Beruflich Dokumente

Kultur Dokumente

Criterio Civil Estruct.

Hochgeladen von

camilo.ponce.ayalaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Criterio Civil Estruct.

Hochgeladen von

camilo.ponce.ayalaCopyright:

Verfügbare Formate

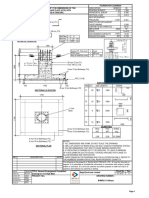

BECHTEL CHILE LTDA.

DESIGN CRITERIA

24017-DC-001

FOR

CIVIL/STRUCTURAL

MINERA ESCONDIDA LIMITADA

ESCONDIDA PHASE IV EXPANSION PROJECT

1 10Mar99 Modified as indicated CN CN CN LDJ CL/OQ M.C.

0 10-2-99 Issued for Construction CN CN CN LDJ CL/OQ M.C. MSK

C 20-12-98 Issued for Approval CN XS XS LDJ CL/OQ M.C.

B 19-11-98 Issued for Coordination CN AL AL LDJ CL/OQ M.C.

A 9-10-98 Issued for Coordination AL AL AL LDJ CL/OQ M.C.

REV. DATE REASON FOR REVISION BY CHECK EGS VEM PE PEM CLIENT

JOB No. 24017 SHEET 1 OF 30

DESIGN CRITERIA NO. REV.

BECHTEL CHILE LTDA. 24017-DC-001

1

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Civil Structural Design Criteria

24017-DC-001, Rev. 1

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

1.0 INTRODUCTION 3

2.0 GOVERNING CODES, REGULATIONS AND 3

REFERENCE DOCUMENTS

3.0 SITE INFORMATION 6

4.0 PLANT AND DESIGN REQUIREMENTS 10

5.0 CIVIL SITE WORK CRITERIA 10 1

6.0 STRUCTURAL DESIGN CRITERIA 15

7.0 DESIGN BASIS 23

8.0 CONSTRUCTION MATERIALS 26

9.0 TRANSPORTATION LIMITS BY TRUCK 29

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 2 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

1.0 INTRODUCTION

These criteria shall govern the design of structures and facilities. These criteria shall

be applied in conjunction with civil/structural specifications governing specific

elements of the project.

All designs shall be tested against the following criteria:

Insure that critical facilities have a design margin appropriate for the risk

involved

Maximize safety

Minimize risk by employing proven technology

Minimize on-site construction activities and reduce on-site labor

Limit capital expenditure by innovation without lowering quality standard

2.0 GOVERNING CODES, REGULATIONS AND REFERENCE DOCUMENTS

2.1 GENERAL

Unless specifically stated otherwise, the design of all structures and facilities

shall be based on the applicable portions of the following codes,

specifications, industry standards, regulations, and other referenced

documents, based on the latest revision or edition thereof.

In addition to the codes and regulations listed below, the design shall comply

with any laws or regulations of the local authorities. In the event of

conflicting requirements between codes and standards, the most stringent

shall apply.

2.2 CODES AND SPECIFICATIONS

Ch.BLDG. Ordenanza General de Construcciones Urbanizaciones

ICHA Instituto Chileno de Acero

NCh. Normas Chilenas Oficiales (NCh), by Instituto

Nacional de Normalizacin (INN):

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 3 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

NCh 432.Of 71 Clculo de la Accin del Viento Sobre las

construcciones

NCh 433. Of 93 Diseo Ssmico de Edificios

NCh 2369.a 96 Diseo Ssmico de Edificios Industriales

UBC International Conference of Building Officials,

Uniform Building Code, 1994

AISC American Institute of Steel Construction

Specification for Structural Steel Buildings -

Allowable Stress Design and Plastic Design

(1989),S335

AWS American Welding Society Structural Welding

Code, AWS D1.1-96

ACI American Concrete Institute

Building Code Requirements for Structural

Concrete, ACI 318-95

API American Petroleum Institute

Welded Steel Tanks for Oil Storage, API 650-93

AWWA American Water Works Association

Steel Pipe Design and Installation, M11-89

Welded Steel Tanks for Water Storage, D100-89

ASCE Minimum Design Loads for Buildings and Other

Structures, ASCE 7-95

AASHTO American Association of State Highway and

Transportation Officials

Policy on Geometric Design of Highways and Streets,

AASHTO-94

Standard Specification for Highway Bridges,

AASHTO-92

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 4 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

NFPA National Fire Protection Association Standards to

meet MSHA requirements

ASCE American Society of Civil Engineers - Manuals

Reports on Engineering Practice No. 37, Design and

Construction of Sanitary and Storm Sewers

AISE Association of Iron and Steel Engineers, Technical

Report No. 13, 1991 - Guide for the Design and

Construction of Mill Buildings

2.3 REGULATIONS

MSHA Mine Safety and Health Administration

Regulations and Standards Applicable to Metal and

Nonmetal Mining and Milling Operations

OSHA Occupation, Safety and Health Administration

Regulatory Authorities for Chile as follows:

Ministerio de Obras Pblicas y Transportes (MOPT)

Ordenanza General de Urbanismo y Construcciones

Direccin General de Aguas

Direccin de Obras Sanitarias

Servicio Nacional de Obras Sanitarias (SENDOS)

Reglamento sobre Condiciones Bsicas Sanitarias y Ambientales en

los Lugares de Trabajo

Secretara y Superintendencia de Servicios Elctricos y Combustibles

Servicio Nacional de Salud (SNS)

Manual de Carreteras M.O.P.

CMAA Crane Manufacturers Association of America

2.4 OTHER REFERENCE DOCUMENTS

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 5 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

2.4.1 Geotechnical Investigation Reports, by E.C. Rowe & Asociados

2.4.2 Civil/structural specifications and civil design guides developed by

Bechtel will be used on this project

3.0 SITE INFORMATION

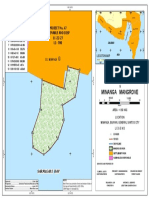

3.1 LOCATION

The mine-site facilities for the Escondida expansion project are located at the

Minera Escondida Limitada (MEL) facilities in the Atacama Desert of

northern Chile at 3200 metres above mean sea level. The site is surrounded

by a mountainous area known as Cordillera de Domeyko and it is adjacent to

the Salar de Hamburgo, 180 kilometres southeast of the port of Antofagasta,

Chile.

3.2 TOPOGRAPHY

The mine-site facilities are on the western slope of a basin formed by the

Cerro Colorado Chico and the Cordillera de Domeyko. Topographical

features are barren, rock-covered hillsides sloping downward to a shallow

salt flat or salar. Extremes in temperatures have weathered the surface rock

extensively and covered the mine-site area with talus material. The higher

elevation of the Cerro Colorado Chico region receive rain and snow that

drain down through the barren soil and is collected in nearby basins. These

basins are evaporation ponds and form dry salt beds.

The surface soils at the plant site are composed of weathered volcanic ash,

underlain by gravel layers intermixed with sandy material. The surface

material in the concentrator area may have a high salt content and will be

removed to expose the unweathered surface below. The specific

characteristics, thickness and depth of the soil strata are defined in the

Project Geotechnical Investigation Report.

The plant site is at approximately 3200 metres above mean sea level.

Wells for fresh water will be located at Salar Punta Negra (approximately 25

kilometres southeast of the site) and at Salar Monturaqui (approximately 70

kilometres northeast of the site).

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 6 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

3.3 ACCESS

The mine-site is accessible from Antofagasta via a branch of the Panamerican

Highway and MELs access road. An existing narrow gauge railroad from

Antofagasta passes within 6.5 kilometres of the site.

3.4 SOIL DATA

The geotechnical report by E.C. Rowe & Asociados, titled Mine Site

Facilities Geotechnical Report dated March 1989, was issued for the existing

mine-site facilities. For the Phase IV Expansion Project the Geotechnical

Report by E.C. Rowe & Asociados, issued in December 1998, shall be used.

3.5 PROJECT DATA

3.5.1 HORIZONTAL

All coordinates shall be in meters and shall be based on the UTM

(Universal Transverse Mercator) grid system.

A Local coordinate system was defined as detailed in a report by

A.G. Ing. Geomensores Asociados, dated July 1988:

The Local grid North is the same as UTM North.

The grid correction factor is 0.99907; to convert local grid

distance to UTM distance, multiply the local grid distance by

the grid correction factor.

Common coordinates for the two grid systems are defined

at the mine-site bench mark BM-2 as follows:

UTM coordinates = N 7 316 915.10 E 493 974.28

Local coordinates = N 108 494.09 E 17 325.91

Elevation = 3 095.145

A Plant coordinate system is used in the Plant Design System (PDS)

modelling in order to have the convenience of a coordinate system

orthogonal to the Plant North and avoid the perception of a plant

rotated with respect to the coordinate grid:

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 7 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

The Plant North is rotated 30 degrees to the east of UTM North

The Plant coordinate system is orthogonal to the Plant North

The correspondence between coordinate systems is established at

a master point in the Phase IV Plant defined as follows:

UTM coordinates = N 7 308 057.049 E 494 150.273

Local coordinates = N 99 627.793 E 17 502.067

Plant coordinates = N 1 000.000 E 5 110.300

The Local coordinate system shall be used to locate the Phase IV 1

Plant site and all other offsite facilities with respect to the minesite

bench mark BM-2.

The Plant coordinate system shall be used exclusively in the PDS and

in all the design drawings for the Phase IV Plant Area, excluding off-

site drawings

3.5.2 VERTICAL

All elevations shall be shown in meters above sea level.

3.5.3 PROJECT SURVEY CONTROLS

Existing control monuments at the mine-site shall be used.

3.6 PRECIPITATION

Minesite Coloso

Rainfall average annual mm 7.2 12.5

Rainfall maximum for 24 hour period mm 55.8

Snowfall design load mm 500 0

3.7 EVAPORATION

Winter (June) mm/d 3.8

Summer (December) mm/d 10.7

3.8 GROUNDWATER TABLE

The groundwater table is deep, in the range of 40 to 60 meters below the

existing ground surface. The definitive elevation of the groundwater table

shall be considered as defined in the Project Geotechnical Report.

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 8 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

3.9 FROST PENETRATION

Depth below grade m 0.7

3.10 AMBIENT AIR TEMPERATURE, DRY BULB

Minesite Coloso

Maximum Summer High C 22 27

Mean C 10

Minimum winter low C -20 7

3.11 WIND

The design shall be based on NCh 432.Of 71.

For equipment suppliers outside Chile, ASCE 7-95, exposure C, with a 3

second gust speed of 175 kilometers per hour will be used. 1

3.12 EARTHQUAKE

Minesite:

The design shall be based on the requirements of NCh 433, NCh 2369 and

UBC codes (see 4.7).

Seismic Zone 2, with soil Type II and importance coefficient I=1 shall be

used for NCh codes.

Seismic Zone 4, with site coefficient S factor = 1.2 and seismic importance

factor I=1 shall be used for UBC.

For equipment suppliers outside Chile, the design shall be based on UBC

code.

1

Coloso:

The design shall be based on the requirements of NCh 433, NCh 2369 and

UBC codes (see 4.7).

Seismic Zone 3, with soil Type I and importance coefficient I=1 shall be used

for NCh codes.

Seismic Zone 4, with site coefficient S factor = 1.2 and seismic importance

factor I=1 shall be used for UBC.

For equipment suppliers outside Chile, the design shall be based on UBC

code.

3.13 SOIL CONDITIONS

For soils data for civil/structural design refer to the Project Geotechnical

Report.

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 9 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

4.0 PLANT AND DESIGN REQUIREMENTS

4.1 The Concentrator building, Flotation/Regrind building, and the Coarse Ore

Stockpile building shall be steel frame structures with metal roofing and

siding, as defined on the design drawings.

4.2 The ore storage reclaim tunnel shall be constructed of reinforced concrete.

4.3 Grade slabs and sump bottoms shall be constructed of reinforced concrete

placed on native competent material or on compacted fill.

4.4 Operating floors and other floors indicated on drawings shall be constructed

of reinforced concrete. The elevated concrete floors shall use noncomposite

steel deck as the formwork

4.5 Elevated floors and access platforms shall be constructed of metal grating,

except where noted on drawings or in areas with potential for crushed ore

spillage.

4.6 Inclined walkways shall be of expanded metal grating.

4.7 The seismic requirements per NCh 433 and NCh 2369 and those per UBC

may be in some respects more severe than each other in terms of ductile

details and redundant force transfer systems, and the factors used to arrive at

the design spectrum. The most severe requirements out of those Codes shall

prevail, and the design engineer must be fully cognizant of such differences

and incorporate them into the design.

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 10 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

5.0 CIVIL SITE WORK CRITERIA

5.1 EARTHWORK

The following slopes shall be used for design purposes:

Cuts in rock - Vertical, for temporary cutting when cut not

exceed 2 meters in vertical measurement.

1(H):3(V) for temporary cuttings when cut

not exceed 6 meters in vertical measurement.

- 1(H):2(V) for temporary cuttings when cut 1

exceed 6 meters in vertical measurement.

- 1(H):2(V) for permanent cuttings. When cut

exceed 8 meters in vertical measurement,

1

benches 4 meters wide minimum shall be

provided each 8 meters height.

Cuts in mine waste - 1.5(H):1(V)

Cuts in original soils - Vertical, for temporary cutting when cut not

exceed 1meter in vertical measurement.

- 1(H):2(V) for temporary cuttings when cut

not exceed 4 meters in vertical measurement

- 1(H):1(V) for temporary cuttings when cut

exceed 4 meters in vertical measurement

- 1.5(H):1(V) for permanent cuttings. When

cut exceed 8 meters in vertical measurement,

benches 4 meters wide minimum shall be 1

provided each 8 meters height.

Compacted fills 1.5(H):1(V) with benches 4 meters wide

provided each 10 meters height.

Fill (ore storage berm) 2(H):1(V)

The Project Geotechnical Report shall be consulted for additional governing

recommendations that may be applicable.

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 11 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

5.2 YARD GRADING

5.2.1 Yard finish grading shall be a minimum of 150 millimetres below the

adjacent floor slabs.

5.2.2 Yard grading shall have a finish grade slope of two percent minimum

away from structures and toward the storm drainage.

5.3 FOUNDATION CRITERIA

Allowable bearing values for mat foundations and spread footings shall be in

accordance with the Project Geotechnical Report.

5.4 ROADS

5.4.1 Plant roads maximum design speed 60 km/h

5.4.2 Maximum grades shall be as follows:

Principal roads 6%

Secondary roads 10 %

5.4.3 Minimum horizontal curve radius shall be as follows:

Principal roads 50 m

Secondary roads 25 m

Maintenance roads and pond inspection roads 25 m

5.4.4 Maintenance roads

Minimum vertical curve radius (parabola) shall be as follows:

Principal roads 30 m

5.4.5 Minimum road widths shall be as follows:

Principal roads (including 1 metre shoulders) 10 m

Secondary roads 6 m

Maintenance roads and pond inspection roads 4 m (one lane)

5.4.6 Road design shall be developed in accordance with the Manual de

Carreteras by Chile M.O.P.

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 12 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

5.4.7 Loading over culverts and pipes shall be in accordance with

AASHTO-HS20-44 except for areas of special equipment operation

(i.e., mine haul trucks) which shall be considered on an individual

basis.

5.4.8 Minimum vertical clearance under overpasses or obstructions shall be

4.6 meters, except for areas with special equipment operation, where

it shall be adequate for 300 ton trucks to pass with the bed up, or for

other specific requirements.

5.5 STORM DRAINAGE

5.5.1 Runoff, resulting from rainfall, generally shall be allowed to follow

natural courses but when necessary shall be conveyed to drainage

ditches or storm sewers by sloping the tributary surface area.

Manholes, if required, shall not exceed a 90 meter spacing.

5.5.2 Storm runoff quantities for small areas in the plant site shall be

determined by the Rational Method using a minimum time of

concentration of 10 minutes.

5.5.3 Design frequency shall be as follows:

Facility Criteria

In-plant storm sewers 10-year frequency storm flowing full

without surcharge; the hydraulic grade

line for a 50 year frequency shall be

designed at a minimum of

300 millimetres below any building

floor or other critical elevation.

Culverts 10-year frequency with the head water

for the 50-year frequency designed at a

minimum of 300 millimetres below any

building floor or other critical

elevation.

Ditches/channels 10-year frequency with 50-year

frequency storm water levels checked

to assure critical areas are not flooded.

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 13 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

5.5.4 Ditches shall be of V-type or trapezoidal design. Trapezoidal ditches

shall have a 0.6 meters minimum width at bottom. The ditch side

slopes shall not be steeper than 1 vertical to 1.5 horizontal. The

intersection of the ditch side slopes and the natural ground shall be

located to allow a 10 meters minimum clear distance from the

existing or contemplated structures or foundations. Longitudinal

slopes shall be 0.2 percent minimum; where velocity exceeds 2

meters per second, ditch liners will be considered, but should

consider the consequences of erosion and cost before installing a liner

based on a general criteria. Liners are not required in medium to

heavy gravel and rock.

5.5.5 Open channel flow calculations shall be made according to the

Mannings Formula.

5.6 SANITARY SYSTEM

5.6.1 Design flows shall be calculated on the basis of:

a) 150 litres per person per day for treatment system operation,

and maintenance with a design flow rate of four times the

average for pipe sizing

b) On the number of equivalent fixture units

The method that results in the largest flow shall be used.

5.6.2 All sanitary sewers shall be at least 150 millimetres in diameter. The

minimum velocity shall be 0.5 meters per second flowing half full.

Maximum velocity shall not exceed 1.5 meters per second to prevent

the water from leaving floating solids behind thus forming dune or

which subsequent flows catch and eventually plug the pipe.

5.6.3 The top of all sanitary sewer line must be 200 mm below the bottom

of any water line.

5.6.4 Spacing between manholes shall not exceed 90 meters.

5.7 FIRE PROTECTION

5.7.1 The yard fire main shall be a minimum of 200 millimetres in diameter.

The minimum depth of cover for the yard pipe shall be 1 meter below

grade.

5.7.2 The yard pipe for fire protection shall be complete with hydrants,

gate valves, and post indicator valves as required.

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 14 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

5.7.3 Fire hydrants shall be placed at a spacing of not more than 90 meters.

5.8 FRESH WATER

The minimum depth of cover for the fresh water pipe will be 0.7 meters

below grade.

5.9 POTABLE WATER

The minimum depth of cover for the potable water pipe will be 0.7 meters

below grade.

6.0 STRUCTURAL DESIGN CRITERIA

6.1 LOADS

6.1.1 DEAD LOADS

The dead loads (DL) shall include the weight of framing, roofs,

floors, walls, partitions, platforms and all permanent equipment and

materials (see Section 6.1.7.a). The static vertical and lateral 1

pressures of liquids shall also be treated as dead load (in accordance

with Section 9.2.5 of ACI 318-95).

6.1.2 LIVE LOADS

The live loads (LL) shall include floor area loads, laydown loads,

equipment handling loads, active earth pressure and truck wheel loads.

The floor area live load shall be omitted from areas occupied by

equipment whose weight is specifically included in the dead load.

Live loads shall not be omitted under equipment where access is

provided, for instance under elevated tanks on four legs. In no case

shall the minimum design live loads be less than specified in Section

7.1.3. The equipment operating loads (LLo), upset operating loads

(LLu) and crane loads (CL) shall be included as described in Section

6.1.7.b, c and e. 1

The design live loads shall be shown both in the calculations and on

the design drawings for the corresponding floors.

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 15 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

6.1.3 MINIMUM DESIGN LIVE LOADS

a) The following minimum live loads shall be used in the design

unless otherwise established by a specific analysis of equipment

loads in certain areas. Certain other applicable loads are listed

separately in succeeding sections.

Roofs (accounts for snow load at 60 kgf/m2) kgf/m2 100

Offices kgf/m2 250

Assembly and locker rooms kgf/m2 500

Laboratories kgf/m2 500

Stairs and walkways kgf/m2 500

Platforms, grating and elevated floors kgf/m2 500

Mill operating floors and platforms kgf/m2 1250

around grinding mills

(except mill liner area)

Ground floors kgf/m2 1250

Surcharge adjacent to plant structures kgf/m2 1250

Control rooms kgf/m2 500

Electric switchgear rooms kgf/m2 1250

Sag or Ball mill liner floors kgf/m2 3200

Conveyor gallery walkways kgf/m2 250

Railings concentrated load applied kgf 90

in any direction at top of railing

Truck support structures AASHTO, HS 20-44 or

mine haul trucks as

applicable

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 16 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

b) A concentrated load on the beams and girders and any one

panel point of the secondary trusses (in addition to all other

loads) of 1000 kgf shall be applied to maximize stresses. This

load is not carried to the columns, and it is not applied in the

office, laboratory, locker rooms or similar areas.

c) A concentrated load on the slabs of the office floors (to be

considered with dead load only) of 1000 kgf shall be applied

over an area of 0.24 m2 and located to maximize stresses. This

load is not carried to the columns.

d) A concentrated load on the slabs of the operating floors (to be

considered with dead load only) of 1400 kgf shall be applied

over an area of 0.24 m2 and located to maximize stresses. This

load is not carried to the columns.

e) A concentrated load of 140 kgf shall be placed at the

center of a stair tread.

f) A concentrated load on any one panel point of the main trusses

(in addition to all other loads) of 3000 kgf shall be located to

maximize stresses. This load is not carried to the columns.

6.1.4 LIVE LOAD REDUCTION

Live load reduction on floors and roofs shall be allowed as follows:

a) No reduction shall be allowed for the warehouse, storage areas

and tanks.

b) For live loads greater than 500 kgf/m2, the following reductions

shall apply for columns, piers and walls supporting:

Roof =0%

Roof and 1 floor = 0 %

Roof and 2 floors = 10 %

1

6.1.5 WIND LOADS

Structures shall be designed for wind loads (WL) determined in

accordance with section 3.11 .

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 17 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

6.1.6 SEISMIC LOADS

1

Structures shall be designed for seismic loads (EL) determined in

accordance with Sections 3.12 and 4.7.

6.1.7 EQUIPMENT LOADS

Equipment loads shall be in accordance with the vendor drawings and

shall include the weight of the product to be handled. The design loads

for equipment supports shall include the following:

a) Equipment dead loads, including piping and platforms

supported from the equipment and internal construction, such

as lining, shall be included in the DL (Section 6.1.1). 1

b) The operating live load (LLo) shall include the contents of fixed

equipment, containers, conveyors, pipeways, etc., with

materials at normal operating densities.

c) The upset operating load (LLu) shall include dead loads plus

equipment filled to maximum capacities with materials of

maximum density, including scale buildup; e.g., plugged chutes

or screw conveyors, etc. These loads may be considered as

short-term loading conditions, with the special considerations

of Section 6.2.1, and shall be included as a special case of LLo

in the loading combinations per Section 7.2. 1

d) Material live load at conveyor transfer points shall be increased

to twice the material live load along the conveyor for a length

of 6 metres.

e) The crane loads (CL) shall be as defined by equipment vendors

for wheel loads for cranes, monorails and other traveling

equipment.

f) Supports shall be checked for vibration for all heavy

reciprocating or centrifugal operating equipment, particularly

mills, fans, crushers, vibrating screens or feeders.

g) Unbalanced dynamic forces for vibration analysis shall be

obtained from the vendor and the project mechanical group for

fans, crushers and reciprocating equipment.

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 18 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

6.1.8 IMPACT LOADS

The minimum increase in equipment loads for impact shall be as

follows:

a) Cranes, motor driven

Vertical, lateral and longitudinal load shall comply with

Sections A4.2 and A4.3 of the AISC Specification:

Cab-operated traveling crane % 25

Pendant-operated traveling crane % 10

b) Conveyors

Along the length of belt conveyors:

Vertical impact none

Shuttle and tripper conveyors: 1

Vertical impact percentage of

of material and conveyor weight % 25

At transfer points:

Vertical impact calculated force required to

decelerate the falling mass

6.1.9 CONVEYOR LOADS

Conveyor trusses and supporting structures shall be designed to carry

their dead load, material loads (including material loads due to clogged

chutes filled to capacity), and the walkway live load. Where

applicable, piping and/or cable tray loads shall be added. Belt tensions,

including the maximum running and maximum motor torque belt

tensions, shall be considered in the design of the support members.

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 19 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

In addition to the primary forces, the design of truss members shall

take into account the secondary forces due to eccentric connections.

1

For load combination purposes, conveyor loads will be treated as

equipment loads and equipment operation loads

The following belt tensions shall be considered:

a) 1.5 x (operating belt tension)

b) Stalling belt tension = (operating belt tension) x F*

factor, F*, equals: 2.15 for DC motor

2.25 for wound rotor motor

1.8 for squirrel cage motor

6.1.10 FOUNDATION LOADS

The foundation design shall be based on the recommendations in the

project Geotechnical Report.

6.1.11 ORE PROPERTIES

For civil/structural design, ore properties shall be as follows:

Crushed Ore

Angle of repose:

Stacking degrees 37.5

Draw down degrees 70

Density for:

Weight t/m3 2.1

Volume t/m3 1.8

6.1.12 THERMAL EXPANSION LOADS

All structures and elements shall be designed to accommodate the

loads or effects produced by a differential temperature of 30C.

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 20 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

6.1.13 MINIMUM LATERAL LOADS (OTHER THAN WIND AND

EARTHQUAKE)

The minimum compression loads in struts, used for lateral stability in

structures, shall be 2 percent of the axial loads in the supported

columns or beams.

6.2 SPECIAL CONSIDERATIONS FOR TEMPORARY/CONSTRUCTION

LOADS

6.2.1 For wind, earthquake and temporary loads caused by upset conditions

or construction sequence, the allowable stress or load capacity may be

increased by a factor of 1.33.

6.2.2 The strength and deflection of the metal decking and support framing

shall be checked for the weight of wet concrete plus 150 kgf/m2

without the allowable stress increase.

6.3 MEMBERS SUBJECT TO VIBRATING EQUIPMENT LOADS

6.3.1 GENERAL

Structural members subject to vibrating shall have a minimum beam

depth-to-span ratio of 1:12 unless a vibration check indicates a

smaller depth can be used.

Floor plates adjacent to vibrating equipment shall have a minimum

thickness in millimetres equal to 10.5 times the span in metres

unless a vibration check indicates a smaller thickness can be used.

In order to minimize vibration caused by resonance in braced

structures, the following ratios of first natural frequency (fn) of

support beams to forcing frequency (f0) shall be maintained. For the

resonance check, members shall be considered to have only one

degree of freedom.

Type of End Support

(framed to) Span (mm) fn/fo

Column 6000 1.5 or 0.8

Column > 6000 2.0 or 0.75

Beam 6000 2.0 or 0.75

Beam > 6000 2.5 or 0.75

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 21 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

Foundations shall be designed to have a natural frequency sufficiently

different from the applied frequency to avoid resonance. Foundations

shall be separated from the slab and building column foundations by 20

millimetre expansion joint materials where possible.

6.3.2 MEMBERS SUBJECT TO VIBRATING EQUIPMENT LOADS

Unbalanced dynamic forces for the design of supports for vibratory

equipment shall be obtained from the vendor.

When a detailed evaluation is warranted, the designer will ensure the

separation of the fundamental mode structural frequency from the

machine frequency. The recommended criteria are as follows:

Structural frequency less than 2/3 of machine frequency, or

Structural frequency greater than 1.5 machine frequency

Particularly, the following equipment supports will be formally

addressed with calculations of frequency and amplitude of vibration to

support design:

Gyratory crushers

Cone crushers

Grinding mills

Flotation cells

Conveyors

Vibrating screens

Soil/structure/interaction will be considered, when calculating the

natural frequency and displacements.

Vibration will be minimized by lateral supports, bracing or mass

damping. Vibration isolators can be used where practical.

6.3.3 SERVICEABILITY REQUIREMENTS

Appendix B of ASCE 7-95 will be used for serviceability of structures

subject to vibration, deflection and drift.

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 22 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

7.0 DESIGN BASIS

7.1 GENERAL

All steel structures shall be designed by the working stress method. Soil-

bearing pressures for the actual loads shall be checked against the allowable

pressures. All reinforced concrete structures shall be designed by the ultimate

strength design method.

The minimum factor of safety provided for all structures shall be as shown

below for each loading condition:

Overturning 1.5 (1.2 with seismic load)

Sliding 1.5 (1.2 with seismic load)

Buoyancy 1.5

For maximum uplift, sliding and overturning, the minimum dead load, which

may occur during construction or with equipment empty, shall be considered in

combination with the wind loads.

7.2 LOADING COMBINATIONS

The loading combinations listed below shall be considered for the design of

structures and elements of structures. The footnotes list the reduction factors

that shall be applied to the individual loads to reflect the improbability of

simultaneous occurrence for infrequent or transient loads.

a) DL + LL + LLo + CL

b) DL(3) + LLo(4) + CL(2) + EL

c) DL + LL(5) + LLo(5) + CL(2) + EL

d) DL + LL + LLo + CL(2) + WL(1)

e) DL(3) + WL (or EL)

For steel structures, allowable stresses may be increased for certain

combinations in accordance with UBC, Division IX, Section A5. For concrete

structures, loads shall be factored in accordance with UBC Sections 1909.2.1

and 1921.2.7.

NOTES

(1) Maximum crane loads need not be combined with more than 0.50 wind

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 23 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

(2) Crane hook load need not be considered for maintenance type cranes in

combination with wind or earthquake.

(3) For materials or designs where working stress procedures are used, dead

loads shall be multiplied by 0.85 to maximize the net uplift caused by

seismic loads

(4) In laydown areas the actual weight of the equipment as spread out on the

floor shall be considered

(5) When used in combination with seismic loads, (LL + LLo) shall be

multiplied by 0.7; this factor does not apply when using LLo alone (without

LL) in combination with seismic loads. The upset load LLU shall be

included as a special case of LLO.

7.3 DEFLECTIONS

Deflections due to live load and wind load or earthquake load shall not exceed

the following:

a) Roofs

Roofing and secondary members Span/240

(purlins and joists)

b) Floors

Floor plate and grating Span/200

Floor beams Span/240

c) Walls (lateral wind load)

Siding and girts Span/180

d) Crane girders and monorail beams. (without impact)

Vertical Span/1000

Horizontal Span/500

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 24 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

e) Conveyors

Vertical deflections of trusses Span/600

due to belt live loads

Horizontal deflections of trusses Span/600

due to lateral loads

Horizontal deflections at the end Span/800

of stacker trusses due to lateral loads

(maximum deflection shall be limited to

150 millimeters)

Steel supporting head pulley frames, Span/800

speed reducers and motors

7.4 CRANE GIRDERS

Crane girders shall be designed in accordance with AISE Technical Report No.

13, 1991 - Guide for the Design and Construction of Mill Buildings.

7.5 FATIGUE STRESSES

Connections of all major structural elements, including crane girders and

conveyor trusses, shall consider the effects of fatigue according to Appendix K

of the AISC Code.

7.6 CORROSION STRESSES

Effects of corrosion shall be considered in areas where steel or concrete is in

contact with the ore, reagents or humid atmospheres.

7.7 TANKS WITH SUPPORTED BOTTOMS

Flat bottom tanks or other tanks with supported bottoms founded at or below

grade, shall be designed to resist the seismic forces calculated by using the

procedures in UBC Section 1632, for rigid structures, considering the entire

weight of the tank and its contents.

Potable water tanks shall be in accordance with AWWA D100.

Process water tanks shall be in accordance with API 650. A corrosion

allowance shall be provided.

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 25 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

7.8 BRACED FRAMES

Braced frames and bracing members shall be designed in accordance with UBC

Section 2211.

7.9 FLOOR DRAINAGE

The minimum floor slab slope shall be as follows:

SAG mill area % 14.5

Ball mill area % 11.5

Flotation area % 4.5

Reclaim tunnel% 1.1

All other floors subject to frequent washdowns or occasional process spills

shall have a minimum slope to drain of 3 percent.

8.0 CONSTRUCTION MATERIALS

8.1 STRUCTURAL STEEL

8.1.1 Structural steel shapes, plates and bars shall conform to ASTM A36,

A42-27ES (NCh 203), or as approved.

8.1.2 Rails shall conform to ASTM A1.

8.2 STRUCTURAL STEEL CONNECTIONS

8.2.1 Shop connections: In general, shop connections will be welded.

In some cases, shop connections should be

bolted and elements should be shop assembled

as indicated on drawings.

8.2.2 Field connections: Bolted; field welded only when indicated on

drawings

All connections will be bearing-type connection with threads included

in shear plane.

Bolts for all members shall conform to ASTM A325.

Where slip-critical connections are required, the faying surfaces of the

connection shall be blast-cleaned and uncoated or blast-cleaned and

coated with a Class B coating as defined in the Specification for

Structural Joints Using ASTM A325 or A490 Bolts.

All bolts shall be fully tightened unless noted otherwise on the

drawings.

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 26 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

Bolts for secondary (nonstructural) members should be ASTM A307

or A42-23 (NCh 206).

8.3 GRATING

8.3.1 Grating and banding A37-24ES (NCh 203) steel

8.3.2 Bearing bars 32 x 5 millimetre spaced at 30 mm c/c

8.3.3 Cross bars Cross-sectional area of not less than 40 mm2

and thickness not less than 6 millimetres

spaced at 100 mm c/c

8.3.4 Grating sections Fastened by HILTI X-FCM grating disk

fasteners as defined on project standard

drawings.

8.3.5Heavy duty grating shall be provided for areas with heavy vehicular traffic:

8.4 CHECKERED PLATE

8.4.1 Checkered plate shall be A37-24ES (NCh 203) steel and shall have a

four-way safety pattern.

8.4.2 Checkered plate shall be field welded to end supports with 40

millimetre long by 5 millimetre fillet welds at 300 mm c/c and to

intermediate members with 15 millimetre plug welds at 450 mm c/c.

8.5 EXPANDED METAL GRATING

Expanded metal grating shall be galvanized.

8.6 ANCHOR BOLTS

Anchor bolts and anchor plates shall conform to ASTM A36/A36M or A42-23

(NCh 206). Nuts shall conform to ASTM A563 and round washers shall

conform to ASTM F436. Minimum diameter of bolts shall be inches.

8.7 HANDRAILS

8.7.1 Top rail 40 millimetre (1-1/2 inch) diameter steel tube

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 27 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

8.7.2 Intermediate rails 40 millimetre (1-1/2 inch) diameter steel tube;

clear open space between intermediate rails shall

not be more than 300 millimetre

8.7.3 Posts 40 millimetre (1-1/2 inch) diameter steel tube,

spaced at 1800 mm c/c maximum. 1200

minimum height from platform to top of rail.

8.7.4 Toe plate 100 x 6 millimetre thick minimum with

10 millimetre clearance above floor or platform

8.8 CONCRETE

8.8.1 Unless otherwise noted on drawings, concrete design compressive

strengths shall be as follows:

Use NCh Cod f 'c

Structural concrete (miscellaneous H30 250 kgf/cm2 (3625psi)

footings, isolated equipment

foundations, mill foundations, etc.)

Electrical duct encasement H20 150 kgf/cm2(2175psi)

Building foundations and H30 250 kgf/cm23625psi)

footings

Slab at grade and elevated H35 300 kgf/cm2(4350psi)

retaining walls, reclaim

tunnel and thickeners

Operating floor at grinding bay H35 300 kgf/cm2(4350psi)

Lean concrete fill and mudmats H10 75 kgf/cm2(1088psi)

8.8.2 Compressive strength (f 'c) refers to strength at 28 days.

8.8.3 Ultimate load capacities for reinforced concrete design shall be

determined in accordance with the ACI 318 code. 1

8.9 REINFORCEMENT STEEL

8.9.1 Reinforcement steel shall be in accordance with ASTM A615 Grade60

or A63-42H (NCh 434) unless shown otherwise on the design

drawings.

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 28 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

8.9.2 Ultimate load capacities for reinforced concrete design shall be

determined in accordance with the ACI-318 Code.

8.10 WELDED WIRE FABRIC

Welded wire fabric shall be in accordance with ASTM A185 or AT56-

50H(NCh 218 and 219), with a minimum yield strength of 450 MPa for

wire diameters of 3 millimeters and greater

8.11 CONCRETE MASONRY

8.11.1 Concrete masonry units shall be in accordance with NCh 181, Class

A, with a minimum compressive strength 70 kgf/cm2 (average of 5

units).

8.11.2 Allowable stresses in concrete masonry shall be determined in

accordance with the UBC or NCh 1928.

8.12 GROUT

For column and equipment bases, the grout shall be nonshrink and nonmetallic

and shall be in accordance with technical specification 24017-GC-005.

8.13 WELDING MATERIALS

Welding materials shall conform to the following specifications:

- AWS A-5.17 bare mild steel electrodes and fluxes for submerged arc

welding

- AWS A-5.18 mild steel electrodes for gas metal arc welding

- AWS A-5.1 mild steel covered arc welding electrodes for shielded metal

arc welding.

8.14 STORM SEWERS AND CULVERTS

8.14.1 Storm sewers shall be of reinforced concrete pipe with a

300 millimeters minimum diameter.

8.14.2 Culverts shall be of galvanized corrugated steel pipe outside coated

with bitumen , 600 millimetre minimum diameter.

9.0 TRANSPORTATION LIMITS BY TRUCK

Normal dimensions and load limits for transportation by truck should be considered as

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 29 of 30

Civil Structural Design Criteria

24017-DC-001, Rev. 1

follows:

Maximum width m 2.5

Maximum height m 3.0

Maximum length m 14.0

Maximum weight t 35.0

Larger dimensions and weights are possible subject to special permit, and shall be

confirmed through the Construction Traffic Department.

IW:24017\job24017\ Design Criteria\Civil\Struct\Architect\CN\sg\rjr

06/02/14

Page 30 of 30

Das könnte Ihnen auch gefallen

- E14-E01 - 1 Main Substation DesignDokument11 SeitenE14-E01 - 1 Main Substation DesignMuhammad IrfanNoch keine Bewertungen

- 220 V2a MHCB 00029Dokument93 Seiten220 V2a MHCB 00029faradioNoch keine Bewertungen

- Steel structure legend and reference detailsDokument1 SeiteSteel structure legend and reference detailszaheerNoch keine Bewertungen

- Zamil Sample CalculationsDokument108 SeitenZamil Sample CalculationsAshraf KhalifaNoch keine Bewertungen

- Lashing Lug Round Bar Design: 1. GeneralDokument3 SeitenLashing Lug Round Bar Design: 1. GeneralinnovativekarthiNoch keine Bewertungen

- ReportDokument52 SeitenReportFeroz Khan PatthanNoch keine Bewertungen

- Fillet Weld Connection DesignDokument1 SeiteFillet Weld Connection Designbalaji gmscNoch keine Bewertungen

- Seismic Coefficients Non Building StructuresDokument3 SeitenSeismic Coefficients Non Building StructuresBunkun15Noch keine Bewertungen

- 200 3PS E00x 00001 000Dokument30 Seiten200 3PS E00x 00001 000Henry MontenegroNoch keine Bewertungen

- Anchor Bolt Design (AISC) - Tt100Dokument2 SeitenAnchor Bolt Design (AISC) - Tt100Jennifer HudsonNoch keine Bewertungen

- Ast For MomentDokument1 SeiteAst For MomenteramitdhanukaNoch keine Bewertungen

- Four Bolt Moment Connection DesignDokument12 SeitenFour Bolt Moment Connection DesignDarshan Panchal0% (1)

- Drawing of Pumphouse and Water TankDokument7 SeitenDrawing of Pumphouse and Water TankNguyễn Đức HữuNoch keine Bewertungen

- Factory Building Design CriteriaDokument13 SeitenFactory Building Design CriteriaFikriansyahIndraSaputraNoch keine Bewertungen

- Construction of Warehouse in Ras Al KhairDokument102 SeitenConstruction of Warehouse in Ras Al KhairFeroz Khan Patthan100% (1)

- SEPA15014 MFSTD CV 00 SPC 003 - Structural Steel Works - Rev 0Dokument26 SeitenSEPA15014 MFSTD CV 00 SPC 003 - Structural Steel Works - Rev 0Pruthviraj JuniNoch keine Bewertungen

- Plate DesignDokument6 SeitenPlate DesignUmesh ChamaraNoch keine Bewertungen

- CraneBeam v1 1Dokument39 SeitenCraneBeam v1 1satya_jayantiNoch keine Bewertungen

- Carbón SteelDokument6 SeitenCarbón SteelJorge LaraNoch keine Bewertungen

- Frame Analysis Ver W2Dokument14 SeitenFrame Analysis Ver W2Sajith RanatungaNoch keine Bewertungen

- Earthquake Load Calculations As Per IS1893-2002.-: Building Xyz at Mumbai. Rev - Mar2003 HSVDokument9 SeitenEarthquake Load Calculations As Per IS1893-2002.-: Building Xyz at Mumbai. Rev - Mar2003 HSVeco protectionNoch keine Bewertungen

- Cranebeam v1 2 AramadaDokument1 SeiteCranebeam v1 2 AramadaronyNoch keine Bewertungen

- Date DRN by DSGD by CHKD by Apprd by ScaleDokument1 SeiteDate DRN by DSGD by CHKD by Apprd by ScaleChandan JhaNoch keine Bewertungen

- Rev G Connection-Double AngleDokument12 SeitenRev G Connection-Double AnglePankaj_Taneja_9684Noch keine Bewertungen

- WeldsDokument1 SeiteWeldsabeyivanNoch keine Bewertungen

- SP 1275 Rev 02 Spec and Criteria For Design of Civil Building Works Update 03 96Dokument200 SeitenSP 1275 Rev 02 Spec and Criteria For Design of Civil Building Works Update 03 96santhosh kumar BudiNoch keine Bewertungen

- Design for Lifting Pad EyeDokument4 SeitenDesign for Lifting Pad EyeAsaru DeenNoch keine Bewertungen

- Civil/Structural Calculation SheetDokument19 SeitenCivil/Structural Calculation Sheetfbaxter22Noch keine Bewertungen

- Appendix 1 - Scope of WorkDokument13 SeitenAppendix 1 - Scope of WorkNimra NaveedNoch keine Bewertungen

- Mezz Portal 10 StoriesDokument4 SeitenMezz Portal 10 StoriesthiệnNoch keine Bewertungen

- Anchoring Conditions: Non-Cracked Concrete 25 6 900 115 100 10 190 40 31.66667 6.666667 150 Hilti HIT-RE 500-SDDokument11 SeitenAnchoring Conditions: Non-Cracked Concrete 25 6 900 115 100 10 190 40 31.66667 6.666667 150 Hilti HIT-RE 500-SDTimothy PinchinNoch keine Bewertungen

- Ar2-En-005-0004-00 Gantry Tower Structural Details Rev. 1Dokument2 SeitenAr2-En-005-0004-00 Gantry Tower Structural Details Rev. 1harold de guzmanNoch keine Bewertungen

- BLNG Ce 818010298560001Dokument66 SeitenBLNG Ce 818010298560001Venkatesh PrasathNoch keine Bewertungen

- Staad Mezzanine DesignDokument15 SeitenStaad Mezzanine Designmbhanusagar.keynesNoch keine Bewertungen

- GB1516 Sac 240 CV RP 0004 - BDokument69 SeitenGB1516 Sac 240 CV RP 0004 - BkkkkNoch keine Bewertungen

- 4.0 Design of Purlin: Kvaerner PowergasDokument4 Seiten4.0 Design of Purlin: Kvaerner PowergasKanchan Raja SinghNoch keine Bewertungen

- Haunch End PlateDokument5 SeitenHaunch End PlateArbiNoch keine Bewertungen

- RPLC DEEP CONVERSION BRACING CONNECTION DESIGNDokument32 SeitenRPLC DEEP CONVERSION BRACING CONNECTION DESIGNHeberth SanchezNoch keine Bewertungen

- Mathcad - Template IndexDokument6 SeitenMathcad - Template IndexKrish ChandNoch keine Bewertungen

- AISC design guide pinned base plate connectionDokument16 SeitenAISC design guide pinned base plate connectionTuấnThanhNoch keine Bewertungen

- WEB - Welding DesignDokument2 SeitenWEB - Welding DesignAdam MillerNoch keine Bewertungen

- AngleDokument7 SeitenAngleNguyễnTúSơnNoch keine Bewertungen

- Peb BuildingDokument4 SeitenPeb BuildingHiren DesaiNoch keine Bewertungen

- Apf Cal Pipe Bridge Rev 2Dokument36 SeitenApf Cal Pipe Bridge Rev 2Edwin RachmanudinNoch keine Bewertungen

- Col-Schedule Staad ResultsDokument3 SeitenCol-Schedule Staad ResultsNitesh SinghNoch keine Bewertungen

- Cross Arm Assembly, 38'-3 1/8" Long Xarm: Sheet 1 of 4Dokument4 SeitenCross Arm Assembly, 38'-3 1/8" Long Xarm: Sheet 1 of 4raulNoch keine Bewertungen

- Z 150X60X20X2 DesignDokument3 SeitenZ 150X60X20X2 DesignRajib GhoshNoch keine Bewertungen

- QP10-Q-617 Rev0 Typical Steel StructuresDokument1 SeiteQP10-Q-617 Rev0 Typical Steel StructuresnawajhaNoch keine Bewertungen

- Larsen & Toubro Limited - Ecc DivisionDokument1 SeiteLarsen & Toubro Limited - Ecc DivisionOuseppachan AmbookenNoch keine Bewertungen

- Long Column Design in KN UnitDokument19 SeitenLong Column Design in KN Unitabhi aroteNoch keine Bewertungen

- Crane Beam Design: AISC Design Guide 7 Example 18.1.2 LRFD Aisc CSD 3/25/2005Dokument39 SeitenCrane Beam Design: AISC Design Guide 7 Example 18.1.2 LRFD Aisc CSD 3/25/2005Sunil RahangdaleNoch keine Bewertungen

- Girt design calculations for major and minor axis loadsDokument4 SeitenGirt design calculations for major and minor axis loadsvijaystructuralNoch keine Bewertungen

- Project No. Date - Sheet No. Computed by 1 of 9 - Subject - Checked by Approved byDokument9 SeitenProject No. Date - Sheet No. Computed by 1 of 9 - Subject - Checked by Approved bysaravananNoch keine Bewertungen

- Analysis Report Jkjt0058 Jaya Sakti 2Dokument46 SeitenAnalysis Report Jkjt0058 Jaya Sakti 2Mochammad Shokeh0% (2)

- DM 002Dokument25 SeitenDM 002Jonathan Romero AlfaroNoch keine Bewertungen

- P20199-Pr-A-Cs-Stc-6007 - Tech STR Design Calculation NativeDokument67 SeitenP20199-Pr-A-Cs-Stc-6007 - Tech STR Design Calculation NativeNitin SakpalNoch keine Bewertungen

- RSSM - Squash Court Building - Design Report-RCC-Single StoreyDokument24 SeitenRSSM - Squash Court Building - Design Report-RCC-Single StoreyAmulyaRajbharNoch keine Bewertungen

- Airport building regulations compliance certificateDokument2 SeitenAirport building regulations compliance certificateThaiNguyenNoch keine Bewertungen

- Structural Engineering Design CriteriaDokument56 SeitenStructural Engineering Design CriteriaAnonymous z4Fe39j100% (1)

- Structural Engineering Services For Tall Concrete Building ProjectsDokument116 SeitenStructural Engineering Services For Tall Concrete Building ProjectsGuillermo AllFatherNoch keine Bewertungen

- About of BuildingDokument1 SeiteAbout of Buildingcamilo.ponce.ayalaNoch keine Bewertungen

- Tubular Steel Structures - Theory and DesignDokument205 SeitenTubular Steel Structures - Theory and DesignEvilaitch100% (7)

- Bearing Solutions For Large Size Machinery: One-Bearing Solutions Two-Bearing Solutions Three-Bearing SolutionsDokument162 SeitenBearing Solutions For Large Size Machinery: One-Bearing Solutions Two-Bearing Solutions Three-Bearing Solutionscamilo.ponce.ayalaNoch keine Bewertungen

- Lubrication of Rolling BearingsDokument228 SeitenLubrication of Rolling Bearingscamilo.ponce.ayalaNoch keine Bewertungen

- Environmental Design CriteriaDokument38 SeitenEnvironmental Design Criteriacamilo.ponce.ayalaNoch keine Bewertungen

- Slip FormingDokument20 SeitenSlip Formingu2asadNoch keine Bewertungen

- Minera Escondida DocumentDokument1 SeiteMinera Escondida Documentcamilo.ponce.ayalaNoch keine Bewertungen

- Chapter 8 - Coordinate Systems and Map ProjectionsDokument27 SeitenChapter 8 - Coordinate Systems and Map ProjectionsJayHatNoch keine Bewertungen

- Methodology and Concept of SurveyDokument20 SeitenMethodology and Concept of SurveyCimanuk Cisanggarung riverNoch keine Bewertungen

- Audit Rspo TMJ - Overlay Jaringan SungaiDokument1 SeiteAudit Rspo TMJ - Overlay Jaringan SungaiWawan WalcottNoch keine Bewertungen

- Topographic Map of FerrisDokument1 SeiteTopographic Map of FerrisHistoricalMapsNoch keine Bewertungen

- Topographic maps display elevation using contour linesDokument5 SeitenTopographic maps display elevation using contour linesElvie Abulencia-BagsicNoch keine Bewertungen

- GTA 03-06-008 - CBRN Warning and Reporting SystemDokument16 SeitenGTA 03-06-008 - CBRN Warning and Reporting SystemBrian PonderNoch keine Bewertungen

- Topographic Map of ClarksvilleDokument1 SeiteTopographic Map of ClarksvilleHistoricalMapsNoch keine Bewertungen

- Section 3 Data Format Definition: 3.1 L2 Image FilesDokument13 SeitenSection 3 Data Format Definition: 3.1 L2 Image FilesArnoldNoch keine Bewertungen

- GT Aide (Global) 1.1: A Freeware For Field PlanningDokument11 SeitenGT Aide (Global) 1.1: A Freeware For Field PlanningInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- ProgramDokument27 SeitenProgrammilekitic2005Noch keine Bewertungen

- C1 Map ProjectionDokument112 SeitenC1 Map ProjectionMohamad AizanNoch keine Bewertungen

- APCWE6 Windpaper InproceedingsDokument17 SeitenAPCWE6 Windpaper InproceedingsSyed Imaduddin ZubairNoch keine Bewertungen

- Topographic Map of MarysvilleDokument1 SeiteTopographic Map of MarysvilleHistoricalMapsNoch keine Bewertungen

- Gencade: Sms 11.2 TutorialDokument27 SeitenGencade: Sms 11.2 TutorialOentoeng KartonoNoch keine Bewertungen

- Central Park MapDokument1 SeiteCentral Park MapfaltadeingenieríaNoch keine Bewertungen

- Topographic Map of HurstDokument1 SeiteTopographic Map of HurstHistoricalMapsNoch keine Bewertungen

- Coordinate ConversionDokument76 SeitenCoordinate ConversionMaccon StivNoch keine Bewertungen

- Topographic Map of RochesterDokument1 SeiteTopographic Map of RochesterHistoricalMapsNoch keine Bewertungen

- 44 Minanga - Buayan - Mangrove PDFDokument1 Seite44 Minanga - Buayan - Mangrove PDFCirilo Jr. LagnasonNoch keine Bewertungen

- Hyperion L1G EO1-DFCB.v.1 TiagoDokument30 SeitenHyperion L1G EO1-DFCB.v.1 TiagoHewerton Alves da SilvaNoch keine Bewertungen

- Cartography: Introduction Datum - Vertical - HorizontalDokument61 SeitenCartography: Introduction Datum - Vertical - HorizontalkeerthanamaniNoch keine Bewertungen

- Topographic SurveyingDokument111 SeitenTopographic SurveyingAhmet DerdiyokNoch keine Bewertungen

- GIS SlidesDokument98 SeitenGIS SlidesdjkmogNoch keine Bewertungen

- Study Guide MapreadingDokument26 SeitenStudy Guide Mapreadingtom2susanNoch keine Bewertungen

- Design & Build MEP & Civil Works at Yassat Island ABu DhabiDokument53 SeitenDesign & Build MEP & Civil Works at Yassat Island ABu DhabimahmoudNoch keine Bewertungen

- Topographic Map of OakwoodDokument1 SeiteTopographic Map of OakwoodHistoricalMapsNoch keine Bewertungen

- Topographic Map of Texas MountainDokument1 SeiteTopographic Map of Texas MountainHistoricalMapsNoch keine Bewertungen

- Map ProjectionDokument45 SeitenMap ProjectionKhenny25Noch keine Bewertungen

- Projection and Transformation CalculationsDokument38 SeitenProjection and Transformation Calculationsnevadamike_001Noch keine Bewertungen

- Converting UTM To Latitude ...Dokument7 SeitenConverting UTM To Latitude ...girish_jagadNoch keine Bewertungen

- To Engineer Is Human: The Role of Failure in Successful DesignVon EverandTo Engineer Is Human: The Role of Failure in Successful DesignBewertung: 4 von 5 Sternen4/5 (137)

- Advanced Modelling Techniques in Structural DesignVon EverandAdvanced Modelling Techniques in Structural DesignBewertung: 5 von 5 Sternen5/5 (3)

- Advanced Design Examples of Seismic Retrofit of StructuresVon EverandAdvanced Design Examples of Seismic Retrofit of StructuresBewertung: 1 von 5 Sternen1/5 (1)

- Marine Structural Design CalculationsVon EverandMarine Structural Design CalculationsBewertung: 4.5 von 5 Sternen4.5/5 (13)

- Transmission Pipeline Calculations and Simulations ManualVon EverandTransmission Pipeline Calculations and Simulations ManualBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsVon EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsNoch keine Bewertungen

- Pocket Guide to Flanges, Fittings, and Piping DataVon EverandPocket Guide to Flanges, Fittings, and Piping DataBewertung: 3.5 von 5 Sternen3.5/5 (22)

- Built: The Hidden Stories Behind Our StructuresVon EverandBuilt: The Hidden Stories Behind Our StructuresBewertung: 4 von 5 Sternen4/5 (27)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingVon EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingNoch keine Bewertungen

- Building Support Structures, 2nd Ed., Analysis and Design with SAP2000 SoftwareVon EverandBuilding Support Structures, 2nd Ed., Analysis and Design with SAP2000 SoftwareBewertung: 4.5 von 5 Sternen4.5/5 (15)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsVon EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNoch keine Bewertungen

- Matrix Methods for Advanced Structural AnalysisVon EverandMatrix Methods for Advanced Structural AnalysisBewertung: 5 von 5 Sternen5/5 (1)

- Pile Design and Construction Rules of ThumbVon EverandPile Design and Construction Rules of ThumbBewertung: 4.5 von 5 Sternen4.5/5 (15)

- Design and Construction of Soil Anchor PlatesVon EverandDesign and Construction of Soil Anchor PlatesBewertung: 5 von 5 Sternen5/5 (1)

- Pipeline Planning and Construction Field ManualVon EverandPipeline Planning and Construction Field ManualBewertung: 5 von 5 Sternen5/5 (3)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsVon EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsBewertung: 4 von 5 Sternen4/5 (16)

- Offshore Pipelines: Design, Installation, and MaintenanceVon EverandOffshore Pipelines: Design, Installation, and MaintenanceBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresVon EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresBewertung: 1 von 5 Sternen1/5 (2)