Beruflich Dokumente

Kultur Dokumente

IST CVCM Accommodations & Registration for Vibration Analysis Level-II Course April 2015

Hochgeladen von

HaseebPiracha0%(1)0% fanden dieses Dokument nützlich (1 Abstimmung)

29 Ansichten2 SeitenOriginaltitel

training-brochure1.docx

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0%(1)0% fanden dieses Dokument nützlich (1 Abstimmung)

29 Ansichten2 SeitenIST CVCM Accommodations & Registration for Vibration Analysis Level-II Course April 2015

Hochgeladen von

HaseebPirachaCopyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

ACCOMMODATIONS Registration Fees & Schedule:

Bachelor & Family Accommodations are available Course Program

on first come first serve basis at IST, Islamabad. Course Registration Fee Rs.12,000/- per Participant

The charges for single room are Rs. 500/- per

Course fee Includes: Course Material

night. Please book your room at earliest, if you have

to avail the accommodation. Workshop Demonstrations

Lunch and Tea

Student Discount 20%

Center for Vibration Analysis and Condition Discount on Group 30 %

Monitoring (CVCM) (for min. 05 participants)

P.O. Box 2750, Islamabad Training Course

Course Venue: IST, Islamabad Highway,

Ph: 051-9075521

Near Rawat. on

Fax: 051-9273310

Kindly send soft or hard copy of form to the e-mails Vibration Analysis Level-II

given below: or to CVCM postal address: P.O. Box

2750, Islamabad

April 27-30, 2015

Islamabad

Please note that registration is required two weeks

prior to the course commencement.

Name

Job Title

Office Address Organized by

Cell #

Center for Vibration Analysis

Fax #

E-Mail and Condition Monitoring

Signature

Contact for more information Institute of Space Technology,

Islamabad

S. Zafar Kazmi: 0300-8561060

Email:szafar_kazmi@yahoo.com

Ghulam Mustafa: 0300-5199075

Email: mustafa786@hotmail.com

ABOUT CVCM COURSE PROGRAMME Fault Analysis

Centre for Vibration & Machine Condition Monitoring Day 1 Vibration due to resonance

(CVCM) has recently been established at IST with the Review of maintenance practices Vibration due to unbalance

following objectives: Maintenance philosophies Bent shaft problems

Evolution of maintenance philosophies Identifying a shaft with a kink or bend close to the

CVCM will provide machinery health monitoring

Plant machinery classification and recommendations bearing

services to the industries of Pakistan. Services include:

Predictive maintenance techniques Identifying a simple shaft bow

Infrared Thermography, Detection of Misalignment

Vibration analysis A key predictive maintenance

Vibration Analysis technique Vibration due to eccentricity

Laser Alignment and Dynamic Balancing Vibration basics and principles Looseness and sub harmonic frequencies

Organize Certification Condition Monitoring Looseness of the rotating system

Benefits of vibration analysis

trainings, workshops and conferences Looseness of the supporting system

Displacement, velocity, acceleration

Defective rolling-element bearings

Acoustic & Vibration Control Orbits; Beats; Modulation

Aerodynamic hydraulic problems

Shock& Vibration Testing Vibration Analysis Techniques

Vibration due to induction motor problems

COURSE OBJECTIVES Spectrum analysis Vibration due to gear problems

This course is designed for Maintenance and Design Harmonics, sidebands, and the analysis methodology

Day 3

Engineers who want to apply modern vibration analysis Time waveform analysis (introduction)

Orbit analysis (introduction) Equipment Testing and Diagnostics

techniques and principles for early fault detection and

damage prevention in critical costly industrial Phase analysis: bubble diagrams and ODS Impact testing (bump tests)

machines. Enveloping (demodulation), shock pulse, spike Phase analysis

VA-II as an Advanced Course energy, Peak Value Corrective action

VA-II course would enable the participants to sit for the Day 2 General Maintenance Repair Activities

VA level-II international certification exam. Data Acquisition Principles Review of Balancing Process

VA-II builds upon the foundation of the ISO 18436.2 Analog to Digital Converters Review of Shaft Alignment Procedure

Cat-2 Standard course. The course covers advanced Accelerometers Mounting Running a successful CM program

techniques of data acquisition and signal processing, Frequency range

waveform analysis, spectral diagnostics, phase analysis, Setting Baseline

Sensitivity

single-channel impact testing and field balancing. The Report Generation

Signal Processing

VA-II course will help the plant maintenance engineers Day 4

in selecting an optimized vibration monitoring program Frequency filtering

in their plants. Fast Fourier Transform (FFT) Practical Hands on Training

Sampling rate Certificate Distribution

LEARNING OUTCOMES

Lines of resolution, F-max, Bandwidth

1. Select appropriate machinery vibration techniques Course Deliverables

Window Functions

2. Perform vibration analysis on typical machines

Averaging Course Manual VA-II

3. Learn modern diagnostic techniques

Overlap Notepad

4. Perform resonance testing

Display/Storage Vibration Analysis Chart

5. Interpret results, make corrective recommendations

Workshop Experience

VA-II participation Certificate

Das könnte Ihnen auch gefallen

- HDMI to ISDB-T H.264 Encoder Modulator User ManualDokument24 SeitenHDMI to ISDB-T H.264 Encoder Modulator User ManualMatheus BuenoNoch keine Bewertungen

- Precision Tool - Zeiss CMM Training 3 Day Basic v2 PDFDokument1 SeitePrecision Tool - Zeiss CMM Training 3 Day Basic v2 PDFNikhil K RameshNoch keine Bewertungen

- ZTE - ZXSDR BS8900A Product DiscriptionDokument51 SeitenZTE - ZXSDR BS8900A Product Discriptionkhurrambilal0193% (15)

- Brochure VAIIDokument1 SeiteBrochure VAIImustafaNoch keine Bewertungen

- Brochure WQF DG FR of WQFDokument2 SeitenBrochure WQF DG FR of WQFAhmed shabanNoch keine Bewertungen

- LRFDDokument2 SeitenLRFDchinhonNoch keine Bewertungen

- Facility Certification Newsletter2!1!2014Dokument5 SeitenFacility Certification Newsletter2!1!2014Orbán NorbertNoch keine Bewertungen

- Yocogawa CENTUM CS3000Dokument35 SeitenYocogawa CENTUM CS3000RabahNoch keine Bewertungen

- Vibration Training Brochure - 2018Dokument24 SeitenVibration Training Brochure - 2018Madhan KannanNoch keine Bewertungen

- ETAP & Relay Testing Training For The Fresh EngineersDokument1 SeiteETAP & Relay Testing Training For The Fresh EngineersNaveed RabbaniNoch keine Bewertungen

- Site Master Advanced Line Sweep Training CourseDokument2 SeitenSite Master Advanced Line Sweep Training CourseOnyekachi JackNoch keine Bewertungen

- SNIS UT 578 - Steel PlatesDokument14 SeitenSNIS UT 578 - Steel PlatesShailesh DeshmukhNoch keine Bewertungen

- STTP On ML & IoT 2019 LeafletDokument2 SeitenSTTP On ML & IoT 2019 LeafletSushant BhargavaNoch keine Bewertungen

- UDokument2 SeitenUKrishnan JayaramanNoch keine Bewertungen

- ASNT UAE Section Webinar FlyerDokument1 SeiteASNT UAE Section Webinar FlyerinsaanNoch keine Bewertungen

- Mdi Vibration Analysis Cat IIIDokument1 SeiteMdi Vibration Analysis Cat IIIMohamed ArafatNoch keine Bewertungen

- ISO Certification TRG BrochureDokument2 SeitenISO Certification TRG BrochureJignesh JaniNoch keine Bewertungen

- Multi-Storey Steel Framed Structures To Eurocode 3 Bs en 1993-1-1:2000Dokument2 SeitenMulti-Storey Steel Framed Structures To Eurocode 3 Bs en 1993-1-1:2000chinhonNoch keine Bewertungen

- Jubail Industrial College WWW - Jic.edu - Sa: Kingdom of Saudi ArabiaDokument2 SeitenJubail Industrial College WWW - Jic.edu - Sa: Kingdom of Saudi ArabiaTasfikNoch keine Bewertungen

- ISO Category II (Analysis I)Dokument5 SeitenISO Category II (Analysis I)nspcl o&eNoch keine Bewertungen

- Qtech Institute Offers Welding Training and Welder CertificationDokument2 SeitenQtech Institute Offers Welding Training and Welder CertificationSathyanarayanan ShivajiraoNoch keine Bewertungen

- 21 January, 2022 (2:00 PM To 5:00 PM)Dokument3 Seiten21 January, 2022 (2:00 PM To 5:00 PM)sadeeskumar.dNoch keine Bewertungen

- Site Supervision Course (Electrical Module) Brochure PDFDokument3 SeitenSite Supervision Course (Electrical Module) Brochure PDFrichard tehNoch keine Bewertungen

- RE10580Dokument59 SeitenRE10580Aníbal FloresNoch keine Bewertungen

- The Institution of Engineers, Malaysia (Sabah Branch)Dokument2 SeitenThe Institution of Engineers, Malaysia (Sabah Branch)Anonymous zpNy2bltNoch keine Bewertungen

- Solar Rooftop Training For Business DevelopmentDokument2 SeitenSolar Rooftop Training For Business DevelopmentJaydip MotisariyaNoch keine Bewertungen

- Vibration Analysis: Level 2 CourseDokument2 SeitenVibration Analysis: Level 2 CourseBilalNoch keine Bewertungen

- CV For Welding InspectorDokument6 SeitenCV For Welding Inspectorkarni MaheshNoch keine Bewertungen

- Assessment Specifications Table (Ast) : Kementerian Pendidikan MalaysiaDokument6 SeitenAssessment Specifications Table (Ast) : Kementerian Pendidikan MalaysiaMohd raziffNoch keine Bewertungen

- Metso Crusher SeminarDokument5 SeitenMetso Crusher SeminarcarrialdiNoch keine Bewertungen

- Prepare For TestingDokument1 SeitePrepare For Testingmanasgupta496Noch keine Bewertungen

- Motor Speed Signature Analysis For Local Bearing Fault Detection With Noise Cancellation Based On Improved Drive AlgorithmDokument11 SeitenMotor Speed Signature Analysis For Local Bearing Fault Detection With Noise Cancellation Based On Improved Drive AlgorithmIradiratu DpkNoch keine Bewertungen

- Alstom MSC VCAT3 2012 Course BrochureDokument3 SeitenAlstom MSC VCAT3 2012 Course BrochureMaxwell KazuvaNoch keine Bewertungen

- D - Internet - Myiemorgmy - Intranet - Assets - Doc - Alldoc - Document - 17289 - FINAL Flyer - 02 Oct - MR Rajavel Inbarajan-2Dokument5 SeitenD - Internet - Myiemorgmy - Intranet - Assets - Doc - Alldoc - Document - 17289 - FINAL Flyer - 02 Oct - MR Rajavel Inbarajan-2Gardener AyuNoch keine Bewertungen

- Fundamental of Ammonia and Nitrogen Removal in Sewage Treatment Plant (STP) Online Training With FormDokument9 SeitenFundamental of Ammonia and Nitrogen Removal in Sewage Treatment Plant (STP) Online Training With Formpeter kijNoch keine Bewertungen

- Prajul KM-1-mergedDokument11 SeitenPrajul KM-1-mergedPradeep ManivannanNoch keine Bewertungen

- Combined BrochureDokument17 SeitenCombined BrochureVictor Pablo VadaláNoch keine Bewertungen

- 5-Day Certified Cat - II Vibration Analyst Training Basic Machinery Vibration (BMV) Certified Exam From Vibration Institute, USADokument1 Seite5-Day Certified Cat - II Vibration Analyst Training Basic Machinery Vibration (BMV) Certified Exam From Vibration Institute, USAChuan SwtsNoch keine Bewertungen

- L22 439 PDFDokument3 SeitenL22 439 PDFOSCAR YOBANY VEGA HERNANDEZNoch keine Bewertungen

- Aerial Lift Certification TrainingDokument1 SeiteAerial Lift Certification Traininglenghiemckt07Noch keine Bewertungen

- 1640702983284d7LATEST NOTIFICATIONS-2021Dokument1 Seite1640702983284d7LATEST NOTIFICATIONS-2021Kishore AyasettiNoch keine Bewertungen

- ISO Category II PDFDokument1 SeiteISO Category II PDFArif FadilahNoch keine Bewertungen

- Prosedur T, K, YDokument28 SeitenProsedur T, K, YMuhammad AsrilNoch keine Bewertungen

- API 577 Welding Certification TrainingDokument7 SeitenAPI 577 Welding Certification TrainingInstech Premier Sdn BhdNoch keine Bewertungen

- CV Mahfud Ridoi - Welding Inspector - NDT Level II PT MTDokument18 SeitenCV Mahfud Ridoi - Welding Inspector - NDT Level II PT MTMahfudRido'iRonggomaniaNoch keine Bewertungen

- Usuf Pathan HD CCTV CablingDokument1 SeiteUsuf Pathan HD CCTV CablingRakesh ChauhanNoch keine Bewertungen

- TS00E v1.2 Student Noteset PDFDokument303 SeitenTS00E v1.2 Student Noteset PDFpatrick morris100% (1)

- PAUT Training BrochureDokument1 SeitePAUT Training BrochureAhmed Ayman AhmedNoch keine Bewertungen

- Instructions: National Accreditation Board For Testing and Calibration LaboratoriesDokument47 SeitenInstructions: National Accreditation Board For Testing and Calibration LaboratoriesKiranNoch keine Bewertungen

- Effect of Threshold Voltage - Static Timing Analysis (STA) Basic (Part-7c) - VLSI ConceptsDokument4 SeitenEffect of Threshold Voltage - Static Timing Analysis (STA) Basic (Part-7c) - VLSI ConceptsIlaiyaveni IyanduraiNoch keine Bewertungen

- Understanding Process Control for Oil & Gas WebinarDokument5 SeitenUnderstanding Process Control for Oil & Gas WebinarOthman Mat YamanNoch keine Bewertungen

- 73 - Vibration Training Brochure 2016Dokument22 Seiten73 - Vibration Training Brochure 2016satfasNoch keine Bewertungen

- I IT - Problen Solving Techniques Arrear Lab ScheduleDokument5 SeitenI IT - Problen Solving Techniques Arrear Lab ScheduleVibin SimonNoch keine Bewertungen

- Iris Power Partial Discharge Course: Topics CoveredDokument2 SeitenIris Power Partial Discharge Course: Topics CoveredarthamonifanNoch keine Bewertungen

- Interview Questions and Answers On Safety Systems Instrumentation ToolsDokument7 SeitenInterview Questions and Answers On Safety Systems Instrumentation ToolsNGASSAKI ATONGUI Christ HubertNoch keine Bewertungen

- Oyuwe VivianDokument1 SeiteOyuwe VivianOrogaNoch keine Bewertungen

- D Internet Myiemorgmy Intranet Assets Doc Alldoc Document 594 OGMTD-25260411-C PDFDokument3 SeitenD Internet Myiemorgmy Intranet Assets Doc Alldoc Document 594 OGMTD-25260411-C PDFRajkumar ANoch keine Bewertungen

- Pagi 2015Dokument6 SeitenPagi 2015jazib qamarNoch keine Bewertungen

- alamadaDokument3 Seitenalamadajoey catotoNoch keine Bewertungen

- Result of The Exam Held On 08.01.2022-09.01.2022 in NUML Group No. 4-A1Dokument2 SeitenResult of The Exam Held On 08.01.2022-09.01.2022 in NUML Group No. 4-A1HaseebPirachaNoch keine Bewertungen

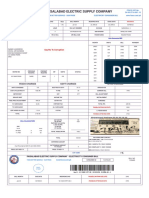

- Fesco Online Bill January 1Dokument1 SeiteFesco Online Bill January 1HaseebPirachaNoch keine Bewertungen

- Result of The Exam Held On 08.01.2022-09.01.2022 in NUML A2Dokument2 SeitenResult of The Exam Held On 08.01.2022-09.01.2022 in NUML A2HaseebPirachaNoch keine Bewertungen

- Result of The Exam Held On 08.01.2022-09.01.2022 in NUML Group No.5-A1Dokument1 SeiteResult of The Exam Held On 08.01.2022-09.01.2022 in NUML Group No.5-A1HaseebPirachaNoch keine Bewertungen

- FESCO GST No. Bill DetailsDokument1 SeiteFESCO GST No. Bill DetailsHaseebPirachaNoch keine Bewertungen

- Result of The Exam Held On 08.01.2022-09.01.2022 in NUML B2: HV LV SA MA 1 2 3 4 5 Sr. No. PTN No. Marks ObtainedDokument1 SeiteResult of The Exam Held On 08.01.2022-09.01.2022 in NUML B2: HV LV SA MA 1 2 3 4 5 Sr. No. PTN No. Marks ObtainedHaseebPirachaNoch keine Bewertungen

- b2 Karachi Result 21.01.2022Dokument1 Seiteb2 Karachi Result 21.01.2022HaseebPirachaNoch keine Bewertungen

- b2 Karachi Result 21.01.2022Dokument1 Seiteb2 Karachi Result 21.01.2022HaseebPirachaNoch keine Bewertungen

- Result of The Exam Held On 08.01.2022-09.01.2022 in NUML B2: HV LV SA MA 1 2 3 4 5 Sr. No. PTN No. Marks ObtainedDokument1 SeiteResult of The Exam Held On 08.01.2022-09.01.2022 in NUML B2: HV LV SA MA 1 2 3 4 5 Sr. No. PTN No. Marks ObtainedHaseebPirachaNoch keine Bewertungen

- Result of The Exam Held On 23.10.2021-25.10.2021 in Lahore B1Dokument2 SeitenResult of The Exam Held On 23.10.2021-25.10.2021 in Lahore B1HaseebPirachaNoch keine Bewertungen

- Result of The Exam Held On 08.01.2022-09.01.2022 in NUML B2: HV LV SA MA 1 2 3 4 5 Sr. No. PTN No. Marks ObtainedDokument1 SeiteResult of The Exam Held On 08.01.2022-09.01.2022 in NUML B2: HV LV SA MA 1 2 3 4 5 Sr. No. PTN No. Marks ObtainedHaseebPirachaNoch keine Bewertungen

- Fesco Online Bill January 2Dokument1 SeiteFesco Online Bill January 2HaseebPirachaNoch keine Bewertungen

- Result of The Exam Held On 18.12.2021-19.12.2021 in Lahore B2Dokument1 SeiteResult of The Exam Held On 18.12.2021-19.12.2021 in Lahore B2HaseebPirachaNoch keine Bewertungen

- Result of The Exam Held On 18.12.2021-19.12.2021 in Lahore B2Dokument1 SeiteResult of The Exam Held On 18.12.2021-19.12.2021 in Lahore B2HaseebPirachaNoch keine Bewertungen

- b2 Karachi Result 21.01.2022Dokument1 Seiteb2 Karachi Result 21.01.2022HaseebPirachaNoch keine Bewertungen

- Result of The Exam Held On 08.01.22-09.01.2022 in NUML B1Dokument2 SeitenResult of The Exam Held On 08.01.22-09.01.2022 in NUML B1HaseebPirachaNoch keine Bewertungen

- Fesco Online Bill January 2Dokument1 SeiteFesco Online Bill January 2HaseebPirachaNoch keine Bewertungen

- Fesco Online Bill January 2Dokument1 SeiteFesco Online Bill January 2HaseebPirachaNoch keine Bewertungen

- Complete Postcode List For Pakistan: Listed in Postcode Order From 10010 To 97320Dokument38 SeitenComplete Postcode List For Pakistan: Listed in Postcode Order From 10010 To 97320allah ditta shafiNoch keine Bewertungen

- Fluid Mechanics 101: Calculators & ToolsDokument11 SeitenFluid Mechanics 101: Calculators & ToolsHaseebPirachaNoch keine Bewertungen

- Fesco Online Bill January 1Dokument1 SeiteFesco Online Bill January 1HaseebPirachaNoch keine Bewertungen

- Ausschreibung Helmut-Schmidt-Programm enDokument7 SeitenAusschreibung Helmut-Schmidt-Programm enGemechuNoch keine Bewertungen

- FESCO GST No. Bill DetailsDokument1 SeiteFESCO GST No. Bill DetailsHaseebPirachaNoch keine Bewertungen

- Complete Postcode List For Pakistan: Listed in Postcode Order From 10010 To 97320Dokument38 SeitenComplete Postcode List For Pakistan: Listed in Postcode Order From 10010 To 97320allah ditta shafiNoch keine Bewertungen

- FESCO GST No. Bill DetailsDokument1 SeiteFESCO GST No. Bill DetailsHaseebPirachaNoch keine Bewertungen

- Fesco Online Bill January 1Dokument1 SeiteFesco Online Bill January 1HaseebPirachaNoch keine Bewertungen

- Fesco Online Bill January 2Dokument1 SeiteFesco Online Bill January 2HaseebPirachaNoch keine Bewertungen

- Faisalabad Electric Supply Company: Say No To CorruptionDokument2 SeitenFaisalabad Electric Supply Company: Say No To CorruptionHaseebPirachaNoch keine Bewertungen

- Faisalabad Electric Supply Company: Say No To CorruptionDokument2 SeitenFaisalabad Electric Supply Company: Say No To CorruptionHaseebPirachaNoch keine Bewertungen

- Fesco Online BillDokument2 SeitenFesco Online BillHaseebPirachaNoch keine Bewertungen

- University of Engineering and Technology, Lahore Department of Electrical EngineeringDokument6 SeitenUniversity of Engineering and Technology, Lahore Department of Electrical EngineeringZbNoch keine Bewertungen

- X710-XXV710-XL710 Feature Summary Rev3.9Dokument22 SeitenX710-XXV710-XL710 Feature Summary Rev3.9nakhleNoch keine Bewertungen

- 4rth LectureDokument10 Seiten4rth LectureAHMED DARAJNoch keine Bewertungen

- Galaxy Owners Manual DX2547Dokument12 SeitenGalaxy Owners Manual DX2547bellscbNoch keine Bewertungen

- An SDR Radio TelescopeDokument15 SeitenAn SDR Radio TelescopekleephNoch keine Bewertungen

- Primasat I LL enDokument2 SeitenPrimasat I LL enNasruddin,S.SosNoch keine Bewertungen

- DSB-SC Lab Report on Carrier SuppressionDokument8 SeitenDSB-SC Lab Report on Carrier SuppressionaravindsnistNoch keine Bewertungen

- User Guide Fu-05B 0.5W FM Transmitter User Guide For 05B 0.5W FM Transmitter FOR 05B 0.5W FM TransmitterDokument4 SeitenUser Guide Fu-05B 0.5W FM Transmitter User Guide For 05B 0.5W FM Transmitter FOR 05B 0.5W FM Transmitterc.tiana.rabaryNoch keine Bewertungen

- ANT-ATR451703-0604 DatasheetDokument2 SeitenANT-ATR451703-0604 DatasheetDris AkliNoch keine Bewertungen

- Interference Based Channel Allocation: Security LevelDokument23 SeitenInterference Based Channel Allocation: Security Levelvkatiyar_3Noch keine Bewertungen

- Sbaa 385 ADokument9 SeitenSbaa 385 AKRISHNA KUMAR ANoch keine Bewertungen

- The Transportation Lag: X (T) X (T-X (S) X(S)Dokument9 SeitenThe Transportation Lag: X (T) X (T-X (S) X(S)ashish guptaNoch keine Bewertungen

- OPT5548TS Modulator PDFDokument6 SeitenOPT5548TS Modulator PDFJefersson Eduardo Sanchez DiazNoch keine Bewertungen

- Toyota Audio Component Service Manual CQ-JT1010X CQ-JS6910X Radio With Cassette Tape Player and CDokument42 SeitenToyota Audio Component Service Manual CQ-JT1010X CQ-JS6910X Radio With Cassette Tape Player and CAdan DariasNoch keine Bewertungen

- Rotate Quattro Long Neck 40mm LNBDokument2 SeitenRotate Quattro Long Neck 40mm LNBCostel MoraruNoch keine Bewertungen

- MOBILE COMMS PROJECT ON WIRELESS TECH & CELLULAR GENERATIONSDokument47 SeitenMOBILE COMMS PROJECT ON WIRELESS TECH & CELLULAR GENERATIONSSUMASRI MNoch keine Bewertungen

- L13Dokument29 SeitenL13ShreyaNoch keine Bewertungen

- 602-LTE ENB System Counter Description - pkg2.5.0 - V2.0Dokument359 Seiten602-LTE ENB System Counter Description - pkg2.5.0 - V2.0tooma123Noch keine Bewertungen

- 555 Timer 40khz IRDokument2 Seiten555 Timer 40khz IRapi-3712130Noch keine Bewertungen

- Performance Analysis of Wired, Wireless and Optical Network Using NS2Dokument7 SeitenPerformance Analysis of Wired, Wireless and Optical Network Using NS2Editor IJRITCCNoch keine Bewertungen

- Gigaset SE567 WLAN DSLDokument7 SeitenGigaset SE567 WLAN DSLvAnTos100% (1)

- Multi Stage AmplifiersDokument9 SeitenMulti Stage AmplifiersMuhammed ThameemNoch keine Bewertungen

- RF Engineer resume objective and experienceDokument6 SeitenRF Engineer resume objective and experienceRavindra Pal ChandelNoch keine Bewertungen

- Spaun Sparos 609: Who Could Ask For More?Dokument6 SeitenSpaun Sparos 609: Who Could Ask For More?Alexander WieseNoch keine Bewertungen

- 3G Wireless Evolution to WCDMADokument39 Seiten3G Wireless Evolution to WCDMAUsman GulNoch keine Bewertungen

- L L A FD GH GH G: Outdoor Propagation ModelsDokument14 SeitenL L A FD GH GH G: Outdoor Propagation ModelsAANCHALNoch keine Bewertungen

- Chapter 3Dokument46 SeitenChapter 3Tewodros ShegawNoch keine Bewertungen

- Econdary Urveillance Adar Irborne Eather Adar: S S R (SSR) & A W R (AWR)Dokument18 SeitenEcondary Urveillance Adar Irborne Eather Adar: S S R (SSR) & A W R (AWR)H R VALA100% (1)