Beruflich Dokumente

Kultur Dokumente

Simulation and Optimisation of An Anaerobic Digester For Wastewater Treatment and Methane Production

Hochgeladen von

Lee Jun HuiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Simulation and Optimisation of An Anaerobic Digester For Wastewater Treatment and Methane Production

Hochgeladen von

Lee Jun HuiCopyright:

Verfügbare Formate

Simulation and Optimisation

of an Anaerobic Digester for

Wastewater Treatment and Methane Production

Kamran Khammadov [00859689], Yue Zheng Neo [00636426], Jun Hui Lee [00876672]

Abstract: This paper deals with the optimisation and cal- dynamics of the process components, and thus is adopted as

ibration of a two-reaction model of anaerobic digestion. A the primary operational strategy. To overcome the inherent

steady-state optimisation of the digester dilution rate was problem of instability, it is necessary to model, simulate and

carried out to obtain optimum values for bacteria concen- optimise such anaerobic digesters.

trations, which were used in the dynamic optimisation of The paper is organised as follows. The first section in-

the digester start-up process. Additional control of the volves modelling, simulation and dynamic optimisation of

digester alkalinity and a constraint on the methane frac- the process with the aid of GAMS and gPROMS. The sec-

tion were then added to refine the optimisation. The re- ond section focuses on enhancing the calibration of the

sults of 4 days of experiments in a 1-m3 digester were

model proposed by [1].

then used to improve the calibration of the model through

the conduct of a general sensitivity analysis to identify the

model parameters to be refined. MODELLING, SIMULATION AND OPTIMISATION OF

Keywords: dynamic optimisation; sensitivity analysis; AN ANAEROBIC DIGESTER

parameter estimation

Equations of a Dynamic Mass-Balance Model

INTRODUCTION Based on the paper [1], the dynamic mass-balance model of

an anaerobic digester is represented by Eqs. (1) to (6):

The anaerobic wastewater treatment, despite many of its

advantages over conventional aerobic wastewater treatment, dX 1

1 D X 1 (1)

has some potential limitations. One of them is the problem dt

of stability, or lack thereof, which makes it particularly im- dX 2

portant to implement an efficient control strategy. 2 D X 2 (2)

dt

Based on the work of Bernard et al. [1], the anaerobic di- dZ

gestion process consists of two reactions involving acido- D Z in Z (3)

dt

genic bacteria X1 and methanogenic bacteria X2: dS1

D S1in S1 k1 1 X 1 (4)

dt

Acidogenesis k1S1 X1 + k2S2 + k4CO2 (r1 = 1 X1)

dS2

D S2in S 2 k2 1 X 1 k3 2 X 2 (5)

Methanisation k3S2 X1 + k5CO2 + k6CH4 (r2 = 2 X2) dt

dC

We considered an upflow anaerobic fixed-bed digester fed D Cin C qC k4 1 X 1 k5 2 X 2 (6)

dt

with industrial wine distillery wastewater similar to the one

described in [1]. It is assumed to be a continuous stirred-

with

tank reactor such that the biomass is uniformly distributed.

S1

First, X1 consumes the organic substrate S1 and produces 1 1max (7)

CO2 and volatile fatty acid S2. S2 is mainly composed of S1 K S 1

acetate and is assumed to behave as pure acetate. Then, X2 S2

2 2 max (8)

consumes S2, forming CO2 and methane. Both gases are the S2

S2 K S 2 2

main components of the outlet gas and their flow rates are KI 2

denoted by qC and qM respectively. 1 and 2 are the specific qC k L a C S 2 Z K H PC (9)

growth rates respectively. The total alkalinity Z, or the sum

of dissociated acids in the medium, can be used for monitor- 2 4 K H PT C S2 Z

PC (10)

ing or even as a control strategy for the plant. The dilution 2K H

rate of the reactor D, which represents the ratio of the influ- k6

C S2 Z K H PT 2 X 2 (11)

ent flow rate to the reactor volume, directly influences the kL a

KHAMMADOV ET AL.: ANAEROBIC DIGESTION MODELLING 1

This model can exhibit multiple steady states. Based on Digester Dilution Rate for Optimal Start-Up via

the paper [1], the system of Eqs. (1) and (4) corresponds to Piecewise-Constant Control Parameterisation

a classical chemostat model with Monod-type kinetics,

which has two steady states: a trivial washout steady state A dynamic optimisation problem was formulated to deter-

mine the optimal digester dilution rate in order for the two

( X1 0 and S1 S1in ) which is unstable, and a non-trivial

biomass concentrations to reach 0.196 g/L and 0.0702 g/L

steady state which is stable. The system composed of Eqs. respectively (as determined earlier for the case of 80% min-

(2) and (5) is a chemostat model with Haldane-type kinetics, imum COD abatement) in minimal time, using the same

which has three steady states: one non-trivial and locally nomenclature used by Bernard et al. [1]:

stable, one non-trivial and unstable, and one trivial and sta-

ble washout state ( X 2 0 and S2 S2in ). min tf

D ( t ), 0 t tf

The existence of multiple steady states have several prac-

tical implications. For instance, the presence of washout 0.01

0.01

arising from multiplicity imposes constraints on the start-up

and control strategies required to maintain the system at a 40

s.t. Kr D Q F, (0)

desired state [2]. The start-up conditions will affect the yield 0

or selectivity of the desired product [2]. Different initial 0

conditions could lead to different steady states [2]. Hence,

50

the initial guesses for the variables must be informed and

X 1 (tf ) 0.196

realistic to obtain a non-trivial steady state which will gen-

X 2 (tf ) 0.0702

erate values that can be used in the subsequent dynamic

optimisations. 0 D (t ) 1

The problem was implemented in gPROMS using a

Optimal Dilution Rate to Maximise Methane Produc- piecewise-constant control parameterisation over 10 equi-

tion Under Steady-State Conditions distant stages. The solution (Fig. 1) is as follows, each stage

lasting 2.65 days for a total duration of 26.5 days:

Here, we considered a digester fed with industrial wine dis-

tillery wastewater with the following average compositions: 0.775/day 0/day 0.0553/day 0.248/day

0.256/day 0.2555/day 0.250/day 0.229/day

S1in 5 g L1 S2in 0 mmol L1 0.247/day 0/day

Cin 50 mmol L1 Z in 40 mmol L1

0.8

An unconstrained optimisation was performed using

GAMS to obtain the optimal dilution rate of 0.347/day in 0.6

order to maximise methane production. This produced a

D (d1)

constant 4.489 mmol/L per day of methane, a steady-state

acidogenic bacteria concentration of 0.180 g/L, a steady- 0.4

state methanogenic bacteria concentration of 0.0570 g/L and

a corresponding COD abatement of 72.3%.

0.2

A repeated optimisation with the imposed constraint of

80% minimum COD abatement was carried out, giving an

optimal dilution rate of 0.262/day, a steady-state acidogenic 0.0

bacteria concentration of 0.196 g/L, a steady-state methano- 0 10 20 30

t (days)

genic bacteria concentration of 0.0702 g/L and a methane Figure 1. Optimal solution for minimum-time start-up of the

output of 4.174 mmol/L per day. digester using the initial control parameterisation.

The lower dilution rate and methane production show that

a trade-off has to be made in order to meet the stricter COD

abatement condition. Refining Control Parameterisation

The control formulation was refined by changing the piece-

wise-constant control parameterisation over 10 equidistant

stages to a piecewise-linear control parameterisation over

100 stages. The optimal solution is shown in Fig. 2, with a

new minimum time of 26.4 days.

KHAMMADOV ET AL.: ANAEROBIC DIGESTION MODELLING 2

This is because a fine grid for the discretisation of the the optimal solution is to such modelling inaccuracies. To

control vector in time enhances the quality of the control assess the sensitivity of the optimal solution obtained to the

strategy. However, a fine grid also has adverse impact on uncertainties associated with 1max , 2max , X 1 (0) and

the computational effort [3]. Hence, to limit the computa- X 2 (0) , we re-determined the optimal digester dilution rate,

tional effort, the optimisation was solved using a piecewise-

with each parameter or initial condition adjusted upwards

linear control parameterisation over 10 equidistant stages

by 10% from its nominal value one by one. As the optimal

(coarse grid) first. When this optimisation has reached a

solution is a variation of dilution rate with time which

plateau, then a fine grid refinement is applied to achieve

makes it difficult to directly compare the change in dilution

better performance in terms of smoother control arcs and an

rate profile following a 10% increment in the value of the

improved performance index [3].

parameter or initial condition, we decided to use the objec-

1.0 tive function, i.e. the time horizon, as the basis for compari-

D (d1) or X1 (g/L) or X2 (g/L) or yM

6 son instead. For each parameter or initial condition, the sen-

sitivity index, SI, was computed as follows:

0.8

S1 (g/L) or S2 (mmol/L)

5

tf t

SI f 10tf

0.6 4 p p 0.1

3 The results are presented in Fig. 3. Note that the sensitivi-

0.4

ty indices are actually negative, i.e. an increase in the value

2

of the parameters or initial conditions results in a corre-

0.2 sponding decrease in minimal time required for start-up.

1

However, for comparison purposes, the absolute values

0.0 0 have been used in the plot instead. It is evident that the key

0 10 20 30 parameter influencing D and hence tf the most is 1max . On

t (days)

D X1 X2 the other hand, the optimal strategy is relatively insensitive

yM S1 S2 to uncertainties in the other three parameters.

This means that it is important to determine 1max as pre-

Figure 2. Optimal solution for minimum-time start-up of the

cisely as possible, minimising its uncertainty as far as pos-

digester using the refined control parameterisation.

sible, to ensure that the optimal strategy is robust. This is

The optimal solution consists of three arcs. In the first arc, because a mere 10% increase in 1max would result in a sig-

the dilution rate remained constant at 1/day. In the second nificant reduction in minimal time required, which means

arc, the dilution rate decreased to 0.043/day, and increased that the existing control structure is no longer the most effi-

thereafter to 0.276/day, and then decreased gradually to cient and cost-effective strategy if the actual value of 1max

0.17/day. Finally, in the third arc, the dilution rate decreased

is indeed 10% higher than its current estimated value.

sharply to a constant 0/day.

The optimal control strategy can be interpreted as follows.

16

In the first reaction of the process, S1 was consumed to pro-

duce X1 and S2. Therefore, the dilution rate took its highest 14

value in the first arc to supply S1. However, since the high 12

dilution rate caused X2 to decrease, the dilution rate had to 10

be reduced in the second arc to ensure that X2 was able to

SI

8

reach its desired steady-state value at the end of the time

horizon. The fluctuations observed in the second arc en- 6

sured that X1 and X2 increased gradually towards their de- 4

sired values at the end. In the last arc, the dilution rate was

2

zero since S1 and S2 had reached sufficient values to in-

crease X1 and X2 to their steady-state values. 0

1max 2max X1 X2

p

Sensitivity Analysis

Figure 3. Sensitivity index of the optimal solution to uncer-

As a large degree of uncertainty is typically associated with tainties (+10%) in the parameters/initial conditions.

bioprocess models, it is important to check how sensitive

KHAMMADOV ET AL.: ANAEROBIC DIGESTION MODELLING 3

Nevertheless, a comparison of the control trajectories for mal digester alkalinity for the two biomass concentrations to

the cases where 1max was at its nominal value and when reach their target values in minimal time, while keeping the

1max was 10% higher (Fig. 3) indicates very little differ- methane fraction in the biogas above 50% vol at all times:

ence between the two in terms of control values and control min tf

D ( t ), 0 t tf

structure, except the minimal time required, as evidenced by Z (t )

the close overlap between both profiles for most part of the

0.01

time horizon. This means that only slight changes need to be 0.01

made towards the end of the time horizon to further opti-

mise the control strategy in response to the uncertainty as- 40

s.t. Kr D Q F, (0)

sociated with 1max . This should not incur too significant a 0

0

cost in practice.

50

1.0 X 1 (tf ) 0.196

X 2 (tf ) 0.0702

0.8

0 D (t ) 1

0 Z (t ) 100

D (d1)

0.6

PC (t )

0.5 for all t , except t 0

PT (t )

0.4

The optimal solutions of the two controls, namely the di-

0.2 lution rate and alkalinity feed concentration, are shown in

Fig. 5, while the responses of the key variables, biomass

0.0 concentrations and methane fraction, are shown in Fig. 6.

0 10 20 30

t (days)

1.0 70

1max = 1.2 1max = 1.32

65

0.8

Figure 4. Optimal control strategy for 1max at nominal value

and 10% higher. 60

Zin (mmol/L)

0.6

D (d1)

55

Methane Composition of Biogas during Optimal

0.4

Start-Up 50

The methane composition of the biogas produced during 0.2

45

optimal start-up as determined earlier using a piecewise-

linear control parameterisation over 100 equidistant stages 0.0 40

is shown in Fig. 2. 0 10 20 30

Given that a typical methane composition for the biogas t (days)

of a healthy digester is between 40% and 60% vol, under D Zin

the current control, the biogas reached a healthy methane Figure 5. Optimal solution with dynamic adjustment of dilu-

composition only after 15.92 days, or after about 60% of tion rate and digester alkalinity.

minimum-time start-up of the digester. The time elapsed

before the desired methane fraction was achieved was

deemed too long and the control strategy was inefficient.

Digester Dilution Rate and Alkalinity for Optimal

Start-Up While Maintaining Healthy Methane Com-

position

The dynamic optimisation formulation earlier was modified

to determine the optimal digester dilution rate and the opti-

KHAMMADOV ET AL.: ANAEROBIC DIGESTION MODELLING 4

Table I. Influent flow rate and composition.

0.20 1.0

Period (day) 0.000 0.266 1.266 2.362 4.000

Flow rate (L/h) 8.0 47.0 47.0 9.0

0.16 0.8

CODin (g/L) 18.5 18.5 37.0 18.5

X1 (g/L) or X2 (g/L)

VFAin (mmol/L) 103 103 206 103

TICin (mmol/L) 9 9 18 9

0.12 0.6 Zin (mmol/L) 98 98 195 98

yM

0.08 0.4

Simulation of Experiment and Comparison with

Available Measurements

0.04 0.2

The model was simulated based on the influent conditions

0.00 0.0 reported in Table I and using the parameter values estimated

0 10 20 30 in [1]. The initial measurement values of S1, S2, C and Z

t (days) were used as initial conditions for the simulation, providing

X1 X2 yM four of the six initial conditions required by the model. The

Figure 6. System response to dynamic optimisation of dilu- remaining two initial conditions have been estimated by

tion rate and digester alkalinity. calculating the values of X1 and X2 that would produce re-

sponse trajectories most similar to those of the experimental

A comparison of these results with those obtained in Fig.

measurements. Fig. 7 represents the simulation results

2 indicates a slight difference in the behaviour of dilution

alongside the experimental data.

rate, due to the introduction of one new control and the me-

thane fraction constraint. The control arc had a similar over- 12 150

all shape, but the dilution rate took on the extreme values of 8 100

S2 (mmol/L)

S1 (g/L)

0 and 1 within the first 6 days as a result of the variation of

4 50

alkalinity. Between days 10 and 12, the maintenance of the

constraint on methane fraction caused the dilution rate to 0 0

0 1 2 3 4 0 1 2 3 4

deviate significantly from the stable value of around 0.2 to t (days) t (days)

180 180

again take on extreme values.

140 160

The methane fraction in the biogas however displays an Z (mmol/L)

C (mmol/L)

140

100

entirely different behaviour from that in Fig. 2, with a sharp 120

60 100

initial increase followed by a steady drop to reach the min-

20 80

imum value dictated by the imposed constraint. Apart from 0 1 2 3 4 0 1 2 3 4

t (days) t (days)

a sharp deviation between days 10 and 12, the methane frac-

7.6

tion was then maintained at this minimum value of 0.5 until 7.4

it increased slightly to 0.6 at the end of the time period. This

pH

7.2

7.0

is in contrast with the behaviour seen in Fig. 2, where the

6.8

methane fraction decreased to a minimum value of around 6.6

0 1 2 3 4

0.2 before increasing gradually to reach a maximum value t (days)

that did not exceed 0.6.

Figure 7. Comparison between simulation results and meas-

urements for S1, S2, C, Z and pH.

CALIBRATION OF AN ANAEROBIC DIGESTION

MODEL USING EXPERIMENTAL DATA

The model correctly reproduces the general trend of the

response trajectories, with particularly good agreement seen

In the second part of the project, we wished to improve the for digester alkalinity, Z. Although the agreement is less

calibration of the model of anaerobic digestion proposed by close for predictions of S1 and S2, their maximum and min-

[1]. We considered a set of real experimental data generated imum values obtained from the simulation correspond well

on the same 1,000 L up-flow anaerobic fixed-bed digester with those in the experimental data. On the other hand, the

as in [1]. Due to the packing and the biomass colonisation simulated minimum values of C and pH differ from experi-

inside the digester, the effective liquid volume was estimat- mental measurements significantly, displaying inadequacies

ed to be about 720 L for this experiment. in the model. This can be attributed to insufficient refine-

The influent flow rate and composition during this 4-day ment of the parameter values or inaccurate specification of

experiment are summarised in Table I. initial conditions.

KHAMMADOV ET AL.: ANAEROBIC DIGESTION MODELLING 5

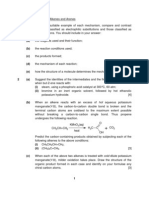

1.5 7

6

1.0

5

4

0.5

3

SIS1

SIS2

0.0 2

1

-0.5

0

-1

-1.0

-2

-1.5 -3

0.3 0.5

0.0

0.0

-0.3

SIX1

SIX2

-0.5

-0.5

-0.8

-1.0 -1.0

1.0 0.5

0.8

0.6 0.0

0.4

-0.5

0.2

SIC

SIZ

0.0

-1.0

-0.2

-0.4 -1.5

-0.6

-0.8 -2.0

Figure 8. Sensitivity for the model parameters. The mean changes of S1, S2, X1, X2, C and Z are represented with respect to a

10% increase in the values of the kinetic, hydrodynamic and stoichiometric parameters.

Local Sensitivity Analysis of Response Trajectories parameter must be integrated over the time horizon in order

to obtain the sensitivity indices as follows:

In order to obtain better agreement between the model and t f y p

experimental data, a refinement of the experimental parame- 0 p y dt

ters can be carried out. However, it is important to first con- SI y tf

duct a sensitivity analysis of the response trajectories to the 0 dt

model parameters as the model contains a large number of This integral can be approximated by discretising the time

parameters and not all of them can be estimated accurately horizon into N intervals and computing the average change:

from the available experimental data. y p

Sensitivity indices for the quantities S1, S2, X1, X2, C and Z N p y

were calculated with respect to small variations in the kinet- SI y

N

ic parameters 1max, KS1, 2max, KS2, KI2 and kLa, the hydro- This above equation was applied to the six quantities and

dynamic parameter , and the stoichiometric parameters k1, 13 parameters, and the results are presented in Fig. 8. It can

k2, k3, k4, k5 and k6. Due to the dynamic nature of the model, be seen that the parameter which plays the largest role in

the change in a quantity resulting from a small change in a influencing the model is , with the largest magnitude of

KHAMMADOV ET AL.: ANAEROBIC DIGESTION MODELLING 6

sensitivity index across all the quantities; this is because it Furthermore, a comparison with experimental data shows

affects the dynamics of the entire model. The other parame- that the new parameters only improve the agreement of the

ters that display a high sensitivity index are 1max and 2max model to experimental measurements to a limited extent, as

as they affect the rates of production and consumption of it can be seen from Fig. 9 that the new simulation results do

S1/X1 and S2/X2 respectively, and k1 and k3 which have a not fit the measurement data much better than with the orig-

strong influence on the gaseous flow rates. inal parameters.

From this sensitivity analysis, it can be concluded that the

12 150

parameters to be selected for estimation are , 1max, 2max,

S2 (mmol/L)

8 100

k1 and k3. Five parameters have been selected as there are

S1 (g/L)

five quantities of which experimental measurements are 4 50

available, and there is likely to be sufficient data to estimate 0

0

these five parameters 0 1 2

t (days)

3 4 0 1 2

t (days)

3 4

180 180

140 160

Z (mmol/L)

Parameter estimation and statistical analysis

C (mmol/L)

140

100

120

60

Using gPROMS, the five parameters as mentioned earlier 100

20 80

were re-estimated for the given set of experimental data. 0 1 2 3 4 0 1 2 3 4

t (days) t (days)

The results are presented in Table II.

7.4

Table II. Nominal values and new estimates of parameters.

7.1

pH

Parameter Unit Nominal value New estimate 6.8

0.5 0.167 6.5

1max d1 1.2 0.360 0 1 2

t (days)

3 4

2max d1 0.74 0.432

42.14 155 Figure 9. Comparison between simulation results with esti-

k1

mated parameters and measurements for S1, S2, C, Z and pH.

k3 mmol/g 268 135

An analysis of the residuals (Fig. 10) also indicates that

The new estimates of the parameters are of somewhat the the estimation of the model parameters may be inadequate

same order of magnitude as their nominal values reported in as the residuals are spread out over a wide range of values

[1]. But this is insufficient to ascertain the robustness of the and are far from zero for all the measured quantities with

parameter estimation, which requires the relevant estimation the exception of alkalinity, Z.

statistics as summarised in Table III.

Table III. Parameters and their estimation statistics. 40

20

Parameter Value 95% Confidence 95% t-value

Residuals

interval 0

0.167 0.0208 8.02 0 1 2 3 4

1max 0.360 0.0541 6.66 -20

2max 0.432 0.0430 10.1 -40

k1 155 23.9 6.49

-60

k3 135 18.6 7.25 t (days)

S1 S2 C Z pH

Reference t-value (95%): 1.65

Figure 10. Plot of residuals of the five measured quantities.

The 95% confidence intervals for all the estimated param-

eters are smaller than their estimated values. Their 95% t- Hence it can be established that it is not possible to obtain

values are larger than the reference t-value (95%) of 1.65. a significantly better estimate of the model parameters using

This implies that the amount of experimental data available the given set of experimental data, as a statistical analysis of

is sufficient to estimate the five parameters required. simulation results with newly estimated parameters does not

However, the confidence ellipsoids of all possible pairs of produce results which suggest an increase in agreement with

parameters are quite large around the estimated point, ex- the experimental data. This is due to insufficient measure-

cept for 1max and k1 . This implies that if another identical ment data, where key quantities such as X1 and X2 are not

experiment is carried out and parameter estimation repeated, available leading to significant uncertainties in the specifi-

the estimates may not be easily reproducible. cation of initial conditions.

KHAMMADOV ET AL.: ANAEROBIC DIGESTION MODELLING 7

CONCLUSION X1 concentration of acidogenic bacteria (g/L)

X2 concentration of methanogenic bacteria (g/L)

In this paper, we have tried to address the problem of insta-

yM methane fraction

bility commonly associated with the anaerobic wastewater

Z , Z in total alkalinity (mmol/L)

treatment process. In the first part of the project, we focused

Z0 anion concentration (mmol/L)

on modelling, simulation and optimisation of the process.

The optimal dilution rate profile was determined in order for

fraction of bacteria in the liquid phase

mean fraction of acidogenic bacteria

the digester to reach the desired steady-state biomass con- 1 specific growth rate of acidogenic bacteria (d1)

centrations in minimum time. The control parameterisation

1max maximum acidogenic bacteria growth rate (d1)

was further fine-tuned and the resultant optimal control

2 specific growth rate of methanogenic bacteria (d1)

strategy was interpreted from a physical process perspec-

2max maximum methanogenic bacteria growth rate (d1)

tive. The sensitivity of the optimal solution to uncertainties

vector of the process variables

in the model parameters was assessed. A new control strate-

gy which involved the dilution rate and the alkalinity was

devised to maintain the methane fraction in the biogas at REFERENCES

above 50% vol at all times.

In the second part of the project, the calibration of the [1] O. Bernard, Z. Hadj-Sadok, D. Dochain, A. Genovesi, and

model of anaerobic digestion was further improved. The J.-P. Steyer. Dynamical model development and parameter

model was simulated and compared with the available ex- identification for an anaerobic wastewater treatment pro-

cess. Biotechnology & Bioengineering, 75:424438, 2001.

perimental data. A sensitivity analysis for the response tra- [2] Y.-S. Chien. A study for multiple steady states of biochem-

jectories was performed. The five most sensitive parameters ical reactions under substrate and product inhibition. Bio-

were re-estimated to improve the robustness of the model, chemical Engineering Journal, 6:5157, 2000.

but to little avail. [3] H. Hadiyanto, D.C. Esveld, R.M. Boom, G. van Straten,

A.J.B. van Boxtel. Control vector parameterization with

sensitivity based refinement applied to baking optimization.

Food and Bioproducts Processing, 86:130141, 2008.

NOMENCLATURE

B bicarbonate concentration (mmol/L)

C, Cin total inorganic carbon concentration (mmol/L)

D dilution rate (d1)

d/dt time derivative

k1 yield for substrate degradation

k2 yield for VFA production (mmol/g)

k3 yield for VFA consumption (mmol/g)

k4 yield for CO2 production (mmol/g)

k5 yield for CO2 consumption (mmol/g)

k6 yield for CH4 production (mmol/g)

K a , Kb equilibrium constants (mol/L)

KH Henrys constant (mmol/L per atm)

kL a liquid-gas transfer coefficient (d1)

K I2 inhibition constant (mmol/L)

KS1 half-saturation constant (g/L)

KS2 half-saturation constant (mmol/L)

p parameter

PC CO2 partial pressure (atm)

PT total pressure (atm)

qC carbon dioxide flow rate (mmol/L per d)

qM methane flow rate (mmol/L per d)

r1 , r2 , r3 reaction rates (d1)

S1 , S1in organic substrate concentration (g/L)

S 2 , S2in volatile fatty acids concentration (mmol/L)

SI sensitivity index

t time (d)

tf final time (of time horizon) (d)

KHAMMADOV ET AL.: ANAEROBIC DIGESTION MODELLING 8

Das könnte Ihnen auch gefallen

- Vectors Revision Exercise (Solutions)Dokument10 SeitenVectors Revision Exercise (Solutions)Lee Jun HuiNoch keine Bewertungen

- Kinetics Revision Worksheet 2 (Solutions)Dokument8 SeitenKinetics Revision Worksheet 2 (Solutions)Lee Jun HuiNoch keine Bewertungen

- Kinetics Questions (Solutions)Dokument11 SeitenKinetics Questions (Solutions)Lee Jun HuiNoch keine Bewertungen

- Chemical Energetics Revision Exercise SolutionsDokument13 SeitenChemical Energetics Revision Exercise SolutionsLee Jun HuiNoch keine Bewertungen

- Recurrence Relations With SolutionsDokument13 SeitenRecurrence Relations With SolutionsLee Jun HuiNoch keine Bewertungen

- Merton's NormsDokument5 SeitenMerton's NormsLee Jun HuiNoch keine Bewertungen

- 2017 H2 Chemistry Paper 1 Suggested SolutionsDokument5 Seiten2017 H2 Chemistry Paper 1 Suggested SolutionsLee Jun HuiNoch keine Bewertungen

- 2011 H2 Chemistry Paper 1 Suggested SolutionsDokument18 Seiten2011 H2 Chemistry Paper 1 Suggested SolutionsLee Jun HuiNoch keine Bewertungen

- Organic Chemistry Structured Questions (Topical)Dokument28 SeitenOrganic Chemistry Structured Questions (Topical)Lee Jun Hui100% (1)

- RI (JC) Probability Tutorial Challenging QuestionsDokument4 SeitenRI (JC) Probability Tutorial Challenging QuestionsLee Jun HuiNoch keine Bewertungen

- RI (JC) Vectors/Induction Tutorial QuestionsDokument4 SeitenRI (JC) Vectors/Induction Tutorial QuestionsLee Jun HuiNoch keine Bewertungen

- 2011 H2 Chemistry Paper 3 Suggested SolutionsDokument7 Seiten2011 H2 Chemistry Paper 3 Suggested SolutionsLee Jun Hui0% (1)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Caribbean Career Opportunity - Cayman Island Water Authority - Plant Operator Cayman Brac Plant Operator (Overseas)Dokument1 SeiteCaribbean Career Opportunity - Cayman Island Water Authority - Plant Operator Cayman Brac Plant Operator (Overseas)Cawasa St-LuciaNoch keine Bewertungen

- The Little MermaidDokument6 SeitenThe Little MermaidBobbie LittleNoch keine Bewertungen

- Shock Cat 2009Dokument191 SeitenShock Cat 2009gersonplovasNoch keine Bewertungen

- IOTA Observers Manual All PagesDokument382 SeitenIOTA Observers Manual All PagesMarcelo MartinsNoch keine Bewertungen

- Computer ArchitectureDokument46 SeitenComputer Architecturejaime_parada3097100% (2)

- MMG 302Dokument164 SeitenMMG 302piyush patilNoch keine Bewertungen

- How To Deliver A Good PresentationDokument9 SeitenHow To Deliver A Good PresentationGhozi Fawwaz Imtiyaazi LabiibaNoch keine Bewertungen

- Congenital Abnormalities of The Female Reproductive TractDokument14 SeitenCongenital Abnormalities of The Female Reproductive TractMary SheshiraNoch keine Bewertungen

- Board of DirectorsDokument2 SeitenBoard of DirectorsjonahsalvadorNoch keine Bewertungen

- Fin 320 - Individual AssignmentDokument14 SeitenFin 320 - Individual AssignmentAnis Umaira Mohd LutpiNoch keine Bewertungen

- The Exchange Student (Dedicated To Rotary International)Dokument163 SeitenThe Exchange Student (Dedicated To Rotary International)Nikita100% (1)

- Kalsi P S - Organic Reactions and Their Mechanisms 5eDokument26 SeitenKalsi P S - Organic Reactions and Their Mechanisms 5eeasy BooksNoch keine Bewertungen

- LAC BrigadaDokument6 SeitenLAC BrigadaRina Mae LopezNoch keine Bewertungen

- Recruitment of Officers in Grade B' (General) - DR - By-2019Dokument2 SeitenRecruitment of Officers in Grade B' (General) - DR - By-2019Shalom NaikNoch keine Bewertungen

- Differentialequations, Dynamicalsystemsandlinearalgebra Hirsch, Smale2Dokument186 SeitenDifferentialequations, Dynamicalsystemsandlinearalgebra Hirsch, Smale2integrationbyparths671Noch keine Bewertungen

- FeCl3 Msds - VISCOSITYDokument9 SeitenFeCl3 Msds - VISCOSITYramkesh rathaurNoch keine Bewertungen

- Concept of InsuranceDokument4 SeitenConcept of InsuranceNazrul HoqueNoch keine Bewertungen

- Deviation Control MethodsDokument4 SeitenDeviation Control MethodsLazuardhy Vozicha FuturNoch keine Bewertungen

- Annual Premium Statement: Bhupesh GuptaDokument1 SeiteAnnual Premium Statement: Bhupesh GuptaBhupesh GuptaNoch keine Bewertungen

- Personal Tutor: 11 + MATHS Test 6Dokument10 SeitenPersonal Tutor: 11 + MATHS Test 6siddhant4uNoch keine Bewertungen

- Service Installation Rules For Connection To Electricity Network (See Chapter 14)Dokument83 SeitenService Installation Rules For Connection To Electricity Network (See Chapter 14)EduardoMorcilloNoch keine Bewertungen

- Ingles - 1 - Bach - Modulo - 2 (20 - 21)Dokument32 SeitenIngles - 1 - Bach - Modulo - 2 (20 - 21)John Alex Almeida50% (2)

- Everyday Life - B1 - ShoppingDokument7 SeitenEveryday Life - B1 - ShoppingAmi BarnesNoch keine Bewertungen

- Clostridium BotulinumDokument37 SeitenClostridium Botulinummaria dulceNoch keine Bewertungen

- SOLIDWORKS 2022 Whitepaper UsingDesignAutomationtoReduceCostsIncreaseProfitability FinalDokument10 SeitenSOLIDWORKS 2022 Whitepaper UsingDesignAutomationtoReduceCostsIncreaseProfitability FinalAlba R.Noch keine Bewertungen

- SFA TRAINING MODULE Week 1Dokument14 SeitenSFA TRAINING MODULE Week 1Ivan Perez100% (1)

- Fluid Mechanics and Machinery Laboratory Manual: by Dr. N. Kumara SwamyDokument4 SeitenFluid Mechanics and Machinery Laboratory Manual: by Dr. N. Kumara SwamyMD Mahmudul Hasan Masud100% (1)

- Noten - Detective Conan - Case ClosedDokument2 SeitenNoten - Detective Conan - Case ClosedBLU-NYTE GamingNoch keine Bewertungen

- ITR-C (Instrument) 16cDokument1 SeiteITR-C (Instrument) 16cMomo ItachiNoch keine Bewertungen

- Product Management Software Director in Austin TX Resume Chad ThreetDokument2 SeitenProduct Management Software Director in Austin TX Resume Chad ThreetChad ThreetNoch keine Bewertungen