Beruflich Dokumente

Kultur Dokumente

HDS

Hochgeladen von

kris_kcpOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

HDS

Hochgeladen von

kris_kcpCopyright:

Verfügbare Formate

ELECTRIC HEATER DATASHEET

1 HEATER DESCRIPTION DRYERS REGENERANT SUPERHEATER (LOOP 1) CUSTOMER SAUDI ARAMCO

2 HEATER Tag No R47-F-0001

3 PROCESS MEDIUM LIGHT ISOMERATE

4 DUTY BUNDLE(@NOM VOLTAGE) 2110 Kw 690 VOLTS 50 Hz

5 DUTY HEATER (@NOM VOLTAGE) 2110 Kw DELTA

6 PROCESS DETAILS CASE 1 CASE 2 CASE 3 CASE 4 CASE 5 CASE 6

7 MASS FLOW RATE (kg/h) 16000,017 16000,017

8 INLET TEMP (deg.C) 165 165

9 OUTLET TEMP (deg.C) 310 325

10 SPECIFIC HEAT (kJ/kg.K) 2,68 2,71

11 THERMAL COND (w/m.k) 0,04 0,04

12 MOLECULAR WEIGHT 80,06 80,06

13 VISCOCITY (cp) 0,013 0,013

14 PRESSURE DROP (bar.g) 0.48 0.48 SEE NOTE 103

15 OPERATING PRESSURE (bar.g.) 10,7 10,7

16 HEAT EXCHANGED (kW) 1729,52 1921,00

17 ELEMENT DETAILS BUNDLE 1 BUNDLE 2 BUNDLE 3 BUNDLE 4 BUNDLE 5 BUNDLE 6

18 No. ACTIVE/TYPE 75

19 No. SPARE 0

20 No. STAGES 2

21 No. ACTIVE ELEMENTS PER STAGE 39/36

22 DIAMETER (mm) 16

23 ACTIVE 'U' (mm) 3499

24 TOTAL LOAD (KW) 2110

25 ELEMENT LOAD (KW) 28,13

26 VOLTAGE 690

27 FLUX (W/SQ.CM) 8,00

28 MAXIMUM SHEATH TEMP (deg.C) 355 373

29 BAFFLE DETAILS BUNDLE 1 BUNDLE 2 BUNDLE 3 BUNDLE 4 BUNDLE 5 BUNDLE 6

30 BAFFLE PITCH (mm) 228,6

31 BAFFLE CUT / TYPE ROD

32 BAFFLE THK (mm) 3

33 No. OF TIE RODS 6

34 TIE RODS DIA (mm) 10

35 TEMPERATURE DEVICES ACTIVE SET Deg C SENSOR TYPE TRANSMITTER

36 ELEMENT HI (Per Bundle)

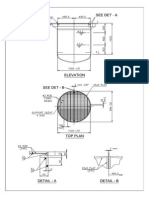

37 ELEMENT HI HI (Per Bundle) - NOTE 104 4 403 T/C TYPE K SIMPLEX Exe Note 87

38 PROCESS (Per Heater)

39 TEMP CLASS PROTECTION 1 190 T/C TYPE K SIMPLEX Exe Note 89

40 OTHER

41 HAZARDOUS AREA CERTIFICATION

42 PROTECTION TYPE Exe (MBG11)

43 ZONE 1 ATEX MARKING II 2 G II T3

44 GAS GROUP IIC

45 TEMP CLASS T3

46 DESIGN DATA

47 DESIGN CODE ASME VIII Div 1

48 PED COMPLIANT NO - OUTSIDE EU

49 DESIGN PRESSURE (BAR.G) FV @ 26,5

50 DESIGN TEMP (DEG.C) 7.7 to 368

51 CORR ALLOW' (mm) 3

52 RADIOGRAPHY (%) To Code

53 AMBIENT (DEG.C) -7 to 40

Vulcanic UK Ltd

South Green Park

www.vulcanic.com

+44 (0) 1603 340015

DRAWN CHECKED DATED DRAWING No REV

Enterprise Centre

Mattishall

1

Dereham

Norfolk

BH 19/04/16 204954-HDS-R47-F-0001 PAGE 1/3

ELECTRIC HEATER DATASHEET

54 WEIGHTS DIMENSIONS (MM)

55 BUNDLE WEIGHT Kg 697 A B C D C2 E F G

56 TOTAL - EMPTY Kg 2168 500 150 57 4104 305 3549 200

57 TEST WEIGHT Kg 2387 H I J K

58 HEAT TRANSFER DATA 300 3504 731

59 TOTAL SURF.AREA M2 26,38

60 HTC w/m2c 1777,78

61 MEAN TEMP DIFF Deg c 45,00

62 MATERIALS CONNECTIONS

63 SHELL 1 1/4Cr - 1/2Mo REF NAME SIZE CLASS PROJECTION ORIENTATION TYPE

64 END CAP 1 1/4Cr - 1/2Mo H1 HEATER 16 300 N/A N/A RFBL

65 FLANGES ASTM A185 Gr. F11 N1 INLET 6 300 200 0 RFWN

66 PLATE 1 1/4Cr - 1/2Mo N2 OUTLET 8 300 200 0 RFWN

67 BOLTS/NUTS ASTM A193B7/1942H (HDG) N3 DRAIN 2 300 100 180 RFWN

68 BAFFLES/TIE RODS Incoloy 800 N4 VENT 4 300 100 0 RFWN

69 GASKETS ST.ST SPIRAL WOUND

70 ELEMENT SHEATH Incoloy 800 (Seamless DOM)

71 MAIN ENCLOSURE Stainless Steel 316/316L

72 INST. ENCLOSURE Stainless Steel 316/316L

73 OFFSET SLEEVES Stainless Steel 316L

74 THERMOCOUPLES Stainless Steel 316L

75 NACE NA MATERIAL CERTIFICATION EN 10204 3,1

76 PAINTING ENCLOSURE Client Paint System

77 PAINTING FLANGE Client Paint System

78 PAINTING VESSEL Client Paint System

79 HYDROTEST To Code (1.3X MAWP)

80 TESTING As per quotation summary

81 HEATER WILL BE OF WELDED CONSTRUCTION

82 TEMPERATURE SENSORS WILL BE TERMINATED IN SEPARATE EXE CERTIFIED JUNCTION BOX (SS316L)

Vulcanic UK Ltd

South Green Park

www.vulcanic.com

+44 (0) 1603 340015

DRAWN CHECKED DATED DRAWING No REV

Enterprise Centre

Mattishall

1

Dereham

Norfolk

BH 19/04/16 204954-HDS-R47-F-0001 PAGE 2/3

ELECTRIC HEATER DATASHEET

83 ANTICONDENSATION HEATER 50W 230V(Exe Certified)

84 PICKLE AND PASSIVATION Not Included

85 TEMPERATURE TRANSMITTERS

86 ELEMENT HI (Per Bundle) Not Fitted

87 ELEMENT HI HI (Per Bundle) - NOTE 104 2x 4-20mA Smart HART Exd, Aluminium Head Mount Enclosure, without LCD

88 PROCESS (Per Heater) Not Fitted

89 TEMP CLASS PROTECTION 1x 4-20mA Smart HART Exd, Aluminium Head Mount Enclosure, without LCD

90 OTHER Not Fitted

91 INSULATION Yes By Others (See Note 100)

92 LIFTING LUGS Yes

93 JACKING SCREWS NA

94 PMI Not Included

95 IP RATING IP66

96 SUNSHADE No

97 U-STAMP Yes

98 SPECIAL REQUIREMENT FOR SAFE OPERATION

99 The assembly complies with the requirements of EN 13463-1 and 13463-5 (2003) according to appendix VIII of the ATEX

European directive 94/9/CE.

Marking: CE II 2 G II T3 for operation within an ambient temperature from -20C up to 60C, and maximum

humidity 95%. Equipment of CAT 2 for surface industries, for use in a hazardous area classified Zone 1 Gas Group

II environment, where the self-ignition temperature is lower than 200 Deg C

- The temperature safety devices must switch off the power supply, by means of a fail safe circuit(a manual reset is necessary).

The set points are written in the contractual file.

- Precautions must be taken so that the heating elements are never in contact with an explosive gas.

- When it is electrically supplied, the heater must be protected with a mass flow switch which removes power to the heater in the

event that the mass flow falls below the minium value.The low flow device must switch off the power supply, by means of a fail

safe circuit (a manual reset is necessary). The set points are written in the contractual file.

100 In operating conditions, the maximum temperature of the vessel must not exceed the values defined below :-

Temperature class : T1 T2 T3 T4 T5 T6

Marking temperature : 450C 300C 200C 135C 100C 85C

Maximum safety setting : 440C 290C 195C 130C 95C 80C

Max. advisable flange temp : 430C 280C 190C 125C 90C 75C

Otherwise, the user must install appropriate insulation : high-density mineral wool laid in a minimum of 2 thicknesses cross-laid

so that no points of the vessel and the hardware come into contact with the dangerous atmosphere. Unless specified otherwise,

the junction box must be placed in an atmosphere varying from between -20C and 60C.

101 CABLE GLANDS CAN BE ACCOMODATED AT EXTRA COST ON CONFIRMATION OF CABLE SIZES/ QUANTITIES.

102 0.25"NPT CONNECTION PROVIDED ON TERMINAL BOX FOR N2O PURGE.

103 ACTUAL PRESSURE DROP CALCULATED AT 0.044BAR

104 1X CONNECTED, 1X UNCONNECTED SPARE.

105 HEATER ORIENTATION (IE: HORIZONTAL/ VERTICAL) TBC BY CLIENT.

106

107

108

109

110

111

Vulcanic UK Ltd

South Green Park

www.vulcanic.com

+44 (0) 1603 340015

DRAWN CHECKED DATED DRAWING No REV

Enterprise Centre

Mattishall

1

Dereham

Norfolk

BH 19/04/16 204954-HDS-R47-F-0001 PAGE 3/3

Das könnte Ihnen auch gefallen

- Hazardous Location Guide: Class I Div 1 Groups A, B, C, D T4Dokument1 SeiteHazardous Location Guide: Class I Div 1 Groups A, B, C, D T4Er Prem PrincepsNoch keine Bewertungen

- 60FA57DEDokument1 Seite60FA57DEkris_kcpNoch keine Bewertungen

- Heater E-501 - MechanicalDokument32 SeitenHeater E-501 - MechanicalLai HuynhNoch keine Bewertungen

- Carpool ScheduleDokument1 SeiteCarpool Schedulekris_kcpNoch keine Bewertungen

- Syllabus Vit PDFDokument112 SeitenSyllabus Vit PDFBhaskar SharmaNoch keine Bewertungen

- VITREE Brochure 18Dokument47 SeitenVITREE Brochure 18kris_kcpNoch keine Bewertungen

- Valve Uses ApplicationsDokument4 SeitenValve Uses ApplicationsMD Shadikul Huq ShezanNoch keine Bewertungen

- Car Pool November 2018 CalendarDokument1 SeiteCar Pool November 2018 Calendarkris_kcpNoch keine Bewertungen

- GratingsDokument371 SeitenGratingskris_kcpNoch keine Bewertungen

- Asme PCC1Dokument18 SeitenAsme PCC1kris_kcp100% (2)

- Ip PDFDokument1 SeiteIp PDFecruz_yhwhNoch keine Bewertungen

- Ip PDFDokument1 SeiteIp PDFecruz_yhwhNoch keine Bewertungen

- Ip PDFDokument1 SeiteIp PDFecruz_yhwhNoch keine Bewertungen

- Using Thyristors in Heating ControlDokument4 SeitenUsing Thyristors in Heating Controlkris_kcpNoch keine Bewertungen

- Acknowledgement Receipt TTDDokument2 SeitenAcknowledgement Receipt TTDkris_kcp100% (2)

- Gratings CatalogDokument33 SeitenGratings CatalogLupul50Noch keine Bewertungen

- Setting of NozzleDokument1 SeiteSetting of Nozzlekris_kcpNoch keine Bewertungen

- Reference No. 13021416178: Hotel Ambrosia Sarovar ProticoDokument3 SeitenReference No. 13021416178: Hotel Ambrosia Sarovar Proticokris_kcpNoch keine Bewertungen

- Asme PCC1Dokument18 SeitenAsme PCC1kris_kcp100% (2)

- VDB, IOM Index Format - r2Dokument1 SeiteVDB, IOM Index Format - r2kris_kcpNoch keine Bewertungen

- Setting of NozzleDokument1 SeiteSetting of Nozzlekris_kcpNoch keine Bewertungen

- North Plant Drawing No. GS-160D-002Dokument1 SeiteNorth Plant Drawing No. GS-160D-002kris_kcpNoch keine Bewertungen

- Packinox Catalytic ReformingDokument2 SeitenPackinox Catalytic Reformingzohaib_farooqNoch keine Bewertungen

- Acknowledgement Receipt TTDDokument2 SeitenAcknowledgement Receipt TTDkris_kcp100% (2)

- 010.shipping SketchDokument1 Seite010.shipping Sketchkris_kcpNoch keine Bewertungen

- Sketch Boot Cover-ModelDokument1 SeiteSketch Boot Cover-Modelkris_kcpNoch keine Bewertungen

- Final PPT Loading ARMDokument15 SeitenFinal PPT Loading ARMkris_kcpNoch keine Bewertungen

- 20150114091810Dokument1 Seite20150114091810kris_kcpNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- SB632B Connecting Rod IdentificationDokument20 SeitenSB632B Connecting Rod IdentificationLuisCheukoCheuquianNoch keine Bewertungen

- Mycotoxin Test ProcedureDokument3 SeitenMycotoxin Test ProcedureKishenthi KerisnanNoch keine Bewertungen

- Large and Medium Manufacturing Industry Survey Report 2018Dokument778 SeitenLarge and Medium Manufacturing Industry Survey Report 2018melakuNoch keine Bewertungen

- 2009 ESC Guidelines On EndocarditisDokument45 Seiten2009 ESC Guidelines On EndocarditisDaondy Friarsa SoehartoNoch keine Bewertungen

- 2nd - Science-Second-Quarter-Week-1Dokument37 Seiten2nd - Science-Second-Quarter-Week-1Arlene AranzasoNoch keine Bewertungen

- Protreat Hydro EngrgDokument6 SeitenProtreat Hydro EngrgAmitkumar SinghNoch keine Bewertungen

- Introducing Inspira's: Managed Noc & Itoc ServicesDokument2 SeitenIntroducing Inspira's: Managed Noc & Itoc ServicesmahimaNoch keine Bewertungen

- Guide to Conducting SAFOP StudiesDokument52 SeitenGuide to Conducting SAFOP Studiesokemma79% (14)

- Gravimetric Analysis Lab ReportDokument5 SeitenGravimetric Analysis Lab Reportclaire_miller_16100% (1)

- Akshay 71 Seminar ReportDokument22 SeitenAkshay 71 Seminar ReportSanket Yadav25% (4)

- Mercedes ManDokument7 SeitenMercedes Manien yeyenNoch keine Bewertungen

- Civil Engineering Subjects (1st - 5th Year) - 1Dokument5 SeitenCivil Engineering Subjects (1st - 5th Year) - 1Vincent TayagNoch keine Bewertungen

- Modeling Vessel Impacts for Lock Wall DesignDokument15 SeitenModeling Vessel Impacts for Lock Wall DesignSalam FaithNoch keine Bewertungen

- อัตราภาษีของไทยที่ลดให้เปรูDokument124 Seitenอัตราภาษีของไทยที่ลดให้เปรูDante FilhoNoch keine Bewertungen

- Medication - Safety - v4 Last Update 2015Dokument81 SeitenMedication - Safety - v4 Last Update 2015Retno PalupiNoch keine Bewertungen

- Design of Steel BeamsDokument4 SeitenDesign of Steel BeamsSankalp LamaNoch keine Bewertungen

- 1 SM PDFDokument14 Seiten1 SM PDFSiti HamsyiahNoch keine Bewertungen

- HHG4M - Lifespan Development Textbook Lesson 4Dokument88 SeitenHHG4M - Lifespan Development Textbook Lesson 4Lubomira SucheckiNoch keine Bewertungen

- Turbine Stress EvaluatorDokument14 SeitenTurbine Stress EvaluatorsumitNoch keine Bewertungen

- 3.1-T.C.Dies PDFDokument6 Seiten3.1-T.C.Dies PDFYahyaMoummouNoch keine Bewertungen

- Unit 3 Assignment - CompletedDokument7 SeitenUnit 3 Assignment - CompletedSu GarrawayNoch keine Bewertungen

- Civil Eng Internship ReportDokument6 SeitenCivil Eng Internship ReportAromatic-O PNoch keine Bewertungen

- Comparison Study of Conventional Hot-Water and Microwave Blanching at Different Timetemperaturepower Combinations On The Quality of Potatoes.Dokument72 SeitenComparison Study of Conventional Hot-Water and Microwave Blanching at Different Timetemperaturepower Combinations On The Quality of Potatoes.DavldSmith100% (1)

- Mathematics: Minimum Level Learning MaterialDokument60 SeitenMathematics: Minimum Level Learning MaterialTusar SardarNoch keine Bewertungen

- Dr. Blyden: Chronic Obstructive Pulmonary Disease (Copd)Dokument63 SeitenDr. Blyden: Chronic Obstructive Pulmonary Disease (Copd)Blyden NoahNoch keine Bewertungen

- Rotary Gear Pump Manufacturers in India, Pulp Valve Manufacturers IndiaDokument3 SeitenRotary Gear Pump Manufacturers in India, Pulp Valve Manufacturers IndiaKirit IndustriesNoch keine Bewertungen

- Raspberry PiDokument19 SeitenRaspberry PiAnonymous E4Rbo2s100% (1)

- Assignment #1: 1 HgjyygbykvrfDokument1 SeiteAssignment #1: 1 HgjyygbykvrfJuan Sebastian ArangoNoch keine Bewertungen

- BBO 2011 ROUND 2 QUESTIONSDokument16 SeitenBBO 2011 ROUND 2 QUESTIONSMalvina YuanNoch keine Bewertungen

- TICSA - Diesel Uno Petroleos Guatemala (13.01.23)Dokument1 SeiteTICSA - Diesel Uno Petroleos Guatemala (13.01.23)Luis M LópezNoch keine Bewertungen