Beruflich Dokumente

Kultur Dokumente

New Mixer at LFL-Specifications Issue 1

Hochgeladen von

Dylan RamasamyOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

New Mixer at LFL-Specifications Issue 1

Hochgeladen von

Dylan RamasamyCopyright:

Verfügbare Formate

LFL

New Mixer at LFL

Structural Specifications

240749-31/JP/S001

Issue 1 | 26 February 2016

This report takes into account the particular

instructions and requirements of our client.

It is not intended for and should not be relied

upon by any third party and no responsibility

is undertaken to any third party.

Job number 240749-31

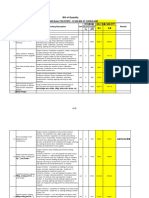

Document Verification

Job title New Mixer at LFL Job number

240749-31

Document title Structural Specifications File reference

Document ref 240749-31/JP/S001

Revision Date Filename MCB-RLB Refurbishment-Specifications Issue 1

Issue 1 26 Feb Description For Tender

2016

Prepared by Checked by Approved by

Name Peritamby Jeannot Fabrice Feliciane Michael Sew

Signature

Filename

Description

Prepared by Checked by Approved by

Name

Signature

Filename

Description

Prepared by Checked by Approved by

Name

Signature

Filename

Description

Prepared by Checked by Approved by

Name

Signature

Issue Document Verification with Document

240749-31/JP/S001 | Issue 1 | 26 February 2016

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-

SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

Contents

Page

1 General 1

1.1 Location and Brief Description 1

1.2 Definitions 1

1.3 Approvals 1

1.4 Notice for Approvals 2

1.5 Responsibility 2

1.6 Rates 2

1.7 Variations 2

1.8 Defective Work 2

1.9 Validity of BS and CP Publications 2

1.10 List of Materials 2

1.11 Drawings of the Works 3

1.12 Programme of the Works 3

1.13 Licences 3

1.14 Datum of Levels 3

1.15 Surveys 3

1.16 Standards 4

1.17 Quality of materials 4

1.18 Choice of materials 4

1.19 Plant and equipment 5

1.20 Design life 5

1.21 Shop drawings of appurtenant works 6

1.22 Notice of Operation 6

1.23 Progress meetings 6

2 The Site 7

2.1 Site 7

2.2 Inspection of Site 7

2.3 Access to Site 7

2.4 Clearance of Site 7

2.5 Site to be tidy 8

2.6 Safety on Site 8

2.7 Maintenance of services and structures 9

2.8 Maintenance of road traffic 9

2.9 Storm water management 9

2.10 Road and track crossings 10

2.11 Reinstatement of Site 10

2.12 Avoidance of pollution 10

240749-31/JP/S001 | Issue 1 | 26 February 2016

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

2.13 Site records 10

2.14 Temporary water and electricity supply 10

2.15 Temporary Works 11

2.16 Latrines 11

2.17 First Aid Outfit 11

3 Earthworks 12

3.1 General 12

3.2 Notice to be given before commencing earthworks 12

3.3 Setting out 12

3.4 Method of excavation 12

3.5 Excavation of unsound material 12

3.6 Support of excavation 13

3.7 Slips, falls and excess excavation 13

3.8 Preparation of excavations for structures 13

3.9 Care of excavated material 14

3.10 Materials for backfill and imported backfill material 14

3.11 Compaction of backfill 14

3.12 Allowance for settlement 14

4 Reinforced Concrete Materials 15

4.1 Code of Practice 15

4.2 Reference Documents 15

4.3 General 15

4.4 Cement 16

4.5 Aggregates 16

4.6 Water 16

4.7 Admixtures 16

4.8 Concrete 17

4.9 Reinforcement 18

4.10 Miscellaneous Materials 18

4.11 Storage of Materials 19

4.12 Rejected Materials 19

5 Reinforced Concrete Workmanship and Construction 20

5.1 Construction and Preparation of Formwork 20

5.2 Falsework 21

5.3 Construction Joints 22

5.4 Movement Joints 22

5.5 Reinforcement 23

5.6 Concreting 24

5.7 Striking of Formwork 25

5.8 Treatment Of Cast Concrete 26

240749-31/JP/S001 | Issue 1 | 26 February 2016

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

5.9 Concrete Finishes 26

5.10 Trial Panels 26

6 Reinforced Concrete Performance and Tests 27

6.1 General 27

6.2 Testing Facilities 27

6.3 Testing of Aggregates 27

6.4 Testing of Concrete 28

6.5 Ready-Mixed Concrete 28

6.6 Test failure of Works Concrete 28

6.7 Batching Plant 28

6.8 Setting Out And Tolerances 29

6.9 Defective Work 30

6.10 Tanking membrane 30

6.11 Load Tests 31

7 Concrete Block work 32

7.1 General 32

7.2 Strength 32

7.3 Drying Shrinkage 32

7.4 Moisture Movement 32

7.5 Manufacturers Certificate 32

7.6 Mortar 32

8 Structural Steelwork 34

8.1 Quality of Materials and Workmanship 34

8.2 Fabrication 34

8.3 Fastenings 35

8.4 Shop and Field Connections 36

8.5 Assembly 37

8.6 Erection 38

8.7 Galvanising And Painting 40

8.8 Paints 40

8.9 Preparation for Painting 40

240749-31/JP/S001 | Issue 1 | 26 February 2016

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

1 General

1.1 Location and Brief Description

This specification is applicable to structural works for the New Mixer at LFL,

Pailles.

This specification should be read in conjunction with the Tender or Construction

drawings, as applicable.

1.2 Definitions

The following definitions and abbreviations are used and have the following

meanings:

Engineer Arup SIGMA

BS - British Standard

CP - British Standard Code of Practice

The Works - the whole of the Works envisaged by this Contract including the

works of nominated Sub-contractors or Suppliers, Local Authority and Public

Undertakings unless specifically stated otherwise.

"Directed" - Directed by the Engineer

"Inspected" - Inspected by the Engineer

"Submitted" or "Submit" - Submitted to or submit to the Engineer for

examination

"Agreed" or "Agreement" - Agreed by or agreement of the Engineer

"Accepted" or Acceptance" - Accepted or acceptance by the Engineer in

writing

"Approved" or "Approval - Approved by or approval of the Engineer in writing

"Testing Authority" - An organisation nominated by the contractor and

approved by the Engineer fully equipped to carry out all tests and checks

required by this specification.

"Required - Required by the terms of this specification or any other contract

documentation.

Satisfactory - To the satisfaction of the Engineer

1.3 Approvals

Approval by or of the Engineer shall have the following limitations:

Any approval given in respect to samples of materials, workmanship or methods

of construction submitted in accordance with the requirements of the

Specification, shall not be interpreted as denoting any degree of satisfaction

with the materials used in, or the execution of the Works.

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 1

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

Any approval given in respect of shop drawings or scheme called for by the

Specification or proposed by the Contractor is for conformance with the design

intent only.

1.4 Notice for Approvals

The Contractor shall agree with the Engineer, whose decision shall be final,

reasonable times for an acceptance or approval before the related work commences.

1.5 Responsibility

No approval or acceptance by the Engineer shall relieve the Contractor of his

responsibility under the Contract.

1.6 Rates

The Contractor's rates for all measured items shall include for all testing as per the

requirements of this specification.

1.7 Variations

No variations to this Specification may be made unless approved by the Engineer.

1.8 Defective Work

Where, in the opinion of the Engineer, any of the finished Works or the materials

or workmanship in any part of the Works fails to comply with this Specification or

relevant drawings, that part of the Works will not be accepted and may be classed

as defective. All work classed as defective shall be cut removed from the Works

and replaced or otherwise dealt with in an approved manner.

Any special tests not specifically covered by this Specification that are proposed by

the Contractor as a result of failure to comply with this specification shall be at the

Contractor's expense. The Contractor shall be responsible for any consequential

costs or delays. The results of such tests will not necessarily be accepted as proof

of adequate materials or workmanship.

1.9 Validity of BS and CP Publications

Unless otherwise directed all BS and CP publications are the latest edition including

any amendments, current 1 month before the date fixed for the return of Tenders.

1.10 List of Materials

The Contractor shall satisfy himself as to the quantities for the materials required

for the works and shall notify the Engineer in writing if he considers that there are

any discrepancies between the Specifications, Drawings and Bills of Quantities or

deficiencies in the quantities indicated in the Drawings.

The aforesaid notification shall be made one calendar week before work is

scheduled to start on Site and an absence of notification within the prescribed period

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 2

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

shall be deemed to be an absence of deficiencies or discrepancies in the Drawings

and Contractual Documents.

The Employer or the Engineer will not be liable to the Contractor for any delay due

to any deficiency or discrepancy unless such deficiency or discrepancy is notified

at that time.

1.11 Drawings of the Works

The drawings of the works will be prepared and issued by the Consultants.

1.12 Programme of the Works

The works shall be constructed according to the programme submitted by the

Contractor and approved by the Engineer prior to commencement. In drawing up

the construction programme, the Contractor is required to programme the works to

ensure timely completion as per the contract documentation. The programme shall

include the planned monthly rates of progress between the programmed date for

commencement and completion for each major item of work for various stages of

construction including dates by which major drawings requiring approval will be

submitted.

1.13 Licences

The Contractor shall keep on Site a copy of licences pertaining to the Works at all

times during the Works and should be able to present the same on demand to

representatives of the local Authorities.

1.14 Datum of Levels

The levels on the plans and drawings are shown in metres. A number of benchmarks

will be established along the routes of work, one of which will be named by the

Engineer as the Master Bench Mark and will be referred to as MBM.

1.15 Surveys

From the MBM, the Contractor shall transfer levels to the benchmarks so that no

level is carried forward more than 1 km without it being transferred to a benchmark.

Such a benchmark shall be called Beacon Bench Mark referred to as BBM.

Such additional beacons shall be established on public land or sites approved by the

Engineer and by the authority having control over such land; the sites of the beacons

to be established by the Contractor shall be near the track of the canal.

Fifteen days after receiving the letter of Acceptance the Contractor shall supply to

the Engineer, in duplicate, maps and records in an approved form giving details of

the location and levels of each bench mark set up or established by the Contractor.

The method of surveying shall be to the approval of the Engineer. Field-books and

tabulated data shall be well maintained and made available for inspection and

checking by the Engineer.

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 3

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

The Contractor shall set up and survey the road alignments immediately following

the site clearance along the aforesaid road alignments, and shall keep proper records

of their survey. At the same time, the Contractor shall inform the Engineer of any

discrepancy between the survey information provided by him and the information

contained in the drawings. The Contractor shall submit the survey data to the

Engineer who will accordingly define the levels of the Works before excavation

commences, and issue the relevant construction drawings within two weeks of

obtaining the survey data. The Contractor shall make the appropriate allowance in

drawing up the construction programme.

1.16 Standards

Except where otherwise specified, all materials shall conform to the requirements

of the relevant and latest standard issued by the International Standard Organisation

(ISO) and the workmanship shall conform to the requirements of the relevant and

latest British Standard Codes of Practice (CP) issued by the British Standard

Institution.

Other equivalent national standard specifications may be used in the absence, or in

the place of a relevant ISO or BSCP standard, at the sole discretion of the Engineer

and with its approval.

All materials and workmanship not fully specified herein or covered by the

standards mentioned before shall be of such kind as is used in first class work. The

Engineer shall determine whether all or any of the materials offered for use in the

works are suitable for the purpose for which they are intended and the Engineers

decision in that respect shall be final.

The Contractor shall supply at his own cost and shall permanently keep on site an

original version of all the main Standard Specifications and Codes of Practice

referred to throughout the Specifications. These documents shall be available at all

times for inspection and use by the Engineers Representative and shall revert to

the Client at the end of the Contract.

1.17 Quality of materials

All materials, fixtures, fittings and specials to be supplied and generally all supplies

to be made under the Contract shall be new and unused and shall be of first grade

quality and of the best design and workmanship. Inferior or low grade supplies shall

be rejected by the Engineer.

For the purpose of obtaining a quotation from Suppliers or Manufacturers for the

supplies, the Contractor shall supply to the said Suppliers or Manufacturers all

information to ensure compliance of the supplies with the Engineers

Specifications. He shall communicate a copy of the relevant clause of the said

Specification to such Supplier or Manufacturers if necessary.

1.18 Choice of materials

Before ordering materials of any description intended for the Works, the names of

the manufacturers or suppliers proposed shall be submitted to the Engineer for

approval together with the Manufacturers specifications, quality, strength, weight,

and description etc., of the material.

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 4

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

The Tenderer shall provide in Annexures to the Bill of Quantities and in Schedules

of Technical Data, information about the materials offered.

Materials used in the works which are, or can be in contact with the untreated or

treated water shall not contain any matter which could impart taste, odour or toxicity

or otherwise be harmful to health or adversely affect the water conveyed. Approval

by the Central Water Authority will generally be regarded as satisfactory evidence

of suitability.

1.19 Plant and equipment

In addition to what has already been specified:

All plant and equipment shall be designed to provide adequate protection

against the entry or vermin and dust and to minimise for risk and consequential

fire damage.

All parts, which can be worn or damaged by dust shall be totally enclosed in

dust proof housings.

All equipment shall operate without excessive vibration and with minimum of

noise.

All similar items of plant and equipment and their components together with

spare parts shall be made from the same materials and shall be fully

interchangeable.

All manually operated plant and equipment shall be provided with facilities for

making it tamper proof. This is in addition to any requirements of the

Specification for securing plant under operational conditions.

The standards of workmanship and finish shall be uniform throughout, and the

final colours shall be designated by the Engineer.

1.20 Design life

All materials and equipment shall be designed for long life and continuous

operation during prolonged periods with a minimum of maintenance and the

Contractor may be called upon to demonstrate this for any component either by the

service records of similar equipment elsewhere or by records of extensive type tests.

Routine maintenance and repair shall, as far as possible, not require the services of

highly skilled personnel.

The materials of construction shall be selected, taking into consideration their

location and duty, such that the economic life of the plant is not less than 15 years.

Except for consumable items, which normally require replacement more frequently,

no part subject to wear shall have a life from new to replacement or repair of less

than three years of continual operation.

Where major dismantling is required to replace a part, such life shall not be less

than five years.

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 5

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

1.21 Shop drawings of appurtenant works

The Contractor shall prepare and submit to the Engineer for approval shop drawings

of valves and fittings, and generally of all specials to be supplied under the Contract.

Any alterations required by the Engineer not involving a change in the Specification

shall be made without a charge.

Drawings, when approved, shall be stamped with the Engineers approval stamp

and one copy will be returned to the Contractor.

If any approved drawing needs to be amended later, the amended drawing shall be

submitted for approval in accordance with the above procedure. When approval has

been given, all copies of the earlier approved drawing shall be destroyed.

1.22 Notice of Operation

The Contractor shall give full and complete written notice of all important

operations to the Engineer to make such arrangements as the Engineer may consider

necessary for the inspection of works and for any other purpose. The Contractor

shall not start any important operation without the written approval of the Engineer.

1.23 Progress meetings

The Contractors Agent shall attend regular progress meetings on Site which will

be convened by the Engineer or Project Manager.

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 6

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

2 The Site

2.1 Site

The Site shall be defined by boundaries where shown on the Drawings and in other

cases shall mean the extent of such public and private lands as in the opinion of the

Engineer are necessary or practical for the construction of the works. The Site shall

be used solely for the purpose of constructing the works.

The Engineer may order the Contractor to place additional marker posts to clarify

or to close the Site boundary.

2.2 Inspection of Site

Prior to commencement of the works the Contractor shall inspect the Site and assess

the presence of all visible structures or services which in his opinion are too close

to the permanent works and which present risk of damage during construction of

the works. The Contractor shall, at his own expense, prepare and submit to the

Engineer a report incorporating the finding of his inspection with respect to the

existence of such structures or services.

Upon receipt of the report, the Engineer shall verify its content and shall convene a

meeting on Site with the Employer, the owners of the structures or services and the

Contractor. During the meeting, the reported endangered structures or services will

be inspected and, if necessary, the Engineer will issue the Contractor with

instructions to avoid damages.

Those structures or services which could be damaged during construction shall be

described and photographed in the presence of all parties, particular attention being

paid to the condition of the said structures or services prior to commencement of

works on Site. The report describing the conditions observed on Site will be signed

by all parties attending the inspection meeting.

Where existing structures or services make it necessary to change the location of

the proposed work, the Engineer shall supply the Contractor with a revised set of

Drawings giving the new location of the works.

2.3 Access to Site

To facilitate access within the site for setting out and construction, the Contractor

shall, where necessary, form continuous access tracks including temporary

diversions and bridge works. The tracks shall be of a size and condition to permit

easy passage of motor transport. They shall be maintained in this condition until

such time as the Engineer deems them to be superfluous, whereupon the access

tracks shall be removed and the ground restored to a state at least equal to its original

condition.

2.4 Clearance of Site

The parts of the Site to be occupied by the Works shall be cleared of any vegetation

including trees, tree stumps, bush, hedges, fences, boulders and specified structures

by the Contractor.

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 7

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

Topsoil shall be removed together with such vegetation and small roots as occur

within the specified depth, and be stockpiled on designated sites for later use.

The Site shall not be cleared of any structure without the prior written permission

of the Engineer. Where such permission has been given, the foundation of structures

to be cleared shall be entirely removed.

No living trees (having a girth more than 0.6 m measured at 1.0 m above the ground

level) shall be damaged or cleared from the parts of the Site not subsequently to be

occupied by the works without consultation with the Forest Department, and upon

notification. The penalty for damaging or removing any such tree shall be the sums

obtained after consultation with the Forest Department for the replacement of the

trees, and shall be payable by the Contractor.

Any hole left by the removal of stumps, roots and foundation of structures shall be

backfilled and compacted to 90% BS heavy density with material to the approval

of the Engineer.

The materials arising from the clearance of the Site shall be removed from the Site

and disposed of in a manner and at a location to the approval of the Engineer.

2.5 Site to be tidy

The Site shall be maintained in a neat, tidy and healthy condition and the Contractor

shall remove all surplus spoil, concrete spills, waste, unwanted materials, debris

and other litter from the Site on a frequent basis or as directed by the Engineer.

2.6 Safety on Site

The Contractor shall take all necessary steps to ensure that the site is run in an

orderly manner and that safety precautions are enforced to avoid accidents to the

personnel of the Contractor and to other parties working on site.

The Contractor shall provide necessary lighting, guards and sign posts for the sites.

Site fencing shall also be provided by the Contractor when considered necessary by

the Engineer.

Access to the demarked portions of the site or specific areas of work shall be

restricted to the personnel of the Contractor employed on the works and to the

named personnel of the Employer and of the Engineer or to such other persons duly

authorised by the Engineer.

The Contractor shall ensure that all necessary precautions are taken to avoid the

works endangering the circulation of public traffic where it has not been diverted.

All safety precautions taken by the Contractor shall be to the Engineers approval.

However, in case of emergency or danger, these safety measures shall be taken by

the Contractor without formal notice being given to the Engineer, who shall

however be notified of any such occurrence with the least possible delay.

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 8

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

2.7 Maintenance of services and structures

As soon as any such service or structure is encountered on, over, under in or through

the Site during the performance of the Contract, the Contractor shall make a record

of the location and detailed description of such service or structure and shall send

the same forthwith to the Engineer.

Before any excavation is carried out within 10m of the approximate position of an

existing service, the Contractor shall notify the owner of the service and the

nominated Inspector that the excavation is to be made and shall ascertain and

comply with any condition that are imposed.

Where permanent diversion, or support of such service or structures, is rendered

necessary as the unavoidable result of the construction of the Works in accordance

with the Contract, the Engineer, after consultation with the Employer, will instruct

the Contractor as to the diversion or support to be provided.

The Contractor shall take all reasonable precautions to protect existing services

during construction and during relocation of such services. Furthermore, any

damage done to existing works and services shall be reported immediately to the

authority concerned and the Engineer shall be notified accordingly in writing. Any

pipe, cable, conduit or other known service of any nature whatsoever, which has

been damaged as a result of the Contractors operations shall be repaired and

reinstated immediately by the Contractor or by the authority concerned, all at the

expense of the Contractor, and to the satisfaction of the Engineer. The settlement

of all claims arising from damage to existing property, works and services shall be

solely the responsibility of the Contractor.

2.8 Maintenance of road traffic

When the constructional work interferes with or presents a danger to road traffic

the Contractor shall provide for the diversion or restriction of the traffic along

portions of road and in a manner that is to the Engineer's satisfaction. The

Contractor shall submit to the Engineer the proposed road traffic diversion or

restriction, at least 15 calendar days before the works are to start on the portion of

the Site concerned.

The Contractor shall obtain from the relevant authority the prior approval of the

proposed traffic diversions and restrictions with regard to the adequacy of the

precautions the Contractor proposes to take and the signs and lights to be installed

and operated before executing such traffic diversions and restrictions. All road signs

and signals shall be clearly visible day and night during the maintenance of such

traffic diversions or restrictions.

The cost of providing all diversions, restrictions, signs, signals, operators, flagmen

and the like are deemed to be included in the rates entered in the Bill of Quantities.

2.9 Storm water management

The Contractor shall provide all Temporary Works necessary for storm water

management during the execution of the works. He shall do whatever is necessary

to maintain those parts of existing surface drainage systems that may be affected by

his operations, in a condition not less satisfactory than they were prior to the

commencement of the Works. He shall maintain the normal flow therein at all

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 9

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

times, except when written permission to vary the discharge capacity of the drains

has been obtained from the Engineer.

All diversions of overland flow routes and minor watercourses shall be agreed with

the Engineer prior to implementation.

2.10 Road and track crossings

The Contractor shall provide proper and adequate temporary bridging of the

trenches during construction wherever an access to private property is obstructed

and at such other places as may be directed by the Engineer.

2.11 Reinstatement of Site

All parts of the Site not forming part of the permanent works shall be reinstated by

the Contractor, upon completion of the Works, to a condition not less satisfactory

than it was prior to commencement of work.

The Site shall be restored to a neat, tidy and healthy condition and the Contractor

shall remove all surplus spoil, welding rods, waste, unused and unwanted materials,

debris and other litter and solid waste from the Site.

2.12 Avoidance of pollution

The Contractor shall take all necessary precautions to ensure the protection of

existing potable water supplies, ground water and surface sources against pollution

by any cause whatsoever.

2.13 Site records

Where specified or ordered by the Engineer, the Contractor shall take and test

samples of the materials and water in and about the excavation and in the fill.

The contractor shall make records of the position and extent in the excavations of

every type of service, stratum and ground water encountered during the

construction of the works and of samples taken and results of tests of such materials

and water.

The Contractor shall also make records of the labour and plant and material

employed on Site. The plant schedules and labour time sheets shall be submitted

for approval to the Engineers Representative on every working day.

The records shall be prepared in a form to the approval of the Engineer and shall be

submitted to him in duplicate as soon as practicable after the events and

observations have been recorded.

2.14 Temporary water and electricity supply

The Contractor shall make his own arrangements and shall be at all time responsible

for the supply of water and electricity for the purposes of the Contract. The quality

of the water shall be to the approval of the Engineer and shall be suitable for the

purpose for which it is intended.

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 10

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

Water and waste derived from the construction, testing and completion of the

Works shall be disposed at an approved waste dumping ground so as to cause no

damage or complaints.

2.15 Temporary Works

Not less than fourteen days before commencing any portion of the Works, the

Contractor shall, if ordered, submit to the Engineer for his approval complete

drawings of all Temporary Works the Contractor may be proposing for the

construction of that part of the Works.

2.16 Latrines

The Contractor shall provide throughout the period of construction of the Works

and shall maintain and clean suitable and sufficient latrines for the use of his

employees; he shall ensure that his employees do not foul the site but make proper

use of the latrines.

2.17 First Aid Outfit

The Contractor shall provide and maintain adequate first aid outfits on site in readily

available locations near the area of work.

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 11

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

3 Earthworks

3.1 General

The extent of the earthworks is defined on the Engineers drawings. The Contractor

is deemed to have visited the site and to have carried out trial pits at his own expense

to ascertain the nature of the soil conditions prior to tendering as no claim will be

entertained on account of the soil being of a different nature from that which he

allowed in his prices.

The Contractor shall also collect the necessary information on the structures or

facilities, which could be affected by the Works, particularly underground, notify

their owners and take all useful precautions for the protection of such structures and

facilities. The Contractor shall be responsible for the removal, re-construction or

repair of any damage caused during excavation to the satisfaction of the Engineer.

3.2 Notice to be given before commencing

earthworks

The Contractor shall give to the Engineer at least seven days written notice of his

intention to commence earthworks on any part of the Site so as to enable the

Engineer to be furnished with all ground levels and other particulars he may require.

The earthworks shall not commence until written approval has been issued by the

Engineer to the Contractor.

The Engineer shall have the right to direct the Contractor as to the length or location

of portions of excavation which shall be opened at any one time, in addition to the

normal limits to lengths of open excavation imposed by the local authorities.

3.3 Setting out

All dimensions and levels on the drawings are shown in metres. The levels shown

on the various drawings relate to Ordinance Datum unless otherwise stated. These

shall be used by the Contractor to establish a benchmark on site and to obtain the

levels shown on the drawings.

Details of all grid lines, setting out stations, benchmarks and profiles shall be

recorded on the site setting out drawing and retained on site throughout the contract

and handed over to the Engineer on completion.

3.4 Method of excavation

If required by the Engineer the Contractor shall submit his proposed method of

excavation including details of necessary supports for the excavations to the

Engineer for his written approval.

3.5 Excavation of unsound material

If the Contractor encounters any unsound material in the formation, he shall

immediately inform the Engineer who will instruct the Contractor in writing as to

whether or not the said material shall be treated as unsound.

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 12

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

Unsound material shall be removed and disposed of at an approved dumping

ground.

Unless otherwise specified or ordered by the Engineer, the voids so formed shall be

filled:

with concrete Grade 10 in the formations to structures, roads and pipe-work

with the same material as that which comprises the fill in the formation to

embankments

If, in the opinion of the Engineer, the unsoundness is due to failure of the Contractor

to comply with the Specification including keeping the excavation free from water,

the cost of dealing with the unsound material shall be borne by the Contractor.

3.6 Support of excavation

The Excavations shall be supported at the Contractors expense as may be necessary

to protect persons, property, traffic or the Works or to prevent caving and harmful

subsidence. Supports shall not be removed until in the opinion of the Engineer the

permanent formwork is sufficiently far advanced to permit such removal. The

Contractor shall submit his proposals for such supports to the Engineer if required.

The Engineer shall have the right to order the proper support of excavation

whenever he considers the installation of the support to be necessary and his

decision shall be final.

If in the opinion of the Engineer the support proposed is insufficient then the

Engineer may order the provision of stronger support which shall be provided to

the satisfaction of the Engineer.

3.7 Slips, falls and excess excavation

Slips and falls of material from the sides of the excavation and embankments shall

be prevented.

In the event of slips or falls occurring in the excavations and where excavations are

made in excess of the dimensions of the Permanent Works, the voids so formed

shall be filled with selected excavated material placed and compacted to the

approval of the Engineer.

3.8 Preparation of excavations for structures

Where the formation of any excavation is to support the foundations or floor of a

structure, the bottom 0.15m thereof shall be carefully excavated and trimmed

immediately before placing the Permanent Work upon it. Where the formation of

such excavation consists of or includes clay soils, the Contractor shall take

reasonable precautions to the satisfaction of the Engineer to ensure that these clay

soils are maintained at the natural moisture content which prevailed before the

excavation commenced. Formation in granular material shall be compacted to the

Engineer's satisfaction using vibrating type compactors.

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 13

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

3.9 Care of excavated material

All excavated material shall be filled in such a manner that it does not endanger the

Works or any building, structure or property or obstruct roads, pavements and

driveways or cause undue obstruction to traffic.

Rocks and boulders from the excavation shall be piled separately from the

excavation material and unless suitable for re-use within the Works shall be

immediately removed from site.

3.10 Materials for backfill and imported backfill

material

The material used for backfill in the Works and the imported backfill material, if

any, shall be subject to the approval of the Engineer. Samples of the proposed

material shall be submitted to the Engineer for approval. The imported backfill

material shall be selected material free from lumps of clay, large stones or rock and

pebbles.

Selected fill material shall pass a sieve of 10mm aperture and ordinary fill material

shall not contain any stone or material greater that 100mm in size.

3.11 Compaction of backfill

All backfill material shall be placed in layers not exceeding 150 mm and then

mechanically rammed or rolled.

The Contractor shall, if necessary, water the fill material prior to or during

compaction so that its moisture content lies within a range of 2% optimum Proctor

values suitable for the fill material and the adopted method of compaction.

Unless otherwise specified, the standard compaction requirement shall be 95%

maximum dry density as defined by the modified Proctor test.

The testing of this material shall comprise grading tests for grain size distribution

and modified Proctor compaction tests carried out in accordance with BS 1377.

3.12 Allowance for settlement

The contractor shall make due allowance for consolidation and settlement of fill,

compacted fill and formations so that the levels of the finished surfaces at the end

of the Defects Liability Period are not less than those specified or ordered by the

Engineer.

If, at any time during the Construction Period, or the Defects Liability Period, any

damage of the surface of the formation has occurred as a result of settlement, the

Contractor shall promptly carry out at his own expense, all necessary repairs and

reinstatement, which may be required as a result of such damage.

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 14

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

4 Reinforced Concrete Materials

4.1 Code of Practice

The references in brackets included in certain clause headings in this specification

are to numbers of clauses or sub-clauses of British Standard BS 8110:1985:

Part 1.

The recommendations of any clause or sub-clause so referred to are requirements

of this specification.

4.2 Reference Documents

BS 12 Specification for Portland Cements

BS 146 Specification for Portland-blast furnace cement

BS 812 Testing Aggregates

BS 1881 Testing Concrete

BS 2690 Part 6 : Methods of testing Water used in industry; Chloride

and sulphate.

BS 3148 Methods of test for water for making concrete including notes on the

suitability of the water)

BS 4449 Specification for carbon steel bars for the reinforcement of concrete.

BS 4483 Specification for steel fabric for the reinforcement of concrete

BS 5328 Concrete

BS 8110 : 1997 Part 1: Code Practice for design & Construction

CP 102 Code of Practice for protection of buildings against water from the

ground.

4.3 General

Concrete shall be made with cement, aggregate and water. No other ingredients

shall be used without approval.

4.3.1 Reinforced Concrete

The reinforced concrete works have been designed generally in accordance with the

recommendations contained in BS 8110:1985 and the contractor shall comply with

the recommendations contained therein unless specifically excluded or modified

hereafter.

4.3.2 Unreinforced Concrete

Unreinforced concrete shall comply with all the relevant requirements of this

Specification.

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 15

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

4.4 Cement

4.4.1 General

All cements used for concrete work shall comply with the relevant British

Standards. The cement types given below are acceptable for use in the works,

however the proportion of extender in factory blended cements shall conform to the

requirements of Table 1. On no account shall masonry cements be used for concrete

work, even if the strength designations are the same as for common cements.

All cement shall be delivered to the site in sealed containers or bulk cement lorries

of suitable design.

Acceptable cement types:

Conform to

PC Portland Cement BS 12

PBFC Portland Blastfurnace Cement BS 146

SRPC Sulfate-resisting Portland Cement BS 4027

PPFAC Portland Pulverized-fuel Ash Cement BS 6588

4.5 Aggregates

4.5.1 General

Aggregate shall comply with BS 812

4.5.2 Uniformity

The Contractor shall obtain an undertaking from the suppliers of both fine and

coarse aggregate of the quality and type selected that sufficient supplies are

available to complete the contract.

4.6 Water

Water shall be clean and free from harmful matter. When so directed the Contractor

shall arrange for tests of the water to be carried out in accordance with BS 3148 and

BS 2690: Part 6 when directed.

4.7 Admixtures

4.7.1 General

Admixture may be permitted in designed mixes provided the details of the

admixture and the associated mix design and trial results are approved.

Calcium chloride and admixtures containing calcium chloride will not be permitted.

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 16

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

4.8 Concrete

4.8.1 Concrete Mixes

Designed mixes shall be used for each grade of concrete listed in Table 1 and shall

be in accordance with BS 5328 except that the Contractor shall obtain approval for

any change in sources of material and change in content.

Table 1

Concrete Classification Cement Extender Grade Max Min Max

Type Type Type N/mm2 Coarse Cement Water/Cenment

Aggregate Content Ratio

size mm Kg/m3

Normal C20 PC - 20 12 260 0.6

Reinforced 20 290

Concrete

C 25 PC - 25 12 280 0.55

20 310

C 30 PC - 30 12 300 0.5

20 330

Water WC 35 PC - 35 20 340 0.45

Retaining

WC 40 PC - 40 20 350 0.45

Concrete

Marine MC 40P PC - 40 20 420 0.35

Concrete*

MC 40F PC FA 25% 40 20 420 0.4

75%

MC 40G 40 20 420 0.4

PC GGBS

40 50

50% 60%

For structural concrete the maximum cement content should not exceed 450 kg/m3

For watertight construction the maximum cement content should not exceed 400

kg/m3

Frequency of sampling:

On first 40 batches 10 samples

On reminder 1 sample per 20 m3

4.8.2 Trial Mixes

Result of all preliminary tests shall be submitted as soon as they are available and

before concrete work starts on site. When tested, the concrete should meet the

appropriate requirement specified in BS 5328.

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 17

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

4.8.3 Redetermination of Mix Proportions

Mix proportions may be adjusted in accordance with 6.2.4 of BS 8110, but changes

of current margin shall be subject to approval.

4.8.4 Ready-Mixed Concrete

Ready-mixed concrete may be used, subject to approval. It shall be produced at an

approved depot. The concrete shall comply with BS 5328, with the specification.

All delivery notes shall be retained by the Contractor and made available for

inspection throughout the duration of the Contract.

If at any time the Engineer is not satisfied that the ready-mixed concrete complies

with this Specification he may alter the frequency of the sampling.

4.8.5 Chloride Content

The chloride content in steel reinforced concrete at the time of placing shall not be

greater than 0.10% by mass of cement.

Primary and/or routine testing may be required depending on the choice of

aggregate and/or mixture.

4.9 Reinforcement

4.9.1 Types of Reinforcement

The types of reinforcement bars will be identified on the Schedules by prefixes to

the bar mark numbers.

The prefixes have the following meanings:-

R Plain round hot rolled mild steel bars with a characteristic strength

of 250N/mm2 and complying with BS 4449

Y Type 2 deformed high yield steel bars complying with BS 4449 with

a characteristic strength of 460N/mm2 for diameters up to and

including 16mm, and 425N/mm2 for diameters exceeding 16mm

Steel fabric shall comply with BS 4483, and shall be delivered to site in flat sheets.

4.10 Miscellaneous Materials

4.10.1 General

Variations to the materials shown on the Drawings may be approved subject to the

Contractor submitting full details of his proposals in writing.

4.10.2 Waterstops

Waterstops shall be jointed with purpose-made junction pieces and in

accordance with the manufacturer's written instructions.

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 18

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

A hydrophilic, expandable elastomer profile waterstop system may be used to

seal all contraction joints.

The hydrophilic waterstop profile to be used shall be either Hydrotite CJ0725-

3K or Sika Swell-P 2507H.

The waterstop system must be a fully continuous barrier throughout the

structure and across all joints.

4.10.3 Damp-proof Membranes

Damp-proof membranes shall be 500-micron polyethylene sheeting laid and jointed

in accordance with the manufacture's specifications.

4.11 Storage of Materials

4.11.1 Cement

Cement shall be used in the order that it is received on site. All cement shall be

stored in a weatherproof shed of adequate size having a raised dried floor or in silos

of approved design.

4.11.2 Aggregates

Aggregate shall be stored on hard paved self-draining areas or in approved hoppers

or containers.

Different aggregate shall be kept separate.

4.11.3 Reinforcement

Reinforcement shall be stored on racks clear of the ground.

4.11.4 Steel Fabric

Steel fabric shall be stored in flat sheets.

Where the materials are to be stored on suspended floor or roofs, the contractor

shall ensure that such storage will not overload or distort the structural frame.

4.12 Rejected Materials

All materials that have been damaged or are contaminated or have deteriorated or

do not comply with the requirement of this specification shall be rejected and shall

be removed from the site immediately at the contractors expense.

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 19

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

5 Reinforced Concrete Workmanship and

Construction

5.1 Construction and Preparation of Formwork

5.1.1 General

Before construction of the formwork begins the Contractor shall submit details of

the systems of formwork he proposes to use for all main structural members.

No metal part of any device for maintaining formwork in the correct location shall

remain permanently within the specified concrete cover to the reinforcement.

In watertight construction, methods of fixing formwork which result in holes

through the concrete section when the formwork is removed shall not be used, all

wall ties shall have water baffles and wall kickers shall be cast monolithically with

the base slab.

The tank walls are to be water-retaining structures and the design of formwork ties

must be such that they do not cause leakage or corrosion in service. The Contractor

shall obtain prior written approval from the Engineer for the formwork tie system

to be used.

The use of concrete retarders or similar preparations on the formwork surfaces shall

be subject to the prior approval of the Engineer.

5.1.2 Cambers

Unless otherwise directed all formwork to suspended beams and slabs shall be

constructed so that the following upward cambers exist immediately before

striking:

a) Spanning between supports

0.1% of span at centre

b) Cantilevers

0.4% of span at free end.

5.1.3 Stiffness of Panels

Formwork panels shall be stiff enough to prevent damage to the concrete surface

caused by excessive movements of the panel during vibration of the concrete.

5.1.4 Repair of Formwork

Damaged formwork shall not be reused if in opinion of the Engineer the making

good would impair the surface appearance of the concrete.

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 20

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

5.1.5 Mortices, Holes Chases in Concrete

Fixing blocks and ends of brackets and bars and bolts etc., shall be cast in the

concrete at the time of placing and together with all mortices and holes and

apertures and chases and grooves etc., shall be accurately set out in the formwork

before the concrete is placed. No part of the concrete works shall be cut away for

any such item or for any other reason without the Engineer's approval.

The Contractor shall obtain from all sub-contractors complete information of their

requirements regarding conduits and pipes and fixing blocks or boxes and chases

and holes and any other items to be cast in.

Where conduits are to be cast in slabs they shall be placed above the bottom

reinforcement and below the top reinforcement and not within 40mm of the top and

bottom surface of the slab.

The Contractor shall ensure that all Sub-Contractors are informed of his programme

for the structural works at the commencement of the Contract. He shall also ensure

that the Sub-Contractor's requirements relating to concrete members are approved

by the Engineer before work is commenced.

At the commencement of the Contract the Contractor shall supply all the Sub-

Contractors with written copies of this section (3.1.5) of the Specification.

5.1.6 Final Preparations

The internal faces of the formwork may be coated with an approved preparation to

prevent adhesion of the concrete to the forms provided that the use of this

preparation will not stain the surface of the finished concrete. None of this

preparation shall be allowed to touch the reinforcement.

Immediately before the concrete is placed in any section of the formwork the

interior of that section shall be completely cleaned of all extraneous materials

including water.

Each section of the formwork to structural members shall be inspected by the

Engineer immediately before concrete is placed in that section.

5.2 Falsework

5.2.1 Formwork Props

If formwork props are to be left in place when soffit forms are removed they shall

not be disturbed during the removal process without approval.

5.2.2 Formwork Props

Formwork props shall be positioned between permanent supports so that all

members are supported at no more than 3m centres in both directions.

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 21

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

5.2.3 Removal of Falsework

The responsibility for the safe removal of any part of the falsework shall rest with

the Contractor.

5.3 Construction Joints

5.3.1 General

If construction joints are not shown on the drawings the Contractor shall obtain

approval for their positions before work starts.

In watertight construction water bars shall be used in all construction joints and

movement joints in accordance with the manufacturer's written instructions and the

Contractor shall obtain approval for the methods to be used to maintain them in

their correct locations while the concrete is being placed and during or after the

removal of the formwork.

5.3.2 Preparation of Construction Joints

The contractor shall obtain approval for his proposals for forming and preparing

construction joints prior to the work commencing on site.

5.3.3 Position of Construction Joints

The position of construction joints proposed by the Contractor shall be such as to

avoid distress or damage to the works particularly from thermal movement or

shrinkage effects.

The position and spacing of joints which will be acceptable will vary from place to

place but the following table gives an indication of acceptable limits.

Construction Max. Area m2 Max. Dimension m

Water tight walls 25 5

Water tight slabs 100 10

Slabs with major restraint at 100 13

both ends

Slabs with major restraint at 250 20

one end only

Slabs with little restraint in 500 30

any direction

Walls 40 10

Where the Contractor's proposals result in alterations to the reinforcement the

Contractor shall be responsible for providing full revised details for approval prior

to the work commencing on site.

5.4 Movement Joints

Concrete shall not be placed on both sides of movement joint at the same time

unless otherwise approved.

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 22

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

5.5 Reinforcement

5.5.1 Cutting and Bending

Reinforcement shall not be bent except as shown in the bending schedules without

approval.

Each bundle of bars shall be clearly tagged with their schedule and mark numbers.

5.5.2 Fixing

5.5.2.1 Conventional Reinforced Concrete

Reinforcement shall be fixed in accordance with 7.3 of BS 8110, but no

reinforcement shall be welded.

Unless otherwise specified the nominal concrete cover shall be in accordance with

Table 3.4 & 3.5 of BS 8110.

Cover to tanks to be 40 mm.

Where spacers are required to maintain the concrete cover to the reinforcement

these may be of either concrete or plastic unless otherwise specified. Plastic spacers

shall not be permitted.

The Contractor shall supply and fix all chairs required to maintain the reinforcement

in the correct position.

5.5.2.2 Water Retaining Structures

Minimum concrete cover from external surfaces, contraction joint surfaces and

water stops to all steel reinforcement shall be 50mm unless shown otherwise on the

drawings or as given in the Particular Specifications, and maintenance of this

minimum cover during casting and concrete shall be strictly enforced. Concrete

which is cast with insufficient cover to the reinforcement shall be demolished and

re-cast at the Contractors cost. Tying wire may not encroach on the specified

minimum cover by more than a single strand thickness.

Cover blocks used to ensure the cover to reinforcement shall be made of cement

mortar. They shall be dense and have a minimum 28 day crushing strength of 50

MPa, and shall be cured in water for at least 14 days before being used. Steeldale

cover blocks or similar approved proprietary items shall be used site made blocks

will not be permitted.

Spacer blocks made of plastic will not be permitted.

5.5.3 Rust Staining

Concrete surfaces which will be exposed to view the finished Works shall be

protected from staining due to rusting of projecting reinforcement either by coating

the reinforcement with cement or by another approved method.

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 23

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

5.6 Concreting

5.6.1 Final Preparation and Inspection

Before each concrete pour the Contractor shall give notice as directed so that an

inspection may be made before the concrete is placed.

5.6.2 Mixing

The volume of mixed materials in each batch shall comply with the mixer

manufacturer's written recommendations. The mixing shall conform to the

requirements of BS 5328.

5.6.3 Transporting

Runs or gangways for concrete transporters and main runs for foot traffic shall not

be supported or allowed to bear on the fixed reinforcement.

5.6.4 Placing

Concrete shall be placed continuously up to construction joints while, in the opinion

of the Engineer, it is still sufficiently plastic for adequate compaction.

5.6.5 Compacting

Unless otherwise specified all structural concrete shall be compacted by mechanical

vibrators of appropriate type.

The Contractor shall submit details of the type, size and number of vibrators to be

used in the Works.

Whenever concrete is being vibrated at least one spare vibrator of each type in use

shall be available in case of breakdown.

Compaction shall start as soon as there is sufficient concrete within the formwork

to immerse the vibrator and vibration shall continue during the placing operations

so that at no time shall there be a large volume of uncompacted concrete in the

formwork.

Starter sections of walls, columns, etc., shall be cast and compacted in such a way

that their strength and other characteristics are at least equal to those specified for

the whole member.

5.6.6 Cleaning

All equipment used for mixing, transporting, placing and compacting concrete shall

be thoroughly cleaned before changing from one type of aggregate or cement to

another and whenever mixing ceases.

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 24

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

5.6.7 Curing

Concrete shall be cured by covering it as soon as practicable after casting with a

layer of sand, hessian or other approved material kept constantly wet during the

curing period, or by other approved method.

5.6.8 Concrete in Hot Weather

On exposed concrete surfaces in high sun temperatures and/or strong drying wind

conditions the Contractor shall use a curing method which also shields the concrete

and this shall be placed in position no later than half an hour after final tamping. If

the surface exhibits cracking while the concrete is still plastic then it shall be re-

tamped to close the cracks.

Any formwork made of metal, concrete or other material of high thermal capacity

shall be cooled with water before the concrete is placed against it.

5.7 Striking of Formwork

5.7.1 General

Before any formwork is removed the Contractor shall ensure that the concrete has

attained sufficient strength for striking to proceed.

The structure shall not be distorted, damaged or overloaded in any way by the

removal of the formwork.

The responsibility for the safe removal of any part of the formwork or props shall

rest with the Contractor.

5.7.2 Minimum Striking Period

The minimum periods before removing formwork to structural members shall be

established in accordance with (6.9.3.2) of BS 8110 except that Table 2 in this

Specification shall be used in place of Table 6.6 of BS 8110.

The earlier striking of forms (but not props) may be approved if the Contractor can

show that this can be done without damage to the concrete.

The making and testing of cubes to establish the period before striking shall be at

the Contractor's expense.

The Contractor's method of measuring the surface temperature of the concrete shall

be submitted for approval.

Location Surface Temperature of Concrete in degrees

Centigrade. Not less than 16oC OPC

Beam sides, walls and columns 12 hrs

Slab soffits (formwork props undisturbed) 4 days

Formwork props to slabs 10 days

Beam soffits (formwork props undisturbed) 10 days

Formwork props to beams 14 days

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 25

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

Table 2 Minimum period before striking

Permission to strike formwork on the basis of the strength of specially cast cubes

will be withdrawn if the Engineer is not satisfied that the strength of the cube is

representative of the strength of the concrete.

Notwithstanding the above, formwork props shall remain in position for at least 3

days.

5.8 Treatment Of Cast Concrete

Unless otherwise directed no treatment of any kind, other than that required for

curing the concrete, shall be applied to the concrete after removal of the forms until

it has been inspected.

The Contractor's methods of making good any defects are to be subject to approval

in each case.

5.9 Concrete Finishes

Where a particular type of finish is required on the concrete surface it will be

indicated on the drawings. Where no finishes are indicated on the drawings the

Contractor shall seek the Engineer's approval of his proposed methods of forming

the concrete surfaces.

5.10 Trial Panels

In order to ensure that specified formed finishes can be obtained by the method of

construction proposed and to provide a standard by which the finishes in the Works

can be assessed, trial panels shall be cast on site. These panels shall be approved

before similar construction is begun in the Works.

The trial panels shall employ the materials, plant and concrete mix proposed for the

Works. They shall be at least one storey height and 1m wide. They shall be of

similar thickness and similarly reinforced to the elements they represent and shall

incorporate all features which may contribute to the final appearance of the work,

i.e.

- horizontal and vertical construction joints

- horizontal and vertical panel joints

- arises and chamfers

- tie bolts or other fixing devices

- means of maintaining concrete cover to reinforcement

- release agent

- any other feature

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 26

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

6 Reinforced Concrete Performance and

Tests

6.1 General

For all cement and reinforcement delivered to the site the Contractor shall obtain a

copy of the manufacturer's certificates of tests carried out at the frequency and using

the methods specified in the relevant British Standards.

Certificates for reinforcement shall be accompanied by details of the manufacturer's

identification marks rolled into each brand of bar supplied.

6.2 Testing Facilities

At the commencement of the contract the Contractor shall nominate a Testing

Authority for the approval of the Engineer. The Testing Authority will be fully

equipped to carry out all the tests and checks required by this Specification.

6.3 Testing of Aggregates

6.3.1 General

All sampling and testing of aggregates shall be carried out in accordance with BS

812.

6.3.2 Preliminary Tests

As soon as the sources of supply of aggregates have been approved the Contractor

shall arrange for the following tests to be carried out:

Sieve analyses

Tests for clay, silt and dust content

Tests for salt content

The results of these tests shall be submitted for approval as soon as they are

available.

Tests (a) and (b), with tests of the moisture content of each aggregate, shall be

carried out on the samples used for each trial mix.

6.3.3 Works Tests

The Contractor shall carry out such tests on the aggregate as are necessary for the

production of the specified concrete.

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 27

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

6.4 Testing of Concrete

6.4.1 General

The sampling of works concrete from designed mixes shall be in accordance with

6.4.2 of BS8110:1985 except that samples shall be taken at the mixer or at the point

of casting as directed. The frequency of sampling shall be not less than specified

in Table 1. In special circumstances an increased rate of sampling may be directed.

At least one sample shall be taken on each day that concrete of that grade is used.

The workability of each sample shall be checked and shall be within the limits given

in 6.3.5.2 of BS8110:1985 relative to the value determined for the trial mix.

6.4.2 Salts

Tests for salt content of hardened concrete specimens shall be made in accordance

with BS 1881: Part 124.

6.5 Ready-Mixed Concrete

Samples of concrete shall be taken in accordance with the requirements of this

Specification at the point and time of delivery.

The concrete shall be sampled and tested in accordance with Clause 9 or 15 of BS

5328 and this specification at least once a day for each mix delivered for the first

five days on which that mix is delivered and thereafter as directed.

In accordance with Clause 14.4 of BS 5328 samples of each mix shall be taken at

the mixer at least once on every day when concrete of that mix is delivered. For

each sample workability tests shall be carried out and two cubes shall be made, one

for test at 7 days and the other for test at 28 days. The results of these tests shall be

submitted weekly, with copies of typical manufacturer's certificates for each type

of cement used.

6.6 Test failure of Works Concrete

The concrete from designed mixes shall comply with the requirements of 6.4.2 of

BS8110:1985. Any concrete which does not comply with these requirements will

not be accepted.

6.7 Batching Plant

6.7.1 General

The method of batching the materials and the accuracy of the equipment used shall

be such as to satisfy the recommendations of BS 5328 and clause 6.3.4 of

BS8110:1985.

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 28

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

6.7.2 Recalibration

Recalibration of the measuring equipment by the manufacturer or his agent shall be

undertaken at intervals of not more than 3 months.

6.7.3 Mixing Plant

Weigh-batching plant shall be checked weekly or as directed by the Engineer. The

checking shall be carried out with approved weights provided by the Contractor for

this purpose.

The water gauging equipment shall be inspected and checked weekly.

If any fault in the mixing plant or water-gauging equipment is detected by these

checks or otherwise the fault shall be rectified to the satisfaction of the Engineer

before any further use is made of the equipment.

6.8 Setting Out And Tolerances

6.8.1 Structural Members

Unless otherwise directed by the Engineer structural members shall be set out from

the references and constructed such that the dimension between any two points on

the structure as built or between any point on the structure and any reference shall

agree with the required dimension, whether shown on or calculated from the

Drawings, within the degree of accuracy indicated in Table 3

Position of Maximum

Member

Up to 2m 2m to 10m 10m Add for each

to 30m additional 30m

Foundation 10 20 30 5

Superstructure 6 10 20 2.5

Table 3 - Maximum deviation in mm from required dimension

The figures given Table 3 apply to such variables as:-

Position of plan of any point from nearest grid line.

Plumb.

Cross section and other linear dimensions of member.

Clear dimension between members.

Bow and camber other than design camber.

Twist (the distance of any corner from a plane containing the other three corners)

Squareness of corners (the longer two adjacent sides shall be taken as the base line).

Deviation is related to the length of the shorter side.

240749-31/JP/S001 | Issue 1 | 26 February 2016 Page 29

\\GLOBAL.ARUP.COM\AFRICA\MAURITIUS\PORT LOUIS\PROJECTS\CURRENT PROJECT\240749-31 - NEW MIXER AT LFL\4.6 - CONTRACTS AND

SPECIFICATIONS\BUILDINGS\NEW MIXER AT LFL-SPECIFICATIONS ISSUE 1.DOCX

LFL New Mixer at LFL

Structural Specifications

Level (measured from the nearest datum).

The Contractor shall advise the Engineer when the tolerances in Table 3 are

exceeded.

6.8.2 Dimensions of Completed Work

The Contractor shall keep records in an approved form of the dimensions of all

work as constructed.

These records shall be available for inspection at any time and shall be submitted

immediately after completion of each section as directed.

6.9 Defective Work

6.9.1 Materials and Workmanship