Beruflich Dokumente

Kultur Dokumente

183-192 - Vdmerwe Siriovision Datamine Cae

Hochgeladen von

Siva Kumar MathanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

183-192 - Vdmerwe Siriovision Datamine Cae

Hochgeladen von

Siva Kumar MathanCopyright:

Verfügbare Formate

Paper 55:text 10/15/09 4:44 PM Page 183

VAN DER MERWE, H.C. Sirovision: a proposed solution for the implementation of a digital geological mapping and modelling system at AngloGold

Ashantis Moab Khotsong Mine interim report. World Gold Conference 2009, The Southern African Institute of Mining and Metallurgy, 2009.

Sirovision: a proposed solution for the implementation of a

digital geological mapping and modelling system at AngloGold

Ashantis Moab Khotsong Mine interim report

H.C. VAN DER MERWE

AngloGold Ashanti Ltd., SA Division Geoscience Technical Office

In the 21st century, dynamic, accurate digital 3-D geological models are essential to the pursuit of

safe, efficient and profitable mining. This is particularly true for the deep-level underground

mines in South Africa. The Sirovision solution is a collaboration project between the Australian

CSIRO (Commonwealth Scientific and Industrial Research Organisation), Datamine Software

Ltd. and AngloGold Ashanti Ltd (AGA). The purpose of the project is to provide a fully

integrated digital rock face imaging, geological mapping and modelling system for the AGA gold

mining operations.

The CSIRO-developed Sirovision Stereo Camera Rig (SCR) consists of two digital cameras, a

lighting system, a laser guidance system and image processing software. The imaging system

works on the principles of photogrammetry, i.e. overlaying of two 2-D images with a central focus

point, with mathematical algorithms extracting 3-D information from the 2-D image pair. The

output from matching several image pairs is a computer-generated, full 3-D, virtual copy of the

mining excavation. The image resolution and relief ares of sufficient quality to distinguish

different rock types and structural contacts. Functionality within Datamine Studio3 is used to add

geological intelligence to the 3-D images provided by Sirovision. The geologist identifies and

draws lines representing geological features directly onto the image. By utilizing the inherent

topography of the 3-D image, the software is able to convert the lines into 3-D surfaces, ready

for use in the 3-D geological model.

Subsequent to promising underground test results from AGAs Sunrise Dam Gold Mine

(SDGM) in Australia and other mining operations worldwide, it was decided to test the

Sirovision system in the South African deep-level gold mines. The first underground tests at

Moab Khotsong Mine began in January 2009. The objectives of these tests entailed the capturing

of 3-D images of selected development ends, mapping of geological features onto the 3-D images

and integration of the mapping data with the 3-D geological model. Some downsides have

cropped up during the feasibility testing, related to practicality of the SCR for acquisition of 3-D

imagery in the deep-level underground operating environment. These constraints will have to be

addressed prior to operational implementation. Facing such difficulties is not unusual when

attempting to implement new technology in such a challenging working environment and test

work is still in progress at the mine in order to prove the concept of using this technology in a

Witwatersrand underground gold mine.

The great advantage of the Sirovision solution is that it offers the geologist the opportunity to

work remotely on a 3-D virtual copy of a mining excavation, without the heat, humidity, hazards

and time constraints associated with physical mapping in an underground workplace.

Introduction geological mapping and modelling system for the AGA

In the 21st century, accurate digital 3-D geological models gold mining operations.

are essential to the pursuit of safe, efficient and profitable The purpose of this paper is threefold:

mining. This is particularly true for deep-level underground To provide an overview of the Sirovision technology

mines in South Africa. New technology is continuously and its intended application to mining geology in

being developed and tested in different mining general

environments in pursuit of a more dynamic geological To consider AGAs experience to date, in terms of the

workflow process. The Sirovision system is a systems suitability, test results and implementation at

collaboration project among the Australian CSIRO different mining operations around the world

(Commonwealth Scientific and Industrial Research To highlight the feasibility study currently underway at

Organisation), Datamine Software Ltd. and AngloGold the companys Moab Khotsong mine, one of its deep-

Ashanti Ltd (AGA). The purpose of the project is to level Witwatersrand gold mines. This study gives a

provide a fully integrated digital rock face imaging, realistic assessment of the opportunities and downsides

SIROVISION: A PROPOSED SOLUTION FOR THE IMPLEMENTATION OF A DIGITAL SYSTEM 183

Paper 55:text 10/15/09 4:45 PM Page 184

associated with the introduction of new technology in a Underground equipment

very challenging mining environment. It also provides The CSIRO-developed Sirovision portable stereo camera

a view of future expectations of the technology. rig for underground use (Figures 2a and 2b) is a single unit

that consists of a built-in rechargeable power supply, a

Overview of the Sirovision technology lighting system, a laser guidance system, two Nikon D200

10.2 megapixel digital cameras, a flash unit (all

Background information synchronised to activate from a single button) and the

The Sirovision technology was developed by the image processing software. The containing unit consists of

Australian CSIRO (Commonwealth Scientific and an aluminium frame with durable transparent Perspex

Industrial Research Organisation) at the Queensland Centre panels for ease of operation. The unit can be mounted on a

for Advanced Technologies in Brisbane, Queensland with tripod or monopod, whichever is appropriate for the

input from relevant scientists, including geologists, operating conditions.

physicists, surveyors, engineers and IT professionals The camera rig unit alone is portable and can be handled

(www.sirovision.com). The first commercial sale of the by one person (Figure 2d). The dimensions are

product was already in 2001, with reported successful approximately 88 cm x 30 cm x 25 cm and it weighs 13 kg.

application from various large mining companies A rugged case for safe transportation has been

(www.sirovision.com). This technology is best described as manufactured (Figure 2c). The dimensions of the case are

a 3-D digital geological mapping acquisition and analysis 98 cm x 25 cm x 38 cm and it weighs 14 kg. The combined

tool. In the initial stages Sirovision was appropriate only weight (27 kg) and dimensions of the camera rig and case is

for geotechnical application, but the system is continuously an important practical consideration in terms of application

being improved to make it suitable as a total structural in South African deep-level underground mines, and is

mapping solution. discussed later on in this paper.

Sirovision equipment

Different sets of equipment and software solutions have

been developed for use in open pit and underground mining

environments. The need for different solutions originates

from the fact that the physical characteristics of the

operating environments are very different and survey

control points are obtained in very different ways.

Open pit equipment

The open pit solution is not the focus of this paper.

However, a brief overview of the system seems to be

appropriate for the sake of providing background

information. The equipment consists of one high quality

digital camera with a selection of lenses appropriate for the

operating environment, a rugged case for safe transportation

of the equipment and a tripod (Figure 1). A Nikon 300D

digital camera was selected for use at Sunrise Dam Gold

Mine in Western Australia, but a whole range of different

Nikon, Olympus and Canon cameras and lenses are

available for use with Sirovision (www.sirovision.com).

The positioning of the camera system is used as input for

survey control in the image processing software, and

therefore is measured with a high precision differential

GPS.

Figure 2. Sirovision underground stereo camera rig. Figure 2a is

a front view of the camera rig, i.e. the camera lenses, flash unit

and lighting system. The control units and LCD camera displays

Figure 1. Sirovision open pit equipment. The camera and lenses on the back view is shown in Figure 2b. A photograph of the

in the container box are shown on the left in Figure 1a. On the camera rig in the rugged transportation case is shown in

right in Figure 1b is an example of field use of the open pit Figure 2c. Operation of the camera rig on a monopod is shown in

equipment (www.sirovision.com) Figure 2c courtesy of www.sirovision.com

184 WORLD GOLD CONFERENCE 2009

Paper 55:text 10/15/09 4:45 PM Page 185

Fundamental theory of the Sirovision software comprehensive range. However, prior to regional

The imaging system operates on the principles of implementation it is important to consider a dedicated

photogrammetry, which is commonly known for its database and appropriate metadata scheme, as was also

application in using a stereoscope to view aerial suggested by van Wyk (2008). This is essential from a

photographs (van Wyk, 2008). The stereophotogrammetric standardizing and data management point of view. Figure 6

process in this application involves the overlaying of two 2- is an example of joint plane traces mapped onto the 3-D

D images with a central focus point, after which image of the rock face. By utilizing the inherent

mathematical algorithms in the Sirovision software extract topography of the 3-D image, the software is able to

3-D information from the 2-D image pair (van Wyk, 2008). convert the lines into 3-D surfaces, ready for use in the 3-D

The principle components of a stereophotogrammetric geological model (Figure 7). Essential information such

system are illustrated in Figure 3. as feature types, lithology, dip and dip direction for each

The output from the image processing algorithm is a of the identified surfaces is stored in a local database. This

computer-generated 3-D model of the spatial arrangement information can be used in analysis applications, e.g.

of the images that were captured in the 2-D view frames. geotechnical analysis of joint set characteristics by using

The 3D model can then be registered in its true spatial the SiroJoint module.

orientation by using known survey control points in the

images for 3-D georeferencing this is done in the

Sirovision software. The output from matching several

image pairs is a computer-generated, full 3-D, virtual copy

of the mining excavation. The image resolution and relief

are of sufficient quality to distinguish different rock types

and structural contacts (Figure 4).

Integration with Datamine software

In order to make optimal use of the acquired digital 3-D

photographic information, the Sirovision software has

been packaged as an integrated module within the

Datamine Studio3 geological modelling environment.

Datamine Software Ltd. completed the following software

developments in association with AngloGold Ashanti Ltd.

as part of the Sirovision-Datamine integration project:

SiroLink (new application): automatically moves the

digital images from the camera and allows the user to

visually validate which images to use as stereo image

pairs as well as the order of matching. The images and

survey information are placed in a data store. The

purpose of this application is to minimize the risk of Figure 3. Schematic representation of the components of a typical

invoking human error in the data handling process. stereophotogrammetric system (van Wyk, 2008)

MineMapper 3D (enhancements to existing

application): retrieves one image of an image pair from

the data store and allows mapping, as digitized line

work with appropriate descriptions, to take place on the

single 3-D image, after which the mapped data are

stored in the MineMapper 3D database. The aim of this

enhancement was to improve efficiency in terms of the

handling of large image file sizes.

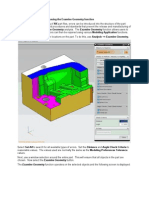

New functionality in Datamine Studio 3:

Functionality to allow the creation and positioning

of 3-D images (integration of Sirovision software

within the Studio 3 environment).

A data driver for Sirovision 3-D images to enable

loading and visualization within the Studio3

modelling environment.

Functionality enabling features to be identified on

the 3-D images and converted to planes (similar

algorithms are used in the SiroJoint module).

The updated functionality within Datamine Studio3 is

used to add geological intelligence to the 3-D images

provided by Sirovision solution. The geologist identifies

and draws lines representing geological features directly

onto the image by means of on-screen digitizing (Figures 5 Figure 4. A virtual copy of the excavation, i.e. a 3-D view

and 6). Figure 5 is an example of geological features generated from a set of matched image pairs for an underground

mapped onto the 3-D image. Currently the list of geological ore drive at Sunrise Dam Gold Mine (image modified after

features is user defined and can be modified to cover a Datamine Software Ltd., 2008)

SIROVISION: A PROPOSED SOLUTION FOR THE IMPLEMENTATION OF A DIGITAL SYSTEM 185

Paper 55:text 10/15/09 4:45 PM Page 186

Figure 5. Mapping of geological features onto the 3-D image (image from Datamine Software Ltd., 2008)

Sirovision trials at AngloGold Ashanti (AGA)

gold mines worldwide

Testing and implementation of the Sirovision system has

been in progress since 2003 at different mining operations

of AGA worldwide. The aim of this section is to provide a

summary of the experience recorded by different

operations. The map of AGA global mining operations

(Figure 8) is provided as a reference in terms of locality of

the operations mentioned in the rest of this section.

Geita, Tanzania

Sirovision is applied for creating 3-D faces of the open pit

walls and subsequent geotechnical analysis. The system is

Figure 6. Joint plane traces (green lines) drawn onto the 3-D reportedly good for mapping large brittle structures, but

image (image from Datamine Software Ltd., 2008)

poor in delineating lithological contacts and ductile

deformational features. This is not regarded as a limitation

of the software, but rather due to weathering effects and

rock staining in the pit walls. Manual field mapping is still

required, but Sirovision might be used to acquire

additional value adding information from areas that are

unsafe or out of reach. In such cases, a lot of emphasis will

be placed on interpretation of the actual field mapping as a

priori data to be used in conjunction with the Sirovision 3-

D imaging. For the moment the focus remains on

geotechnical application.

Siguiri, Guinea

Siguiri reported similar results to Geita, where the

Sirovision system is in use only for geotechnical data

acquisition and analysis in an open pit environment. The

only noteworthy complaint raised was aboutg the intense

computing power required to run the virtual reality graphics

Figure 7. Joint planes calculated from traces and extended and image processing algorithms, which are at times

beyond the face (image from Datamine Software Ltd., 2008) frustratingly slow.

186 WORLD GOLD CONFERENCE 2009

Paper 55:text 10/15/09 4:45 PM Page 187

Figure 8. Map of AngloGold Ashanti global mining operations (from www.anglogoldashanti.com)

AGA Minerao, Brazil Time: a considerable reduction in mapping time was

Sirovision testing is in progress at Cuiab mine, an recorded, i.e. manual mapping of 4 hours replaced by

underground trackless mining operation in Brazil. The test Sirovision process of 1 hours (166% improvement).

results are summarized as follows: Geological data archive: a full 3-D record of the rock

Hardware constraints were reported. The camera lenses face exposure can be kept for future reference.

take approximately 40 minutes to acclimatize to hot Consistent electronic recording of geological attributes

and humid conditions underground and cannot be used to a database will enable simple retrieval and analysis

until all of the fog build up disappears. At times the of data.

flash unit malfunctioned, and the source of the problem Accuracy: a 20% increase in accuracy is reported,

could not be traced. based on the consistent mapping by the system, as

Image resolution is of sufficient quality to identify opposed to the varied physical skills and capabilities of

lithological contacts, geological structures (foliation individual geologists.

and faults) and reference points, whereas time of image Exposure: an increase of 122% in the amount of

acquisition is short (46 image pairs in one day). exposure mapped is achieved. This is because the

Reference points are surveyed by means of Total camera rig can capture the full picture (4 m high) from

Station, which is also quick and precise. the bottom to the top of the excavation, whereas a

Image processing time is the main problem. Geometric geologist is limited to approximately 1.8 m height for

correction takes at least 5 minutes per image plus an accurate observation and recording of data.

additional 15 minutes to process each 3-D image pair. Geological mapping: Sirovision is good for the

The mine only recently upgraded its software to mapping of large scale structures, but detailed mapping

Datamine Studio3, which will now enable the testing of - e.g. mineral lineations, slickensides and foliations -

the integrated Sirovision-Datamine solution. requires manual observation and recording.

Sunrise Dam Gold Mine (SDGM), Australia Sirovision at AngloGold Ashantis Moab

SDGM is one of the operations where both the open pit and Khotsong Mine, South Africa

underground applications of Sirovision could be tested. Subsequent to promising underground test results from

No noteworthy problems were reported for the open pit Sunrise Dam Gold Mine (SDGM), it was decided to test the

application and results were considered to be of good Sirovision system in AGAs South African deep-level

quality. A pilot project was undertaken early in 2008 to put underground gold mines. A feasibility study is currently in

Sirovision to the test in the trackless underground ore progress to assess the value and suitability of the system in

drives (van Wyk, 2008 and Datamine Software Ltd., 2008), this type of operating environment. The aim of the study is

producing promising results. Conclusions from the test to successfully capture 3-D images of exposed rock faces in

results are summarized as follows: selected development ends, map geological features onto

Safety is one of the main reasons for developing the 3-D images and integrate the mapping data with the

Sirovision. The system makes it possible to capture current 3-D geological model. The first underground tests

images of exposed rock from some distance away from began at Moab Khotsong Mine in January 2009. These tests

the face. indicated that, conceptually, the Sirovision system has

Illumination: the powerful flash unit of the camera rig huge potential to add value to the geological workflow

provides excellent illumination in order to capture clear process. However, it is also important to take note of the

images in true 3-D. potential pitfalls encountered during this study. The

SIROVISION: A PROPOSED SOLUTION FOR THE IMPLEMENTATION OF A DIGITAL SYSTEM 187

Paper 55:text 10/15/09 4:45 PM Page 188

remainder of this section is dedicated to discussing these or more persons to carry the equipment whilst

pitfalls and the measures that have been put in place to travelling on foot.

ameliorate their associated risks, as well as to present some Horizontal transportation on some levels is done by

of the results obtained to date. means of man carriages. In such cases the SCR is

transported to the designated carriage bay of that level.

Risk assessment From the man carriage bay persons are generally

A valid risk assessment document must be available for all required to walk up to 3 km to the development

equipment utilized on the mine premises or in the working places. It is not always possible to arrange

underground working places. The risk assessment additional carriage transport, as the conveyances are

documentation for the Sirovision Stereo Camera Rig used for production activities. Walking long distances

(SCR) was compiled by Datamine South Africa and underground on rail tracks, while carrying an

accepted by the Moab Khotsong Mine Safety and Health uncomfortable load, is very strenuous and time

department (a copy of the document can be supplied upon consuming, and probably the main limitation with

request). The key issues addressed in the risk assessment respect to operational implementation of the system.

are the handling of the heavy equipment, and the fact that Datamine Software Ltd. has taken note of this, and is in

the equipment is not classified as intrinsically safe (i.e. the the process of redesigning and building a new SCR,

SCR is not fireproof). The Witwatersrand gold mines are which should be more practical for underground use.

well known for containing sources of flammable gas that

can possibly ignite due to the slightest electrical spark or Humidity

the use of a camera flash unit. Therefore it is imperative During underground tests at Moab Khotsong Mine, it was

that a burning permission document is obtained from the noted that the camera lenses take up to 45 minutes (after

appointed section manager prior to each underground test. being removed from the case) to acclimatize to the humid

Furthermore, it is required that flammable gas underground conditions. The cameras cannot be used

concentration measurements are conducted continuously by before the fog build up disappears, as it causes hazy,

means of a certified flammable gas monitoring device. unusable photographs. This is problematic, as underground

time at the face is extremely limited in this type of mining

Practical constraints and limitations environment.

Size matters Hardware malfunction

The dimensions (98 cm x 25 cm x 38 cm) and weight During the initial underground tests only one of the cameras

(27 kg) of the SCR is not problematic in a trackless mining on the SCR functioned at times. This meant that for some

environment where the equipment can be transported on the images the stereo pairs could not be generated as the

back of a pick-up truck and handled over short distances by anticipated matching image did not exist. The only

one person. However, this is a very important practical explanation for this was that the shutter release system was

consideration in terms of transportation in a South African temporarily faulty and did not trigger the second camera.

deep-level underground mine: Being intermittent, the fault is difficult to remedy. It might

The SCR equipment has to travel down a vertical shaft be that transportation of the equipment, combined with the

in a cage (conveyance used to transport persons and heat and humidity present at the test site led to temporary

materials). In this situation the persons travelling in the malfunctioning of some electronic components this has

cage are at risk of being injured by the equipment. The been observed in other electronic equipment tested in some

equipment is also at risk of being damaged by persons of AGAs other Witwatersrand gold mines.

leaning against or standing on the case. At Moab

Khotsong Mine, there is often water seepage into the Focal length and camera positioning

shaft. To accommodate this, a waterproof bag was The focal length of the Sirovision SCR is optimized for

designed to cover the SCR case (Figure 9). The bag photography approximately 5 m away from the camera

was designed with 6 handles to make it possible for two lenses. In principle, this should work well when recording

Figure 9. The photograph on the left (Figure 9a) shows the rugged case which is used to transport the Sirovision Stereo camera rig. The

waterproof bag used to protect and carry the SCR underground is shown on the right (Figure 9b)

188 WORLD GOLD CONFERENCE 2009

Paper 55:text 10/15/09 4:45 PM Page 189

images of the advancing face of the development tunnel. ensure the safety of the persons that will be drilling the face

The underground development ends at Moab Khotsong for the next blast. This process leaves very little time

Mine have dimensions of approximately 4 m in height and available for the acquisition of images for use in the 3-D

3.8 m in width, which is problematic for the photography of model. During underground trials it was found that in most

sidewalls as images are out of focus. The SiroLink image cases the temporary support was installed before the

pairing process still creates a 3-D image from the two 2-D photographs could be taken.

images, but the matching algorithm has difficulty matching

out of focus points. The resultant 3-D wireframe is spiky Underground test results from Moab Khotsong Mine

as shown in Figure 10 and not useful for mapping or

combining with adjacent image pairs. In the preceding sections a few results from underground

Another problem encountered was the orientation of the tests at Moab Khotsong mine were presented (Figures 10 to

camera relative to the rock face to be photographed. If this 12) and discussed. In Figure 14 an example is shown of

relative angle is not close to 90 degrees, a curved model is geological features drawn onto the 3-D image by means

derived, due to the different relative distances of the camera of on-screen digitizing along with the 3-D planes generated

to the rock face. An example is shown in Figure 11. Even from the line work. This image pair was again slightly out

though the image resolution is good, geological mapping in of focus, and therefore the 3-D model was not to the

3-D space cannot be done by using this image pair. required standard of accuracy. As a result it can be

observed that the calculated planes do not coincide exactly

Interfering objects with the features on the image.

During the underground trial another important observation

was made. Figure 12 is an example of how objects (hoses, Project status discussion

in this case) between the SCR lenses and the observed rock

face will cause distortion in the 3-D model. This The feasibility study underway at Moab Khotsong Mine is

interference is problematic when acquiring underground 3- still at a very early stage. The concept and its suitability to

D image pairs at Moab Khotsong Mine. this type of mining environment still need to be proven.

Figure 13 shows a blasted rock face before temporary Limitations and errors are documented in detail in order to

support is installed. Temporary support is installed directly derive the suitable best practice when utilizing the

after the broken rock has been removed, (Figure 13.b.) to Sirovision in these conditions.

Figure 10. The 3-D photograph obtained from capturing images of the sidewall of a cross-cut is shown in Figure 10a on the left. When the

photograph is rotated in 3-D space the spikes in the model are evident, as shown on the right in Figure 10b

Figure 11. The 3-D photograph obtained from capturing images of the sidewall of a cross-cut is shown in Figure 11a on the left. When the

photograph is rotated in 3-D space the apparent curvature in the model is evident, as shown on the right in Figure 11b

SIROVISION: A PROPOSED SOLUTION FOR THE IMPLEMENTATION OF A DIGITAL SYSTEM 189

Paper 55:text 10/15/09 4:45 PM Page 190

Figure 12. The 3-D photograph obtained from capturing images of the sidewall of a cross-cut is shown in Figure 12a on the left. When the

photograph is rotated in 3-D space the spikes caused by the interfering object are evident, as shown on the right in Figure 12b

Figure 13. A 2-D photograph of a blasted, unsupported rock face is shown on the left (Figure 13a). The picture on the right is a 2-D

photograph of a supported rock face (Figure 13b)

Figure 14. The image on the left (Figure 14a) is shown to illustrate how lines are digitally drawn onto the 3-D image. Planes of the mapped

surfaces, generated from the line work, are shown on the right (Figure 14b)

To date, no perfect set of 3-D images has been captured, Image resolution is of a high standard and the Sirovision

and could thus not be combined to generate a completely imaging system has the potential to add value to the

accurate 3-D virtual copy of the mining excavation as geological workflow process in the form of input for the 3-

anticipated. Nevertheless, valuable lessons have been learnt D geological and geotechnical models. It will also provide a

during the underground trials at Moab Khotsong Mine, as permanent true 3-D record of the mined-out excavations.

discussed in the preceding sections. Another important Therefore, further tests are planned to take place at Moab

factor to consider is the extensive processing time required Khotsong. Another test site of appropriate dimensions will

to produce the 3-D image models. In ideal conditions the be selected, and timing will be planned carefully, in order

photography will be quicker than conventional mapping, to conclude the imaging process prior to support

but the processing of images can take up to 4 hours, installation. As soon as a useful set of 3-D images is

depending on computer specifications. Digital mapping of obtained, attempts will be made to integrate the acquired

elements onto the images can begin only after this data with the existing 3-D geological model in use at Moab

processing is complete. Khotsong Mine. This will also be a challenging exercise, as

190 WORLD GOLD CONFERENCE 2009

Paper 55:text 10/15/09 4:45 PM Page 191

AGAs South African mines do not currently use Datamine however, important to note that ground-truthing of

products for 3-D modelling and some customization to the detailed underground geological mapping data will still be

applications and data management systems will have to be required.

considered in order to achieve full integration.

Additional underground testing is also planned to take Acknowledgements

place at AGAs Mponeng Mine on the West Wits line,

The author would like to thank a number of persons who

where an appropriate test site might be more easily

have played a role in this feasibility study. Vaughan

accessible and more often available.

Chamberlain and Richard Peattie are acknowledged for

ensuring high level management support and sponsorship

Conclusions and recommendations from AngloGold Ashanti Limited for the Sirovision

Results from test work underway at Moab Khotsong mine project. Moab Khotsong mine management and particularly

indicate that the Sirovison system could be beneficial in role players in the Geosciences department Terry Adam,

the acquisition of high quality digital geological mapping Peter Schmidt, Andrew Matlala and Adele Hoffmann are

data, ready for integration with the 3-D geological model. A thanked for their contributions. The staff from Datamine

permanent 3-D record of the underground excavations South Africa that have played a part in this project are Roy

would add value to the geological workflow process. Irvine, Kathleen Hansmann and Hennie Coetzee.

However, the system still has to be proven to deliver useful AngloGold Ashanti colleagues from different operations

results in the required operating environment. To date, no world-wide are thanked for sharing information and

perfect set of 3-D images has been captured, and could thus personal experience with the Sirovision systems, i.e.

not be combined to generate a 3-D virtual copy of the Andr de Rezende Jardim (Brazil), Mariana Gomide

mining excavation as anticipated. Nevertheless, a number (Brazil), Jon Hill (South America), Matthew Brayshaw

of valuable lessons have been learnt during the (Geita), Roric Smith (Australia), Peter Winkler (Siguiri),

underground trials at Moab Khotsong mine, which will aid Drissa Sankare (Siguiri). Jeff Kennedy is thanked for his

in refining and ultimately perfecting the 3-D imaging valuable input during internal review. A special word of

process. thanks to Paul van der Plas for offering his time for external

Some practical constraints related to the application of review of this paper.

the Sirovision system in a Witwatersrand gold mine need

to be considered. The current format of the Sirovision References

Stereo Camera Rig (SCR) is impractical for daily routine ANGLOGOLD ASHANTI intranet website

usage at Moab Khotsong mine. The size and weight of the http://moss/sites/it/ informatrix/Maps/AngloGold%20

camera rig has a large impact on transportation within the Ashanti%20Global/AGA%20ops%20%20major%20p

underground mining environment. The Sirovision SCR in opulation%20 centres.jpg INTRANET, cited 15

its current format would most likely be suitable only for August 2009.

application in high priority development projects where the

time and effort required to acquire and process 3-D images DATMINE SOFTWARE LTD. Sirovision Pilot Project A

are warranted. Datamine Software Ltd. has reported that a description of the Sirovision Pilot Project for

redesigned SCR is currently being built, as a result of the enhanced mapping of mine geology and geotechnical

impracticalities associated with the current SCR, but no features undertaken at AngloGold Ashantis Sunrise

details have been disclosed to date. Test work will continue Dam Gold Mine in January 2008.

in the feasibility study in order to prove that the concept

will work for AngloGold Ashantis South African deep- DATAMINE SOUTH AFRICA (PTY) LTD. Proposal for

level underground gold mines. The introduction of the the Implementation of a Digital Mapping and

improved and more practical hardware will assist in the Modeling System at AngloGold Ashantis Moab

implementation process. Khotsong Mine, 2008.

The great advantage of the Sirovision system is that it SIROVISION INTERNET website http://www.sirovision.

would offer the geologist the opportunity to work remotely com INTERNET, cited 23 March 2009.

on a 3-D virtual copy of a mining excavation, without the

heat, humidity, hazards and time constraints associated with VAN WYK, J. Sirovision Pilot Porject (AGA internal

physical mapping in an underground workplace. It is, report). 2008.

Hendrik Christoffel van der Merwe

Technical Assistant Geoscience, AngloGold Ashanti Ltd, SA Division Geoscience Technical Office

Directly after graduating from the University of Pretoria in 2003 my career within AngloGold

Ashanti commenced. I have had the opportunity to work at two of the Witwatersrand gold mines in

the Vaal River region (Moab Khotsong and Tau Lekoa), fulfilling different roles within the mining

geology and local resource estimation sub-disciplines. I have also had the opportunity of fulfilling

exploration duties from the SA Exploration office. I am currently based at the SA Division

Geoscience Technical Office (GTO) with responsibility for geoscience technical systems and

technology.

SIROVISION: A PROPOSED SOLUTION FOR THE IMPLEMENTATION OF A DIGITAL SYSTEM 191

Paper 55:text 10/15/09 4:45 PM Page 192

192 WORLD GOLD CONFERENCE 2009

Das könnte Ihnen auch gefallen

- Text Map 4-5 Geology: X X X + - Tunduma Nako '8g+ - .. - +-SDokument2 SeitenText Map 4-5 Geology: X X X + - Tunduma Nako '8g+ - .. - +-SSiva Kumar MathanNoch keine Bewertungen

- Butha Neri PDFDokument11 SeitenButha Neri PDFSiva Kumar Mathan100% (1)

- PDF3D Report Gen - HelpDokument136 SeitenPDF3D Report Gen - HelpSiva Kumar MathanNoch keine Bewertungen

- Com - 20100723 - 43-101 - Claya Comparison of Table Ni 43 101 Vs Samrec TableDokument8 SeitenCom - 20100723 - 43-101 - Claya Comparison of Table Ni 43 101 Vs Samrec TableSiva Kumar MathanNoch keine Bewertungen

- 011-Rupprecht - Samrec Proposal 2016Dokument10 Seiten011-Rupprecht - Samrec Proposal 2016Siva Kumar MathanNoch keine Bewertungen

- Spoken English Flourish Your Language PDFDokument1 SeiteSpoken English Flourish Your Language PDFSiva Kumar MathanNoch keine Bewertungen

- Basic GrammarDokument74 SeitenBasic GrammarSiva Kumar MathanNoch keine Bewertungen

- JVB WorkshopFlyer0710Dokument1 SeiteJVB WorkshopFlyer0710Siva Kumar MathanNoch keine Bewertungen

- B652 Dust ControlDokument20 SeitenB652 Dust ControlSiva Kumar MathanNoch keine Bewertungen

- Geology Resume TemplateDokument1 SeiteGeology Resume TemplateSiva Kumar MathanNoch keine Bewertungen

- Chuchill Mining DisputeDokument1 SeiteChuchill Mining DisputeSiva Kumar MathanNoch keine Bewertungen

- DRT Users GuideDokument51 SeitenDRT Users GuideSiva Kumar MathanNoch keine Bewertungen

- Functional Design of RoadsDokument12 SeitenFunctional Design of RoadsSiva Kumar MathanNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Python Melli Bank - IrDokument10 SeitenPython Melli Bank - IrnafasNoch keine Bewertungen

- E8044 M5a99x Evo R20 V2 WebDokument180 SeitenE8044 M5a99x Evo R20 V2 Webdanut_dumitruNoch keine Bewertungen

- Sap Workflow TipsDokument3 SeitenSap Workflow TipsBro Jeff100% (1)

- GDOH HIS SAP Business Client ConfigurationDokument14 SeitenGDOH HIS SAP Business Client ConfigurationxolanembatsanaNoch keine Bewertungen

- GM CommandsDokument3 SeitenGM CommandsAnnie ViNoch keine Bewertungen

- Tutorials - Automatic Storage Management (Asm) - Oracle DBADokument6 SeitenTutorials - Automatic Storage Management (Asm) - Oracle DBAHeshamAboulattaNoch keine Bewertungen

- Sect 6 Priority Panel (K01-11-036) ManualDokument68 SeitenSect 6 Priority Panel (K01-11-036) ManualJose Luis Jimenez InfanteNoch keine Bewertungen

- Developed by Whatsapp: Telegram ID: Support Website:: Egyfixlab 00201283689946 @egyfixlabDokument28 SeitenDeveloped by Whatsapp: Telegram ID: Support Website:: Egyfixlab 00201283689946 @egyfixlabview starNoch keine Bewertungen

- 5 Successful Open Innovation ExamplesDokument44 Seiten5 Successful Open Innovation ExamplesSambhav MehtaNoch keine Bewertungen

- Surgical Procedure Manual Surgical Procedure ManualDokument76 SeitenSurgical Procedure Manual Surgical Procedure ManualCariti91100% (2)

- Servo Motor Modeling in SimulinkDokument10 SeitenServo Motor Modeling in SimulinkRose GutierrezNoch keine Bewertungen

- HPE Integrated LightsDokument6 SeitenHPE Integrated LightsMohammad AliNoch keine Bewertungen

- Geamar 120 ISL: Integrated Monitoring and Control SystemDokument35 SeitenGeamar 120 ISL: Integrated Monitoring and Control SystemcastelNoch keine Bewertungen

- IREBDokument7 SeitenIREBMauricio Bustamante0% (1)

- Design and Implementation of An Electronic Patient Management SystemDokument94 SeitenDesign and Implementation of An Electronic Patient Management SystemGlenn Asuncion Pagaduan100% (2)

- AVR USB Programmer ManualV2Dokument20 SeitenAVR USB Programmer ManualV2annbennNoch keine Bewertungen

- Final Proposal EditedDokument34 SeitenFinal Proposal Editedshankar bcNoch keine Bewertungen

- Inheritance in C++Dokument25 SeitenInheritance in C++Raghav DabgotraNoch keine Bewertungen

- Disa 3.0 - Revision - Module 4Dokument33 SeitenDisa 3.0 - Revision - Module 4rp.mssvNoch keine Bewertungen

- Improved 8-Point Approximate DCT For Image and Video Compression Requiring Only 14 AdditionsDokument6 SeitenImproved 8-Point Approximate DCT For Image and Video Compression Requiring Only 14 AdditionsTechnosIndiaNoch keine Bewertungen

- M2000 Basic Skill Training Compress - PART1Dokument24 SeitenM2000 Basic Skill Training Compress - PART1iqbalcanNoch keine Bewertungen

- NX Find Repair Part Errors Examine GeometryDokument4 SeitenNX Find Repair Part Errors Examine GeometryAhmed BdairNoch keine Bewertungen

- Canadian CustomsDokument239 SeitenCanadian CustomsPrashanth Venugopal100% (1)

- Triple A Global - Pitch DeckDokument28 SeitenTriple A Global - Pitch DeckIan DañgananNoch keine Bewertungen

- XML VersionDokument14 SeitenXML Versionluis gustavo morocco quispeNoch keine Bewertungen

- Scilympics ScheduleDokument2 SeitenScilympics ScheduleJozel M. ManuelNoch keine Bewertungen

- Ent102 - Reference Handbook PDFDokument76 SeitenEnt102 - Reference Handbook PDFAman GandhiNoch keine Bewertungen

- Module 4 Lecture Notes 1Dokument8 SeitenModule 4 Lecture Notes 1Alfred JengoNoch keine Bewertungen

- SolidWorks Advanced Part ModelingDokument1 SeiteSolidWorks Advanced Part ModelingCAD MicroSolutions100% (1)