Beruflich Dokumente

Kultur Dokumente

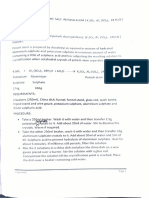

Process Flow Diagram

Hochgeladen von

kennethmsorianoCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Process Flow Diagram

Hochgeladen von

kennethmsorianoCopyright:

Verfügbare Formate

Water

T = 140 oC

5m3 H2O/tonnes of Steam

P = 361.53 kPa

Banana Peel

0.15 kg Steam/kg

Hot Humid Air

Particles > 1.168 mm Screened Peels

Mesh #14 Vapor

(Particle Size <

1.168mm)

W-1 D-1 C-1

Banana Peels Washed P eels P = 101 kPa Dr ied Pee ls T = 60oC Crushed Peels Scr eened P eels

F-1 P=101 kPa

o T = 60-70 oC P =P40.30

= 40.30

kPakPa

T=25-30 C Carbohydrates 57.82% T=25-30oC Carbohydra tes 56.97% Carbohydra tes 61.97%

K-1 Carbohydra tes 61.97%

Crude Fiber 31.06% Crude Fiber 30.61% Crude Fiber 33.30% Crude Fiber 33.30% T = 35 oC

Water 9.91% Water 2.00% Water 2.00% P = 5.49 kPa

Water 6.56%

Impurities 2.00%

Crude Lipid 1.64% Crude Lipid 1.79% Crude Lipid 1.79% D-2

Ash 0.87% Hot Air Ash 0.94% Ash 0.94%

Crude Lipid 1.67% (T = 70oC) Air

Ash 0.89% T = 26.4oC

RH = 78%

NaOH Sol n

0.10 kg

Water and Impurities kg Ste rilize d M edium

L-Leuci ne

Water 99.60%

0.70 kg

Impurities 0.40% NaOH 10%

kg Sterilized Medium Aspe rgillus niger

Water 90%

Inoculum

Water 69.61%

Steam Nutrie nts 26.38% Sterilize d Me dium T = 35oC

T = 140 oC K-2 Fermentation

Bioma ss 4.01%

o Gases

T=25-35 C CO2

Carbohydra tes 62.68%

P = 150 kPa Saccharomyc es cerev isiae Crude Fiber 33.67%

o NH3 Inoculum Crude Lipid 1.81%

D-3 T = 35-110 C

Fi lter ed Liquid Water 69.43% Ash 0.96%

Fe rmentation Br oth

J-1 Nutrie nts 27.57% Water 0.88%

Isoamyl A lcohol 54.24% Bioma ss 3.01%

Isoamyl A lcohol 28.86% 200 rpm

Et hanol 27.14%

We t Solids Crude Fiber 22.75% F-3 Fe rmentation Br oth Sterilize d Me dium T = 35oC

Condensate Water 17.80%

T = 95 oC Isobutanol 0.82%

Crude Fiber 39.61% Et hanol 14.44% P-4 T=25-35oC

Bioma ss 14.89% Water 9.47% Isoamyl A lcohol 28.86% Carbohydra tes 62.68% F-2

F-2

L-leucine 13.18% Bioma ss 8.55% P-3 Crude Fiber 22.75% Crude Fiber 33.67%

Pre-heated Liquid Isoamyl A lcohol 10.05% Le uc ine 7.57% Et hanol 14.44% pH=5-6 Crude Lipid 1.81%

T = 105oC Nutrie nts 7.51% Nutrie nts 4.31% Water 9.47% T=25-35oC Ash 0.96%

P-2 T=25-35oC P-1

Et hanol 5.03% Starch 1.74% Bioma ss 8.55% Water 0.88%

P= 180 KPa

Water 3.30% Crude Lipid 1.22% Le uc ine 7.57%

Isoamyl A lcohol 54.24% Ash 0.65%

Starch 3.02% Nutrie nts 4.31%

Et hanol 27.14% Isobuta nol 0.44% 10:1

Chilled Water Crude Lipid 2.13% Starch 1.74%

Water 17.80% (T = 5oC) Sterilized Medium:Inoculum

Ash 1.13% Crude Lipid 1.22%

Isobutanol 0.82% 10% Ethylene G lycol Specific Growth

Isobuta nol 0.15% Ash 0.65%

(C2H6O2)

90% Water Isobuta nol 0.44% Rate () = 0.14/hr

D-4 Chilled Water QP = 0.85 g/Lhr

Steam

(T = 5oC) (YX/S ) = 0.15 g/g

Chilled Water 10% Ethylene G lycol

(YP/S ) = 0.32 g/g

(T = 1oC)

10% Ethylene G lycol

E-2 (C2H6O2)

90% Water rp=0.232 kmol/m3min

T = 64 oC (C2H6O2)

P = 35 kPa 90% Water

Chilled Water

(T = 1oC)

1 F-4 10% Ethylene G lycol

(C2H6O2)

90% Water

E-1 Reflux By-Product

Ethanol 59.41%

Water 38.68%

6

Ethanol

Top

59.41%

F-5 Isoamyl Alcohol 1.00%

P-5 Water 38.68% Isobutanol 0.91%

T = 25-30oC

Steam Isoamyl Alcohol 1.00%

T = 140 oC

Isobutanol 0.91%

Cooling Water

(T = 40oC)

D-6

28 Bottom

D-5 Isoamyl Alcohol 99.00 % Cooling Water

F-6

T = 114.9 oC

Isobutanol 0.75% (T = 30oC)

P = 74.66 kPa T = 25-30oC

Water 0.25%

Condensate

Product

T = 95 oC

Isoamyl Alcohol 99.00 %

Isobutanol 0.75%

Water 0.25%

P-6

PRODUCTION OF 3-METHYL-1-BUTANOL (ISOAMYL ALCOHOL) FROM BANANA PEELS VIA FERMENTATION

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Security Blanket BunnyDokument8 SeitenSecurity Blanket BunnyFlorelisa100% (2)

- Method Statement For Rehabilitation WorksDokument11 SeitenMethod Statement For Rehabilitation WorksNordin Yunus88% (34)

- Two Phase Vertical Separator - Design ProcedureDokument31 SeitenTwo Phase Vertical Separator - Design ProcedurekennethmsorianoNoch keine Bewertungen

- Successfully Specify 3 Phase SeparatorsDokument12 SeitenSuccessfully Specify 3 Phase Separatorsmyself_ritesh0% (1)

- 2520.petroleum Refinery Distillation by Robert N. WatkinsDokument162 Seiten2520.petroleum Refinery Distillation by Robert N. Watkinsnchoniates100% (5)

- Design Two-Phase Separators Within The Right LimitsDokument8 SeitenDesign Two-Phase Separators Within The Right Limitschipiloo100% (1)

- Process Calculations 2nd Ed. - V. Venkataramani, N. Anantharaman & K.M. Meera Sheriffa Begum 2011 PDFDokument260 SeitenProcess Calculations 2nd Ed. - V. Venkataramani, N. Anantharaman & K.M. Meera Sheriffa Begum 2011 PDFantonino69100% (6)

- Two Phase Horizontal Separator - Design ProcedureDokument24 SeitenTwo Phase Horizontal Separator - Design ProcedurekennethmsorianoNoch keine Bewertungen

- Settling and Sedimentation: Particle Movement and Hindered SettlingDokument28 SeitenSettling and Sedimentation: Particle Movement and Hindered SettlingPratiksha GoreNoch keine Bewertungen

- STOICHIOMETRY (Yield, Conversion, Selectivity)Dokument4 SeitenSTOICHIOMETRY (Yield, Conversion, Selectivity)kennethmsoriano67% (3)

- DWCDokument10 SeitenDWCkennethmsorianoNoch keine Bewertungen

- Defects of TimberDokument10 SeitenDefects of TimberSandro Soriano100% (1)

- Fluidized Bed ReactorDokument25 SeitenFluidized Bed Reactorkennethmsoriano0% (1)

- Drag Force Fundamentals ExplainedDokument12 SeitenDrag Force Fundamentals ExplainedkennethmsorianoNoch keine Bewertungen

- Mixer and Tee (Splitter)Dokument23 SeitenMixer and Tee (Splitter)kennethmsorianoNoch keine Bewertungen

- Drag Coë Cent: The Basics of Transport PhenomenaDokument9 SeitenDrag Coë Cent: The Basics of Transport PhenomenakennethmsorianoNoch keine Bewertungen

- Stokes Law: The Basics of Transport PhenomenaDokument11 SeitenStokes Law: The Basics of Transport PhenomenakennethmsorianoNoch keine Bewertungen

- Optimization MethodsDokument15 SeitenOptimization MethodskennethmsorianoNoch keine Bewertungen

- Flash Separation - Conversion Reaction - Equilibrium ReactionDokument81 SeitenFlash Separation - Conversion Reaction - Equilibrium ReactionkennethmsorianoNoch keine Bewertungen

- Optimize heat exchanger, cooler and heater operationsDokument37 SeitenOptimize heat exchanger, cooler and heater operationskennethmsorianoNoch keine Bewertungen

- PE Exam Review SchedDokument7 SeitenPE Exam Review SchedkennethmsorianoNoch keine Bewertungen

- 5 Energy Balance 041416Dokument42 Seiten5 Energy Balance 041416kennethmsorianoNoch keine Bewertungen

- PD Comments - Oxalic AcidDokument6 SeitenPD Comments - Oxalic AcidkennethmsorianoNoch keine Bewertungen

- Chapter 4 PDDokument11 SeitenChapter 4 PDkennethmsoriano100% (1)

- 16-Splines and Piecewise InterpolationDokument17 Seiten16-Splines and Piecewise InterpolationkennethmsorianoNoch keine Bewertungen

- Diffusion HandoutDokument12 SeitenDiffusion HandoutJayson SorianoNoch keine Bewertungen

- Gauss Elimination SolverDokument21 SeitenGauss Elimination SolverkennethmsorianoNoch keine Bewertungen

- asset-v1-DelftX+TP102x+3T2016+type@asset+block@Formula Sheet ATPDokument12 Seitenasset-v1-DelftX+TP102x+3T2016+type@asset+block@Formula Sheet ATPkennethmsorianoNoch keine Bewertungen

- PD Comments - Propylene GLycolDokument4 SeitenPD Comments - Propylene GLycolkennethmsorianoNoch keine Bewertungen

- Balancing Redox Reactions by Oxidation Number Change MethodDokument4 SeitenBalancing Redox Reactions by Oxidation Number Change MethodkennethmsorianoNoch keine Bewertungen

- Chapter 3 PDDokument31 SeitenChapter 3 PDkennethmsorianoNoch keine Bewertungen

- SM4 Shortcut PDFDokument11 SeitenSM4 Shortcut PDFRian MumtazNoch keine Bewertungen

- Chapter 1 PDDokument24 SeitenChapter 1 PDkennethmsorianoNoch keine Bewertungen

- Unit+1 Some+Basic+Concepts+In+Chemistry PDFDokument20 SeitenUnit+1 Some+Basic+Concepts+In+Chemistry PDFParth GargNoch keine Bewertungen

- 35 - 01 Introduction Training AidsDokument100 Seiten35 - 01 Introduction Training AidsElliank QueirozNoch keine Bewertungen

- Chem Breadth 2022Dokument24 SeitenChem Breadth 2022tauNoch keine Bewertungen

- TDS Sadecol P 440 - EN Rev 1Dokument4 SeitenTDS Sadecol P 440 - EN Rev 1paosilvisNoch keine Bewertungen

- 027 - Section 3C Precast Concrete GrilleDokument2 Seiten027 - Section 3C Precast Concrete GrilleMark Roger II HuberitNoch keine Bewertungen

- ABS - P430: Production-Grade Thermoplastic For Design Series 3D PrintersDokument2 SeitenABS - P430: Production-Grade Thermoplastic For Design Series 3D PrintersqualityfreekNoch keine Bewertungen

- Mobilith SHC GreaseDokument3 SeitenMobilith SHC Greasealexander900616Noch keine Bewertungen

- Class 12 Expt 18 Preparation of Inorganic SaltDokument2 SeitenClass 12 Expt 18 Preparation of Inorganic Saltsridemass321Noch keine Bewertungen

- Rugged AC Magnetic Particle Inspection ProbeDokument2 SeitenRugged AC Magnetic Particle Inspection ProbeNubia BarreraNoch keine Bewertungen

- C - Ficha Tecnica - M2T MEGAFLEX SAE 100 R16Dokument1 SeiteC - Ficha Tecnica - M2T MEGAFLEX SAE 100 R16Rafael TorresNoch keine Bewertungen

- User's Guide: BondekDokument8 SeitenUser's Guide: BondekMing ChongNoch keine Bewertungen

- Ecoquip 2: Vapor Abrasive Blast EquipmentDokument20 SeitenEcoquip 2: Vapor Abrasive Blast EquipmentdimasjosesmithNoch keine Bewertungen

- Basic Civil - Module 3 - RoofDokument19 SeitenBasic Civil - Module 3 - RoofSEKHAR JNoch keine Bewertungen

- Gel Transparente para Afeitar Claro PDFDokument1 SeiteGel Transparente para Afeitar Claro PDFbeto_412Noch keine Bewertungen

- Potassium Carbonate: Product Data Sheet (PDS)Dokument1 SeitePotassium Carbonate: Product Data Sheet (PDS)Iqbal batchaNoch keine Bewertungen

- June 2022 PaperDokument17 SeitenJune 2022 PaperAthula Dias NagahawatteNoch keine Bewertungen

- Pre-PDI Form for 38-Storey Residential BlockDokument9 SeitenPre-PDI Form for 38-Storey Residential BlockMohd Jamal Mohd MoktarNoch keine Bewertungen

- BS EN 13411-4 Termination of Wire Ropes-Safety - MetalDokument22 SeitenBS EN 13411-4 Termination of Wire Ropes-Safety - MetalWalid Bdeir100% (1)

- Types and Causes of Cracks in Concrete StructuresDokument11 SeitenTypes and Causes of Cracks in Concrete Structuresraahul_nNoch keine Bewertungen

- Rockwood 2013 Price BookDokument80 SeitenRockwood 2013 Price BookSecurity Lock DistributorsNoch keine Bewertungen

- Hydrocarbons: AlkanesDokument12 SeitenHydrocarbons: AlkanesFredrick HeffersonNoch keine Bewertungen

- Unsur Transisi Deret 1Dokument62 SeitenUnsur Transisi Deret 1Miniatur IniNoch keine Bewertungen

- 8TH Online Preparing Common SaltsDokument4 Seiten8TH Online Preparing Common Salts20I1190 G-7CNoch keine Bewertungen

- Alumigrip 4250Dokument7 SeitenAlumigrip 4250Choirul AnamNoch keine Bewertungen

- Sigma Vyrobni Program enDokument12 SeitenSigma Vyrobni Program enEntropay UserNoch keine Bewertungen

- Stock CompletoDokument1 SeiteStock CompletoFaraz HaiderNoch keine Bewertungen