2 Extension of VSM with WIDe

mixing workstation (CRMin, 1) is given by the cost of the

main raw material (Table 2). As the mixing incorporates

In order to enhance VSM with the inclusion of relevant

the raw material B, the cost of the product rises to 40

economic figures, it is proposed the VSM+WIDe

MU/Kg. Naturally, the product cost at the packing exit

extension. Hence, the construction of this kind of map

(CRMout, 4) equals the cost of the final product (CMR).

implies the gathering of economic data, namely, raw

The economic takt time (TTe,i) and the economic

material costs, setup costs and workers payroll. The

cycle time (TCe,i) of each workstation are presented on

example in the previous section will be used here and,

Table 4. It is important to understand that TTe,i is

as currency, it is adopted the concept of monetary unit

associated to the demand of a monetary unit, placed by

(MU). Table 2 presents the involved costs.

the market to workstation i, and, because the cost of the

Table 2. Costs product at the workstation exit depends on the

Designation Cost incorporated raw materials, the TTe,i varies depending on

Worker payroll 750 MU/man.month the workstation.

Unitary cost of setup 110 MU/h Table 4. TTe and TCe of each workstation

Unitary cost of transportation 0.1 MU/Kg.m

Workstation TTe,i [s] TCe,i [s] Equation

Main raw mat. (A) cost (mixing) 30 MU/Kg

1. Mixing 0,315 0.225

Raw material B cost (mixing) 10 MU/Kg

2. Bagging 0,313 0.045

Raw material C cost (bagging) 0.25 MU/Kg (2,3)

3. Weighing 0,313 0.025

Raw material D cost (packing) 1 MU/Kg 4. Packing 0,305 0.073

Total raw material cost 41.25 MU/Kg

Note that the economic takt time in the packing

Based on the values indicated on Table 2 as well as workstation, equals the economic takt time (8) and also

on information from the VSM+WID represented in that TTe,3 equals TTe,2 because the weighing workstation

Figure 6, the necessary VSM+WIDe (Figure 7) does not add any raw material.

indicators can be calculated. Thus, according to (1) the In terms of WIP cost (cost of raw materials) and

economic takt time is: setup cost (per setup) inherent to each workstation, i.e.

T 12.6 CWIP,i and CS,i, respectively, the values are presented in

TTe = T = = 0.305 s . (8) Table 5.

CRM 41.25

This means that the market demands one MU every Table 5. CWIP and CS of each workstations

0,305 seconds. Regarding the cost of product (raw Workstation CWIP,i [MU] CS,i [MU] Equation

materials cost), Table 3 contains the values before and 1. Mixing 12000 110 MU

after each workstation, i.e. CRMin,i and CRMout,i 2. Bagging 6000 110 MU

respectively. (4,5)

3. Weighing 241.5 110 MU

Table 3. Product cost before and after processing 4. Packing 6037.5 110 MU

Workstation CRMin,i [MU/Kg] CRMout,i [MU/Kg] Regarding the transportation cost between locations i

1. Mixing 30 40 and j, i.e. CT,i,j, the necessary data is on Table 2 (unitary

2. Bagging 40 40.25 cost of setup) and on the WID+VSM map of Figure 6

3. Weighing 40.25 40.25 (transportation effort). The values are presented on

4. Packing 40.25 41.25 Table 6.

FME Transactions VOL. 43, No 4, 2015 291

Figure 7. Extension VSM+WIDe

Table 6. Transportation cost between locations

quantity of WIP (narrow block on VSM+WID map)

may imply a high inventory cost (wide block on

Transportation CT,i,j [MU] Equation VSM+WIDe).

0. Warehouse 1. Mixing 6400 From the frontal area of the blocks it is immediately

1. Mixing 2. Bagging 1600 perceived that the mixing workstation is the place where

2. Bagging 3. Weighing 400 (6) one MU spends more time (throughput time).

3. Weighing 4. Packing 880 The highest transportation cost occurs between the

4. Packing 5. Customer 2000 warehouse and the mixing workstation and the circular

graph represents now the costs associated to workforce

Lastly, the calculation of the cost inherent to the occupation. As can be observed, the waiting time of the

workforce occupation is based on the workers payroll workforce represents a monthly cost of 3960 MU,

(Table 2) and on the circular graph included in the surpassing thus the cost associated to added-value

VSM+WID map (Figure 6). The total cost of the activities (2970 MU).

wastes related to workforce occupation, i.e. CWW (6), is: The setup cost is 110 MU in every workstation

because in this case the setup unitary cost is always the

CWW = PWW CWU n = 067 750 12 = 6030 MU same (110 UM/h), regardless the involved workstation.

(9)

Recall that the working day has 2 shifts, each one 4. CONCLUSION

with 6 workers. The partial costs associated to the

different types of occupation are included in Table 7. This work successfully introduced an extension of the

well-known Value Stream Mapping (VSM) in order to

Table 7. Workforce occupation costs

overcome some of its limitations, especially in terms of

Workforce occupation Cost [MU] Total [MU] ability to represent wastes (activities without added

Added-value operation 2970 2970 value) and economic indicators.

Waiting 3960 The extension was achieved by including on VSM

Transport 720 some features of the designated Waste Identification

6030

Motion 720 Diagram (WID), a representation tool developed in the

Other 630 Production and Systems Department of University of

Minho, Portugal. As WID (section 2.2) has also an

Based on the calculated data, the VSM+WIDe map economic version, named WIDe (section 2.3), in fact,

was constructed, being depicted on Figure 7. two variants of the VSM extension were developed: the

The same aspects already identified in the VSM+WID map (section 3.1) and the VSM+WIDe map

VSM+WID extension can now be interpreted in (section 3.2).

monetary terms. Both variants inherit a distinctive characteristic of

As can be observed, the highest WIP cost occurs on WID (and WIDe) which is the dimensional meaning of

the mixing workstation, followed by the packing its symbols, allowing an immediate perception of

workstation. On the VSM+WID map (Figure 6) the important aspects of the represented production unit,

blocks representing the bagging and the packing even without reading the values on the map. The easy

workstations have the same width (WIP2 = WIP4 = perception, through the simple observation of the

150Kg). However, the VSM+WIDe map (Figure 7) dimensions of the symbols, include the identification of

clearly shows that the cost of that quantity of WIP is the workstation with the highest: (i) throughput time

higher on the packing workstation (due to the higher (per product or monetary unit), (ii) setup time, (iii) setup

cost of raw materials at its exit). Obviously, a small cost, (iv) available capacity, (v) WIP (quantity or

292 VOL. 43, No 4, 2015 FME Transactions

monetary cost), (vi) OEE losses, etc. Similarly, a quick [7] Kemper, B., de Mast, J. and Mandjes, M.:

glance to a VSM+WID map allows the immediate Modeling Process Flow Using Diagrams, Quality

identification of the point where the highest and Reliability Engineering International, Vol. 26,

transportation effort occurs and, in the case of the No. 4, pp. 341-349, 2010.

VSM+WIDe map, also the corresponding cost. [8] Singh, B., Garg, S. K. and Sharma, S. K.: Value

Regarding the identification of waste related to stream mapping: literature review and implications

people (waiting, transport, motion and rework), the for Indian industry, International Journal of

circular graph representing the workforce occupation Advanced Manufacturing Technology, Vol. 53, No.

expressed in percentage was inherited from the WID or 5-8, pp. 799-809, 2011.

from the WIDe when expressed as cost. Thus, an

[9] Teichgraber, U. K. and Bucourt, M.: Applying

important limitation of VSM was overcome.

value stream mapping techniques to eliminate non-

Despite the acquired advantages, the VSM+WID

value-added waste for the procurement of

and VSM+WIDe maps neither represent the production

endovascular stents, European Journal of

units layout nor production units with multiple routes

Radiology, Vol. 81, 2012.

(these are distinctive features of WID and WIDe).

An adequate representation of a production unit is a [10] Irani, S. A. and Zhou, J.: Value Stream Mapping of

crucial task not only to formalize the current state of the a Complete Product, MS thesis, The Ohio State

production processes, but especially to identify the main University, Columbus, OH, 1999.

problems and, consequently, the corresponding [11] Lovelle, J.: Mapping the value stream, IIE

improvement opportunities. Power of representation and Solutions, Vol. 33, No. 2, pp. 26-33, 2001.

ease of interpretation are mandatory characteristics for [12] Huang, C. C. and Liu, S H.: A novel approach to

any representation tool wishing to play a relevant role in lean control for Taiwan-funded enterprises in

the industrial engineering area. mainland China. International Journal of

Accordingly, the authors consider that the developed Production Research, Vol. 43, No. 12, pp. 2553-

VSM extensions bring concrete benefits to the issue of 2575, 2005.

representation of production units, namely the

dimensional meaning and the representation of people [13] Khurum, M., Petersen, K. and Gorschek, T.:

Extending value stream mapping through waste

related waste, constituting thus effective communication

tools between analysts and workers. definition beyond customer perspective, Journal of

In terms of future work, new developments are being Software: Evolution and Process, Vol. 26, No. 12,

pp. 10741105, 2014.

studied, mainly in the WIDe context.

[14] M. Braglia, M., Carmignani, G. and Zammori, F.: A

new value stream mapping approach for complex

REFERENCES production systems, International Journal of

[1] Ohno, T.: Toyota Production System: Beyond Production Research, Vol. 44, No. 1819, pp.

large-scale production, Productivity Press, 39293952, 2006.

Portland, Oregon, 1988. [15] Little, J.: A proof for the queuing formula: L = W,

[2] Dinis-Carvalho, J., Moreira, F., Bragana, S., Operations Research, Vol. 9, pp. 383-389, 1961.

Costa, E., Alves, A. and Sousa, R.: Waste [16] Dinis-Carvalho, J., Guimares, L., Moreira, F.,

Identification Diagram, Production Planning & Rodrigues, J. and Lima, R. M.: Waste Identification

Control, The Management of Operations, Published Diagrams with OEE data, in Proceedings of the

online: 24 Mar 2014. CIO-ICIEOM-IIIE 2014, July 23-25, Malaga Spain,

[3] Rother M. and Shook, J.: Learning to see - value ISBN-13978-84-616-9935-3, pp. 313-320, 2014.

stream mapping to create value and eliminating [17] Blocher, E. J., Stout, D. E. and Cokins, G.: Cost

muda, 1.2 ed. Brookline: The Lean Enterprise Management: a strategic emphasis (5th ed.), New

Institute, 1999. York: Mcgraw-Hill, 2010.

[4] Lian, Y. H. and van Landeghem, H.: Analysing the [18] Hansen, D. R., Mowen, M. M. and Guan, L.: Cost

effects of Lean manufacturing using a value stream management accounting & control (6th ed.),

mapping-based simulation generator, International Mason: South-Western Cengage Learning, 2009.

Journal of Production Research, Vol. 45, No. 13, [19] Goldratt, E. M. and Fox, R. E.: The Race, North

pp. 3037-3058, 2007. River Press, New-York, 1986.

[5] Serrano, I., Ochoa, C. and De Castro, R.:

Evaluation of value stream mapping in

manufacturing system redesign, International

Journal of Production Research, Vol. 46, No. 16, :

pp. 4409-4430, 2008.

[6] Xinyu, L. and Jian, L.: Research on the Integration

of the Methods of Enterprise Value Stream and

Material Flow, in Proc. of the IEEE 16th

International Conference on Industrial Engineering . -, . . , . .

and Engineering Management, 2009, Beijing, , . . , . . , . .

China.

FME Transactions VOL. 43, No 4, 2015 293

.

:

. , , , ,

, , .

,

(

). ,

,

: , .

294 VOL. 43, No 4, 2015 FME Transactions

Das könnte Ihnen auch gefallen

- IoT Streams for Data-Driven Predictive Maintenance and IoT, Edge, and Mobile for Embedded Machine Learning: Second International Workshop, IoT Streams 2020, and First International Workshop, ITEM 2020, Co-located with ECML/PKDD 2020, Ghent, Belgium, September 14-18, 2020, Revised Selected PapersVon EverandIoT Streams for Data-Driven Predictive Maintenance and IoT, Edge, and Mobile for Embedded Machine Learning: Second International Workshop, IoT Streams 2020, and First International Workshop, ITEM 2020, Co-located with ECML/PKDD 2020, Ghent, Belgium, September 14-18, 2020, Revised Selected PapersNoch keine Bewertungen

- Waste Identification DiagramsDokument8 SeitenWaste Identification DiagramsAhmed YousryNoch keine Bewertungen

- Value Stream Mapping: Reduce waste and maximise efficiencyVon EverandValue Stream Mapping: Reduce waste and maximise efficiencyBewertung: 4 von 5 Sternen4/5 (4)

- Virtual Manufacturing: Tools For Improving Design and ProductionDokument12 SeitenVirtual Manufacturing: Tools For Improving Design and ProductionDestinifyd MydestinyNoch keine Bewertungen

- Productivity Improvement by Using Value Stream Mapping in Stainless Steel Utensils Manufacturing IndustryDokument3 SeitenProductivity Improvement by Using Value Stream Mapping in Stainless Steel Utensils Manufacturing IndustryVIVA-TECH IJRINoch keine Bewertungen

- Roessler2015EnhancedVSM PDFDokument11 SeitenRoessler2015EnhancedVSM PDFTHULASI MANOHARANNoch keine Bewertungen

- VSM 1 A Novel Dynamic and Fuzzy Value Stream Mapping (DFVSM) System Dynamics and Fuzzy Logic IntegrationDokument9 SeitenVSM 1 A Novel Dynamic and Fuzzy Value Stream Mapping (DFVSM) System Dynamics and Fuzzy Logic IntegrationElif CeylanNoch keine Bewertungen

- Technologies 10 00098Dokument30 SeitenTechnologies 10 00098Gopinath GangadhariNoch keine Bewertungen

- Modeling and Monitoring Methods For Spatial and Image DataDokument19 SeitenModeling and Monitoring Methods For Spatial and Image DataniladrioramaNoch keine Bewertungen

- VSMDokument6 SeitenVSMLGUIMARA12Noch keine Bewertungen

- VSM-brief ExplanationDokument6 SeitenVSM-brief ExplanationGopalakrishnanNoch keine Bewertungen

- Promodel Research FileDokument5 SeitenPromodel Research Fileshourav2113Noch keine Bewertungen

- Fuzzy Value Stream Mapping for Parts ManufacturerDokument12 SeitenFuzzy Value Stream Mapping for Parts ManufacturerElif CeylanNoch keine Bewertungen

- Value Stream Mapping: A Case Study of Automotive Industry: Palak P. Sheth, Vivek A. Deshpande, Hiren R. KardaniDokument5 SeitenValue Stream Mapping: A Case Study of Automotive Industry: Palak P. Sheth, Vivek A. Deshpande, Hiren R. Kardanisubhan aliNoch keine Bewertungen

- Product-Part Level Digital Twin Modeling Method For Digital Thread FrameworkDokument21 SeitenProduct-Part Level Digital Twin Modeling Method For Digital Thread FrameworkJ MrNoch keine Bewertungen

- Computer Aided DesignDokument51 SeitenComputer Aided DesignshranjuNoch keine Bewertungen

- O M P U T e R I D e D e S I G NDokument27 SeitenO M P U T e R I D e D e S I G NErAmolDhakaneNoch keine Bewertungen

- 1 s2.0 S221282712300848X MainDokument6 Seiten1 s2.0 S221282712300848X MainAlexNicolaeNoch keine Bewertungen

- Value Stream Mapping A Case Study of AutomotiveDokument5 SeitenValue Stream Mapping A Case Study of AutomotiveInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Process Improvement by Using Value Stream Mapping A Case Study in Small Scale Industry IJERTV1IS5333Dokument10 SeitenProcess Improvement by Using Value Stream Mapping A Case Study in Small Scale Industry IJERTV1IS5333Praveen KumarNoch keine Bewertungen

- The Virtual Manufacturing ConceptDokument11 SeitenThe Virtual Manufacturing ConceptAbid YusufNoch keine Bewertungen

- VSM and Non-Value-Added WasteDokument6 SeitenVSM and Non-Value-Added WastebarijitNoch keine Bewertungen

- From Knowledge-Based To Big Data Analytic ModelDokument16 SeitenFrom Knowledge-Based To Big Data Analytic ModelLuchia MinayaNoch keine Bewertungen

- VSM 3 Dynamic Iiot Balaji2020 - Article - DVSMSDynamicValueStreamMappingDokument13 SeitenVSM 3 Dynamic Iiot Balaji2020 - Article - DVSMSDynamicValueStreamMappingElif CeylanNoch keine Bewertungen

- Attachment 0-10Dokument20 SeitenAttachment 0-10api-528527472Noch keine Bewertungen

- A Framework For Developing A Microchip PIC Microcontroller Based ApplicationsDokument9 SeitenA Framework For Developing A Microchip PIC Microcontroller Based ApplicationsBASEER AHMADNoch keine Bewertungen

- Modelling of An Additive 3D-Printing Process Based On Design of Experiments MethodologyDokument24 SeitenModelling of An Additive 3D-Printing Process Based On Design of Experiments MethodologyAli SarfrazNoch keine Bewertungen

- Balancing Shock Absorbers Manufacturing Line With The Mtm-Uas MethodologyDokument21 SeitenBalancing Shock Absorbers Manufacturing Line With The Mtm-Uas MethodologyAuraNoch keine Bewertungen

- Thesis DTSDokument7 SeitenThesis DTSAhmed AmrNoch keine Bewertungen

- 7 - 2022 - SMED - Iris - Roberto - Ricardo - Amauri - Gustavo - 21.01.22Dokument20 Seiten7 - 2022 - SMED - Iris - Roberto - Ricardo - Amauri - Gustavo - 21.01.22Brian VellanedaNoch keine Bewertungen

- Relationship Between Lean Manufacturing Tools and Their Sustainable Economic Benefitsinternational Journal of Advanced MDokument16 SeitenRelationship Between Lean Manufacturing Tools and Their Sustainable Economic Benefitsinternational Journal of Advanced MLucia QuispeNoch keine Bewertungen

- Bitstream 124441Dokument12 SeitenBitstream 124441Vratislav Němec ml.Noch keine Bewertungen

- Journal of Manufacturing Systems: Taho Yang, Yiyo Kuo, Chao-Ton Su, Chia-Lin HouDokument8 SeitenJournal of Manufacturing Systems: Taho Yang, Yiyo Kuo, Chao-Ton Su, Chia-Lin HoujanellaNoch keine Bewertungen

- Implementation of Maintenance Strategies in The Life Cycle Costing of Product Service SystemsDokument10 SeitenImplementation of Maintenance Strategies in The Life Cycle Costing of Product Service SystemsGisela DelgadoNoch keine Bewertungen

- Waste Reduction in Production Processes Through Simulation and VSMDokument14 SeitenWaste Reduction in Production Processes Through Simulation and VSMLuis Alejandro Cuervo GalvisNoch keine Bewertungen

- Importance of Artificial Intelligence-Expert Systems-In Computer Integrated ManufacturingDokument7 SeitenImportance of Artificial Intelligence-Expert Systems-In Computer Integrated ManufacturingtavolenNoch keine Bewertungen

- Project-Based Learning of Advanced CADCAE Tools in PDFDokument14 SeitenProject-Based Learning of Advanced CADCAE Tools in PDFSOMYA RANJAN TRIPATHYNoch keine Bewertungen

- Value Stream Mapping Case StudyDokument5 SeitenValue Stream Mapping Case StudyHaythem MejriNoch keine Bewertungen

- Methodology For An Automatic ManuDokument19 SeitenMethodology For An Automatic ManuHerbertNoch keine Bewertungen

- Sustainability 12 01088 PDFDokument17 SeitenSustainability 12 01088 PDFOlivia MayatikaNoch keine Bewertungen

- Condition Assessmnt Scheme For Ship Hull MaintenanceDokument22 SeitenCondition Assessmnt Scheme For Ship Hull MaintenanceAnilKumar100% (1)

- Applsci 10 08350 v2Dokument10 SeitenApplsci 10 08350 v2Kaustubh DwivediNoch keine Bewertungen

- Lean Construction - Application of Value Stream Mapping On Infra Structure ProjectDokument4 SeitenLean Construction - Application of Value Stream Mapping On Infra Structure ProjectnidhiNoch keine Bewertungen

- Integrated DesignDokument6 SeitenIntegrated Designsmani170Noch keine Bewertungen

- Framework For A Digital Twin in Manufacturing Scope and RequirementsDokument3 SeitenFramework For A Digital Twin in Manufacturing Scope and RequirementsJoão Vitor100% (1)

- Implementing Lean Manufacturing in the Sewing IndustryDokument11 SeitenImplementing Lean Manufacturing in the Sewing IndustryWilliam CamposNoch keine Bewertungen

- 3 - Braglia, 2006, A New Value Stream Mapping Approach For Complex Production Systems.Dokument25 Seiten3 - Braglia, 2006, A New Value Stream Mapping Approach For Complex Production Systems.Daniel PantojaNoch keine Bewertungen

- Digital Manufacturing For Aerospace IndustryDokument3 SeitenDigital Manufacturing For Aerospace IndustryShashi ShekharNoch keine Bewertungen

- VM Seminar Report NewDokument22 SeitenVM Seminar Report NewAkshay Deshpande100% (3)

- Manual - Lastenheft en 2009Dokument29 SeitenManual - Lastenheft en 2009kuervoNoch keine Bewertungen

- Akash PPPP NewDokument7 SeitenAkash PPPP NewAkash AkuNoch keine Bewertungen

- Paper DLRK - 01Dokument8 SeitenPaper DLRK - 01M Hassaan KhalidNoch keine Bewertungen

- White Paper 4Dokument5 SeitenWhite Paper 4maxwellNoch keine Bewertungen

- VillegasRobioloJE FV PDFDokument19 SeitenVillegasRobioloJE FV PDFGGNoch keine Bewertungen

- Mapping Current State Value Stream ManufacturingDokument12 SeitenMapping Current State Value Stream ManufacturingKhodayar SadeghiNoch keine Bewertungen

- PLCM, Module-5Dokument41 SeitenPLCM, Module-5Sunil Kumar M50% (2)

- Programme: Plenary Session Moderation: Frank Härtig, PTB, GermanyDokument5 SeitenProgramme: Plenary Session Moderation: Frank Härtig, PTB, Germanypm089Noch keine Bewertungen

- DocumentgverDokument16 SeitenDocumentgverMohit RajaiNoch keine Bewertungen

- Cirp Journal of Manufacturing Science and Technology: P. Kuhlang, T. Edtmayr, W. SihnDokument9 SeitenCirp Journal of Manufacturing Science and Technology: P. Kuhlang, T. Edtmayr, W. SihnMohammed SirelkhatimNoch keine Bewertungen

- Applied Sciences: Fficiency Analysis of Manufacturing Line WithDokument15 SeitenApplied Sciences: Fficiency Analysis of Manufacturing Line WithBenjamin RaposoNoch keine Bewertungen

- TIMReview August2017Dokument50 SeitenTIMReview August2017Irshad AliNoch keine Bewertungen

- Vijay 2014 IdentifyingDokument7 SeitenVijay 2014 IdentifyingIrshad AliNoch keine Bewertungen

- Ijcet: International Journal of Computer Engineering & Technology (Ijcet)Dokument6 SeitenIjcet: International Journal of Computer Engineering & Technology (Ijcet)bibeka_kalita9490Noch keine Bewertungen

- Fakhri 2019 IOP Conf. Ser. Earth Environ. Sci. 278 012022Dokument9 SeitenFakhri 2019 IOP Conf. Ser. Earth Environ. Sci. 278 012022Irshad AliNoch keine Bewertungen

- Rheology SvecDokument3 SeitenRheology SvecIrshad AliNoch keine Bewertungen

- Ihg Logo Folio477134Dokument1 SeiteIhg Logo Folio477134Irshad AliNoch keine Bewertungen

- Team Leader Portal PresentationDokument8 SeitenTeam Leader Portal PresentationIrshad AliNoch keine Bewertungen

- Talk 2.2 - Timothy PorterDokument28 SeitenTalk 2.2 - Timothy PorterIrshad AliNoch keine Bewertungen

- WatermarkDokument1 SeiteWatermarkIrshad AliNoch keine Bewertungen

- Team Leader Portal PresentationDokument8 SeitenTeam Leader Portal PresentationIrshad AliNoch keine Bewertungen

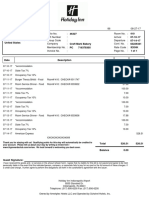

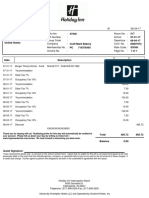

- Hotel invoice for Arshia AliDokument1 SeiteHotel invoice for Arshia AliIrshad AliNoch keine Bewertungen

- Model Based On Matern Process For ICI Mitigation in Multi Cell CooperationDokument2 SeitenModel Based On Matern Process For ICI Mitigation in Multi Cell CooperationIrshad AliNoch keine Bewertungen

- Section 11b Fta Lecture Slides Compatibility ModeDokument12 SeitenSection 11b Fta Lecture Slides Compatibility ModeIrshad AliNoch keine Bewertungen

- Relative Navigation of Autonomous GPS-Degraded Micro Air VehiclesDokument20 SeitenRelative Navigation of Autonomous GPS-Degraded Micro Air VehiclesIrshad AliNoch keine Bewertungen

- IJRS 2017 1 2 SiddiquiDokument2 SeitenIJRS 2017 1 2 SiddiquiIrshad AliNoch keine Bewertungen

- Talk 2.2 - Timothy PorterDokument28 SeitenTalk 2.2 - Timothy PorterIrshad AliNoch keine Bewertungen

- Full TextDokument118 SeitenFull TextIrshad AliNoch keine Bewertungen

- Value Stream Mapping Lean Six Sigma PPT DesignDokument7 SeitenValue Stream Mapping Lean Six Sigma PPT DesignIrshad AliNoch keine Bewertungen

- Paper1 PDFDokument6 SeitenPaper1 PDFIrshad AliNoch keine Bewertungen

- Irjet V4i848Dokument10 SeitenIrjet V4i848Irshad AliNoch keine Bewertungen

- Taguchi Based Optimization of Cutting Parameters Affecting Surface Roughness in Dry CNC Turning of 16Mncr5Dokument11 SeitenTaguchi Based Optimization of Cutting Parameters Affecting Surface Roughness in Dry CNC Turning of 16Mncr5Irshad AliNoch keine Bewertungen

- Simplificaton of Six Sigma Implementation Using Shainin Tools For Process ImprovementDokument5 SeitenSimplificaton of Six Sigma Implementation Using Shainin Tools For Process ImprovementIrshad AliNoch keine Bewertungen

- Rafat Madani May 2017aDokument437 SeitenRafat Madani May 2017aIrshad AliNoch keine Bewertungen

- Six Sigma Improves ProductivityDokument6 SeitenSix Sigma Improves ProductivityIrshad AliNoch keine Bewertungen

- 0814 Seven Staged Agenda For Time MangementDokument6 Seiten0814 Seven Staged Agenda For Time MangementIrshad AliNoch keine Bewertungen

- Sample Value Stream Mapping Template PPT Infographics WDDokument7 SeitenSample Value Stream Mapping Template PPT Infographics WDIrshad AliNoch keine Bewertungen

- Golden STS268Dokument34 SeitenGolden STS268Irshad AliNoch keine Bewertungen

- Sample Value Stream Mapping Template PPT Infographics WDDokument7 SeitenSample Value Stream Mapping Template PPT Infographics WDIrshad AliNoch keine Bewertungen

- EnneagramDokument263 SeitenEnneagramWes Art100% (3)

- Business Operational Plan Complete Powerpoint Deck With SlidesDokument52 SeitenBusiness Operational Plan Complete Powerpoint Deck With SlidesIrshad AliNoch keine Bewertungen

- Engineering Utilities 2: Engr. Ervin John D. Melendres InstructorDokument24 SeitenEngineering Utilities 2: Engr. Ervin John D. Melendres InstructorStephanie CanibanNoch keine Bewertungen

- Florida SUS Matrix Guide 2020Dokument3 SeitenFlorida SUS Matrix Guide 2020mortensenkNoch keine Bewertungen

- Important PIC'sDokument1 SeiteImportant PIC'sAbhijit SahaNoch keine Bewertungen

- Network Marketing - Money and Reward BrochureDokument24 SeitenNetwork Marketing - Money and Reward BrochureMunkhbold ShagdarNoch keine Bewertungen

- Globalization Winners and LosersDokument2 SeitenGlobalization Winners and Losersnprjkb5r2wNoch keine Bewertungen

- Gender, Race, and Semicolonialism: Liu Na'ou's Urban Shanghai LandscapeDokument24 SeitenGender, Race, and Semicolonialism: Liu Na'ou's Urban Shanghai Landscapebaiqian liuNoch keine Bewertungen

- RAS MARKAZ CRUDE OIL PARK SITE INSPECTION PROCEDUREDokument1 SeiteRAS MARKAZ CRUDE OIL PARK SITE INSPECTION PROCEDUREANIL PLAMOOTTILNoch keine Bewertungen

- Buyer List For GarmentsDokument3 SeitenBuyer List For GarmentsLatha Kandasamy100% (5)

- Rationale For Instruction: Social Studies Lesson Plan TemplateDokument3 SeitenRationale For Instruction: Social Studies Lesson Plan Templateapi-255764870Noch keine Bewertungen

- Acts and Statutory Instruments: The Volume of UK Legislation 1850 To 2019Dokument24 SeitenActs and Statutory Instruments: The Volume of UK Legislation 1850 To 2019Adam GreenNoch keine Bewertungen

- Decathlon - Retail Management UpdatedDokument15 SeitenDecathlon - Retail Management UpdatedManu SrivastavaNoch keine Bewertungen

- Life Member ListDokument487 SeitenLife Member Listpuiritii airNoch keine Bewertungen

- UCPB Violated Truth in Lending Act in Loan to SpousesDokument4 SeitenUCPB Violated Truth in Lending Act in Loan to SpousesMark Xavier Overhaul LibardoNoch keine Bewertungen

- James M Stearns JR ResumeDokument2 SeitenJames M Stearns JR Resumeapi-281469512Noch keine Bewertungen

- Ecocritical Approach To Literary Text Interpretation: Neema Bagula JimmyDokument10 SeitenEcocritical Approach To Literary Text Interpretation: Neema Bagula JimmyhafizhNoch keine Bewertungen

- Mind Map All in One PBA-2021-08-20 12-38-51Dokument1 SeiteMind Map All in One PBA-2021-08-20 12-38-51MikosamirNoch keine Bewertungen

- Sohan vs. Mohan PlaintDokument6 SeitenSohan vs. Mohan PlaintKarandeep Saund100% (5)

- Investment Decision RulesDokument113 SeitenInvestment Decision RulesHuy PanhaNoch keine Bewertungen

- SECTION 26. Registration of Threatened and Exotic Wildlife in The Possession of Private Persons. - NoDokument5 SeitenSECTION 26. Registration of Threatened and Exotic Wildlife in The Possession of Private Persons. - NoAron PanturillaNoch keine Bewertungen

- IPR and Outer Spaces Activities FinalDokument25 SeitenIPR and Outer Spaces Activities FinalKarthickNoch keine Bewertungen

- Company Profile-SIPLDokument4 SeitenCompany Profile-SIPLShivendra SinghNoch keine Bewertungen

- MKT201 Term PaperDokument8 SeitenMKT201 Term PaperSumaiyaNoorNoch keine Bewertungen

- Intermediate Accounting 1 - Cash Straight ProblemsDokument3 SeitenIntermediate Accounting 1 - Cash Straight ProblemsCzarhiena SantiagoNoch keine Bewertungen

- Esmf 04052017 PDFDokument265 SeitenEsmf 04052017 PDFRaju ReddyNoch keine Bewertungen

- Flowserve Corp Case StudyDokument3 SeitenFlowserve Corp Case Studytexwan_Noch keine Bewertungen

- CHRO 3.0 Lead Future HR Function India PDFDokument40 SeitenCHRO 3.0 Lead Future HR Function India PDFpriteshpatel103100% (1)

- Pradeep Kumar SinghDokument9 SeitenPradeep Kumar SinghHarsh TiwariNoch keine Bewertungen

- International Marketing StrategiesDokument19 SeitenInternational Marketing StrategiesHafeez AfzalNoch keine Bewertungen

- Public-International-Law Reviewer Isagani Cruz - Scribd 2013 Public International Law (Finals) - Arellano ..Dokument1 SeitePublic-International-Law Reviewer Isagani Cruz - Scribd 2013 Public International Law (Finals) - Arellano ..Lylanie Alexandria Yan GalaNoch keine Bewertungen

- Lord Kuthumi UnifiedTwinFlameGrid Bali2013 Ubud 5 Part11 StGermain 24-04-2013Dokument6 SeitenLord Kuthumi UnifiedTwinFlameGrid Bali2013 Ubud 5 Part11 StGermain 24-04-2013Meaghan MathewsNoch keine Bewertungen

- Algorithms to Live By: The Computer Science of Human DecisionsVon EverandAlgorithms to Live By: The Computer Science of Human DecisionsBewertung: 4.5 von 5 Sternen4.5/5 (722)

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldVon EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldBewertung: 4.5 von 5 Sternen4.5/5 (54)

- Defensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityVon EverandDefensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityBewertung: 5 von 5 Sternen5/5 (1)

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveVon EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveNoch keine Bewertungen

- CompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideVon EverandCompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideBewertung: 5 von 5 Sternen5/5 (2)

- ChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessVon EverandChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessNoch keine Bewertungen

- Generative AI: The Insights You Need from Harvard Business ReviewVon EverandGenerative AI: The Insights You Need from Harvard Business ReviewBewertung: 4.5 von 5 Sternen4.5/5 (2)

- 8-Bit Apocalypse: The Untold Story of Atari's Missile CommandVon Everand8-Bit Apocalypse: The Untold Story of Atari's Missile CommandBewertung: 3.5 von 5 Sternen3.5/5 (10)

- The Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldVon EverandThe Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldBewertung: 4.5 von 5 Sternen4.5/5 (107)

- Chip War: The Quest to Dominate the World's Most Critical TechnologyVon EverandChip War: The Quest to Dominate the World's Most Critical TechnologyBewertung: 4.5 von 5 Sternen4.5/5 (227)

- Artificial Intelligence: The Insights You Need from Harvard Business ReviewVon EverandArtificial Intelligence: The Insights You Need from Harvard Business ReviewBewertung: 4.5 von 5 Sternen4.5/5 (104)

- Data-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseVon EverandData-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseBewertung: 3.5 von 5 Sternen3.5/5 (12)

- So You Want to Start a Podcast: Finding Your Voice, Telling Your Story, and Building a Community that Will ListenVon EverandSo You Want to Start a Podcast: Finding Your Voice, Telling Your Story, and Building a Community that Will ListenBewertung: 4.5 von 5 Sternen4.5/5 (35)

- Who's Afraid of AI?: Fear and Promise in the Age of Thinking MachinesVon EverandWho's Afraid of AI?: Fear and Promise in the Age of Thinking MachinesBewertung: 4.5 von 5 Sternen4.5/5 (12)

- Mastering Large Language Models: Advanced techniques, applications, cutting-edge methods, and top LLMs (English Edition)Von EverandMastering Large Language Models: Advanced techniques, applications, cutting-edge methods, and top LLMs (English Edition)Noch keine Bewertungen

- Everybody Lies: Big Data, New Data, and What the Internet Can Tell Us About Who We Really AreVon EverandEverybody Lies: Big Data, New Data, and What the Internet Can Tell Us About Who We Really AreBewertung: 4.5 von 5 Sternen4.5/5 (911)

- Dark Data: Why What You Don’t Know MattersVon EverandDark Data: Why What You Don’t Know MattersBewertung: 4.5 von 5 Sternen4.5/5 (3)

- AI Money Machine: Unlock the Secrets to Making Money Online with AIVon EverandAI Money Machine: Unlock the Secrets to Making Money Online with AINoch keine Bewertungen

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindVon EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNoch keine Bewertungen

- AI and Machine Learning for Coders: A Programmer's Guide to Artificial IntelligenceVon EverandAI and Machine Learning for Coders: A Programmer's Guide to Artificial IntelligenceBewertung: 4 von 5 Sternen4/5 (2)

- Make Money with ChatGPT: Your Guide to Making Passive Income Online with Ease using AI: AI Wealth MasteryVon EverandMake Money with ChatGPT: Your Guide to Making Passive Income Online with Ease using AI: AI Wealth MasteryNoch keine Bewertungen