Beruflich Dokumente

Kultur Dokumente

Contract Documents

Hochgeladen von

oaklamOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Contract Documents

Hochgeladen von

oaklamCopyright:

Verfügbare Formate

AFRICAN CIRCLE SNAKE ISLAND PLANT LAGOS Document Number

TECHNICAL CONTRACT DOCUMENTATION / BOQ FOR THE ACPML-102-HAR-CTR-001001_00

REPAIR OF CORRODED TANK AT THE SNAKE ISLAND FACILITY Revision : 00 Status : IFI Approval Class : -

Document Type : RPT System / Subsystem : REPAIR Zone :ONE - Rev. Date : 08 August-2017

Page 1 of 28

TECHNICAL CONTRACT DOCUMENTATION /

UNPRICED BOQ FOR THE REPAIR AND

REFURBISHMENT OF CORRODED TANK AT THE

SNAKE ISLAND FACILITY

Rev. Satus Rev. Date Revision Mem o Prepared by Checked by Approved by

00 IFI 26-Jul-2017 ISSUE FOR INFORMATION OKEY. A KANAYO A. OYENIKE S.

This document has been generated by an Electronic Document System. When printed it is considered as a form of information only copy. The

controlled copy is the screen version and it is the holders responsibility that he/she holds the latest valid version.

This document is the property of African Ci rcle Pollution Management Limited,

It must not be reproduced or transmitted to others without written authorization from the Company.

ACPML-102-HAR-CTR-001001_00 TECHNICAL CONTRACT DOCUMENTATION / BoQ FOR THE REPAIR AND

REFURBISHMENT OF THE CORRODED TANK AT THE SNAKE ISLAND FACILITY

AFRICAN CIRCLE SNAKE ISLAND PLANT LAGOS Document Number :

TECHNICAL CONTRACT DOCUMENTATION/ BOQ FOR THE ACPML-102-HAR-CTR-001001_00

REPAIR OF CORRODED TANK AT THE SNAKE ISLAND Revision : 00 Status : IFI Approval Class : -

FACILITY

Document Type : CAL System / Subsystem : 101 Zone : - Rev. Date : 08 August 2017

Page 2 of 17

REVISION DESCRIPTION

Rev. index Revision Description

00 Issue for Information

This document is the property of African Circle Pollution Management Limited,

It must not be reproduced or transmitted to others without written authorization from the Company.

ACPML-101-HAR-RPT-008002_00 TECHNICAL CONTRACT DOCUMENTATION / BOQ FOR THE REPAIR AND

REFURBISHMENT OF THE CORRODED TANK AT THE SNAKE

ISLAND FACILITY

AFRICAN CIRCLE SNAKE ISLAND PLANT LAGOS Document Number :

TECHNICAL CONTRACT DOCUMENTATION/ BOQ FOR THE ACPML-102-HAR-CTR-001001_00

REPAIR OF CORRODED TANK AT THE SNAKE ISLAND Revision : 00 Status : IFI Approval Class : -

FACILITY

Document Type : CAL System / Subsystem : 101 Zone : - Rev. Date : 08 August 2017

Page 3 of 17

CONTENTS

1 GENERALITIES 4

1.1 ABSTRACT 4

2 S COPE 4

2.1 DETAILS OF THE WORK AND PROCEDURE TO BE CARRIED OUT 4

2.2 SCOPE OUTLINE 4

2.3 GENERA L CONDITIONS 5

3 REFERENCES 6

4 ABBREVIATIONS AND DEFINITIONS 7

4.1 REQUEST ED DOCUMENTATIONS: 7

4.2 SPLIT OF SCOPE AND RESPONSIBILITIES 8

5 MILES TONE 9

5.1 ENGINEERING 9

5.2 PROCUREMENT 10

5.3 PRE-FABRICAT ION 10

5.4 PRE-MOBILIZATION INSPECTION 11

5.5 EQUIPMENTS, M AT ERIALS AND TOOLS M OBILIZATION 11

5.6 PERSONNEL M OBILIZATION 11

5.7 SIT E W ORKS 11

5.8 QA/QC AND NDT INSPECT ION 11

5.9 A NT I CORROSION W ORKS 12

5.10 PRE-COMMISSIONING 12

5.11 REPORT ING 12

5.12 DEMOBILIZATION 12

6 GUIDELINES 13

6.1 W ORKING LANGUAGE 13

6.2 W ORK PAT T ERN 13

6.3 LOGIST ICS (A CCOMMODATION, CAT ERING, TRANSPORT ) 13

6.4 M INUT ES OF M EETING 13

6.5 APPENDICES 13

6.6 TECHNICA L, HSE AND DOCUMENTATION CONTACTS 13

6.7 RATE 14

6.8 TIME OF START / COMPLETION 14

6.9 GUARANTEE 14

6.10 SAFETY & HOUSEKEEPING 14

ANNEXURE 1 : SCHEDULE OF QUANTITIES / PRICE SCHEDULE 14

6.11 FORCE MAJEURE: 15

6.12 ARBITRATION AND LEGAL JURISDICTION: 15

6.13 FAILURE AND TERMINATION: 15

6.14 WORK SCHEDULE 16

6.15 TANK DRAWINGS 17

This document is the property of African Circle Pollution Management Limited,

It must not be reproduced or transmitted to others without written authorization from the Company.

ACPML-101-HAR-RPT-008002_00 TECHNICAL CONTRACT DOCUMENTATION / BOQ FOR THE REPAIR AND

REFURBISHMENT OF THE CORRODED TANK AT THE SNAKE

ISLAND FACILITY

AFRICAN CIRCLE SNAKE ISLAND PLANT LAGOS Document Number :

TECHNICAL CONTRACT DOCUMENTATION/ BOQ FOR THE ACPML-102-HAR-CTR-001001_00

REPAIR OF CORRODED TANK AT THE SNAKE ISLAND Revision : 00 Status : IFI Approval Class : -

FACILITY

Document Type : CAL System / Subsystem : 101 Zone : - Rev. Date : 08 August 2017

Page 4 of 17

1 GENERALITIES

1.1 ABSTRACT

AFRICAN CIRCLE POLLUTION MANAGEMENT LIMITED subsequently referred to as COMPANY is a

private Nigerian company, licensed to operate MARPOL port reception facilities for the collection, storage

and processing of ship generated waste on behalf of the Nigerian Ports Authority on a BOT (build-operate-

transfer) contract, wishes to repair and refurbish one of her treatment tanks, in one of their plants located at

Snake Island, Lagos. To achieve this aim, COMPANY therefore engaged the services of HARCON

CONTRACTING ENERGY COMPANY LIMITED subsequently referred to as CONTRACTOR who

conducted a site visit on the 20th of June, 2017 to determine the current status of the the received SGS

report. After inspection and analysis, the following were recommended:

Replace the entire Tank roof plates.

Repair / Replace corroded section of the roof railing, Grit blast same and apply suitable coating

system to arrest corrosion propagation

Install vacuum breaker on the tank to prevent overpressure / collapse

Perform sectional replacement of the bottom plate sections of the Tank with severe internal pitting

corrosion and hole.

Replace the sump flange gasket

Grit blast the tank support base plates and apply suitable coating system to arrest active corrosion

and prevent further corrosion attack.

Replace instrumentations on the tanks

2 SCOPE

2.1 DETAILS OF THE WORK AND PROCEDURE TO BE CARRIED OUT

The tank cover plates which is completely corroded shall be removed by the contractor, completely

refabricated and replaced. The bottom section of the tank shall be sectionally reapired in all areas identified

to be corroded. The waste material generated from the work has to be bagged and shifted to designated

location as directed by the plant supervisor in charge on daily basis. The legs of tanks, pedestal etc need

also to be repaired and coated. The patch worked area of the tank has to be thoroughly cleaned after patch

working and is to be painted with one coat of chemical resistant primer and two coats of chemic al

resistantant paint of appropriate colors in accordance with project specifications.

2.2 SCOPE OUTLINE

CONTRACTOR shall perform the works specified in this section in conformity with the applicable drawings,

specifications, guidelines and work scope describe herein. CONTRACTOR shall limit himself only to this

Scope of Work, and any modification or extra work demanded by COMPANY will be confirmed in writing by

COMPANY before execution.

The scopes outline is as follows:

Site surveys and develop site survey report and perform follow up works of the surveys

Provision of project management and engineering

This document is the property of African Circle Pollution Management Limited,

It must not be reproduced or transmitted to others without written authorization from the Company.

ACPML-101-HAR-RPT-008002_00 TECHNICAL CONTRACT DOCUMENTATION / BOQ FOR THE REPAIR AND

REFURBISHMENT OF THE CORRODED TANK AT THE SNAKE

ISLAND FACILITY

AFRICAN CIRCLE SNAKE ISLAND PLANT LAGOS Document Number :

TECHNICAL CONTRACT DOCUMENTATION/ BOQ FOR THE ACPML-102-HAR-CTR-001001_00

REPAIR OF CORRODED TANK AT THE SNAKE ISLAND Revision : 00 Status : IFI Approval Class : -

FACILITY

Document Type : CAL System / Subsystem : 101 Zone : - Rev. Date : 08 August 2017

Page 5 of 17

Preparation of all necessary procedures, calculation, list of utilities, work packs, Job Risk

Assessments, Permit To Works, schedule development, certificates and qualifications,

equipment calibrations, reports. Some of which includes but not limited to:

PQR

WPS

WQT

Provision of qualified and certified personnel

Provision of all necessary Regulatory permissions, Visa Applications and air flight tickets

where applicable, road transportation, accommodation and security for mobilization and

demobilization of his personnel including his sub-contractors from/to abroad,

Preparation of transportation, accommodation and security support for his personnel

including his sub-contractor while in Nigeria

Preparation of valid personnel documentations, technical certifications including HSE

certifications required to perform the job at Snake Island as required on COMPANY HSE

Procedure

Mobilization/Demobilization of all CONTRACTOR and his Sub-CONTRACTORs personnel

to work location (snake Island) unless stated otherwise

Prepare all required HSE protective equipments, tools, materials and consumables required

by his personnel and his Sub-CONTRACTOR as per COMPANY standard/ specific

requirement for the tank repairs activities.

Advice and assist COMPANY to prepare mandatory spare parts if required,

Mobilization/Demobilization of all equipments, materials, tools and consumables belong to

CONTRACTOR and its Sub-CONTRACTOR to/from work location at snake Island ONNE.

Site supervision and effective work during pre- tank repairs activities (surveys, actual

measurements, scaffolding, man-holes unbolting)

Site supervision and effective work during tank repairs activities

Site supervision and effective work post tank repairs activities

Prepare and distribute Minute of Meetings, daily reports, weekly reports and As -Built dossier

Temporary removal of spools with the associated valves and re-instatement after tank

repairs.

Cleaning and Gas Freeing of the tank prior to dismantling

Repair of Defective Welds on the tank bottoms

Sectional Dismantling and Reconstruction / repair of the tank bottoms.

Complete Reconstruction of tank Fixed Roofs

Perform all necessary testing as per applicable code viz:

NDT

Radiographs

MPI

Hydrostatic Testing

Leak Testing where applicable

All anti corrosion works including but not limited to Blasting and Coating with a qualified

three coat system to be reviewed and approved by COMPANY.

2.3 GENERAL CONDITIONS

2.3.1 The work as related to bottom of the tank shall be started one at a time, done continuously and completed in

the shortest period.

2.3.2 The waste /cut pieces generated from the work shall be cleaned on daily basis. The location for disposing

the waste material will be shown by the plant supervisor

2.3.3 The CS plate/ structurals required for the work shall be supplied by the contractor only in straight lengths.

2.3.4 The contractor shall bend the plate as per the requirement either for the cylindrical or conical portion, and the

angles or other structurals for the stiffeners. The contractor can do the bending works at site or at his

workshop as the situation demands. The CS Sheet material shall be bent on area basis and the structurals

bent on length basis.

This document is the property of African Circle Pollution Management Limited,

It must not be reproduced or transmitted to others without written authorization from the Company.

ACPML-101-HAR-RPT-008002_00 TECHNICAL CONTRACT DOCUMENTATION / BOQ FOR THE REPAIR AND

REFURBISHMENT OF THE CORRODED TANK AT THE SNAKE

ISLAND FACILITY

AFRICAN CIRCLE SNAKE ISLAND PLANT LAGOS Document Number :

TECHNICAL CONTRACT DOCUMENTATION/ BOQ FOR THE ACPML-102-HAR-CTR-001001_00

REPAIR OF CORRODED TANK AT THE SNAKE ISLAND Revision : 00 Status : IFI Approval Class : -

FACILITY

Document Type : CAL System / Subsystem : 101 Zone : - Rev. Date : 08 August 2017

Page 6 of 17

2.3.5 The period of contract shall be three months from the date of placement of order. However work has to be

done continuously once site is handed over to contractor.

2.3.6 Any damage caused to nearby equipments in the course of repair has to be repaired free of cost by t he

contractor.

2.3.7 Contractor shall quote for all the works in the price schedule attached. The successful bidder will be the

lowest considering all the works together. However the COMPANY is not obliged to award the contract to the

lowest bidder

2.3.8 Offer once submitted will be final and no further amendments will be tolerated.

3 REFERENCES

Reference number Title

API 579-1/ASME FFS-1 Fitness For Service

API RP 580 Risk Based Inspection

Recommended Rules for Design and Construction of Large, Welded, Low -

API STD 620

Pressure Storage Tanks

API STD 650 Welded Tanks For Oil Storage

API STD 653 Tank Inspection, Repair, Alteration and Reconstruction

ASME BPVC Section II Materials

ASME BPVC Section V Non Destructive Testing

ASME BPVC Section IX Non Destructive Welding

ASME B31.3 Process Piping / ASME Code for Pressure Piping

Standard Test Method for Conductimetric Analysis of Water Soluble Ionic

ASTM D4940

Contamination of Blast Cleaning Abrasives

Standard Practice for Discontinuity (Holiday) Testing of Nonconductive Protective

ASTM D5162

Coating on Metallic Substrates

Paints and varnishes - Corrosion protection of steel structures by protective paint

ISO 12944 (Parts 1; 3; 4; 7; 8)

systems - Parts 1; 3; 4; 7; 8

Corrosion protection of steel structures by protective paints systems - Assessment

ISO 16276 (Parts 1; 2) of, and acceptance criteria for, the adhesion/cohesion (fracture strength) of a

coating - Parts 1; 2

Paints and varnishes - Corrosion protection of steel structures by protective paint

ISO 19840 systems - Measurement of, and acceptance criteria for, the dry-film thickness of

coating on rough surfaces

ISO 8501 (Parts 1; 3) Preparation of steel substrates before application of paints and related products.

Visual assessment of surface cleanliness - Parts 1; 3

ISO 8502 (Parts 3; 6; 9) Preparation of steel s ubstrates before application of paints and related products.

Tests for the assessment of surface cleanliness - Parts 3; 6; 9

ISO 8503 (Parts 1; 2) Preparation of steel substrates before application of paints and related products -

Surface roughness characteristics of blast-cleaned steel substrates - Parts 1; 2

RAL 840 HR Colors standard

SSPC SP1 Solvent Cleaning

SGS Tank NDT, integrity assessment and calibration Inspection Report for one

TIT/62/ACL/17/LA/001 Storage tank

This document is the property of African Circle Pollution Management Limited,

It must not be reproduced or transmitted to others without written authorization from the Company.

ACPML-101-HAR-RPT-008002_00 TECHNICAL CONTRACT DOCUMENTATION / BOQ FOR THE REPAIR AND

REFURBISHMENT OF THE CORRODED TANK AT THE SNAKE

ISLAND FACILITY

AFRICAN CIRCLE SNAKE ISLAND PLANT LAGOS Document Number :

TECHNICAL CONTRACT DOCUMENTATION/ BOQ FOR THE ACPML-102-HAR-CTR-001001_00

REPAIR OF CORRODED TANK AT THE SNAKE ISLAND Revision : 00 Status : IFI Approval Class : -

FACILITY

Document Type : CAL System / Subsystem : 101 Zone : - Rev. Date : 08 August 2017

Page 7 of 17

4 ABBREVIATIONS AND DEFINITIONS

Abbreviation Definition

API American Petroleum Institute

ASME American Society of Mechanical Engineer

COMPANY African Circle Pollution Management Limited

CONTRACTOR Harcon Contracting Energy Company Limited

MPI Magnetic Particle Inspection

NDE / NDT Non Destructive Examination / Non Destructive Test

PIC Person In Charge

PQR Procedure Qualification Record

ACPML African Circle Polution Management Limited

QA/QC Quality Assurance / Quality Control

SGSISNL SGS Inspection Services Nigeria Lim ited

UTM Ultrasonic Thickness Measurement

CONTRACTOR Tank fabricator / Repair Contractor

WPS Welding Procedure Specification

WQT Welders Qualification Test

4.1 REQUESTED DOCUMENTATIONS :

Requested Documentations:

The following documentation shall be prepared by CONTRACTOR and submitted to COMPANY for validation before

commencement of fabrication works:

A detailed work schedule,

QA/QC documentation (this shall include but not be limited to the following documents):

Project Quality Plan (PQP) in accordance with the requirement of ISO 9001 or equivalent,

Inspection and Test Plans (ITP). All workshop inspection records to be submitted to COMPANY on

completion of works,

Mill certificate for raw materials and consumables (electrodes, paints and chemicals etc) to be retained

by CONTRACTOR, and to be submitted to COMPANY on requests.

Calibration Certificates of Equipments and Instruments be available and to be submitted to TUPNI on

requests

Welding documentation (this shall include but not be limited to the following documents):

Welding Procedure Specification (WPS),

Procedure Qualification Records (PQR),

Welder Certificate (Valid and Approved by third party),

Weld Maps with particular attention to position of Golden Welds

NDT Plan. All NDT inspection records to be submitted to COMPANY on completion of works.

Works procedures (this shall include but not be limited to the following documents):

Fabrication procedure,

Scaffolding Procedures,

Blasting and Painting Procedures,

As much as applicable, COMPANY will provide all piping and fitting materials including installation materials

required. However, COMPANY may ask CONTRACTOR to provide and procure piping, fitting and installation

materials if required and the conditions of materials provided by CONTRACTOR shall be found satisfactory

(complete with certificate acceptable to COMPANY).

This document is the property of African Circle Pollution Management Limited,

It must not be reproduced or transmitted to others without written authorization from the Company.

ACPML-101-HAR-RPT-008002_00 TECHNICAL CONTRACT DOCUMENTATION / BOQ FOR THE REPAIR AND

REFURBISHMENT OF THE CORRODED TANK AT THE SNAKE

ISLAND FACILITY

AFRICAN CIRCLE SNAKE ISLAND PLANT LAGOS Document Number :

TECHNICAL CONTRACT DOCUMENTATION/ BOQ FOR THE ACPML-102-HAR-CTR-001001_00

REPAIR OF CORRODED TANK AT THE SNAKE ISLAND Revision : 00 Status : IFI Approval Class : -

FACILITY

Document Type : CAL System / Subsystem : 101 Zone : - Rev. Date : 08 August 2017

Page 8 of 17

4.2 SPLIT OF SCOPE AND RESPONSIBILITIES

Activity CPY CTR

- Initial PID mark up/ isolation/ spading plan Battery limit of SERVICE

- Intrusive / Non-Intrusive Vessel Cleaning Scope of Work O

- Originial Drawings and Mark Up drawings if necessary

SITE SURVEYS

- Validating main equipments, auxiliary equipments, tools, materials and

consumables required for the scope

- Validating HSE equipments, tools and consumables to support the

intervention

- Validating spade locations, conditions of bolts/ nuts and flanges

- Validating the requirement of access platform and load bearing scaffold to

O

remove and reinstate the blinds/ spades

- Validating the Laydown area, equipment spread and transfer method

- Validating lifting plan, lifting gears (manual & pneumatic), and lifting beams

available and its SWL

- Validating the method of vessel cleaning and draining, hose size, where to

route the hoses and all arrangements related to that to empty tanks where

necessary

DELIVERABLES

Engineering

'- Prepare Un-Bolting Plan

- Prepare Work Package documents (Procedure, Method statement,

Certificate, Calibration, approvals) of each service

- Prepare Job Risk Assessments

- Prepare Permit To Work documents

O

- Prepare welding map, WPS and PQR

- Prepare NDE/ NDT plans as per applicable code

- Prepare Final Dossier for intervention / Repairs

- Prepare drawings / PID Mark up for

- Prepare correct rigging tools (correct types, SWL and quantity)

- Prepare Equipment Calibrations and Ceritification

- Prepare Flange Identification Tag with tie wrap O

- Develop HSE deliverables for the intervention (JRA, HSE Procedure, etc) O

Manpower Estimation, allocation and mob-demob schedule O O

Consumables types, estimation and mob-demob schedule O

Site Survey report and feedback on COMPANYs Scope of Work O

All Equipments, Tools, Material and Consumables to perform the service O

Reinstatement consumables (Gaskets, Rings, Studbolts, Clamps, etc) O

Valves where applicable O

Temporary spools and prefabrication (include workshop NDE, hydrostatic

Procurement O

testing, flushing and transportation protection)

Necessary additional equipment to perform the SERVICE O

Storage cabin of materials onsite O

Permit for Outdoor light for night shift operation (ATEX certified) if

O O

applicable

Consumables definition, quantity and allocation O

Test Tape, Tags, plastic wrap O

Consumables

Supply of diesel fuel for Equipment operation O

Supply of lubricants of contractor equipments and tools O

This document is the property of African Circle Pollution Management Limited,

It must not be reproduced or transmitted to others without written authorization from the Company.

ACPML-101-HAR-RPT-008002_00 TECHNICAL CONTRACT DOCUMENTATION / BOQ FOR THE REPAIR AND

REFURBISHMENT OF THE CORRODED TANK AT THE SNAKE

ISLAND FACILITY

AFRICAN CIRCLE SNAKE ISLAND PLANT LAGOS Document Number :

TECHNICAL CONTRACT DOCUMENTATION/ BOQ FOR THE ACPML-102-HAR-CTR-001001_00

REPAIR OF CORRODED TANK AT THE SNAKE ISLAND Revision : 00 Status : IFI Approval Class : -

FACILITY

Document Type : CAL System / Subsystem : 101 Zone : - Rev. Date : 08 August 2017

Page 9 of 17

Supply of water for cleaning and Testing O

Supply of instrument air/ utility air for equipment and tools operation where

O

applicable

Supply of electricity for operation and for light (night shift) O

Certification of all personnel O

Certification of all equipments, tools and external testing eqiupments

Certification

Certification of all Lifting Tools O

Certification of all containers O

Supply of all facility and lifting equipments (cabin, container, b ox, slings, O

lifting lug, shackles, etc)

Pre-mobilization Inspection (COMPANY to lead, CONTRACTOR to

O O

Freight Forwarding prepare)

Transportation from/to Origin to/from Quayside O

Loading/Unloading at Quayside and onsite (COMPANY to perform,

O O

CONTRACTOR to monitor or supervise)

Gas Depressurisation, draining of liquids, hydrocarbon gas concentration

O O

check

Equipment preparation, spading / despading, tagging of flanges, etc (all

O

scope as per SOW)

Preparation Work Inspection O O

Activity with Scaffolders (COMPANY & CONTRACTOR to supervise) O O

Isolation (process, mechanical, electrical) O

Scaffolding and Load bearing preparation O

Site Office and Tool Room (Test Cabin) O

Equipment Lay-Down Area allocation and arrangement O O

Facilities

Scaffolding, Cranes (incl. riggers) and associated Technician O

Food, Freshwater O

Transportation, accommodation, security, etc of CONTRACTOR's

O

expatriates

Transportation of personnel to Site / base O

Indirect Transportation of personnel from NAF Base to COMPANY site (AKPO O

FPSO)

Transportation of equipment and tanks from Site to Snake Island (and vice

O

versa)

5 MILESTONE

5.1 ENGINEERING

The following deliverables shall be prepared by CONTRACTOR and submitted to COMPANY before

commencement of site works:

During Site Survey and Engineering phase, CONTRACTOR shall:

o Review and fully comprehend of this Scope Of Work (COMPANY spading plan, Isol ation Plan, Tank

Intrusive and Non-Intrusive Plan, Sectional Piping Replacement, Valves Replacement, etc).

This document is the property of African Circle Pollution Management Limited,

It must not be reproduced or transmitted to others without written authorization from the Company.

ACPML-101-HAR-RPT-008002_00 TECHNICAL CONTRACT DOCUMENTATION / BOQ FOR THE REPAIR AND

REFURBISHMENT OF THE CORRODED TANK AT THE SNAKE

ISLAND FACILITY

AFRICAN CIRCLE SNAKE ISLAND PLANT LAGOS Document Number :

TECHNICAL CONTRACT DOCUMENTATION/ BOQ FOR THE ACPML-102-HAR-CTR-001001_00

REPAIR OF CORRODED TANK AT THE SNAKE ISLAND Revision : 00 Status : IFI Approval Class : -

FACILITY

Document Type : CAL System / Subsystem : 101 Zone : - Rev. Date : 08 August 2017

Page 10 of 17

o Review and asses the list of main equipments, auxiliary equipments, tools, materials and

consumables required for the scope.

o Review and asses the list of HSE equipments, tools and consumables to support the intervention.

o Review and asses HSE plan for the intervention. Prepare JRA draft.

o Review and asses equipments spread on available lay down area

o Review and asses scaffolding requirement, load bearing requirement, and prepare a scaffolding

schedule

o Review and asses lifting plan, lifting gears (manual & pneumatic), and lifting beams as may be

required on site.

o Review and asses the method of tank cleaning and draining, hose size, where to route the hoses

and all arrangements related to that.

o Review and asses the location of sectional small bore pipe replacement, prepare mark up drawing.

o Review the manpower requirements and duration to complete the job. Develop a level 3 work

schedule in coordination with COMPANY Planning Engineer

The engineering milestone shall be completed with the issuance of deliverables as below:

o Site Survey Report

o All engineering deliverables (procedure, method statement, mark up drawing, material list,

equipment list, consumables list, tools list, etc)

o All HSE deliverables (Job Risk Assessment, valid offshore work permit, valid yearly medical

certificate, valid BOSIET/ HUET certificate, swimming passport etc)

o All QA/QC deliverables (Certificates, Calibrations, etc)

o Permit To Work and all work pack documents attached to it.

o Detail of procurement plan, pre-mob inspection, mobilization plan (single or multiple) and

demobilization plan

o Detailed site work schedule (Level 3 hourly basis)

o List of personnel and rotation schedule (including mob-demob plan)

o Organization chart and CVs of personnel

o Details of equipments, tools materials and consumables to be used on site

o Scaffolding plan and schedule

o Lifting Plan includes with all lifting tools certificates

o Equipment Spread Plan on site (mark up drawing with equipment foot print)

To carry out these tasks, adequate preparation has to be put in place by the CONTRACTOR with the help

from COMPANY teams.

5.2 PROCUREMENT

COMPANY shall be in charge for procurement of all installation materials (gas ket, rings, bolts, clamps,

Flanges) and replacement materials (small bore pipe, valve and fittings) unless stated otherwise.

Materials required for tank repair shall be part of COMPANY supply items unless stated otherwise in

writing.

CONTRACTOR shall be in charge for procurement or rental of all required equipments, tools, materials and

consumables related to his service.

5.3 PRE-FABRICATION

Pre-fabrication may be required for some piping replacements, tank roof plate rolling / folding to form the

cone shape, tank internals baffles. A mark up drawing shall be developed by CONTRACTOR in

coordination with COMPANY.

All CONTRACTOR deliverables (WPS, PQR, ITP, Hydrostatic Plan, Air Flushing procedure, Blasting and

Painting procedure, etc) shall be submitted to COMPANY for review and approval prior the execution of

pre-fabrication.

This document is the property of African Circle Pollution Management Limited,

It must not be reproduced or transmitted to others without written authorization from the Company.

ACPML-101-HAR-RPT-008002_00 TECHNICAL CONTRACT DOCUMENTATION / BOQ FOR THE REPAIR AND

REFURBISHMENT OF THE CORRODED TANK AT THE SNAKE

ISLAND FACILITY

AFRICAN CIRCLE SNAKE ISLAND PLANT LAGOS Document Number :

TECHNICAL CONTRACT DOCUMENTATION/ BOQ FOR THE ACPML-102-HAR-CTR-001001_00

REPAIR OF CORRODED TANK AT THE SNAKE ISLAND Revision : 00 Status : IFI Approval Class : -

FACILITY

Document Type : CAL System / Subsystem : 101 Zone : - Rev. Date : 08 August 2017

Page 11 of 17

COMPANY QA/QC personnel will be present at CONTRACTORs premises as detailed on Inspection and

Testing Plan to witness pre-fabrication process by CONTRACTOR.

5.4 PRE-MOBILIZATION INSPECTION

Before mobilization of CONTRACTORs equipments, tools, materials and consumables to COMPANYs

Site at Snake Island, COMPANY will organize a multi-discipline inspection and visit at CONTRACTOR yard

to ensure the equipments, tools, materials and consumables has been tested, calibrated, certified and

confirmed good to use.

Any HSE findings or technical findings will be informed to CONTRACTOR and CONTRACTOR shall rectify

the findings As soon as reasonable practicable, or find an equal replacement to avoid losing time prior

mobilization.

5.5 EQUIPMENTS, M ATERIALS AND T OOLS M OBILIZATION

After approval of CONTRACTORs equipments, tools, materials and consumables, CONTRACTOR shall

mobilize it to COMPANYs work location at Snake Island using COMPANYs logistics arrangement.

COMPANY will notify CONTRACTOR the schedule of equipments mobilizations.

5.6 PERSONNEL M OBILIZATION

Prior mobilization, CONTRACTOR personnel must have and submit copy of below documents to

COMPANY:

o Valid temporary work permit to work offshore (TBC)

o Valid yearly medical Fit To Work certificate

o Valid swimming passport / BOSIET/FOET & SAS or STCW 95 certificate

o Valid MEDEVAC/MEDRESCUE Bridging Plan (shall be requested also during initial site visit)

o Valid DPRs OSP (Offshore Safety Passport) (TBC)

Personnel shall come with his PPE (coveralls, safety shoes, eye protection, gloves and helmet). Should

any specific helmet colour coding required by COMPANY to differentiate the CONTRACTORs and

COMPANYs personnel, it shall be communicated properly. CONTRACTOR shall prepare the hard hat

required for the service with correct colour.

5.7 SITE WORKS

Here below are listed pre-requisite before starting any work on COMPANY site:

All Induction to be done when going onboard the COMPANY site for the first time.

The PTW system shall be fully implemented for any works performed by CONTRACTOR in COMPANY

site.

Full PPE are mandatory and CONTRACTOR personnel should arrive on site with their own PPE.

CONTRACTOR should comply with the COMPANY Personal Protective Equipment as detailed on

COMPANY HSE POLICY

To carry out the activity safely, CONTRACTOR personnel shall work closely with COMPANYs field /

Maintenance teams as CONTRACTOR may require input from both parties. No modification shall be made

by CONTRACTOR on their approved work procedure before by COMPANY approval on site. In this case,

all approval shall be known by COMPANYs Engineer / Supervisor In Charge, COMPANYs Site manager /

Repair Coordinator and COMPANY Project Manager.

5.8 QA/QC AND NDT INSPECTION

In principal, CONTRACTOR shall be responsible to Control and Ensure the Quality of his work.

CONTRACTOR shall minimize a repair on each activity, (cutting, alignment, welding, painting, testing, etc).

This document is the property of African Circle Pollution Management Limited,

It must not be reproduced or transmitted to others without written authorization from the Company.

ACPML-101-HAR-RPT-008002_00 TECHNICAL CONTRACT DOCUMENTATION / BOQ FOR THE REPAIR AND

REFURBISHMENT OF THE CORRODED TANK AT THE SNAKE

ISLAND FACILITY

AFRICAN CIRCLE SNAKE ISLAND PLANT LAGOS Document Number :

TECHNICAL CONTRACT DOCUMENTATION/ BOQ FOR THE ACPML-102-HAR-CTR-001001_00

REPAIR OF CORRODED TANK AT THE SNAKE ISLAND Revision : 00 Status : IFI Approval Class : -

FACILITY

Document Type : CAL System / Subsystem : 101 Zone : - Rev. Date : 08 August 2017

Page 12 of 17

However, COMPANY will assign dedicated personnel / team to ascertain CONTRACTORs work has met

COMPANY standard as specified on the contract.

NDE / NDT shall be performed by a third party CONTRACTOR who shall be validated by COMPANY.

5.9 ANTI CORROSION WORKS

CONTRACTOR shall develop a three paint coating system for this scope of work that meets the applicable

codes and standard as listed in section 2 of this document to be applied on the completed repair section of

the tank. Prior to coating, blasting shall be done using blasting grit that is environmentally friendly.

CONTRACTOR may be requested to paint the entire tank after repair to ensure uniformity / consistency.

5.10 PRE-COMMISSIONING

In principal, CONTRACTOR will be in charge for Pre-commissioning of the tank. Before start / hook- up,

Leak Test w will be performed CONTRACTORs third-party Sub-CONTRACTOR or directly under

COMPANY supervision. COMPANY may provide input on this activity when as at necessary.

5.11 REPORTING

CONTRACTOR shall keep continuous record of tank repairs activities and this shall include:

o Minutes of Meeting

o Equipment, Tools, material and consumables procurement and delivery

o Job Log in general, summary of HSE objective

o Disassembly and reassembly log in particular/ activity of the day (daily report)

o Methods used,

o Progress,

o Anomalies,

o Forecast of the next days work

o Personal on site / POB

o Final Dossier

CONTRACTOR shall supply to COMPANY the above listed documents in their latest version at the end of

the project and issue these records upon completion of the scope of work to the operating team of

COMPANY. COMPANY will provide report template (if no CONTRACTORs standard template used) prior

to mobilization.

5.12 DEMOBILIZATION

CONTRACTOR shall be required to demobilize both personnel and equipment when work is completed to

COMPANY satisfaction and all work areas are cleaned, wastes generated properly disposed and the work

site restored to its original state prior to commencement of work. Details of demobilization plan shall be

arranged by CONTRACTOR in alignment with COMPANY.

For any equipment mobilization and demobilization, CONTRACTOR shall notify COMPANY material

coordinator in order to manage the temporary location on site.

Name Position Phone number Email

Material Coordinator

Material Controller

This document is the property of African Circle Pollution Management Limited,

It must not be reproduced or transmitted to others without written authorization from the Company.

ACPML-101-HAR-RPT-008002_00 TECHNICAL CONTRACT DOCUMENTATION / BOQ FOR THE REPAIR AND

REFURBISHMENT OF THE CORRODED TANK AT THE SNAKE

ISLAND FACILITY

AFRICAN CIRCLE SNAKE ISLAND PLANT LAGOS Document Number :

TECHNICAL CONTRACT DOCUMENTATION/ BOQ FOR THE ACPML-102-HAR-CTR-001001_00

REPAIR OF CORRODED TANK AT THE SNAKE ISLAND Revision : 00 Status : IFI Approval Class : -

FACILITY

Document Type : CAL System / Subsystem : 101 Zone : - Rev. Date : 08 August 2017

Page 13 of 17

6 GUIDELINES

6.1 WORKING LANGUAGE

The working language on the WORKSITE is English and shall be the language for oral and written

communication. CONTRACTORs employees shall be sufficiently proficient in this language to be able to

communicate orally both on routine matters and in emergency situations; they shall be able to read and

understand technical documents, and shall be able to write reports or clear instructions.

6.2 WORK PATTERN

The work pattern of CONTRACTORs employees on COMPANY Sites would be:

Onsite Day Shift normal working hours shall be 07:30hrs to 18:00hrs TBC

6.3 LOGISTICS (ACCOMMODATION, CATERING, T RANSPORT)

At COMPANYs expense, COMPANY shall provide CONTRACTORs employees working on the project at site

(snake island) for the duration of their stay with:

o Offices equipped with computer and telecommunication facilities, for those personnel that require

them.

o Accommodation and related services (food, laundering, cleaning of premises), TBC

o Transport within COMPANY site,

o Transport by COMPANYs approved means of water transportation between the SITE and town for

crew changes / resumption and close of work and during emergency evacuations

6.4 M INUTES OF M EETING

CONTRACTOR shall be responsible for the preparation of the minutes of meeting (MoM) for all meetings held

during the project. All MoM shall be reviewed and approved by COMPANY before they are issued.

6.5 APPENDICES

Reference Number Title Attachment

Tank Drawings

Piping Connection Drawings

6.6 TECHNICAL, HSE AND DOCUMENTATION CONTACTS

Name Position Phone number Email

Head of Construction (PIC)

CONSTRUCTION

Superintendent

This document is the property of African Circle Pollution Management Limited,

It must not be reproduced or transmitted to others without written authorization from the Company.

ACPML-101-HAR-RPT-008002_00 TECHNICAL CONTRACT DOCUMENTATION / BOQ FOR THE REPAIR AND

REFURBISHMENT OF THE CORRODED TANK AT THE SNAKE

ISLAND FACILITY

AFRICAN CIRCLE SNAKE ISLAND PLANT LAGOS Document Number :

TECHNICAL CONTRACT DOCUMENTATION/ BOQ FOR THE ACPML-102-HAR-CTR-001001_00

REPAIR OF CORRODED TANK AT THE SNAKE ISLAND Revision : 00 Status : IFI Approval Class : -

FACILITY

Document Type : CAL System / Subsystem : 101 Zone : - Rev. Date : 08 August 2017

Page 14 of 17

QA/QC Engineer

Operation Safety Leader

Engineering Manager

Lead DCC

6.7 RATE

Contractors are required to quote their most competitive rate in the given price schedule (Annexure 1). The

rate for the fabrication/repair charges should include the cost of dismantling of damaged structural which

need replacement. Rates once quoted will be firm and should remain for t he period of the contract.

6.8 TIME OF START / COMPLETION

The work has to be started within 7 days from the date of acceptance of work order. The work has to start

immediately once the site is handed over to the contractor. From site hand over, the work need to be done

on continuous basis and completed in the minimum time with out causing any hindrance to the p lant

activities. The period of contract is three months from the date of placement of order.

The normal working hours is 07 :30 Hrs 18 :00Hrs on any working day. Any change in the time of

completion must be sought by written request by the contractor well in advance.

6.9 GUARANTEE

The work done by the contractor must be guaranteed against defective workmanship for a minimum period

of one year from the date of completion of the work.

6.10 SAFETY & HOUSEKEEPING

It is the sole responsibility of contractor to carry out the work in an utmost safe manner. Successful

contractor will have to carry out the work as per the rules laid down by ACPML Safety Department. The

necessary safety equipments like safety helmet, shoes, gloves etc has to be provided by the contractor.

The work spot should be cleaned daily and the waste material disposed appropriately to designated area.

1. Annexure 1 : SCHEDULE OF QUANTITIES / PRICE SCHEDULE

S/ Description of Work Estimated Unit Unit Total

NO Quantity Price Amount

(=N=) (=N=)

1 Mobilisation to site of Equipment, LUMP SUM

materials and Personnel

2 Demolition and cutting works at the tank 39 M2

bottom and roof

3 Fabrication and repair works at the tank 10 M2

bottom

4 Fabrication of new Tank Roof, in 76.35 M2

accordance with design and specification

5 NDT Testing LUMP SUM

6 Hydro Testing LUMP SUM

7 Grit blasting and coating LUMP SUM

8 Instrumentation LUMP SUM

This document is the property of African Circle Pollution Management Limited,

It must not be reproduced or transmitted to others without written authorization from the Company.

ACPML-101-HAR-RPT-008002_00 TECHNICAL CONTRACT DOCUMENTATION / BOQ FOR THE REPAIR AND

REFURBISHMENT OF THE CORRODED TANK AT THE SNAKE

ISLAND FACILITY

AFRICAN CIRCLE SNAKE ISLAND PLANT LAGOS Document Number :

TECHNICAL CONTRACT DOCUMENTATION/ BOQ FOR THE ACPML-102-HAR-CTR-001001_00

REPAIR OF CORRODED TANK AT THE SNAKE ISLAND Revision : 00 Status : IFI Approval Class : -

FACILITY

Document Type : CAL System / Subsystem : 101 Zone : - Rev. Date : 08 August 2017

Page 15 of 17

9 Demobilisation LUMP SUM

10 Sub Total

11 Any other Tax and Contingencies

12 GRAND TOTAL

6.11 FORCE MAJEURE:

On account of emergency declared by government, reasons of go slow, strike or lockout at the Contractors

works location, war, civil commotion, fire, storm, flood, acts of God, acts of government, sabotage, riot,

revolution, unforeseen circumstance or other hindrance beyond ones control, there shall be no liability on

the part of the defaulting party for consequent losses.

6.12 ARBITRATION AND LEGAL JURISDICTION:

All disputes or difference whatsoever arising between the parties out of or relating to the supply and

erection of equipments shall be settled through discussions between the authority of ACPML and the

Authorised contact person of the contractor. In case an amicable settlement is not arrived at, the matter will

be settled through The Arbitration and conciliation Act (CAP 19- LFN 1990) which provides for the right to

settle disputes by conciliation. Part II of the Act i.e. Section 37 to 42 and 55 which stipulates detailed

provisions for conciliation. Section 37 also provides that the parties to any agreement may seek amicable

settlement of any dispute in relation to the agreement by conciliation under the provisions of the Act. In

addition, Section 55 provides that parties to an international commercial agreement may agree in writing

that a dispute in relation to the agreement shall be settled by conciliation under the Conciliation Rules set

out in the Third Schedule to the Act10. Rules made there under and/or any statuary modifications or re-

enactment thereof for the time being in force shall apply to such arbitration proceedings. The language of

the arbitration proceedings shall be English. The Contractor shall not in any way delay or default or cause

to delay or default the carrying out of the work by reason of the fact that any matter has been agreed to be

referred to and/or referred to Arbitration.

6.13 FAILURE AND TERMINATION:

If the contractor fails in the performance of the contract in the manner and within the time fixed or there is

likelihood of an anticipatory breach of whole or part of the contract, the Company will have the right to

rescind the contract and have it performed through other agencies at the risk and cost of the contractor.

This document is the property of African Circle Pollution Management Limited,

It must not be reproduced or transmitted to others without written authorization from the Company.

ACPML-101-HAR-RPT-008002_00 TECHNICAL CONTRACT DOCUMENTATION / BOQ FOR THE REPAIR AND

REFURBISHMENT OF THE CORRODED TANK AT THE SNAKE

ISLAND FACILITY

AFRICAN CIRCLE SNAKE ISLAND PLANT LAGOS Document Number :

TECHNICAL CONTRACT DOCUMENTATION/ BOQ FOR THE ACPML-102-HAR-CTR-001001_00

REPAIR OF CORRODED TANK AT THE SNAKE ISLAND Revision : 00 Status : IFI Approval Class : -

FACILITY

Document Type : CAL System / Subsystem : 101 Zone : - Rev. Date : 08 August 2017

Page 16 of 17

6.14 WORK SCHEDULE

This document is the property of African Circle Pollution Management Limited,

It must not be reproduced or transmitted to others without written authorization from the Company.

ACPML-101-HAR-RPT-008002_00 TECHNICAL CONTRACT DOCUMENTATION / BOQ FOR THE REPAIR AND

REFURBISHMENT OF THE CORRODED TANK AT THE SNAKE

ISLAND FACILITY

AFRICAN CIRCLE SNAKE ISLAND PLANT LAGOS Document Number :

TECHNICAL CONTRACT DOCUMENTATION/ BOQ FOR THE ACPML-102-HAR-CTR-001001_00

REPAIR OF CORRODED TANK AT THE SNAKE ISLAND Revision : 00 Status : IFI Approval Class : -

FACILITY

Document Type : CAL System / Subsystem : 101 Zone : - Rev. Date : 08 August 2017

Page 17 of 17

6.15 TANK DRAWINGS

This document is the property of African Circle Pollution Management Limited,

It must not be reproduced or transmitted to others without written authorization from the Company.

ACPML-101-HAR-RPT-008002_00 TECHNICAL CONTRACT DOCUMENTATION / BOQ FOR THE REPAIR AND

REFURBISHMENT OF THE CORRODED TANK AT THE SNAKE

ISLAND FACILITY

Das könnte Ihnen auch gefallen

- Project Close and HandoverDokument4 SeitenProject Close and Handover4chi11esNoch keine Bewertungen

- QCS 2014 - Comparision Review ReportDokument28 SeitenQCS 2014 - Comparision Review ReportJaijeev Pali100% (1)

- Contractual ProcedureDokument44 SeitenContractual Proceduredasun100% (7)

- Seminar International Development FractalTime MDokument26 SeitenSeminar International Development FractalTime MoaklamNoch keine Bewertungen

- Construction PlanDokument45 SeitenConstruction Planoaklam100% (1)

- Inspection of Heat ExchangersDokument20 SeitenInspection of Heat Exchangersadel100% (1)

- VP Director Supply Chain Logistics in United States Resume David StonichDokument2 SeitenVP Director Supply Chain Logistics in United States Resume David StonichDavid StonichNoch keine Bewertungen

- Copper Technology RoadmapDokument50 SeitenCopper Technology RoadmapleniucvasileNoch keine Bewertungen

- Solid Ground CuringDokument2 SeitenSolid Ground Curingbhuvanesh85Noch keine Bewertungen

- Construction ManagerDokument4 SeitenConstruction ManageruygarkoprucuNoch keine Bewertungen

- Final Project Report 1Dokument39 SeitenFinal Project Report 1Praful E. PawarNoch keine Bewertungen

- 20 - RT609 - U - RSD - 001 - A RTA Spare DuctsDokument1 Seite20 - RT609 - U - RSD - 001 - A RTA Spare DuctsanooppattazhyNoch keine Bewertungen

- 6.290 Project Handover Plan TempateDokument6 Seiten6.290 Project Handover Plan Tempatetuanthanh16Noch keine Bewertungen

- Tender Interview Questionnaire 01-Gamuda-ADokument7 SeitenTender Interview Questionnaire 01-Gamuda-Akimura takuyaNoch keine Bewertungen

- Business Development and Marketing ProcedureDokument5 SeitenBusiness Development and Marketing ProcedureTravis Kwentua100% (2)

- Construction Completion Report FormDokument2 SeitenConstruction Completion Report FormAnonymous zwSP5gvNoch keine Bewertungen

- Sub-Contractor Performance Quality Evaluation System (PQeVS)Dokument27 SeitenSub-Contractor Performance Quality Evaluation System (PQeVS)Shilla JasniNoch keine Bewertungen

- 08 Concrete FinishesDokument4 Seiten08 Concrete FinishesChristian HutterNoch keine Bewertungen

- Associate Assessment Submission Document FinalDokument13 SeitenAssociate Assessment Submission Document FinalAshraf MohamedNoch keine Bewertungen

- Attachment 11 Subcontractor Evaluation ReportDokument1 SeiteAttachment 11 Subcontractor Evaluation ReportWANKHAMA100% (1)

- QA-QC Control P1Ch16Dokument8 SeitenQA-QC Control P1Ch16jasolanoroNoch keine Bewertungen

- Construction Contracts: Learning OutcomesDokument29 SeitenConstruction Contracts: Learning Outcomessadaf_gul_7100% (1)

- Unit 8 Project and Programme Management - P2M For Enterprise Innovation StructureDokument12 SeitenUnit 8 Project and Programme Management - P2M For Enterprise Innovation StructurebevinjNoch keine Bewertungen

- Standard Operating ProcedureDokument23 SeitenStandard Operating Procedurezhangj5Noch keine Bewertungen

- Self-Discovery Reflection QuestionsDokument1 SeiteSelf-Discovery Reflection QuestionsSURJIT SINGHNoch keine Bewertungen

- Plinth Beam: S.No. Task Description Duration Plan Start Plan ENDDokument4 SeitenPlinth Beam: S.No. Task Description Duration Plan Start Plan ENDAnushree guptaNoch keine Bewertungen

- CHAPTER-1: Basic of Construction Planning and ManagementDokument3 SeitenCHAPTER-1: Basic of Construction Planning and ManagementmulualemNoch keine Bewertungen

- Cleaner Resume: Name: Felix Ugochukwu RolandDokument4 SeitenCleaner Resume: Name: Felix Ugochukwu RolandMetchidji Armand FuengueNoch keine Bewertungen

- QC Job Descriptions (Overview)Dokument3 SeitenQC Job Descriptions (Overview)George ManuelNoch keine Bewertungen

- MFMF-1-PC-043 Attachment E Safety Plan Rev1Dokument14 SeitenMFMF-1-PC-043 Attachment E Safety Plan Rev1Thomas JohnNoch keine Bewertungen

- Health and Safety Plans For TenderingDokument4 SeitenHealth and Safety Plans For TenderingHesham Hassan100% (1)

- Tepng Onshore Const Itt Project Quality PlanDokument42 SeitenTepng Onshore Const Itt Project Quality PlanTrustEmma50% (2)

- Trans Gulf Electro-Mechanical L.L.C: Request For Information (Rfi)Dokument2 SeitenTrans Gulf Electro-Mechanical L.L.C: Request For Information (Rfi)Thushan MaduNoch keine Bewertungen

- Quality Assessment ProcedureDokument3 SeitenQuality Assessment ProcedureAlina OnţaNoch keine Bewertungen

- Cost Management Plan-Template1Dokument5 SeitenCost Management Plan-Template1Zac Usaf100% (1)

- EPC Schedule May.2021Dokument8 SeitenEPC Schedule May.2021gauravNoch keine Bewertungen

- Primavera P6notes-2020Dokument12 SeitenPrimavera P6notes-2020Faraj MohamedNoch keine Bewertungen

- Job Description: Ambarnath Estimation L1 0 NA Estimation EngineerDokument1 SeiteJob Description: Ambarnath Estimation L1 0 NA Estimation Engineerராபர்ட் ஆன்றோ ரெனிNoch keine Bewertungen

- PDO Material Receipt Document ChecklistDokument1 SeitePDO Material Receipt Document ChecklistJames KentNoch keine Bewertungen

- Chapter 4 Project ExecutionDokument16 SeitenChapter 4 Project ExecutionczuberekNoch keine Bewertungen

- PQPDokument24 SeitenPQPkaandiNoch keine Bewertungen

- PQFDokument544 SeitenPQFjossyjosephNoch keine Bewertungen

- PMI PMP Certification Handbook PDFDokument46 SeitenPMI PMP Certification Handbook PDFIPINoch keine Bewertungen

- Permission To MortgageDokument14 SeitenPermission To MortgageAabad BrandNoch keine Bewertungen

- 10 - PM - Communication ManagementDokument16 Seiten10 - PM - Communication ManagementEmran HossainNoch keine Bewertungen

- Management of Project Communication Pub3711Dokument13 SeitenManagement of Project Communication Pub3711Tsholofelo Majipos StlhanohNoch keine Bewertungen

- 14 Site Office ChecklistDokument1 Seite14 Site Office ChecklistRosli Bin Abdul Shukor100% (2)

- SA2-2375 Risk AssessmentDokument12 SeitenSA2-2375 Risk AssessmentZameer AhmedNoch keine Bewertungen

- PMPDokument26 SeitenPMPvibhu singhNoch keine Bewertungen

- M - Scheme: Full Time, Sandwich & Part Time Course Code: 1010, 2010 & 3010Dokument37 SeitenM - Scheme: Full Time, Sandwich & Part Time Course Code: 1010, 2010 & 3010Vignesh DhuruvanNoch keine Bewertungen

- Check List For Contract ReviewDokument1 SeiteCheck List For Contract ReviewavaisharmaNoch keine Bewertungen

- WMC - Contractor Management StandardDokument19 SeitenWMC - Contractor Management StandardGuntur E. AdiwinataNoch keine Bewertungen

- NANGA CV WaitressDokument2 SeitenNANGA CV WaitresspowellarryNoch keine Bewertungen

- A Full-Day Conference (09:00-18:00 HRS) Date: May 15, 2014 Location: Dubai, UAE Venue: JW Marriott Dubai Address: Abu Baker Al Siddique Road, Hamarain Centre, DeiraDokument6 SeitenA Full-Day Conference (09:00-18:00 HRS) Date: May 15, 2014 Location: Dubai, UAE Venue: JW Marriott Dubai Address: Abu Baker Al Siddique Road, Hamarain Centre, DeirazawadimranNoch keine Bewertungen

- Terms of ReferenceDokument2 SeitenTerms of ReferenceSeble GetachewNoch keine Bewertungen

- 002 Engineering and PM Services PresentationDokument9 Seiten002 Engineering and PM Services PresentationjakalegawaNoch keine Bewertungen

- NIQS BESMM4 SAMPLE BILLDokument116 SeitenNIQS BESMM4 SAMPLE BILLAli Abubakar AuduNoch keine Bewertungen

- 02 INSP 0002 BackHoe CheckDokument1 Seite02 INSP 0002 BackHoe Check89simbu100% (1)

- A. Gis and SWGR: 1. Precast Beam and Wall Panel Erection GIS 2. Hollow Core Slab InstallationDokument4 SeitenA. Gis and SWGR: 1. Precast Beam and Wall Panel Erection GIS 2. Hollow Core Slab InstallationSyed Munawar Ali100% (1)

- Essential Information For IOSH TrainersDokument5 SeitenEssential Information For IOSH TrainersElshan HuseynovNoch keine Bewertungen

- Cost Control Techniques PDFDokument3 SeitenCost Control Techniques PDFHosamMohamedNoch keine Bewertungen

- Introduction To PMBOK - 2014 PDFDokument49 SeitenIntroduction To PMBOK - 2014 PDFNAHNoch keine Bewertungen

- Auditing PresentationDokument95 SeitenAuditing PresentationTaha KhanNoch keine Bewertungen

- Public Consultation A Complete Guide - 2020 EditionVon EverandPublic Consultation A Complete Guide - 2020 EditionNoch keine Bewertungen

- Acpml 101 Har RPT 008005 Analysis of Sgs Report2Dokument19 SeitenAcpml 101 Har RPT 008005 Analysis of Sgs Report2oaklamNoch keine Bewertungen

- ACPML-101-HAR-RPT-008006 Spec Fire Fighting SystemDokument14 SeitenACPML-101-HAR-RPT-008006 Spec Fire Fighting SystemoaklamNoch keine Bewertungen

- Techhnical Report For Cfa PilesDokument2 SeitenTechhnical Report For Cfa PilesoaklamNoch keine Bewertungen

- Acpml 101 Har RPT 008005 Analysis of Sgs Report2Dokument19 SeitenAcpml 101 Har RPT 008005 Analysis of Sgs Report2oaklamNoch keine Bewertungen

- Slide Presentation of Cfa Installation (Benisede) Final 04-04-16-1Dokument33 SeitenSlide Presentation of Cfa Installation (Benisede) Final 04-04-16-1oaklamNoch keine Bewertungen

- SSG-NG01012401-869393-F07-00047 - R01-MDS For Ogbotobo CFA Pile Installation & Testing - RV - 02 - 19.03.16Dokument61 SeitenSSG-NG01012401-869393-F07-00047 - R01-MDS For Ogbotobo CFA Pile Installation & Testing - RV - 02 - 19.03.16oaklamNoch keine Bewertungen

- METHOD Statement For Citadel Fence and Concrete Removal at The IGRF LOPDokument8 SeitenMETHOD Statement For Citadel Fence and Concrete Removal at The IGRF LOPoaklamNoch keine Bewertungen

- Chapter 11 - International Trade. Introduction PDFDokument37 SeitenChapter 11 - International Trade. Introduction PDFLisa OlgaNoch keine Bewertungen

- The Differences Between Galvalume and Galvanized in Metal Roofing ProjectsDokument4 SeitenThe Differences Between Galvalume and Galvanized in Metal Roofing ProjectssaravanakumarpalaniNoch keine Bewertungen

- 7-11 Case Solution Section - B - Group 2Dokument12 Seiten7-11 Case Solution Section - B - Group 2Prashant ChavanNoch keine Bewertungen

- A AaaaaaaDokument8 SeitenA AaaaaaaVani VaniNoch keine Bewertungen

- RisksDokument19 SeitenRisksCUTto1122Noch keine Bewertungen

- Ramset Specifiers Resource Book Ed3 - Brick and Block AnchorDokument13 SeitenRamset Specifiers Resource Book Ed3 - Brick and Block AnchorJoshua Gibbings100% (1)

- Philippine Agribusiness: An Introduction: Vicky GuiebDokument21 SeitenPhilippine Agribusiness: An Introduction: Vicky GuiebMaria Charlene Grace AringoNoch keine Bewertungen

- An Over View of The Godiva Chocolatier Company Marketing EssayDokument10 SeitenAn Over View of The Godiva Chocolatier Company Marketing EssayHND Assignment Help0% (1)

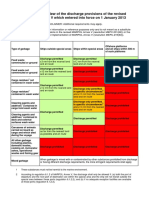

- Annex V Discharge Requirements 07-2013Dokument1 SeiteAnnex V Discharge Requirements 07-2013Rachit SharmaNoch keine Bewertungen

- List of Garment Factory Accidents in Bangladesh 2013-2017Dokument10 SeitenList of Garment Factory Accidents in Bangladesh 2013-2017Jashim UddinNoch keine Bewertungen

- Martensitic Stainless Steel EN 1.4021-QT 700Dokument2 SeitenMartensitic Stainless Steel EN 1.4021-QT 700LebasNoch keine Bewertungen

- The World's Biggest Zinc ProducersDokument8 SeitenThe World's Biggest Zinc Producersrubencito1Noch keine Bewertungen

- Roofcladding DesignerDokument54 SeitenRoofcladding DesignerserlabtxoNoch keine Bewertungen

- Unit 4 Sandwich Composite Materials and StructuresDokument43 SeitenUnit 4 Sandwich Composite Materials and StructuresprsnthNoch keine Bewertungen

- First Assignment Course Code: MS-03 Course Title: Economic and Social Environment Assignment Code: 03/TMA-1/SEM-I/2003Dokument48 SeitenFirst Assignment Course Code: MS-03 Course Title: Economic and Social Environment Assignment Code: 03/TMA-1/SEM-I/2003arun1974Noch keine Bewertungen

- CIVIL Daily Construction Report DCR FormatDokument6 SeitenCIVIL Daily Construction Report DCR FormatXozanNoch keine Bewertungen

- Business Marketing-Presentation On Mohammadi Group (RMG)Dokument17 SeitenBusiness Marketing-Presentation On Mohammadi Group (RMG)Mehedi HassanNoch keine Bewertungen

- Literature Resources For Chemical Process Industries (Advances in Chemistry Series 010)Dokument578 SeitenLiterature Resources For Chemical Process Industries (Advances in Chemistry Series 010)Rian PuspitasariNoch keine Bewertungen

- Tablet Tooling: Advantages of Standard ToolingDokument11 SeitenTablet Tooling: Advantages of Standard ToolingByunghoon LeeNoch keine Bewertungen

- SAP For PharmaDokument36 SeitenSAP For PharmaAbdulla Fatiya100% (3)

- S.No Reg. No Company - Name: List of Defaulting Companies in CoimbatoreDokument101 SeitenS.No Reg. No Company - Name: List of Defaulting Companies in CoimbatoreMohamed Afsal100% (1)

- Style and Trends AmnaDokument3 SeitenStyle and Trends AmnaHaris Habib0% (1)

- Cellular Manufacturing ThesisDokument60 SeitenCellular Manufacturing Thesissdfsdfsadfwsfewe100% (1)

- Brushbond TGP PDFDokument2 SeitenBrushbond TGP PDFmilanbrasinaNoch keine Bewertungen

- Fastener Industry and Boeing White PaperDokument28 SeitenFastener Industry and Boeing White Papermasrit123Noch keine Bewertungen

- Resources and Trade: The Heckscher-Ohlin Model: Eleventh EditionDokument24 SeitenResources and Trade: The Heckscher-Ohlin Model: Eleventh EditionJonny FalentinoNoch keine Bewertungen