Beruflich Dokumente

Kultur Dokumente

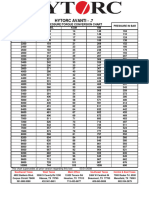

HV10 To HRC

Hochgeladen von

GaneshOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

HV10 To HRC

Hochgeladen von

GaneshCopyright:

Verfügbare Formate

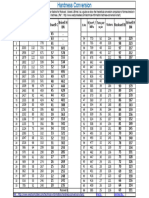

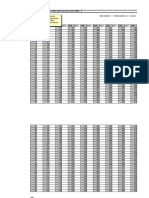

Comparsion of Hardness

Tens. strength Tens. strength

(N/mm2) HRC HB30 HV10 (N/mm2) HRC HB30 HV10

240 71 75 940 29 278 293

255 76 80 970 30 287 302

270 81 85 995 31 295 310

285 86 90 1020 32 301 317

305 90 95 1050 33 311 327

320 95 100 1080 34 319 336

335 100 105 1110 35 328 345

350 105 110 1140 36 337 355

370 109 115 1170 37 346 364

385 114 120 1200 38 354 373

400 119 125 1230 39 363 382

415 124 130 1260 40 372 392

430 128 135 1300 41 383 403

450 133 140 1330 42 393 413

465 138 145 1360 43 402 423

480 143 150 1400 44 413 434

495 147 155 1440 45 424 446

510 152 160 1480 46 435 458

530 157 165 1530 47 449 473

545 162 170 1570 48 460 484

560 166 175 1620 49 472 497

575 171 180 1680 50 488 514

595 176 185 1730 51 501 527

610 181 190 1790 52 517 544

625 185 195 1845 53 532 560

640 190 200 1910 54 549 578

660 195 205 1980 55 567 596

675 199 210 2050 56 584 615

690 204 215 2140 57 607 639

705 209 220 2180 58 622 655

720 214 225 59 675

740 219 230 60 698

755 223 235 61 720

770 228 240 62 745

785 233 245 63 773

800 22 238 250 64 800

820 23 242 255 65 829

835 24 247 260 66 864

860 25 255 268 67 900

TECHNICAL

SECTION

870 26 258 272 68 940

900 27 266 280

920 28 273 287

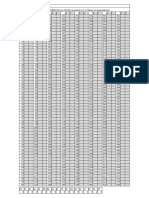

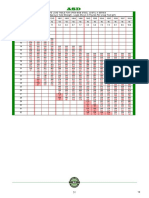

Tolerances to DIN ISO 286

Nominal diameter range in m/tolerances in m

from 1 over 3 over 6 over 10 over 18 over 30 over 50 over 80 over 120 over 180

up to 3 up to 6 up to 10 up to 18 up to 30 up to 50 up to 80 up to 120 up to 180 up to 250

h6 0 0 0 0 0 0 0 0 0 0

Tolerances: Position and Grade

-6 -8 -9 -11 -13 -16 -19 -22 -25 -29

h7 0 0 0 0 0 0 0 0 0 0

-10 -12 -15 -18 -21 -25 -30 -35 -40 -46

h8 0 0 0 0 0 0 0 0 0 0

Shafts

-14 -18 -22 -27 -33 -39 -46 -54 -63 -72

h9 0 0 0 0 0 0 0 0 0 0

-25 -30 -36 -43 -52 -62 -74 -87 -100 -115

h 10 0 0 0 0 0 0 0 0 0 0

-40 -48 -58 -70 -84 -100 -120 -140 -160 -185

e 8* -14 -20 -25 -32 -40 -50 -60 -72 -85 -100

-28 -38 -47 -59 -73 -89 -106 -126 -148 -172

*Milling cutters to tolerance e8 produce key slots to tolerance P9 with one cut.

92

Das könnte Ihnen auch gefallen

- Kemenyseg-Szakitoszil OsszehasDokument1 SeiteKemenyseg-Szakitoszil OsszehasLaszlo BirkasNoch keine Bewertungen

- Steel Hardness Conversion TableDokument3 SeitenSteel Hardness Conversion TableVajid MadathilNoch keine Bewertungen

- Discrimination Salariale, La Verite Par Les ChiffresDokument2 SeitenDiscrimination Salariale, La Verite Par Les ChiffresKet PhilipsNoch keine Bewertungen

- AVANTI-.7 Conversion Chart ALL 2023Dokument1 SeiteAVANTI-.7 Conversion Chart ALL 2023Ana De la cruzNoch keine Bewertungen

- Tabela de Peso Parafuso SXT Din 931Dokument1 SeiteTabela de Peso Parafuso SXT Din 931engenharia0333Noch keine Bewertungen

- Calulo EsclerometroDokument1 SeiteCalulo EsclerometroElvis Ichevarria GarciaNoch keine Bewertungen

- Tabel Duritati OtelDokument2 SeitenTabel Duritati Otelgagarin1965Noch keine Bewertungen

- HSBM-30K enDokument1 SeiteHSBM-30K enAlexandre GiliiNoch keine Bewertungen

- Tabela de DurezaDokument1 SeiteTabela de DurezacoelhoanthonioNoch keine Bewertungen

- Tablas Norma API 6dDokument44 SeitenTablas Norma API 6dAndres CastilloNoch keine Bewertungen

- Abaque Sections Cable TriphaseDokument1 SeiteAbaque Sections Cable TriphasePélagie DAH SERETENONNoch keine Bewertungen

- Wave AbhikDokument4 SeitenWave Abhik002AADHARGUPTANoch keine Bewertungen

- Catalog Lating t4.2021Dokument32 SeitenCatalog Lating t4.2021tienktsa4Noch keine Bewertungen

- 1 - L MentiraDokument1 Seite1 - L MentiraKelin Stefania Flores SuarezNoch keine Bewertungen

- EJERCICIODokument1 SeiteEJERCICIOVanessa VallejosNoch keine Bewertungen

- 3 K CorreccionDokument1 Seite3 K CorreccionKelin Stefania Flores SuarezNoch keine Bewertungen

- InventoryDokument5 SeitenInventoryGERALDINENoch keine Bewertungen

- Planilha de HinosDokument1 SeitePlanilha de HinosAna Cecília SantosNoch keine Bewertungen

- 4 - Hs HipocondriaDokument1 Seite4 - Hs HipocondriaKelin Stefania Flores SuarezNoch keine Bewertungen

- TP CristallisationDokument3 SeitenTP CristallisationJoël RebNoch keine Bewertungen

- Cities No. of Inhabitants Random Sample No. of Inhabitants Random Sample No. of InhabitantsDokument1 SeiteCities No. of Inhabitants Random Sample No. of Inhabitants Random Sample No. of Inhabitantskshitijmalh2004Noch keine Bewertungen

- Ducting Size (According To 0.07 - 0.1in - WC) - LooperDokument12 SeitenDucting Size (According To 0.07 - 0.1in - WC) - LooperaniqqaimanNoch keine Bewertungen

- Hardness Conversion 14.03.2016Dokument1 SeiteHardness Conversion 14.03.2016Muniyappan TNoch keine Bewertungen

- Test MMPI 2 (Hoja de Respuestas) 2Dokument1 SeiteTest MMPI 2 (Hoja de Respuestas) 2Andres HincapieNoch keine Bewertungen

- Hinos Mais Dificeis para OficializaçãoDokument1 SeiteHinos Mais Dificeis para OficializaçãoNeila NogueiraNoch keine Bewertungen

- CPI ScorareDokument1 SeiteCPI ScorareMaria PruteanuNoch keine Bewertungen

- Listagem de HinosDokument1 SeiteListagem de HinosIsadora Ferreira ZaniNoch keine Bewertungen

- 2 F IncoherenciaDokument1 Seite2 F IncoherenciaKelin Stefania Flores SuarezNoch keine Bewertungen

- Datos Sensor VDO Temperatura PDFDokument2 SeitenDatos Sensor VDO Temperatura PDFSgly ZemogNoch keine Bewertungen

- Tabel Echivalente Duritati HB-HRCDokument1 SeiteTabel Echivalente Duritati HB-HRCdanmertzNoch keine Bewertungen

- Ambot Unsa NiDokument2 SeitenAmbot Unsa Nil.razol.126176.tcNoch keine Bewertungen

- Manuj NathDokument4 SeitenManuj Nathmanna.dass76Noch keine Bewertungen

- Jueves 1Dokument1 SeiteJueves 1davidestrada7323Noch keine Bewertungen

- Vulcraft TABLESDokument4 SeitenVulcraft TABLESLeomariniNoch keine Bewertungen

- Tripas TablaDokument1 SeiteTripas Tablacarlos manquerosNoch keine Bewertungen

- Product Sheet Accessories Kenter Type Joining ShackleDokument3 SeitenProduct Sheet Accessories Kenter Type Joining ShackleYarham SuaibNoch keine Bewertungen

- GHDokument26 SeitenGHsoukainabelarbi0Noch keine Bewertungen

- Tablas Canones Tipo NelsonDokument2 SeitenTablas Canones Tipo NelsonDiana Lorena Vergara MurilloNoch keine Bewertungen

- Hoja de Respuestas MMPI-2 CompletaDokument1 SeiteHoja de Respuestas MMPI-2 CompletaPau RochaNoch keine Bewertungen

- 01 ParetoDokument1 Seite01 ParetoImane El KasmiNoch keine Bewertungen

- LogdesDokument3 SeitenLogdesDuy HoNoch keine Bewertungen

- Butterfly Valve Flow Coefficient CV Value SB71 SB41 SB42Dokument1 SeiteButterfly Valve Flow Coefficient CV Value SB71 SB41 SB42bhaaskarNoch keine Bewertungen

- Coffee Brew Ratio Guide Pull&PourDokument1 SeiteCoffee Brew Ratio Guide Pull&PourBenjaNoch keine Bewertungen

- Tabela Conversao de ViscosidadeDokument2 SeitenTabela Conversao de ViscosidadedouglasNoch keine Bewertungen

- Mueller Calibration Chart O-500Dokument2 SeitenMueller Calibration Chart O-500Ordom RdNoch keine Bewertungen

- Rev Page 16Dokument1 SeiteRev Page 16GADAL SOLOMONNoch keine Bewertungen

- Score Sheet 1Dokument1 SeiteScore Sheet 1Jesse OsbornNoch keine Bewertungen

- DIN931 WeightDokument1 SeiteDIN931 WeightАндрей МеренковNoch keine Bewertungen

- Data Shear FractureDokument1 SeiteData Shear FractureFriska AgustinNoch keine Bewertungen

- BULYEDDokument7 SeitenBULYEDagus wahyudiNoch keine Bewertungen

- LIST BOX RPB - Sheet1Dokument2 SeitenLIST BOX RPB - Sheet1arya mahendraNoch keine Bewertungen

- MMPI 2 HOMBRES para CursosDokument37 SeitenMMPI 2 HOMBRES para CursosAlejandra ZegarraNoch keine Bewertungen

- Practice Test Conversion TableDokument3 SeitenPractice Test Conversion Tablepepito grilloNoch keine Bewertungen

- Practice Test Conversion TableDokument3 SeitenPractice Test Conversion TableestefaniaNoch keine Bewertungen

- Taille de L'échantillonDokument1 SeiteTaille de L'échantillonHarold TSOBDJOUNoch keine Bewertungen

- Halveringstid For Barium 222222Dokument3 SeitenHalveringstid For Barium 222222huss0530Noch keine Bewertungen

- Tabelul 7.1-Tabele Privind Suprafata Sectiunilor Transversale-0Dokument1 SeiteTabelul 7.1-Tabele Privind Suprafata Sectiunilor Transversale-0Adrian NegoitaNoch keine Bewertungen

- APLICATIIDokument7 SeitenAPLICATIIManuela eNoch keine Bewertungen

- Tarea Calificada Semana 4 A Semana 5 - C.gomeZDokument22 SeitenTarea Calificada Semana 4 A Semana 5 - C.gomeZRosalina CadilloNoch keine Bewertungen

- TP03 Pratique AOPDokument2 SeitenTP03 Pratique AOPZain GaradiNoch keine Bewertungen

- Vidéo Et Audio Sur IPDokument4 SeitenVidéo Et Audio Sur IPINTTICNoch keine Bewertungen

- Fiche 1 Leçon 1quelques Matériaux Utilisés Dans La Vie Quotidienne Prof - Abouelmajd (WWW - Pc1.ma)Dokument2 SeitenFiche 1 Leçon 1quelques Matériaux Utilisés Dans La Vie Quotidienne Prof - Abouelmajd (WWW - Pc1.ma)mohamed aoubyNoch keine Bewertungen

- These Matthieu RauchDokument248 SeitenThese Matthieu RauchBoutef El HachemiNoch keine Bewertungen

- Livret TD - TP Pac - Version Corrigee - Janvier 2019Dokument46 SeitenLivret TD - TP Pac - Version Corrigee - Janvier 2019Stéphane HuguetNoch keine Bewertungen

- Elements de Construction Mixte - G. MasyDokument100 SeitenElements de Construction Mixte - G. Masymathilde.jacques.94Noch keine Bewertungen

- 44-TP-Voies Et Ouvrages D'artDokument55 Seiten44-TP-Voies Et Ouvrages D'artdjimy_dzNoch keine Bewertungen

- Glossaire Matériaux CompositesDokument34 SeitenGlossaire Matériaux CompositesYoussef Khali100% (1)

- Les Equivalences Energetiques Et La Nouvelle Methodologie D Etablissement Des Bilans Energetiques de La France Cle79f5f1Dokument2 SeitenLes Equivalences Energetiques Et La Nouvelle Methodologie D Etablissement Des Bilans Energetiques de La France Cle79f5f1Kris MoutoussamyNoch keine Bewertungen

- Séminaire Fours & Chaudieres (2006)Dokument79 SeitenSéminaire Fours & Chaudieres (2006)Sarra BÉCHIRI100% (1)

- Produit RaccordDokument22 SeitenProduit RaccordAnonymous NonQwK3qL2Noch keine Bewertungen

- ALROCDokument2 SeitenALROCAnonymous xBi2FsBxNoch keine Bewertungen

- TD 2 CorrigeDokument2 SeitenTD 2 CorrigeIbrahimFaroukSolar100% (2)

- Perspective IsométriqueDokument12 SeitenPerspective IsométriqueRemy AwomoNoch keine Bewertungen

- Etude Theorique Aile Et Foils Avec Mecaflux Standard Et HelicielDokument37 SeitenEtude Theorique Aile Et Foils Avec Mecaflux Standard Et HelicielenguerrandvaubyNoch keine Bewertungen

- LDokument4 SeitenLAmi Zaki100% (1)

- Serie N°2 - Cinématique Des FluidesDokument10 SeitenSerie N°2 - Cinématique Des FluidesJasmine Yasmine100% (4)

- 2022 09 11 01 25 32 - 09a31f84Dokument7 Seiten2022 09 11 01 25 32 - 09a31f84hamil.oumaima21Noch keine Bewertungen

- Séries Chro InseaDokument116 SeitenSéries Chro InseaEL Hafa AbdellahNoch keine Bewertungen

- ANJOS - Renovation en CollectifDokument12 SeitenANJOS - Renovation en Collectifj_chichouNoch keine Bewertungen

- Polycopie Initiation Aux BiomateriauxDokument27 SeitenPolycopie Initiation Aux BiomateriauxMohamed meNoch keine Bewertungen

- Topographie Elementaire InitiationDokument138 SeitenTopographie Elementaire InitiationAlinsafi Oussama75% (4)

- Vérifications ELU Et ELS (Poutre 39)Dokument62 SeitenVérifications ELU Et ELS (Poutre 39)Asting elboujidi abdessamadNoch keine Bewertungen

- Ge Esa 2018Dokument16 SeitenGe Esa 2018othmane mrichNoch keine Bewertungen

- Présentation Détaillée Nouvelle NFC 15 100-30-07-02-W2Dokument34 SeitenPrésentation Détaillée Nouvelle NFC 15 100-30-07-02-W2Yacine MezianiNoch keine Bewertungen

- 18 LachimieverteDokument17 Seiten18 Lachimievertehakimbil100% (1)

- Session 7 s1 Mohamed El Moctar Ould Taleb SnimDokument35 SeitenSession 7 s1 Mohamed El Moctar Ould Taleb SnimargiNoch keine Bewertungen

- PHD PubliDokument182 SeitenPHD PublimouadNoch keine Bewertungen

- Fiche Technique Prise OPTIMADokument1 SeiteFiche Technique Prise OPTIMAalexNoch keine Bewertungen

- LTM 1090/1 - Porteur UW-01: Table Des MatièresDokument28 SeitenLTM 1090/1 - Porteur UW-01: Table Des MatièresncirNoch keine Bewertungen