Beruflich Dokumente

Kultur Dokumente

Reflectivity of Thin Plywood Panels

Hochgeladen von

The PieonicBritzCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Reflectivity of Thin Plywood Panels

Hochgeladen von

The PieonicBritzCopyright:

Verfügbare Formate

Sound System Design Reference Manual

More recent publications usually express the Although we commonly use published

absorption in an enclosed space in terms of the absorption coefficients without questioning their

average absorption coefficient. For example, if a accuracy and perform simple arithmetic averaging to

room has a total surface area of 1000 square meters compute the average absorption coefficient of a

consisting of 200 square meters of material with an room, the numbers themselves and the procedures

absorption coefficient of .8 and 800 square meters of we use are only approximations. While this does not

material with an absorption coefficient of .1, the upset the reliability of our calculations to a large

average absorption coefficient for the entire internal degree, it is important to realize that the limit of

surface area of the room is said to be .24: confidence when working with published absorption

coefficients is probably somewhere in the

Area: Coefficient: Sabins: neighborhood of 10%.

200 x 0.8 = 160 How does the absorption coefficient of the

800 x 0.1 = 80 material relate to the intensity of the reflected sound

1000 240 wave? An absorption coefficient of 0.2 at some

specified frequency and angle of incidence means

= 240 = 0.24 that 20% of the sound energy will be absorbed and

1000 the remaining 80% reflected. The conversion to

decibels is a simple 10 log function:

The use of the average absorption coefficient

has the advantage that it is not tied to any particular 10 log10 0.8 = -0.97 dB

system of measurement. An average absorption

coefficient of 0.15 is exactly the same whether the In the example given, the ratio of reflected to

surfaces of the room are measured in square feet, direct sound energy is about -1 dB. In other words,

square yards, or square meters. It also turns out that the reflected wave is 1 dB weaker than it would have

the use of an average absorption coefficient been if the surface were 100% reflective. See the

facilitates solving reverberation time, direct-to- table in Figure 5-3.

reverberant sound ratio, and steady-state sound Thinking in terms of decibels can be of real help

pressure. in a practical situation. Suppose we want to improve

the acoustics of a small auditorium which has a

pronounced slap off the rear wall. To reduce the

intensity of the slap by only 3 dB, the wall must be

surfaced with some material having an absorption

coefficient of 0.5! To make the slap half as loud (a

reduction of 10 dB) requires acoustical treatment of

the rear wall to increase its absorption coefficient to

0.9. The difficulty is heightened by the fact that most

materials absorb substantially less sound energy

from a wave striking head-on than their random

incidence coefficients would indicate.

Most acoustic materials are porous. They

belong to the class which acousticians elegantly

label fuzz. Sound is absorbed by offering resistance

to the flow of air through the material and thereby

changing some of the energy to heat.

But when porous material is affixed directly to

solid concrete or some other rigid non-absorptive

surface, it is obvious that there can be no air motion

and therefore no absorption at the boundary of the

two materials.

Figure 5-3. Reflection coefficient in decibels

as a function of absorption coefficient

5-3

Das könnte Ihnen auch gefallen

- Ertekin Turcay Basic Applied Reservoir Simulation 1Dokument1 SeiteErtekin Turcay Basic Applied Reservoir Simulation 1The PieonicBritzNoch keine Bewertungen

- Double WedgeDokument9 SeitenDouble WedgeKarthick MurugesanNoch keine Bewertungen

- Acoustical Properties of Building Materials: Prepared By: Julius A. Reyes Submitted To: Archt. Sharlene M. IjanDokument32 SeitenAcoustical Properties of Building Materials: Prepared By: Julius A. Reyes Submitted To: Archt. Sharlene M. IjanMary Sharlene MalicayNoch keine Bewertungen

- Sound AbsorptionDokument73 SeitenSound AbsorptionDINGLE, Ana Lerizze B.Noch keine Bewertungen

- Sound AbsoptionDokument18 SeitenSound Absoptionpiretto77Noch keine Bewertungen

- Sound Absorption & ReverberationDokument30 SeitenSound Absorption & ReverberationGeley EysNoch keine Bewertungen

- Sound AbsorptionDokument12 SeitenSound AbsorptionJustine DomingoNoch keine Bewertungen

- Ais 191Dokument3 SeitenAis 191Hassan Ali SadiqNoch keine Bewertungen

- Architectural Lighting & Acoustics Mid-TermDokument5 SeitenArchitectural Lighting & Acoustics Mid-TermCharles Harvey DaabayNoch keine Bewertungen

- 010 Strebord v91 Section 10 AcousticsDokument64 Seiten010 Strebord v91 Section 10 AcousticsMohamed BarjNoch keine Bewertungen

- Acoustics HomeworkDokument3 SeitenAcoustics HomeworkCynthia DengNoch keine Bewertungen

- Topic 11 Room AcousticDokument44 SeitenTopic 11 Room AcousticAizat ZameerNoch keine Bewertungen

- Unit 2 Part 3 AcausticDokument7 SeitenUnit 2 Part 3 AcausticSmita DasNoch keine Bewertungen

- Sound Absorbing MaterialsDokument26 SeitenSound Absorbing MaterialsCarlorel AnteNoch keine Bewertungen

- Sound Absorbing MaterialsDokument26 SeitenSound Absorbing MaterialsCarlorel AnteNoch keine Bewertungen

- Sound Absorbing MaterialsDokument26 SeitenSound Absorbing Materialsfranobeljo27Noch keine Bewertungen

- Acoustics of Buildings: HapterDokument10 SeitenAcoustics of Buildings: HapterDebanuj BasakNoch keine Bewertungen

- Engineering-Physics-Notes 3 U8 PDFDokument78 SeitenEngineering-Physics-Notes 3 U8 PDFKarthik KumarNoch keine Bewertungen

- Engineering-Physics-Notes 3 U8 PDFDokument78 SeitenEngineering-Physics-Notes 3 U8 PDFKarthik KumarNoch keine Bewertungen

- Chapter 3Dokument45 SeitenChapter 3jaja100% (1)

- Building Acoustics TerminologyDokument10 SeitenBuilding Acoustics TerminologyanhnguyenhaiNoch keine Bewertungen

- Topic 11 Room AcousticDokument44 SeitenTopic 11 Room AcousticaileehzreenNoch keine Bewertungen

- Abs or Ti OnDokument5 SeitenAbs or Ti OnKurcatNoch keine Bewertungen

- Sound Absorption of Acoustic Resonant Absorbers With Rough Oblique PerforationsDokument8 SeitenSound Absorption of Acoustic Resonant Absorbers With Rough Oblique PerforationsComm PropertyNoch keine Bewertungen

- Unit-4 OkDokument20 SeitenUnit-4 Oksaahasitha 14Noch keine Bewertungen

- On Site Validation of Sound Absorption MDokument11 SeitenOn Site Validation of Sound Absorption MMina ChiuNoch keine Bewertungen

- Glass and Acoustic InsulationDokument5 SeitenGlass and Acoustic InsulationAnonymous vQewJPfVXa100% (1)

- Sound Absorption All ReportsDokument76 SeitenSound Absorption All Reportssheyndaga12Noch keine Bewertungen

- AcousticsDokument9 SeitenAcousticsbobbyNoch keine Bewertungen

- 4 - Sound AbsorptionDokument11 Seiten4 - Sound Absorptionjun005Noch keine Bewertungen

- Frecuencias de SonidoDokument41 SeitenFrecuencias de SonidoALONDRA SALINAS OROZCONoch keine Bewertungen

- Jeong - 2009 - A Correction of Random Incidence Absorption Coefficients For The Angular Distribution of Acoustic Energy Under Measurement ConditionsDokument9 SeitenJeong - 2009 - A Correction of Random Incidence Absorption Coefficients For The Angular Distribution of Acoustic Energy Under Measurement Conditionsadonak36Noch keine Bewertungen

- Knowledge Guide: Sound Absorption - Free-Hanging Units vs. Full CeilingDokument23 SeitenKnowledge Guide: Sound Absorption - Free-Hanging Units vs. Full CeilinganhnguyenhaiNoch keine Bewertungen

- AcousticsDokument24 SeitenAcousticsjaejjiNoch keine Bewertungen

- 01 Studio AcousticDokument10 Seiten01 Studio AcousticVijayant Kumar SinghNoch keine Bewertungen

- Room Acoustics PDFDokument34 SeitenRoom Acoustics PDFFranchesca RosalesNoch keine Bewertungen

- Part 4 - Architectural Acoustics - HandoutDokument8 SeitenPart 4 - Architectural Acoustics - HandoutMike PosktovaNoch keine Bewertungen

- Acoustics Part IIDokument6 SeitenAcoustics Part IIAnony MousNoch keine Bewertungen

- Acoustic RoomsDokument9 SeitenAcoustic RoomsanandalaharNoch keine Bewertungen

- Topic 11 Room AcousticDokument46 SeitenTopic 11 Room AcousticMuhammad HaziqNoch keine Bewertungen

- AuditoriumDokument15 SeitenAuditoriummoonNoch keine Bewertungen

- 3.0 Sound Absoption Reflection and TransmissionDokument16 Seiten3.0 Sound Absoption Reflection and TransmissionallysonNoch keine Bewertungen

- Engineering Acoustics Lecture 7Dokument34 SeitenEngineering Acoustics Lecture 7Isuru KasthurirathneNoch keine Bewertungen

- How Much Scattering Is Sufficient To Soften The Hard Case?: Magne SkålevikDokument6 SeitenHow Much Scattering Is Sufficient To Soften The Hard Case?: Magne SkålevikagrimaNoch keine Bewertungen

- Acoustics of BuildingsDokument23 SeitenAcoustics of BuildingsharshitNoch keine Bewertungen

- Reverberation Calculation and ModellingeditedDokument69 SeitenReverberation Calculation and Modellingeditedvansteven0178Noch keine Bewertungen

- The Making of Soundproof Panel Coated by Compound Natural Fiber CompositesDokument13 SeitenThe Making of Soundproof Panel Coated by Compound Natural Fiber CompositesDania Hasna NingtyasNoch keine Bewertungen

- Acoustic DesignDokument21 SeitenAcoustic DesignAhmed FreehNoch keine Bewertungen

- Acoustics ARCH 255 - Liapu Wasif 11 21Dokument11 SeitenAcoustics ARCH 255 - Liapu Wasif 11 21Aurka JamanNoch keine Bewertungen

- Room Acoustics (Part 3) : Example Problem (Reverberation Times)Dokument8 SeitenRoom Acoustics (Part 3) : Example Problem (Reverberation Times)Roland CepedaNoch keine Bewertungen

- Chapter2 Part2Dokument53 SeitenChapter2 Part2hajjiyare2016Noch keine Bewertungen

- Acoustics of Buildings: Applications in The PentagonDokument5 SeitenAcoustics of Buildings: Applications in The PentagonMudrikaNoch keine Bewertungen

- Coustics in Ports Acilities: Solutions To Acoustic Problems in Sports FacilitiesDokument4 SeitenCoustics in Ports Acilities: Solutions To Acoustic Problems in Sports FacilitiesAshrutha HarshiniNoch keine Bewertungen

- L9 Laws AcousticsDokument42 SeitenL9 Laws AcousticsLiza MokhtarNoch keine Bewertungen

- Acoustics of BuildingsDokument3 SeitenAcoustics of BuildingsLin DanNoch keine Bewertungen

- NI Tutorial 4131 enDokument7 SeitenNI Tutorial 4131 envvasileNoch keine Bewertungen

- The in Uence of The Scattering Coefficient On The Reverberation TimeDokument7 SeitenThe in Uence of The Scattering Coefficient On The Reverberation TimeNurul Izzati Raihan RamziNoch keine Bewertungen

- Acoustics 4Dokument24 SeitenAcoustics 4That GuyNoch keine Bewertungen

- Lecture - 39 - Shankhapratim BhattacharyaDokument23 SeitenLecture - 39 - Shankhapratim BhattacharyaDivya VarshneyNoch keine Bewertungen

- Propagation of Sound in Porous Media: Modelling Sound Absorbing Materials 2eVon EverandPropagation of Sound in Porous Media: Modelling Sound Absorbing Materials 2eBewertung: 5 von 5 Sternen5/5 (1)

- Interactive Petrophysics Basic User S Guide 1Dokument1 SeiteInteractive Petrophysics Basic User S Guide 1The PieonicBritzNoch keine Bewertungen

- Emachines El1358 Service Guide: Printed in TaiwanDokument1 SeiteEmachines El1358 Service Guide: Printed in TaiwanThe PieonicBritzNoch keine Bewertungen

- What Questions Are You Asking Customers To Verify An MVP 3Dokument1 SeiteWhat Questions Are You Asking Customers To Verify An MVP 3The PieonicBritzNoch keine Bewertungen

- Structure of DissertationDokument1 SeiteStructure of DissertationThe PieonicBritzNoch keine Bewertungen

- Conservation of MassDokument1 SeiteConservation of MassThe PieonicBritzNoch keine Bewertungen

- Regional Geology BackgroundDokument1 SeiteRegional Geology BackgroundThe PieonicBritzNoch keine Bewertungen

- Mass BalanceDokument30 SeitenMass BalanceThe PieonicBritzNoch keine Bewertungen

- Standard Construction Contracts 5Dokument1 SeiteStandard Construction Contracts 5The PieonicBritzNoch keine Bewertungen

- This Error Term, Sometimes Called Discretization Error, Which in This Case Is of Second Order, Is Neglected in The Numerical SolutionDokument1 SeiteThis Error Term, Sometimes Called Discretization Error, Which in This Case Is of Second Order, Is Neglected in The Numerical SolutionThe PieonicBritzNoch keine Bewertungen

- 1.7.1 Miri Formation (Middle Miocene Miri) : Final Year ProjectDokument1 Seite1.7.1 Miri Formation (Middle Miocene Miri) : Final Year ProjectThe PieonicBritzNoch keine Bewertungen

- Final Year Project: (Fi ReDokument1 SeiteFinal Year Project: (Fi ReThe PieonicBritzNoch keine Bewertungen

- Subcontract Agreement 3Dokument1 SeiteSubcontract Agreement 3The PieonicBritzNoch keine Bewertungen

- Major CharacteristicsDokument1 SeiteMajor CharacteristicsThe PieonicBritzNoch keine Bewertungen

- Introduction To Enhanced Oil RecoveryDokument1 SeiteIntroduction To Enhanced Oil RecoveryThe PieonicBritzNoch keine Bewertungen

- Subcontract Agreement 1aDokument1 SeiteSubcontract Agreement 1aThe PieonicBritzNoch keine Bewertungen

- Subcontract Agreement 2Dokument1 SeiteSubcontract Agreement 2The PieonicBritzNoch keine Bewertungen

- 8.2 Heat Losses During Steam Injection: Example 8.1 Heat Loss From A Steam-Distribution Line - Heat Loss FromDokument1 Seite8.2 Heat Losses During Steam Injection: Example 8.1 Heat Loss From A Steam-Distribution Line - Heat Loss FromThe PieonicBritzNoch keine Bewertungen

- Permeability Upscaling: 1 Single-Phase FlowDokument1 SeitePermeability Upscaling: 1 Single-Phase FlowThe PieonicBritzNoch keine Bewertungen

- Introduction and Case Studies: 2.1 The Task of Reservoir SimulationDokument1 SeiteIntroduction and Case Studies: 2.1 The Task of Reservoir SimulationThe PieonicBritzNoch keine Bewertungen

- Malaysia Lost RM2m To PhishinMCDokument1 SeiteMalaysia Lost RM2m To PhishinMCThe PieonicBritzNoch keine Bewertungen

- Chapter 7: System Architecture and Layout: Typical Signal Flow DiagramDokument1 SeiteChapter 7: System Architecture and Layout: Typical Signal Flow DiagramThe PieonicBritzNoch keine Bewertungen

- ECG353 Week 10 - 11 Chapter 4Dokument44 SeitenECG353 Week 10 - 11 Chapter 4Muhd MuqhreyNoch keine Bewertungen

- Applied Thermodynamics and Engineering Fifth Edition by TDokument593 SeitenApplied Thermodynamics and Engineering Fifth Edition by TDazzy SmoothNoch keine Bewertungen

- Converting Dynamic Impact Events To Equivalent Static Loads in Vehicle ChassisDokument62 SeitenConverting Dynamic Impact Events To Equivalent Static Loads in Vehicle ChassisRm1262Noch keine Bewertungen

- Physic Traducido PDFDokument123 SeitenPhysic Traducido PDFBrashan CassidyNoch keine Bewertungen

- Objectives: Laboratory 1. The Structure of Mechanisms, Fundamentals and ExamplesDokument11 SeitenObjectives: Laboratory 1. The Structure of Mechanisms, Fundamentals and ExamplesGabriel IulianNoch keine Bewertungen

- Bequette 1 Y2Dokument25 SeitenBequette 1 Y2Kami JaraNoch keine Bewertungen

- Methods of Heat Transfer: Grade 1VDokument4 SeitenMethods of Heat Transfer: Grade 1VAnne 닌 야 PiedadNoch keine Bewertungen

- Chapter 1Dokument19 SeitenChapter 1raghu ramNoch keine Bewertungen

- Mechanical Behaviour and Testing of MaterialsDokument811 SeitenMechanical Behaviour and Testing of MaterialsMohammed AbdulkedirNoch keine Bewertungen

- Time Dependent Perturbation ProblemsDokument6 SeitenTime Dependent Perturbation ProblemsgitanoganaNoch keine Bewertungen

- Kas 201 T MCQ Sol Set BDokument10 SeitenKas 201 T MCQ Sol Set BsudheshNoch keine Bewertungen

- Code AsterDokument16 SeitenCode AsterStefano MilaniNoch keine Bewertungen

- Chem 114 - Quiz 1Dokument1 SeiteChem 114 - Quiz 1anon_915449609Noch keine Bewertungen

- Introduction To Heat Exchangers: Types, Classification and AnalysisDokument13 SeitenIntroduction To Heat Exchangers: Types, Classification and AnalysisPrinceJohnNoch keine Bewertungen

- A Critical Review of Thermal Analysis of Concrete DamsDokument17 SeitenA Critical Review of Thermal Analysis of Concrete DamsTony MeriNoch keine Bewertungen

- wph11 01 Que 20190515Dokument28 Seitenwph11 01 Que 20190515Victor VictorNoch keine Bewertungen

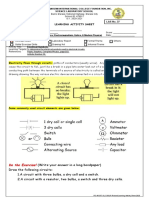

- Learning Activity Sheet: Do The Exercise!Dokument9 SeitenLearning Activity Sheet: Do The Exercise!Najmah Sirad AmpaNoch keine Bewertungen

- Blank 7th Grade Science Midterm Assessment Study Guide 2012 - 2013Dokument5 SeitenBlank 7th Grade Science Midterm Assessment Study Guide 2012 - 2013lauriajNoch keine Bewertungen

- EN 10025 Grade S355J2C Normalized or Normalized Formed (+N)Dokument3 SeitenEN 10025 Grade S355J2C Normalized or Normalized Formed (+N)melvin ekboteNoch keine Bewertungen

- Over Unity Concepts-3Dokument55 SeitenOver Unity Concepts-3beanhead43Noch keine Bewertungen

- PRINTED ChemT4HLQDokument18 SeitenPRINTED ChemT4HLQtaengooNoch keine Bewertungen

- Coplanar Non Concurrent Force SystemsDokument23 SeitenCoplanar Non Concurrent Force SystemsLester MarquezNoch keine Bewertungen

- DD 41 Manhole Flotation AnalysisDokument4 SeitenDD 41 Manhole Flotation AnalysishutuguoNoch keine Bewertungen

- How To Calculate Eft by Mott-Schottky1Dokument4 SeitenHow To Calculate Eft by Mott-Schottky1José Augusto LucenaNoch keine Bewertungen

- Discussion of The Propeller-Assisted Straight-Downwind Land Sailing Faster Than WindDokument9 SeitenDiscussion of The Propeller-Assisted Straight-Downwind Land Sailing Faster Than WindFavio Alejandro Herrera ZapataNoch keine Bewertungen

- Electrode Kinetics 1Dokument15 SeitenElectrode Kinetics 1Shriram NandagopalNoch keine Bewertungen

- Yield Line Method AppliedDokument144 SeitenYield Line Method AppliedUmed ADA-ALSATARNoch keine Bewertungen

- Nuclear Power at Zahurul SirDokument43 SeitenNuclear Power at Zahurul SirFarhan IstiaqueNoch keine Bewertungen

- Bate and Mueller Astrophysics Homework 5 SolutionsDokument2 SeitenBate and Mueller Astrophysics Homework 5 SolutionsAliNoch keine Bewertungen