Beruflich Dokumente

Kultur Dokumente

Ls - 2012 11 01 PDF

Hochgeladen von

Ashok Suresh0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

22 Ansichten5 SeitenOriginaltitel

ls_2012-11-01 .pdf

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

22 Ansichten5 SeitenLs - 2012 11 01 PDF

Hochgeladen von

Ashok SureshCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 5

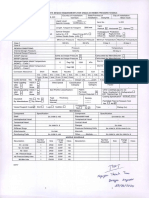

SIUE STEEL BRIDGE FABRICATION Job Safety Analysis

JOB/TASK NAME DATE

Steel Bridge Fabrication 11/22/2011

JOB TITLE PERFORMING THE JOB/TASK TEAM CAPTAINS

Students

SAFETY OFFICERS

REQUIRED PERSONAL Safety glasses, face shield, gloves, work boots/shoes

PROTECTIVE EQUIPMENT

EQUIPMENT / TOOLS REQUIRED FOR JOB (Complete Tool Inspection Prior to Start of Job):

Welder, Grinder, Torch, Electrical Tools.

JOB STEPS POTENTIAL HAZARDS HAZARD CONTROL METHOD

1. Safety Training See items listed below

1) All persons actively engaged in fabrication

activities must have safety training. The training

shall include the following parts:

a) General Shop Rules

b) Hand and power tool safety

c) Electrical safety

d) Fire safety

e) Personal protective equipment (PPE)

2) In addition to items listed above, welding

equipment operators and designated safety

officers must also have welding safety training.

3) Documentation that shows such training must be

on file for each person. The documentation must

consist of at least one of the following:

a) Certificate or diploma showing successful

completion of training that includes at least

the safety items listed in item 1 above, or

b) Completed Student Projects Shop Safety

Rules exam, or

c) other evidence provided to the project

faculty advisor that shows successful

completion of training meeting the safety

items listed in item 1 above.

SIUE School of Engineering | Student Projects | Steel Bridge Team Page 1 of 5

2. Hot Work Permit

4) Hot Work may be done ONLY if there is a valid

Hot Work permit posted.

5) If any condition exists that conflicts with the

terms of the Hot Work permit then Hot Work

shall NOT be performed until the condition is

properly corrected.

6) Only persons specifically named on the

appropriate, valid Hot Work permit may operate

the welding equipment for the project.

7) If a Firewatch is required by the permit, a

designated Firewatch is required for 30 minutes

after hot work is completed for inspection.

3. Housekeeping a. Slips, trips, falls

8) Keep work area clean and clear of debris.

b. Fire

c. Tool Conditions 9) Be aware of everything going on around.

d. Sharp Objects

10) Keep an eye on fellow workers and alert them of

any potential risk/harm.

11) Locate fire extinguishers, fire blankets, and eye

wash stations.

12) Clean work area after work is complete.

13) Black trash cans are for metal only.

14) Silver trash cans are for non-metallic trash and

are to be kept out of the hot work area.

15) Always sign in/out tools being used outside the

designated work area.

SIUE School of Engineering | Student Projects | Steel Bridge Team Page 2 of 5

4. Tools and a. Cut/Burn

16) While tools or equipment are being used properly

Equipment b. Electrical Hazards

fitted personal protective equipment must be

c. Noise levels

worn by the operator and others in the area.

17) Before use of any powered equipment or tool, a

thorough inspection must be completed to insure

proper working condition. Make any proper

necessary corrections before use of the

equipment.

18) Do not use equipment or tool that is damaged

beyond repair or has any safety features missing

(guards). Report damaged tool/equipment to

team captain or safety advisor for DO NOT

OPERATE tag.

19) Portable power equipment shall be unplugged

when not in use.

20) All power cords shall be inspected before the

cord or tool is used, periodically while being

used, and when work with the cord or equipment

is done for the day. Any damaged cord must be

taken out of service immediately.

SIUE School of Engineering | Student Projects | Steel Bridge Team Page 3 of 5

5. Welding, Cutting, a. Electrical Hazards

21) Inspect all cords, connectors, ground clamps,

and Grinding b. Eye Injuries

etc. for defects. Assure all protective

i. flying debris

covers/boots are in place to prevent contact with

ii. flash burn

energized parts.

c. Hand and Burn

Injuries 22) Inspect all hoses, regulators, and torches prior to

d. Fumes and gases use.

e.

23) Safety glasses must be worn in an area while

grinding, cutting, or welding are being conducted

in that area.

24) Use the appropriate shade filter for the materials

to be welded. Inspect all welding hoods/lenses

for scratches, chips, or other damage.

25) Place welding screens around welding operations

areas.

26) Inform all persons in the vicinity where welding

may be performed of welding in progress.

27) Use proper ventilation during hot work or any

dust producing processes.

28) Wear a properly fitted N-95 particulate mask

designed for welding applications.

29) Do not weld painted or plated steel. Zinc or

galvanized coatings and other coating produce

poisonous fumes.

30) Remove excess oil and other contaminates from

vicinity of the welded connection the prior to

welding.

31) Use the appropriate gloves for each welding,

cutting, and grinding activity. Use long sleeve

shirts, welding sleeves, or jackets to prevent

burns from welding slag.

32) A fire extinguisher needs to be available while

welding or hot work is being performed close by.

SIUE School of Engineering | Student Projects | Steel Bridge Team Page 4 of 5

Welding, Cutting, f. Gas Cylinder Handling

33) Follow all Hot Work Manual/Safety Rules.

and Grinding and Storage

(continued) g. Fire Prevention 34) Store all cylinders in an upright position, with

their valve protective caps screwed in place,

secured in a manner to prevent inadvertent tip-

over, and in an area isolated away from

vehicle/equipment traffic.

35) Keep all grease or oil away from oxygen

cylinders. Inspect all regulators and valves for

oil/grease contamination prior to use.

36) Use proper lifting techniques when transferring

cylinders from storage cages to gas bottle carts

to prevent back/shoulder strains.

37) Remove regulators prior to moving cylinders.

38) Replace all valve cover caps after you remove

regulators from the cylinder.

39) Store fuel-gas cylinders (propane, acetylene,

etc.) 20 feet from Oxygen cylinders at all times.

40) Always stand to the side of the regulator gage

and not facing it while opening the cylinder

valve.

41) The shield gas must be appropriate for the type

of welding and materials used.

42) Inspect all cylinders for defects prior to use.

43) Cylinders not being used in the welding work

shall be kept far enough away from areas where

welding, sparks, or flame producing activities are

present. Cylinders used directly for the welding

work shall be protected from direct exposure to

heat and sparks from the welding operation.

44) Keep all flammable/combustible materials out of

the hot work zone.

45) Keep all hot work tools within the hot work zone.

SIUE School of Engineering | Student Projects | Steel Bridge Team Page 5 of 5

Das könnte Ihnen auch gefallen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Third Party Inspection ScopeDokument1 SeiteThird Party Inspection ScopeAshok SureshNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Small Engine Reassembly - GDLCDokument40 SeitenSmall Engine Reassembly - GDLCAshok SureshNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- P16MBA3Dokument4 SeitenP16MBA3Ashok SureshNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- P16MBA4Dokument2 SeitenP16MBA4Ashok SureshNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Technical Information APP. 5 Field of Application:: 6 Bar/10 Bar /16 BarDokument2 SeitenTechnical Information APP. 5 Field of Application:: 6 Bar/10 Bar /16 BarAshok SureshNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Adapter CouplingDokument48 SeitenAdapter CouplingIan_SmythNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- PVCMC 0501 Us PDFDokument40 SeitenPVCMC 0501 Us PDFAshok SureshNoch keine Bewertungen

- Demco DM Iom PDFDokument24 SeitenDemco DM Iom PDFAshok SureshNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Drilling Chokes BrochureDokument12 SeitenDrilling Chokes BrochureAshok SureshNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Design Calculation: Part No: 16 FS 4950 CAL 001 Material: AISI 4130 Yield Strength, Sy 75,000 Psi. MinDokument1 SeiteDesign Calculation: Part No: 16 FS 4950 CAL 001 Material: AISI 4130 Yield Strength, Sy 75,000 Psi. MinAshok SureshNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Appendix B Approved List of MaterialsDokument33 SeitenAppendix B Approved List of MaterialsAshok Suresh0% (1)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Chiksan Original Swivel Joints: A Complete Line of Swivel Joints For Drilling, Production, and Well ServicingDokument16 SeitenChiksan Original Swivel Joints: A Complete Line of Swivel Joints For Drilling, Production, and Well Servicingger80Noch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- For Reference: Material: SS 304 3 MM ThickDokument2 SeitenFor Reference: Material: SS 304 3 MM ThickAshok SureshNoch keine Bewertungen

- BOM, Rig PlatformDokument1 SeiteBOM, Rig PlatformAshok SureshNoch keine Bewertungen

- Gate ValvesDokument20 SeitenGate ValvesaliNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Bhel ProductDokument10 SeitenBhel ProductAshok Suresh100% (1)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Gemeinsam Etwas Planen b1 MT 1 5 - CompressDokument5 SeitenGemeinsam Etwas Planen b1 MT 1 5 - CompressDịu Trần ThịNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- ABS Anglo Belgian CorporationDokument6 SeitenABS Anglo Belgian CorporationDammiam GaticaNoch keine Bewertungen

- Impact of Industrialization On Region and Community WelfareDokument7 SeitenImpact of Industrialization On Region and Community WelfareTejaswini RastogiNoch keine Bewertungen

- BPCL PPT NitwDokument45 SeitenBPCL PPT NitwChintu SanthuNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Question No 1: Experiment: To Measure Electrical Conductivity by Using Two Probe or Four Probe MethodDokument17 SeitenQuestion No 1: Experiment: To Measure Electrical Conductivity by Using Two Probe or Four Probe Methodzrish100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1091)

- Basic Fire Awarness Traing - New Element 1 - Ammended Nov 2019.Ppt-2Dokument67 SeitenBasic Fire Awarness Traing - New Element 1 - Ammended Nov 2019.Ppt-2L MNoch keine Bewertungen

- Data Sheet 3KL8431-3UA00: ModelDokument2 SeitenData Sheet 3KL8431-3UA00: Modeliotaathi tNoch keine Bewertungen

- Monday 20 May 2019: ChemistryDokument24 SeitenMonday 20 May 2019: Chemistryahumad aliNoch keine Bewertungen

- Challenger ITRDokument64 SeitenChallenger ITRcesar luis gonzalez rodriguezNoch keine Bewertungen

- Thermodynamics MRCP 2017Dokument47 SeitenThermodynamics MRCP 2017Calvin LabialNoch keine Bewertungen

- How Does A Cooling System of A Generator WorkDokument3 SeitenHow Does A Cooling System of A Generator WorkSaad jamilNoch keine Bewertungen

- RCA CTC185A (3960) EfDokument17 SeitenRCA CTC185A (3960) Efapi-19523062Noch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- JPMorgan Equity Premium Income ETF ETF Shares Holdings 05 05 2023Dokument2 SeitenJPMorgan Equity Premium Income ETF ETF Shares Holdings 05 05 2023Dario MartinelliNoch keine Bewertungen

- E Instruction sk7615 7625Dokument7 SeitenE Instruction sk7615 7625Abdalhakeem AlturkyNoch keine Bewertungen

- Halal Tariqay Say Kamanay Kay 50 Madani PhoolDokument28 SeitenHalal Tariqay Say Kamanay Kay 50 Madani PhoolMazharul IslamNoch keine Bewertungen

- OSHA Training Toolbox Talk - Lockout-Tagout Energy Isolation DevicesDokument2 SeitenOSHA Training Toolbox Talk - Lockout-Tagout Energy Isolation DevicesZeeshan BajwaNoch keine Bewertungen

- HPM M66uaDokument78 SeitenHPM M66uallopez100% (3)

- PADHLENOTES - 9 - SCIENCE - CH11-Work Energy and PowerDokument13 SeitenPADHLENOTES - 9 - SCIENCE - CH11-Work Energy and PowerMehul GautamNoch keine Bewertungen

- Student Name Student ID Qualification Code and Name Trainer NameDokument56 SeitenStudent Name Student ID Qualification Code and Name Trainer Namejoe joyNoch keine Bewertungen

- GEH-6789-EX2100e Excitation Control Diagnostic Alarms For Thyristor Systems Troubleshooting GuideDokument188 SeitenGEH-6789-EX2100e Excitation Control Diagnostic Alarms For Thyristor Systems Troubleshooting GuideLê Trung Dũng100% (1)

- Hamriyah Free Zone (Hfza)Dokument76 SeitenHamriyah Free Zone (Hfza)Shihabudeen Shihab100% (1)

- Chater Three 3-1-Introduction:: 3-2-1-1-Profile MethodDokument7 SeitenChater Three 3-1-Introduction:: 3-2-1-1-Profile MethodMohammed DawoodNoch keine Bewertungen

- Description: Wattstopper Occupancy SensorDokument1 SeiteDescription: Wattstopper Occupancy SensorJeffery OsvoldNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Drives br011 - en P PDFDokument8 SeitenDrives br011 - en P PDFreynhardsNoch keine Bewertungen

- Ngurv Ter - : de en Ow06/002.0Dokument2 SeitenNgurv Ter - : de en Ow06/002.0tranhonghakd5533Noch keine Bewertungen

- Sultanate of Oman: WWW - Duqm.gov - OmDokument35 SeitenSultanate of Oman: WWW - Duqm.gov - OmAli MustafaNoch keine Bewertungen

- 3303.0002 Micropack FDS303 Multi Spectrum IR Flame Detector - Datasheet Rev 1.4Dokument2 Seiten3303.0002 Micropack FDS303 Multi Spectrum IR Flame Detector - Datasheet Rev 1.4Landi ManusNoch keine Bewertungen

- Process Synthesis and Optimization of Propylene - Propane Separation Using Vapor Recompression and Self-Heat RecuperationDokument8 SeitenProcess Synthesis and Optimization of Propylene - Propane Separation Using Vapor Recompression and Self-Heat RecuperationForcus onNoch keine Bewertungen

- Lecture No.4 The Ideal Regenerative Rankine CycleDokument22 SeitenLecture No.4 The Ideal Regenerative Rankine CycleJohn Michael Go AbalosNoch keine Bewertungen

- Chapter 1 Mathematical Modelling by Differential Equations: Du DXDokument7 SeitenChapter 1 Mathematical Modelling by Differential Equations: Du DXKan SamuelNoch keine Bewertungen