Beruflich Dokumente

Kultur Dokumente

Howto Heat Resistance of Paints

Hochgeladen von

carlainspirationOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Howto Heat Resistance of Paints

Hochgeladen von

carlainspirationCopyright:

Verfügbare Formate

McCONNELLS

SURFACE PREPARATION

HEAT RESISTANT PAINTS

“The heat resistance of a paint film” is generally referred to when discussing paints to be applied to

radiators, steam pipes, boilers, metal chimneys, etc., and relates to the temperature a given paint is

capable of withstanding without discolouring or breaking down.

Discolouration usually occurs as a darkening of the medium when subjected to heat, and the degree of

darkening will vary according to the type of medium and the temperature to which it is subjected.

Certain pigments are also susceptible to heat, but the temperature at which discolouration occurs can

vary considerably.

A paint film may discolour to a marked degree yet still provide a protective coating to the surface onto

which it has been applied. However, this discolouration can spoil a colour scheme, or affect an

“identification colour” to the extent that a dangerous error could occur through wrong identification

during maintenance work.

In many cases it has been found that standard paints are suitable for low temperature surfaces such as

hot water radiators, etc., and although some discolouration may occur at approximately 65oC (250oF) in

white and very light pastel colours, the discolouration may not be apparent in the darker colours such as

browns and black.

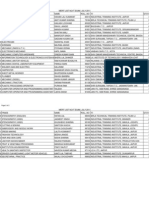

After laboratory trials, carried out for 100 hours on a clean iron pipe with a point source of heat giving

graduated heat from warm to hot along its length, and using various types of paint finishes, the following

results were obtained:-

Gloss (White & Brilliant White)

0 oC - 54 oC (32 oF - 130 oF) No discolouration

o o

54 C - 82 C (130 oF - 180 oF) Very sight yellowing

82 C -121 C (180 oF - 250 oF)

o o

Slight yellowing

121 oC -149 oC (250 oF - 300 oF) Turned to cream colour

149 oC -177 oC (300 oF - 350 oF) Turned to stone colour. Film beginning to lose gloss.

177 oC -204 oC (350 oF - 400 oF) Very dark stone colour. Film lost gloss.

Aluminium Paint

0 oC - 204 oC (32 oF - 400 oF) No change in lustre.

260 oC (500 oF) Slight Yellowing

Eggshell (White)

38 oC (100 oF) Slight Darkening

93 oC (200 oF) Dark, dirty appearance

149 oC (300 oF) Very dark brown colour. This paint cannot be considered

satisfactory even on surfaces of low temperature.

Matt Emulsion (Brilliant White)

0 oC - 99 oC (32 oF - 210 oF) Quite satisfactory.

Apart from the actual resistance of a paint film, it should be noted that the radiation and heating

efficiency of a hot water or steam heating system depends upon the type of paint applied to the radiators

and heating pipes. Bright metal surfaces, aluminium paint, bronze paints and gloss enamel paints (as will

be seen from the following figures) give minimum radiation, whilst matt finishes and metal surfaces in a

rusty condition give maximum radiation.

1

TECHNICAL ADVISORY:

The information contained in this Technical Data sheet is based on many years experience and usage of the product. However, all

recommendations and suggestions are made without guarantee, since the conditions of use are beyond our control.

More detailed Technical Data Sheets are available on request.

www.mcconnellspaints.com Industrial Coatings, Adhesives and Paint

Manufacturers Ireland

McCONNELLS

SURFACE PREPARATION

HEAT RESISTANT PAINTS

Taking the amount of heat radiated from a new pipe as 100 units, the following relative figures have been

observed for the heat radiated under the following conditions from a pipe tested under steam at 200 psi.

pressure.

New pipe 100 Painted glossy white 100.5

Fair condition 116 Cleaned with potash again 116

Rusty and black 119 Coated with cylinder oil 116

Cleaned with caustic potash inside and out 116 Painted dull black 120

Painted dull white 120 Painted glossy black 101

It would appear that the above figures demonstrate that the colour of the pipe has little or no effect on

the radiation of heat, but that radiation varies considerably in relation to the glossiness or dullness of the

surface. The figures demonstrate therefore, that there is no serious loss of efficiency through making

pipes and radiators harmonize with the general colour scheme of the rooms in which they are placed.

The method of painting radiators and hot water pipes should be to keep the elasticity of the film build-up

as similar as possible, otherwise unequal expansion of the different coats in the paint film might cause

cracking and subsequent flaking. This may be achieved by the use of a good adhesive primer such as Zinc

Phosphate Primer, followed by two coats of the required finishing material (i.e. omitting an undercoating

in the case of gloss finishes).

Before priming, the metal should be thoroughly prepared to remove all rust, dirt and loose material. It

should then be subjected, if possible, to mild heat 38 oC (approx 100 oF) to dry off any moisture which has

condensed on the surface and in the pores of the metal, and the primer applied whilst the metal is still

warm.

Special heat resisting paints such as our Firglo 393 do not require primers, as these may disintegrate

at lower temperatures than the finishes themselves, but it is absolutely essential that the metal is

perfectly clean and dry before the paints are applied. Firglo 393 is applied direct to the clean dry

metal.

When choosing paints for particular purposes in industry, their particular properties should be considered

in order to maximise the use of the paint.

Ensure that the material to be used will, first and foremost, withstand the degree of temperature to

which it is likely to be subjected. Paint can be used to prevent loss of heat through radiation or it can

increase radiation. Decorative effect, durability and economy should also be taken into account before

the final decision is taken. The surface temperature to be encountered should always be stated when

ordering paints. Further details not within the scope of this data sheet can be obtained from

McConnells Technical Department.

Revision reference: 2 Issued on 22/08/2009.

2

TECHNICAL ADVISORY:

TECHNICAL ADVISORY:

The information contained in this Technical Data sheet is based on many years experience and usage of the product. However, all

The information contained

recommendations in this Technical

and suggestions are madeData sheet

without is based since

guarantee, on many

the years experience

conditions and beyond

of use are usage ofour

the product. However,

control.

all

Morerecommendations andData

detailed Technical suggestions areavailable

Sheets are made without guarantee, since the conditions of use are beyond our control.

on request.

More detailed Technical Data Sheets are available on request.

www.mcconnellspaints.com Industrial Coatings, Adhesives and Paint

Manufacturers Ireland

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Casestudy Energy Recovery From Farm WasteDokument2 SeitenCasestudy Energy Recovery From Farm WastecarlainspirationNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Howto Lime Washed Cement Painted SurfacesDokument2 SeitenHowto Lime Washed Cement Painted SurfacescarlainspirationNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Casestudy Alcon Process Analysis and Optical MetrologyDokument2 SeitenCasestudy Alcon Process Analysis and Optical MetrologycarlainspirationNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Why GIS Geographic Information SystemsDokument2 SeitenWhy GIS Geographic Information SystemscarlainspirationNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- SPD Electric Glass Smart Glass TheoryDokument2 SeitenSPD Electric Glass Smart Glass TheorycarlainspirationNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- 2010 EU Insights Into Continued Adult EducationDokument7 Seiten2010 EU Insights Into Continued Adult EducationcarlainspirationNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The History of GlassDokument2 SeitenThe History of Glasscarlainspiration100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Boolean Operations in 3D - AutoCAD 2016 Tutorial and VideosDokument19 SeitenBoolean Operations in 3D - AutoCAD 2016 Tutorial and VideosRohit Chandrakant SalveNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- 08 Saad Introduction Too o ConceptsDokument26 Seiten08 Saad Introduction Too o ConceptsMohammed ABDO ALBAOMNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Ravens Advanced Progressive Matrices Practice Book IQ Test Previewinjaplus - IrDokument10 SeitenRavens Advanced Progressive Matrices Practice Book IQ Test Previewinjaplus - IrFriend KatsumataNoch keine Bewertungen

- Is 800-2007 - Indian Code of Practice For Construction in SteelDokument41 SeitenIs 800-2007 - Indian Code of Practice For Construction in SteelshiivendraNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Examples and Non-ExamplesDokument5 SeitenExamples and Non-ExamplesslidegaeNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Liter Ature - 4A: Start ThinkingDokument2 SeitenLiter Ature - 4A: Start ThinkingNour AlkaloutiNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Orient Technologies Profile PresentationDokument27 SeitenOrient Technologies Profile PresentationNisarg ShahNoch keine Bewertungen

- Enabling Secure Broadband Access Anywhere Anytime Access Anywhere, AnytimeDokument4 SeitenEnabling Secure Broadband Access Anywhere Anytime Access Anywhere, AnytimeEmmanuelNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Tavistock PrimerDokument13 SeitenTavistock PrimerSharon Schaff100% (1)

- Worksheet - StatisticsDokument3 SeitenWorksheet - StatisticsGabriel Ch MendezNoch keine Bewertungen

- AquaMapPublic v202Dokument26 SeitenAquaMapPublic v202engfeupNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Practicality and Efficiency: Presented By: Grace EscabasDokument11 SeitenPracticality and Efficiency: Presented By: Grace EscabasMiaeNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Module 6: Stresses Around Underground Openings: 6.6 Excavation Shape and Boundary StressDokument10 SeitenModule 6: Stresses Around Underground Openings: 6.6 Excavation Shape and Boundary Stressفردوس سليمانNoch keine Bewertungen

- Dramix: Dramix Economic Concrete Reinforcement For Safe Floors On PilesDokument9 SeitenDramix: Dramix Economic Concrete Reinforcement For Safe Floors On PilesMohammad IqbalNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Probability spaces and σ-algebras: Scott SheffieldDokument12 SeitenProbability spaces and σ-algebras: Scott SheffieldRikta DasNoch keine Bewertungen

- I. Company Data 1.1. Company ProfileDokument19 SeitenI. Company Data 1.1. Company ProfileMhy AcajaNoch keine Bewertungen

- Ass AsDokument2 SeitenAss AsMukesh BishtNoch keine Bewertungen

- Product Leaflet Seawater ElectrochlorinationDokument4 SeitenProduct Leaflet Seawater Electrochlorinationgkdora574Noch keine Bewertungen

- SCCA2103 Leadership CommunicationDokument6 SeitenSCCA2103 Leadership CommunicationsarahNoch keine Bewertungen

- ResearchDokument12 SeitenResearchIsla, AltheaNoch keine Bewertungen

- European Foundation Design For Seasonally Frozen GroundDokument127 SeitenEuropean Foundation Design For Seasonally Frozen GroundLevente SikoNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Cultural Diversity in Vikram Seth's A Suitable Boy'Dokument3 SeitenCultural Diversity in Vikram Seth's A Suitable Boy'Sneha PradhanNoch keine Bewertungen

- One Word SubstitutionDokument5 SeitenOne Word SubstitutionPranaykant Singh PanwarNoch keine Bewertungen

- De Cuong On Thi HK2 Tieng Anh 10Dokument5 SeitenDe Cuong On Thi HK2 Tieng Anh 10hoangtouri2512Noch keine Bewertungen

- Multimedia Critique Paper 1Dokument4 SeitenMultimedia Critique Paper 1api-345838334Noch keine Bewertungen

- Acc Inter 3 AtsiriDokument9 SeitenAcc Inter 3 AtsiriZania Putri100% (1)

- Mody M100T 50 60Dokument2 SeitenMody M100T 50 60NAHASALI11Noch keine Bewertungen

- Bantilan Maureen Lhee RDokument8 SeitenBantilan Maureen Lhee RAlexa Anne Louise BercillaNoch keine Bewertungen

- TSS Training Package Implementation Guidefinal 0Dokument18 SeitenTSS Training Package Implementation Guidefinal 0hanabbecharaNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)