Beruflich Dokumente

Kultur Dokumente

Flowchart 2.0

Hochgeladen von

walidghoneim1970Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Flowchart 2.0

Hochgeladen von

walidghoneim1970Copyright:

Verfügbare Formate

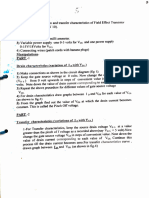

Start X Y Y

* single layer, double

layer, overlapping, Step 9

Step 1 Step 4

non-overlapping, Full Step 7

pitch coil, short pitch Calculate main and Leakage

Set Rated : Set basic Air gap length, PM coil, concentrated reluctance.

Lag, Calculate Flux density in tooth

Power, thickness winding, fractional slot Eq 1:5 & xm : Eq.xn

P,, Lpm and slot

Speed, (Eq. 37 & 38) winding, fractional

V,f Eq.16 & 17

Voltage & pole winding, etc

Frequency. Calculate Inductances

SRo, 2

single phase, 2-

Set basic SRo,SRi,RRi Eq.xm : Eq.xn

SRi, phase,3-phase or more

(Eq. 39:42)

RRi

Set Number of phases, Change

Q Is Flux density

Winding configuration * slot and Develop Equivalent magnetic

within limits N

tooth circuit Fig.5

Step 5 Eq. 15 & 13

dimension

Set initial number of poles Use (Eq. 1:5) to calculate the

p

(Eq. 43) load line of the magnetic Y Step 10

circuit Change

dimensions Slot and tooth Calc. no-load Voltage induced

From Table 3.8, 3.9 dimensions

S,p, Eq.25:29 (V,rated)

Chose the suitable pole/slot Define

combination. design

Is Magnet operating at

N

= max. energy point ? strategy Calc. mean length per turn

variable** Calculate Slot area Eq.34 (MLT)

Step 2 Eq. 30:32

**

Hm,Br, Y

Chose Magnet (Max Energy, Fixed PM

Calc. Rcoil & Rphase

HBmax, High Br, lowest cost, lowest thickness or

SRi, SRo, RRo, Step 8 (Eq. 35 & 36)

m weight, Available) Fixed Air gap

RRi, lm,lg length

Calculate Flux density in Calc. KE and Kt

Create Data Set of the stator & rotor Eq. 17 Eq. YY:YY

B,H Step 6

Magnet Magnetization curve

Calc. Number of turns Develop Equivalent electric

Nc

per coil. (Eq. 24) circuit Fig.x

Step 3 Is Flux density

Increase

within limits? N

back iron

Calc. Rated torque ( Eq. 15) Step 11

Trated Dw, Calc. Conductor diameter

(Eq.6) Aw ( Eq. 22 & 33 )

Calc. Voltage at full Load

Eq. X2

Y

Calc. Rotor volume Calc. Coil cross section area,

Vo Ac,

(Eq.7 & 8) Ast Required slot area

Sro, RRi Calc. Voltage Regulation, Losses,

Efficiency

Eq. X3:X10

Slot,

Set Length to Rotor outer Tooth

Lstk, Set Tooth and Slot dimension

radius dime- Step 12

RRo nsion (Eq. 11 , 12 , 18:21 & 44)

(Eq. 9, 9', 9')

s Build FEM model

Step 13

X Y Z

Add parametric and optimize for the

desired target

End

Das könnte Ihnen auch gefallen

- Linear Network Theory: The Commonwealth and International Library: Applied Electricity and Electronics DivisionVon EverandLinear Network Theory: The Commonwealth and International Library: Applied Electricity and Electronics DivisionNoch keine Bewertungen

- VLF Radio Engineering: International Series of Monographs in Electromagnetic WavesVon EverandVLF Radio Engineering: International Series of Monographs in Electromagnetic WavesNoch keine Bewertungen

- Adobe Scan May 20, 2023Dokument22 SeitenAdobe Scan May 20, 2023sp066135Noch keine Bewertungen

- (Boldea) - The Induction Machines Design Handbook, Second Edition-Trang-456-482 PDFDokument27 Seiten(Boldea) - The Induction Machines Design Handbook, Second Edition-Trang-456-482 PDFHùng Nguyễn MạnhNoch keine Bewertungen

- Ees 12 El Ici I Wi 2010 Ees 512 - Electric Circuits - Winter 2010Dokument20 SeitenEes 12 El Ici I Wi 2010 Ees 512 - Electric Circuits - Winter 2010armon_domingoNoch keine Bewertungen

- Field Effect TransistorDokument5 SeitenField Effect TransistorNanssjjsNoch keine Bewertungen

- 6 Electro Magnetic InductionDokument9 Seiten6 Electro Magnetic Inductionpsyco4513Noch keine Bewertungen

- Exp 1 Ohm's LawDokument4 SeitenExp 1 Ohm's LawaryendrapariharNoch keine Bewertungen

- Physics Practical 2022 23Dokument15 SeitenPhysics Practical 2022 23Dwip DasNoch keine Bewertungen

- DSPFirst L05A pp4Dokument4 SeitenDSPFirst L05A pp4Belkız Nur BayramNoch keine Bewertungen

- Reconfigurable Pico-Pulse Generator For Applications: FathyDokument4 SeitenReconfigurable Pico-Pulse Generator For Applications: Fathyrangana banerjeechaudhuriNoch keine Bewertungen

- B.E. Degree Examination Analog Electric CircuitsDokument10 SeitenB.E. Degree Examination Analog Electric CircuitsAPURV ANANDNoch keine Bewertungen

- Resistance ExperimentDokument21 SeitenResistance ExperimentAnvi MantriNoch keine Bewertungen

- Analysis and Performance Assessment of Six-Pulse Inverter-Fed Three-Phase and Six-Phase Induction MachinesDokument9 SeitenAnalysis and Performance Assessment of Six-Pulse Inverter-Fed Three-Phase and Six-Phase Induction MachinessouravghimireyNoch keine Bewertungen

- RA01 Both E and B - Amit SharmaDokument21 SeitenRA01 Both E and B - Amit SharmaPadam MantryNoch keine Bewertungen

- Electrostatics + Magnetostatic + Current_Dokument1 SeiteElectrostatics + Magnetostatic + Current_rudraveer2805Noch keine Bewertungen

- 3 Wattmeter MethodDokument5 Seiten3 Wattmeter MethodS ARSHIYA VU21CSEN0500245Noch keine Bewertungen

- Dec 2013 Jan 2014Dokument1 SeiteDec 2013 Jan 2014mabhatNoch keine Bewertungen

- Adobe Scan 17 Oct 2023Dokument1 SeiteAdobe Scan 17 Oct 2023harinijeyasri7Noch keine Bewertungen

- lec 5 V-F controlDokument7 Seitenlec 5 V-F controlLương Ngọc ThànhNoch keine Bewertungen

- Simulation Patch AntennaDokument4 SeitenSimulation Patch AntennasalusivasankaranNoch keine Bewertungen

- B - Inductance ProfileDokument4 SeitenB - Inductance ProfileAlisha AnjumNoch keine Bewertungen

- OE44100 Wk05a Handout1 PDFDokument2 SeitenOE44100 Wk05a Handout1 PDFnielssievdNoch keine Bewertungen

- Design For Shear Reinforcement: Earthquake Engineering Management Master ProgramDokument27 SeitenDesign For Shear Reinforcement: Earthquake Engineering Management Master ProgramAnggi Novi Andri100% (1)

- Mind Maps EMI & Alternating CurrentDokument2 SeitenMind Maps EMI & Alternating CurrentAyush KushwahaNoch keine Bewertungen

- IGBT Parasitic Thyristor StructureDokument1 SeiteIGBT Parasitic Thyristor StructureGagneNoch keine Bewertungen

- Synchronous K-NotesDokument11 SeitenSynchronous K-Notesomkar budigeNoch keine Bewertungen

- Tarea Primer Parcial Circuitos Electricos II Irvin 10a EdiciónDokument7 SeitenTarea Primer Parcial Circuitos Electricos II Irvin 10a EdiciónMauricio OlguínNoch keine Bewertungen

- Chemistry 11 Short Notes of Structure of AtomDokument2 SeitenChemistry 11 Short Notes of Structure of Atomkanit8713Noch keine Bewertungen

- Semiconductor Optical Communication Components and Devices: Lecture 19: Introduction To Diode Lasers - IIDokument11 SeitenSemiconductor Optical Communication Components and Devices: Lecture 19: Introduction To Diode Lasers - IIkomal sharmaNoch keine Bewertungen

- Finite-Element Simulation of A Synchronous Generator Under The Case Symmetrical Sudden Short-Circuit in Q-AxisDokument3 SeitenFinite-Element Simulation of A Synchronous Generator Under The Case Symmetrical Sudden Short-Circuit in Q-AxisFelix GamarraNoch keine Bewertungen

- EEE MachineDokument14 SeitenEEE Machinepranjal farhanNoch keine Bewertungen

- DRAW THE CIRCLE DIAGRAM STEP-BY-STEPDokument6 SeitenDRAW THE CIRCLE DIAGRAM STEP-BY-STEPajitNoch keine Bewertungen

- LTE Link Budget ProcessDokument17 SeitenLTE Link Budget ProcessSami DohaNoch keine Bewertungen

- Admbs 2Dokument3 SeitenAdmbs 2Swapnil KNoch keine Bewertungen

- CPT TK03 001Dokument46 SeitenCPT TK03 001Şəhriyar ƏliyevNoch keine Bewertungen

- E M Waves New Notes 2024Dokument9 SeitenE M Waves New Notes 2024pingjin010Noch keine Bewertungen

- Massachusetts Institute of Technology: Back IronDokument10 SeitenMassachusetts Institute of Technology: Back IronJack SoNoch keine Bewertungen

- Physics Imp Mind MapDokument15 SeitenPhysics Imp Mind MapShubhansh Nigam 43Noch keine Bewertungen

- Physics Practical (1 To 4)Dokument15 SeitenPhysics Practical (1 To 4)ShantanuNoch keine Bewertungen

- First Time User Guide To PN Junction V1.31: Network For Computational Nanotechnology (NCN)Dokument16 SeitenFirst Time User Guide To PN Junction V1.31: Network For Computational Nanotechnology (NCN)G.R.Mahendrababau AP - ECE departmentNoch keine Bewertungen

- First Time User Guide To PN Junction V1.31: Network For Computational Nanotechnology (NCN)Dokument16 SeitenFirst Time User Guide To PN Junction V1.31: Network For Computational Nanotechnology (NCN)Amey JadhavNoch keine Bewertungen

- p1632 eDokument4 Seitenp1632 ejohn saenzNoch keine Bewertungen

- Script Lecture 4Dokument11 SeitenScript Lecture 4jsebas635Noch keine Bewertungen

- UOM Electromagnetic Induction Notes 2Dokument5 SeitenUOM Electromagnetic Induction Notes 2Arctic TurtleNoch keine Bewertungen

- NDT 06 ET ModifDokument32 SeitenNDT 06 ET ModifHerry Eci MuhammadNoch keine Bewertungen

- Exam KIMP APS & DM UE1 15-12-2022 - 1Dokument12 SeitenExam KIMP APS & DM UE1 15-12-2022 - 1Achraf BradaNoch keine Bewertungen

- 1990.04.15 - Vanderbilt - PRB - Soft Self-Consistent PseudopotentialsDokument4 Seiten1990.04.15 - Vanderbilt - PRB - Soft Self-Consistent PseudopotentialsAlejandra AwimbaweNoch keine Bewertungen

- Microstrip Discontinuity Capacitances For Right-An81e Bends, T Junctions, and CrossingsDokument6 SeitenMicrostrip Discontinuity Capacitances For Right-An81e Bends, T Junctions, and CrossingsElectronic BoyNoch keine Bewertungen

- EEE CH 5 Three Phase 16052018 010215PMDokument10 SeitenEEE CH 5 Three Phase 16052018 010215PMVjayNoch keine Bewertungen

- Most Expected Topics - JEE April 2023 PDFDokument7 SeitenMost Expected Topics - JEE April 2023 PDFrajNoch keine Bewertungen

- Tutorial CH 13 GearsDokument32 SeitenTutorial CH 13 GearsQassim AlattarNoch keine Bewertungen

- Vienna 2020Dokument82 SeitenVienna 2020feñamenNoch keine Bewertungen

- 6.6. DR Riven Pile La Ateral Load - Deflection ( (P-Y) Respon NsesDokument1 Seite6.6. DR Riven Pile La Ateral Load - Deflection ( (P-Y) Respon NsesKavan Gt12Noch keine Bewertungen

- Typo, WesselinkDokument1 SeiteTypo, WesselinkGuru PrasadNoch keine Bewertungen

- Series Voltage Negative Feedback AmplifierDokument4 SeitenSeries Voltage Negative Feedback AmplifierArohon DasNoch keine Bewertungen

- Resumen Handbook MotoresDokument23 SeitenResumen Handbook MotoresingjsierraNoch keine Bewertungen

- Active Components Part 1Dokument3 SeitenActive Components Part 1Dhiraj PatilNoch keine Bewertungen

- Lecture Lossy DielectricsDokument15 SeitenLecture Lossy DielectricsBill WhiteNoch keine Bewertungen

- 78 Loss of Excitation SIEMENS PaperDokument10 Seiten78 Loss of Excitation SIEMENS PapermohamedseragNoch keine Bewertungen

- A17. Six-Phase Fractional-Slot-per-Pole-per-Phase Permanent-Magnet Machines With Low Space Harmonics For Electric Vehicle ApplicationDokument10 SeitenA17. Six-Phase Fractional-Slot-per-Pole-per-Phase Permanent-Magnet Machines With Low Space Harmonics For Electric Vehicle Applicationwalidghoneim1970Noch keine Bewertungen

- A6. Design Features of Low Speed Permanent Magnet GeneratorDokument4 SeitenA6. Design Features of Low Speed Permanent Magnet Generatorwalidghoneim1970Noch keine Bewertungen

- Wind Energy in EgyptDokument3 SeitenWind Energy in Egyptwalidghoneim1970Noch keine Bewertungen

- Almost ExcellentDokument8 SeitenAlmost Excellentwalidghoneim1970Noch keine Bewertungen

- Design Requirements For Brushless Permanent Magnet Generators For Use in Small Renewable Energy SystemsDokument6 SeitenDesign Requirements For Brushless Permanent Magnet Generators For Use in Small Renewable Energy SystemsAlaa OmarNoch keine Bewertungen

- A10. Pole Number Selection Strategy of Low-Speed Multiple-Pole Permanent Magnet Synchronous MachinesDokument8 SeitenA10. Pole Number Selection Strategy of Low-Speed Multiple-Pole Permanent Magnet Synchronous Machineswalidghoneim1970Noch keine Bewertungen

- A15. Method For Multi-Objective Optimized Designs of Surface Mount Permanent Magnet Motors With Concentrated or Distributed StatorDokument6 SeitenA15. Method For Multi-Objective Optimized Designs of Surface Mount Permanent Magnet Motors With Concentrated or Distributed Statorwalidghoneim1970Noch keine Bewertungen

- A15. Method For Multi-Objective Optimized Designs of Surface Mount Permanent Magnet Motors With Concentrated or Distributed Stator PDFDokument6 SeitenA15. Method For Multi-Objective Optimized Designs of Surface Mount Permanent Magnet Motors With Concentrated or Distributed Stator PDFwalidghoneim1970Noch keine Bewertungen

- A14. Design Study of FSPM Generator With Novel Outer Rotor PDFDokument5 SeitenA14. Design Study of FSPM Generator With Novel Outer Rotor PDFwalidghoneim1970Noch keine Bewertungen

- A9. Fractional-Slot Concentrated-Windings Synchronous Permanent Magnet Machines Opportunities and ChallengesDokument15 SeitenA9. Fractional-Slot Concentrated-Windings Synchronous Permanent Magnet Machines Opportunities and Challengeswalidghoneim1970Noch keine Bewertungen

- A13. Design of A Synchronous Machine With Concentric Stator Windings and Permanent PDFDokument6 SeitenA13. Design of A Synchronous Machine With Concentric Stator Windings and Permanent PDFwalidghoneim1970Noch keine Bewertungen

- A New Concentrated Windings Surface Mounted Permanent Magnet Synchronous Machine For Wind Energy ApplicationDokument6 SeitenA New Concentrated Windings Surface Mounted Permanent Magnet Synchronous Machine For Wind Energy Applicationwalidghoneim1970Noch keine Bewertungen

- A14. Design Study of FSPM Generator With Novel Outer RotorDokument5 SeitenA14. Design Study of FSPM Generator With Novel Outer Rotorwalidghoneim1970Noch keine Bewertungen

- A11. Design of Brushless Permenant Magnet MachinesDokument582 SeitenA11. Design of Brushless Permenant Magnet Machineswalidghoneim197088% (8)

- Design Requirements For Brushless Permanent Magnet Generators For Use in Small Renewable Energy SystemsDokument6 SeitenDesign Requirements For Brushless Permanent Magnet Generators For Use in Small Renewable Energy SystemsAlaa OmarNoch keine Bewertungen

- A7. Design of Several Permanent Magnet Synchronous Generators For High Power Traction ApplicationsDokument7 SeitenA7. Design of Several Permanent Magnet Synchronous Generators For High Power Traction Applicationswalidghoneim1970Noch keine Bewertungen

- Recent Advances in Desalination Technologies Final 1Dokument190 SeitenRecent Advances in Desalination Technologies Final 1walidghoneim1970Noch keine Bewertungen

- Acceptance Letter IECON2016Dokument2 SeitenAcceptance Letter IECON2016walidghoneim1970Noch keine Bewertungen

- Feasibility Study For Self-Sustained Wastewater Treatment PlantsDokument10 SeitenFeasibility Study For Self-Sustained Wastewater Treatment Plantswalidghoneim1970Noch keine Bewertungen

- HighlightsDokument1 SeiteHighlightswalidghoneim1970Noch keine Bewertungen

- A3. Design of A Synchronous Machine With Concentric Stator Windings and Permanent Magnets in Focusing ConfigurationDokument6 SeitenA3. Design of A Synchronous Machine With Concentric Stator Windings and Permanent Magnets in Focusing Configurationwalidghoneim1970Noch keine Bewertungen

- Design and Analysis of An Outer Rotor Low Speed PMSGDokument7 SeitenDesign and Analysis of An Outer Rotor Low Speed PMSGwalidghoneim1970Noch keine Bewertungen

- Energy Conversion Submission ChecklistDokument1 SeiteEnergy Conversion Submission Checklistwalidghoneim1970Noch keine Bewertungen

- Ecm S 14 01542Dokument35 SeitenEcm S 14 01542walidghoneim1970Noch keine Bewertungen

- SGRE - 2013052913585955 - WWTP FinalDokument9 SeitenSGRE - 2013052913585955 - WWTP Finalwalidghoneim1970Noch keine Bewertungen

- Wireless Power Transfer Using Resonant Inductive Coupling For 3D Integrated IcsDokument5 SeitenWireless Power Transfer Using Resonant Inductive Coupling For 3D Integrated Icswalidghoneim1970Noch keine Bewertungen

- Paper 15Dokument6 SeitenPaper 15walidghoneim1970Noch keine Bewertungen

- Letters: Selective Wireless Power Transfer To Multiple Loads Using Receivers of Different Resonant FrequenciesDokument5 SeitenLetters: Selective Wireless Power Transfer To Multiple Loads Using Receivers of Different Resonant Frequencieswalidghoneim1970Noch keine Bewertungen

- Simulation of Wireless EV Charging with Power Factor CorrectionDokument6 SeitenSimulation of Wireless EV Charging with Power Factor Correctionwalidghoneim1970Noch keine Bewertungen

- Pacific Antenna 20 and 40M Lightweight Dipole Kit: Diagram Showing Configuration and Approximate LengthsDokument6 SeitenPacific Antenna 20 and 40M Lightweight Dipole Kit: Diagram Showing Configuration and Approximate LengthsedosviracNoch keine Bewertungen

- Advanced Physics ReviewDokument3 SeitenAdvanced Physics ReviewalNoch keine Bewertungen

- Understanding idioms and synonyms in EnglishDokument50 SeitenUnderstanding idioms and synonyms in EnglishSakshi RastogiNoch keine Bewertungen

- Design and Construction of A Electronics Trainer KitDokument42 SeitenDesign and Construction of A Electronics Trainer KitToheebdareNoch keine Bewertungen

- Manual Medidor LCR Motech 4080ADokument55 SeitenManual Medidor LCR Motech 4080AGaldo7Noch keine Bewertungen

- Chapter 11 Resonance in AC CircuitsDokument40 SeitenChapter 11 Resonance in AC CircuitsGaurav SinghalNoch keine Bewertungen

- The Technology and Application of Voice Coil Actuator: X.M.Feng, Z.J.Duan, Y.Fu, A.L.Sun D.W.ZhangDokument4 SeitenThe Technology and Application of Voice Coil Actuator: X.M.Feng, Z.J.Duan, Y.Fu, A.L.Sun D.W.ZhangjarkaasNoch keine Bewertungen

- Electromagnetic InductionDokument25 SeitenElectromagnetic InductionthejaswinisunilNoch keine Bewertungen

- RFIC Group: Advanced VLSI Design Lab IIT KharagpurDokument7 SeitenRFIC Group: Advanced VLSI Design Lab IIT Kharagpurg.ven18Noch keine Bewertungen

- EEC 239 TheoryDokument55 SeitenEEC 239 Theorysunrinpark100% (2)

- Grade 10 Physics 4TH MP ExamDokument3 SeitenGrade 10 Physics 4TH MP ExamJoel LogboNoch keine Bewertungen

- Cat Generator PDFDokument64 SeitenCat Generator PDFmarkigldmm918100% (2)

- Jawapan Soalan Pahang Fizik - BaruDokument2 SeitenJawapan Soalan Pahang Fizik - Baruyktay2Noch keine Bewertungen

- Handbook 05Dokument132 SeitenHandbook 05joseftalerNoch keine Bewertungen

- Inductor DesignDokument10 SeitenInductor DesignMuthuRajNoch keine Bewertungen

- 700W Leach AmplifierDokument5 Seiten700W Leach AmplifierYung SangNoch keine Bewertungen

- MAN Truck Edc TroubleshootingDokument70 SeitenMAN Truck Edc TroubleshootingNuno Silva89% (44)

- 600W PFC Power Supply For Audio AmplifierDokument37 Seiten600W PFC Power Supply For Audio Amplifierpgamez833Noch keine Bewertungen

- Zilano Update May 9 UpdateDokument82 SeitenZilano Update May 9 UpdateFiditti100% (2)

- Baldor - Spindle Drive Instructions, 7500 WD Tuning v11-4Dokument7 SeitenBaldor - Spindle Drive Instructions, 7500 WD Tuning v11-4Asif JamilNoch keine Bewertungen

- HW10 Chapter 33 and 34 QuestionsDokument4 SeitenHW10 Chapter 33 and 34 QuestionsNgọc Diệp NgôNoch keine Bewertungen

- Most Scoring Concepts: For Neet 2022Dokument48 SeitenMost Scoring Concepts: For Neet 2022Rajesh K Singh0% (1)

- Simulia Emc Analysis of Electrical Machines Whitepaper ENDokument4 SeitenSimulia Emc Analysis of Electrical Machines Whitepaper ENkutlu küçükvuralNoch keine Bewertungen

- Electrical QuestionsDokument122 SeitenElectrical QuestionsBiju Mathson MathewNoch keine Bewertungen

- Tubing TestDokument16 SeitenTubing Testbenergy84100% (1)

- SSC Physsmaple MCQ and CQDokument22 SeitenSSC Physsmaple MCQ and CQMohammad AnisuzzamanNoch keine Bewertungen

- Electronic and Electrical Engineering Principles and Practice Third Edition by Lionel WarnesDokument611 SeitenElectronic and Electrical Engineering Principles and Practice Third Edition by Lionel Warneshatem100% (1)

- Physics Homework 8Dokument7 SeitenPhysics Homework 8Petra Elang PradanaNoch keine Bewertungen

- MET NumericalsDokument2 SeitenMET NumericalsSamarendu TiwariNoch keine Bewertungen

- Chapter 5Dokument39 SeitenChapter 5Portia ShilengeNoch keine Bewertungen