Beruflich Dokumente

Kultur Dokumente

ELMAR Catalog

Hochgeladen von

ngueadoumCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ELMAR Catalog

Hochgeladen von

ngueadoumCopyright:

Verfügbare Formate

PRESSURE CONTROL

EQUIPMENT

Section 4:

4 Pressure Control Equipment Page

Slickline Pressure Control Equipment:

Slickline Pressure Control Equipment String 1

Wellhead Adapter Flange 2

Pump-in Sub 3

Single Silver Series Wireline Valve 4

Dual Gold Series Wireline Valve 5

Lightweight Wireline Valve 6

Quick Test Sub 7

Hydraulic Tool Trap with External Indicator 8

Wireline Lubricator with Integral Unions 9

Wireline Lubricator with Screwed Unions 10

Bleed-Off Sub 11

Lightweight Lubricator 12

Chemical Injection Sub 13

Hydraulic Wireline Tool Catcher 14 S

4

Quick-Interchange Tool Catcher 15

Hydraulic Stuffing Box 16

Manual Stuffing Box 17

Lightweight Stuffing Box 18

Liquid Seal Slickline Control Head 19

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL

EQUIPMENT

Section 4:

4 Pressure Control Equipment Page

Electric Line Pressure Control Equipment:

Electric Line Pressure Control Equipment String 20

Lightweight Pressure Control Equipment String 21

Wellhead Adapter Flange 22

Pump-in Sub 23

Compact Wireline Valve 24

Lightweight Wireline Valve 25

Quick Test Sub 26

Hydraulic Tool Trap with External Indicator 27

Wireline Lubricator with Integral Unions 28

Wireline Lubricator with Screwed Unions 29

Bleed-Off Sub 30

Lightweight Lubricator 31

Chemical Injection Sub 32

Hydraulic Wireline Tool Catcher 33 S

4

Quick-Interchange Tool Catcher 34

Wireline Grease Injection Control Head 35-36

Enviro Wireline Grease Injection Control Head 37-38

Enviro Combination Stuffing Box and Line Wiper 39

Enviro Single Compact Pack-Off 40

Enviro Dual Compact Pack-Off 41

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL

EQUIPMENT

Section 4:

4 Pressure Control Equipment Page

Transport Racks:

Slickline Transport Baskets 42

5 Series 10,000 psi 2-BOP Pressure

Equipment System 43

10 Series 10,000 psi 3-BOP Pressure

Equipment System 44

E-Lite Transport System 45

15 Series 15,000 psi 3-BOP Pressure

Equipment System 46

Open Hole / Large Bore Equipment:

5 1/2 Single Manual Heavy Duty Wireline Valve 47

Hydraulic Wireline Annular Valve 48

Dual Hydraulic Wireline Annular Valve 49

M3000 - Dual Hydraulic Wireline Annular Valve 50-51

Slimline and Slimlite Equipment 52 S

4

Auxiliary Equipment:

Hydraulic Ball Valve 53

Multi Line Ram Seal 54

Q-GUIDE Wireline Ram 55

Shear and Seal Wireline Ram Assembly 56

Safety Flow Diverter and Cable Clamp 57

Turn Around Sheave (TAS) 58

MPA2 Series Hay Pulley Assembly 59

Copyright Varco International Inc, 2002 www.elmar.co.uk

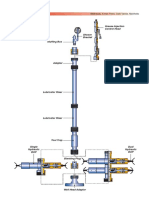

PRESSURE CONTROL Slickline Pressure Control

EQUIPMENT Equipment String

SSR Design and Manufacture Pressure Control Equipment and Accessories for Slickline and

Braided Cable Operations.

A full range of equipment is available, from the basic 2 1/2" ID 5,000psi WP manual items such as

Stuffing Boxes and the Silver Series Wireline Valve, through to the SSR Gold Series Dual and Triple

Wireline Valves that have been manufactured for applications with a WP of up to 15,000psi and a

maximum 9" through bore.

The range of accessories is extensive with items such as:

Test Caps

Lift Caps

Wireline Valve Work Stands

Stuffing Box Clamps for Slickline

Braided Cable and Lubricator Clamps

Hay Pulley's

Sheave Wheels

Chemical Lubricator Dolly's

Injection Sub Crossovers

Flanged Adaptors

Optional Tool These items provided by SSR International are only a

Catcher selection of the product range and capabilities available.

For a more composite range of all the various products and

Lubricator services on offer

contact SSR

International.

1

4

Lubricator

Lightweight Sheave

SSR International

design, manufacture and certify Pressure Control Products to

Ported Lubricator meet and exceed the following

established industry standards:

API 6A

API 17D

NACE MR0175

NPD Regulations

Statutory Instrument 1996 No. 913

Tool Trap Statutory Instrument 1998 No. 2306

Statutory Instrument 1998 No. 2307

Single Hydraulic Products are fully traceable and interchangeable, inspected

Wireline Valve 100% to assure a product of the highest quality exceeds

our customer expectations in accordance with SSR

established QMS accredited to BS EN ISO 9001:1994

(SSR Product Line)

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL

EQUIPMENT

Wellhead Adapter Flange

The Elmar Wellhead Adapter Flange provides a means of connecting the wireline valve and

lubricator assembly to the wellhead in a safe and secure manner.

The Elmar Wellhead Adapter Flange consists of a quick union machined on a standard API flange.

The upper end has a standard Bowen type, Otis type or Elmar quick union and can be supplied

with a blanking plug and collar if required.

Elmar wellhead adapter flanges are available in various bore sizes from 2 1/16" to 7 1/16" and

working pressure up to 15,000 psi.

Elmar will design and manufacture well-head adapter flanges for all API standard models. Elmar

adapter flanges are fully traceable and certified to API 6A.

TYPICAL ELMAR WELLHEAD ADAPTER FLANGE SECTION

Thread

Size

Seal Dia

Thread Per

Inch (TPI)

2

4

I.D.

API Ring

Groove

Typical Elmar Number

Adapter Flange L-972237

API Ring Gasket

PART NUMBERS

Part Flange Ring Working Quick Union

Number Size Groove Pressure Service Female Box

L-972237 3 1/16 BX-154 10,000 psi H2S 4 3/4-4x2 (3.750) Elmar

L-975187 3 1/16 BX-154 10,000 psi H2S 6 5/16-4thd (3.750) Bowen

L-974529 4 1/16 R-39 5,000 psi H2S 7-5thd (5.250) Bowen

L-976006 4 1/16 BX-155 10,000 psi H2S 7 1/2-4thd (5.500) Otis

L-972366 4 1/16 BX-155 10,000 psi H2S 6 1/8-4x2 (4.750) Elmar

L-974533 5 1/2 R-44 5,000 psi H2S 8 1/4-4x2 (6.750) Bowen

L-974775 7 1/16 R-46 5,000 psi H2S 9-4thd (6.750) Otis

L-978774 3 1/16 BX-154 15,000 psi H2S 7-5thd (4.375) Bowen

L-979123 4 1/16 BX-155 15,000 psi H2S 7-5thd (4.375) Bowen

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL

EQUIPMENT

Pump-in Sub

The Pump-In Sub (PIS) is normally positioned below the Wireline Valve and above the Wellhead.

Its main function is to allow well control by pumping fluid below a closed Wireline Valve.

The PIS has quick unions top and bottom, and a WECO (Hammer Union) type side connection.

Pump-in Subs are normally supplied with a blind plug & nut on the WECO port. A suitable valve is

needed to operate the PIS, replacing the blind plug. Pump-in Subs can also be used for fluid

sampling or inhibitor injection. Specially designed Pump-in Subs, with different top and bottom

unions are used as wellhead adapter x-overs.

PUMP-IN SUB IN POSITION

Quick Test Sub

Wireline Valve

3

4

Pump-in Sub

Plug

Valve

Wellhead

Adapter

Flange

ACCESSORIES

Typical Elmar 3 Pump-in Sub Part Number Description Working Pressure Service Connection

L-840805 Plug Valve 10,000 psi H2S 2 1502

L-840605 Plug Valve 15,000 psi H2S 2 2202

PART NUMBERS

Part Working

I.D. Service Connection Side Outlet

Number Pressure

L-972052 3 10,000 PSI H2S 4 3/4-4x2 (3.750) Elmar 2 1502

L-979873 3 10,000 PSI STD 4 3/4-4thd (3.750) Bowen 2 1502

L-979098 3 10,000 PSI H2S 5 3/4-4thd (4.000) Otis 2 1502

L-977282 3 10,000 PSI H2S 6 5/16-4thd (4.375) Bowen 2 1502

L-978771 3 15,000 PSI H2S 7-5thd (4.375) Bowen 2 2202

L-978110 4 10,000 PSI H2S 8 1/4-4x2 (6.000) Bowen 2 1502

L-972224 4.06 10,000 PSI H2S 6 1/8-4x2 (4.750) Elmar 2 1502

L-979733 4.5 15,000 PSI H2S 9 1/2-4thd (6.250) Otis 2 2202

L-978891 5.5 5,000 PSI H2S 8 1/4-4x2 (6.750) Elmar 2 1502

L-979264 6 3/8 10,000 PSI H2S 11 1/2-4thd (8.250) Otis 2 1502

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL Single Silver Series

EQUIPMENT Wireline Valve

The SSR Silver Series Wireline Valve is a hydraulic compact wireline valve of monobloc

construction designed specifically to be used as a Single or Dual, for Slickline and Braided Line

operations.

No Welding - Quick Unions are screwed into the Manual Back-up Stems fitted as Back-up to Hydraulic System.

Body with SSR ACME thread which incorporates

primary 'O' Ring Seal with Metal to Metal Back-up. All Inner and Outer Seals are

interchangeable with other major

manufacturers.

The Wireline Valve has single

point Equalizer Valve Assembly. Det Norske Veritas and Lloyds

Design type approval for use in the

North Sea.

Hydraulic Cylinders held in position with ACME

type Quick Union Collars thereby eliminating the Sizes: 3" through to 6 3/8"

need for special tools or Flogging Hammers during

Ram Change-out or Re-dress. Operating Pressure: Up to 10,000psi.

Standard or H2S Service.

5 DIAMETER THROUGH BORE

Working Pressure Unions Wire Size Assembly Number

5,000psi 8 1/4 4x2 'BB' 0.125" A007-139

(6.750") Seal Dia. 3/16" A007-140

7/32" A007-141

5/16" A007-142

5,000psi 8 1/4" - 4THD 'OO' 0.125" A007-135

2 1/2 DIAMETER THROUGH BORE 3/16" A007-143

7/32" A007-144

Working Pressure Unions Wire Size Assembly Number 5/16" A007-145

5,000psi 4 3/4" - 4THD 'BB' 0.125" A001-017 10,000psi 8 7/8" - 4x2 'BB' 0.125" A007-146

4 3/16" A001-018 3/16" A007-147

4 7/32" A001-019 7/32" A007-148

5/16" A001-020 5/16" A007-149

5,000psi 5 3/4" - 4THD 'OO' 0.125" A001-021 10,000psi 9" - 4THD 'OO' 0.125" A007-104

3/16" A001-022 3/16" A007-150

7/32" A001-023 7/32" A007-151

5/16" A001-024 5/16" A007-152

10,000psi 6 5/16" - 4THD 'BB' 0.125" A001-025

3/16" A001-026

7/32" A001-027

6 3/8 DIAMETER THROUGH BORE

5/16" A001-028

10,000psi 5 3/4" - 4THD 'OO' 0.125" A001-029 Working Pressure Unions Wire Size Assembly Number

3/16" A001-030 5,000psi 9 7/8" - 4x2 'BB' 0.125" A009-085

7/32" A001-031 3/16" A009-143

5/16" A001-032 7/32" A009-144

5/16" A009-145

3 DIAMETER THROUGH BORE 5,000psi 9 1/2" - 4THD 'OO' 0.125" A009-068

Working Pressure Unions Wire Size Assembly Number 3/16" A009-069

5,000psi 4 3/4" - 4x2 'BB' 0.125" A003-173 7/32" A009-070

3/16" A003-174 5/16" A009-071

7/32" A003-175 10,000psi 12 1/4" - 4THD 'BB' 0.125" A009-146

5/16" A003-176 3/16" A009-147

5,000psi 5" - 4THD 'OO' 0.125" A003-168 7/32" A009-148

3/16" A003-170 5/16" A009-149

7/32" A003-171 10,000psi 11 1/2" - 4THD 'OO' 0.125" A009-073

5/16" A003-172 3/16" A009-074

10,000psi 6 5/16" - 4THD 'BB' 0.125" A003-165 7/32" A009-075

3/16" A003-166 5/16" A009-076

7/32" A003-177

5/16" A003-178

10,000psi 5 3/4" - 4THD 'OO' 0.125" A003-144 'OO' - OTIS type Union 'BB' - BOWEN type Union

3/16" A003-179

7/32" A003-180

5/16" A003-181

4 DIAMETER THROUGH BORE

Working Pressure Unions Wire Size Assembly Number

5,000psi 7" - 5THD 'BB' 0.125" A005-093

3/16" A005-121

7/32" A005-122

5/16" A005-123

5,000psi 6 1/2" - 4THD 'OO' 0.125" A005-092

3/16" A005-124

7/32" A005-125

5/16" A005-126

10,000psi 8 1/4"- 4x2 'BB' 0.125" A005-098

3/16" A005-127

7/32" A005-128

5/16" A005-129

10,000psi 8 3/8" - 4THD 'OO' 0.125" A005-111

3/16" A005-130

7/32" A005-131 (SSR Product Line)

5/16" A005-132

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL

EQUIPMENT

Dual Gold Series Wireline Valve

The SSR Gold Series Wireline Valve is a hydraulic compact wireline valve of monobloc

construction designed specifically to be used as a single, Dual, Triple or Quadruple Wireline Valve

for Slickline, Braided Line and Electric Line Well Service operations.

Forged Monobloc Construction allowing Single, Dual, Triple or Unique 'Gib Key' design eliminates the need for a slot in the Ram

Quadruple configurations. Cavity and therefore allows complete flexibility to arrange Ram

configuration as required to include inverting Rams for Grease

No Welding - Quick Unions are screwed into the Monobloc Injection.

Body with SSR ACME thread which incorporates

primary 'O' Ring Seal with Metal to Metal Easy Ram Inner and Outer Seal Change-out on

Back-up. Wellhead possible, due to Guide Brackets supplied

as standard.

The Wireline Valve has

Integral Equalizer Valve Non-Rising Manual Back-up

Assembly allowing Stems eliminate 'Stem Damage'.

equalizing in any

combination between All Inner and Outer Seals are

Rams and eliminates interchangeable with other major

damage to Equalizing manufacturers.

Assembly.

Det Norske Veritas and Lloyds Design type

Main Body is machined with Grease Injection Port approval for use in the North Sea.

between Rams.

Sizes: 3" through to 9"

Hydraulic Cylinders held in position with ACME type Quick

Union Collars thereby eliminating the need for special tools or Operating Pressure: Up to 15,000psi.

Flogging Hammers during Ram Change-out or Re-dress.

Standard or H2S Service.

3 DIAMETER THROUGH BORE

Working Pressure Unions Wire Size Assembly Number

6 3/8 DIAMETER THROUGH BORE

5,000psi 4 1/2" - 4x2 'BB' 0.125" A003-186 5

3/16" A003-187 Working Pressure Unions Wire Size Assembly Number

7/32" A003-188 5,000psi 9 7/8" 4x2 'BB' 0.125" A009-082 4

5/16" A003-189 3/16" A009-150

5,000psi 5" - 4THD 'OO' 0.125" A003-193 7/32" A009-084

3/16" A003-190 5/16" A009-151

7/32" A003-191 5,000psi 9 1/2" - 4THD 'OO' 0.125" A009-152

5/16" A003-192 3/16" A009-153

10,000psi 6 5/16" - 4THD 'BB' 0.125" A003-119 7/32" A009-154

3/16" A003-182 5/16" A009-155

7/32" A003-149 10,000psi 12 1/4" - 4THD 'BB' 0.125" A009-156

5/16" A003-114 3/16" A009-157

10,000psi 5 3/4" - 4THD 'OO' 0.125" A003-185 7/32" A009-158

3/16" A003-183 5/16" A009-159

7/32" A003-121 10,000psi 11 1/2" - 4THD 'OO' 0.125" A009-160

5/16" A003-184 3/16" A009-101

7/32" A009-161

4 DIAMETER THROUGH BORE 5/16" A009-099

Working Pressure Unions Wire Size Assembly Number

5,000psi 7" - 5THD 'BB' 0.125" A005-086

3/16" A005-133

7/32" A005-135

5/16" A005-134 9 DIAMETER THROUGH BORE

5,000psi 6 1/2" - 4THD 'OO' 0.125" A005-136 Working Pressure Unions Wire Size Assembly Number

3/16" A005-137 5,000psi 12" - 4THD 'OO' 0.125" A104-004

7/32" A005-138 3/16" A104-005

5/16" A005-139 7/32" A104-006

10,000psi 8 1/4" - 4x2 'BB' 0.125" A005-140 5/16" A104-007

(6.000") Seal Dia. 3/16" A005-141

7/32" A005-142

5/16" A005-143 'OO' - OTIS type Union 'BB' - BOWEN type Union

10,000psi 8 3/8" - 4THD 'OO' 0.125" A005-144

3/16" A005-145

7/32" A005-146

5/16" A005-147

5 DIAMETER THROUGH BORE

Working Pressure Unions Wire Size Assembly Number

5,000psi 8 1/4" - 4x2 'BB' 0.125" A007-093

(6.750") Seal Dia. 3/16" A007-121

7/32" A007-122

5/16" A007-123

5,000psi 8 1/4" - 4THD 'OO' 0.125" A007-092

3/16" A007-124

7/32" A007-125

5/16" A007-126

10,000psi 8 7/8"- 4x2 'BB' 0.125" A007-098

3/16" A007-127

7/32" A007-128

5/16" A007-129

10,000psi 9" - 4THD 'OO' 0.125" A007-111

3/16" A007-130 (SSR Product Line)

7/32" A007-131

5/16" A007-132

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL

EQUIPMENT

Lightweight Wireline Valve

The Elmar Lightweight Wireline Valve is available in 3 I.D., 10,000 psi working pressure, H2S

service, in either single, dual or triple configurations. (Soon to be available in 4, 5 and 6 3/8 I.D.)

The Elmar Lightweight Wireline Valve gives positive protection during well service operations,

when operating with slickline, braided wireline and electric line.

All Elmar Lightweight Wireline Valves are up to 60% lighter than previous generation Wireline

Valves and incorporate the following features as standard :-

Lightweight, allowing easier handling

3 Single 66kg, (146lb), Dual 114kg, (251lb)

and Triple 162kg, (357lb)

Compact size, allowing shorter rig-up heights

Back-up manual closure

Threaded quick unions, allowing the use of any

Bowen type or Otis type union without changing

the body

Ram position indicator rods

Manifold blocks with integral equalisation, glycol

and grease injection facilities

Maximum working pressure 10,000 psi H2S service

Maximum hydraulic working pressure 3,000 psi

API 6A and NACE compliant

6 Third Party Design Approval

4 Keyless Q-GUIDE ram design providing flexible

Part Number L-974111

(Patent Pending) ram configuration and positive wireline guiding

Multiline inner seal accommodating a range of

LIGHTWEIGHT BOP, LUBRICATOR AND STUFFING BOX

wireline sizes

PART NUMBERS

Part Working Single/Dual

I.D. Service Quick Union

Number Pressure Triple

L-974111 3 10,000 PSI H2S Single 4 3/4-4x2 (3.750) Elmar

L-974223 3 10,000 PSI H2S Dual 4 3/4-4x2 (3.750) Elmar

L-974224 3 10,000 PSI H2S Triple 4 3/4-4x2 (3.750) Elmar

Lightweight

Note: Ram line size to be specified at time of ordering

Slickline

Stuffing Box MANIFOLDS

Grease/Glycol Injection Bleed Off and Gauge

and Equalistion

Equalisation Valve

Lightweight

Lubricator

Glycol Bleed Off Gauge Port

Section Injection

Grease

3 Lightweight Injection

Manual

Wireline Valve Handle

Stored

Equalisation Valve

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL

EQUIPMENT

Quick Test Sub - QTS

The Elmar Quick Test Sub (QTS) is designed to save rig time while pressure testing the Wireline

Pressure Control Equipment String when multiple wireline runs are required.

The Elmar Quick Test Sub is inserted either above or below the wireline valve at the position of the

joint normally opened to insert and retrieve tools from the well. After performing the first pressure

test to check the integrity of the whole String, subsequent pressure tests can be made using the

Quick Test Sub to verify the integrity of the joint disconnected, rather than having to test the whole

assembly. This is achieved by connecting a small hydraulic hand-pump to the Quick Test Sub and

testing the joint O ring seal from the outside. It is estimated that the use of the Elmar Quick Test

Sub can reduce the time needed to pressure test the String at each subsequent test by more than

1/2 hour.

Saves time on pressure test due to design features

Eliminates prospect of contaminating well with

test fluids

Saves on glycol

Eliminates risks of pressure testing with

perforating guns

Metal to metal seal,

seals valve after

pressure test

7

4

Hand pump connection

PART NUMBERS

Part Working

Number I.D. Pressure Service Connections Seal Kit

L-971404 3 10,000 psi H2S 4 3/4-4x2 (3.750) Elmar L-971404K

L-972235 3 10,000 psi H2S 5 3/4-4thd (4.000) Otis L-972235K

L-970918 3 10,000 psi H2S 6 1/2-4thd (4.750) Otis L-970918K

L-971299 4 10,000 psi H2S 8 1/4-4x2 (6.000) Bowen L-971299K

L-972222 4.06 10,000 psi H2S 6 1/8-4x2 (4.750) Elmar L-972222K

HAND PUMP ASSEMBLY (10,000 PSI W.P.) L-973101 5.125 10,000 psi H2S 9-4thd (6.750) Otis L-973101K

Part Number

L-690573

HYDRAULIC HOSE ASSEMBLY

Part Number Description

Hose Assembly

25ft 6mm ID, 10,000psi Hose

L-690587

with Quick Connectors

and Dust Covers

L-690586 50ft

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL Hydraulic Tool Trap

EQUIPMENT with External Indicator

The Elmar Hydraulic Tool Trap with external indicator is installed between the Wireline Valve and

the lubricator string. It prevents the loss of wireline tools downhole in the event of the wire being

pulled-off the rope socket, by retaining the dropping tool on a flapper. The flapper has an opening

larger than the wireline, but smaller than the tool string.

The flapper is operated by a hydraulic actuator, through an external handle, connected to the

flapper with a low-torque pressure-balanced shaft. The external handle doubles as a tool passage

indicator. The tool string may be pulled freely upwards through the tool trap. The flapper will move

upwards, together with the external handle, indicating tool passage. As soon as the string bottom

has cleared the flapper, the flapper will drop back into the trap position, pushed by a torsion spring.

The flapper can be lifted remotely when running a tool in the well by activating the piston in the

hydraulic actuator. Pumping back the piston to its original position allows the flapper to return to its

trap position.

The hydraulic actuator can be operated by a dual output manual pump or with an Elmar Hydraulic

Control Module.

Lightweight: L-971169

Positive tool passage indicator

Pressure-balanced flapper shaft

Remote hydraulic operation. Enhanced

operational safety

Can be operated manually in case of hydraulic

failure

Hydraulic Option:

Actuator Manual Tool Trap with external indicator

8

4 CROSS SECTION DETAIL

Flapper

Handle

ACCESSORIES

Part Number Description

PART NUMBERS L-690750 Tool Trap Hand Pump

Part Number I.D. Working Pressure Service Quick Union

L-974814 2 1/2 15,000 psi H2S 6 5/16-4thd (3.750) Bowen

L-976271 2 1/2 10,000 psi H2S 6 5/16-4thd (4.375) Bowen L-690615 50ft Hose Assembly

L-971169 3 10,000 psi H2S 4 3/4-4x2 (3.750) Elmar

L-978383 3 5,000 psi H2S 5 3/4-4thd (4.000) Otis

L-974828 3 10,000 psi H2S 6 5/16-4thd (4.375) Bowen

L-974794 4 10,000 psi H2S 8 1/4-4x2 (6.000) Bowen

L-972219 4 1/16 10,000 psi H2S 6 1/8-4x2 (4.750) Elmar

L-978441 5 1/2 5,000 psi STD 8 1/4-4x2 (6.750) Bowen

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL Wireline Lubricator with

EQUIPMENT Integral Unions

The SSR Integral Lubricator Section is a pressure containing cylinder used when performing

wireline operations. Its purpose is to allow the Wireline Tool String to be raised above the wellhead

prior to and after wireline operations, thereby enabling the wellhead valve to be opened and closed,

allowing entry and exit from the well bore. During slickline operations, three Lubricator Sections are

normally used, each having a different ID, the uppermost section having the smallest, then

opening out to the lower section with largest ID. During electric line operations the lubricators

normally have the same ID.

3 DIAMETER THROUGH BORE

Working Pressure Unions Length Assembly Number

5,000psi 5 1/2" - 4x2 'BB' 8ft. A014-123

10ft. A014-137

5,000psi 5" - 4THD 'OO' 8ft. A014-098

10ft. A014-138

10,000psi 6 5/16" - 4THD 'BB' 8ft. A014-100

10ft. A014-139

10,000psi 5 3/4" - 4THD 'OO' 8ft. A014-116

10ft. A014-140

4 DIAMETER THROUGH BORE

Working Pressure Unions Length Assembly Number

5,000psi 7" - 5THD 'BB' 8ft. A016-059

10ft. A016-089

5,000psi 6 1/2" - 4THD 'OO' 8ft. A016-067

10ft. A016-076

10,000psi 8 1/4" - 4x2 'BB' 8ft. A016-060

(6.000") Seal Dia. 10ft. A016-090

10,000psi 8 3/8" - 4THD 'OO' 8ft. A016-091

10ft. A016-097

SPECIFICATIONS

9

Pressure Rating Up to 15,000psi

4

Service H2S and Standard Service

'OO' - OTIS type Union 'BB' - BOWEN type Union

SSR Integral Lubricator A014/A016

(SSR Product Line)

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL Wireline Lubricator with

EQUIPMENT Screwed Unions

The SSR Lubricator Section is used when performing wireline or electric line operations with 1/2

NPT Bleed Port Fitted. Quick Unions are of the screwed type with a SSR ACME thread, which

incorporates primary O Ring Seal with metal back-up. Det Norske Veritas and Lloyds Design type

approval is available if required.

2 1/2 DIAMETER THROUGH BORE

Working Pressure Unions Length Assembly Number

5,000psi 4 3/4" - 4THD BB 8ft. A012-002

10ft. A012-003

5,000psi 5" - 4THD 'OO' 8ft. A012-043

10ft. A012-044

10,000psi 6 5/16" - 4THD 'BB' 8ft. A012-006

10ft. A012-007

10,000psi 5 3/4" - 4THD 'OO' 8ft. A012-008

10ft. A012-009

3 DIAMETER THROUGH BORE

Working Pressure Unions Length Assembly Number

5,000psi 5 1/2" - 4x2 'BB' 8ft. A014-014

10ft. A014-015

5,000psi 5" - 4THD 'OO' 8ft. A014-092

10ft. A014-011

10,000psi 6 5/16" - 4THD 'BB' 8ft. A014-009

10ft. A014-003

10,000psi 5 3/4" - 4THD 'OO' 8ft. A014-019

10ft. A014-021

4 DIAMETER THROUGH BORE

Working Pressure Unions Length Assembly Number

5,000psi 7" - 5THD 'BB' 8ft. A016-004

10ft. A016-002

5,000psi 6 1/2" - 4THD 'OO' 8ft. A016-006

10ft. A016-007

10,000psi 8 1/4" - 4x2 'BB' 8ft. A016-008

(6.000") Seal Dia. 10ft. A016-026

10,000psi 8 3/8" - 4THD 'OO' 8ft. A016-009

10ft. A016-010

10

5 DIAMETER THROUGH BORE

4 Working Pressure Unions Length Assembly Number

5,000psi 8 1/2" - 4x2 'BB' 8ft. A018-009

(6.750") Seal Dia. 10ft. A018-010

5,000psi 8 1/4" - 4THD 'OO' 8ft. A018-055

10ft. A018-114

10,000psi 8 7/8" - 4x2 'BB' 8ft. A018-115

10ft. A018-001

10,000psi 9" - 4THD 'OO' 8ft. A018-013

10ft. A018-002

6 3/8 DIAMETER THROUGH BORE

Working Pressure Unions Length Assembly Number

5,000psi 9 7/8" - 4x2 'BB' 8ft. A020-005

10ft. A020-006

5,000psi 9 1/2" - 4THD 'OO' 8ft. A020-007

10ft. A020-008

10,000psi 12 1/4" - 4THD 'BB' 8ft. A020-116

10ft. A020-117

10,000psi 11 1/2" - 4THD 'OO' 8ft. A020-011

10ft. A020-012

SPECIFICATIONS

Pressure Rating Up to 15,000psi

Service H2S and Standard Service

'OO' - OTIS type Union 'BB' - BOWEN type Union

SSR Screwed Lubricator

(SSR Product Line)

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL

EQUIPMENT

Bleed-Off Sub

For applications when a bleed-off port is required on the lubricator string , subs are available with

a 1/2" NPT Port for connection of a suitable valve.

BLEED-OFF SUB IN POSITION

ELMAR

Slickline

Head

Ball Check Valve

Tool Catcher

Needle

Valve

Lubricator Sections

11

Bleed-Off Sub 4

Quick Test Sub

Lightweight

Wireline Valve

PART NUMBERS

Part Working Bleed

Number I.D. Pressure Service Quick Union Port

L-974292 3 10,000 psi H2S 4 3/4-4x2 (3.750) Elmar 1/2 NPT Pump-in

L-974293 4 1/16 10,000 psi H2S 6 1/8-4x2 (4.750) Elmar 1/2 NPT Sub

L-970915 3 10,000 psi STD 4 3/4-4thd (3.750) Bowen 1/2 NPT

L-970916 3 10,000 psi H2S 6 5/16-4thd (4.375) Bowen 1/2 NPT Wellhead Adapter

ACCESSORIES Flange

Part Number Description

L-500060 Needle Valve, 10,000 psi H2S 1/2 NPT

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL

EQUIPMENT

Lightweight Lubricator

The Elmar "Lite" lubricators enable the wireline tool string to be introduced or retrieved from a well

bore under pressure. They are normally positioned above the Wireline Valve, Tool Trap or Quick

Test Sub. By using high strength Stainless Steel Alloys, the weight of a lubricator section is reduced

by up to 70% with respect to conventional integral lubricators.

The Elmar "Lite" lubricator consists of four basic parts: a quick union collar, a male quick union, a

lubricator tube, and a female quick union. The quick unions are manufactured in H2S resistant alloy

steel to prevent galling.

Elmar "Lite" lubricators are supplied with a 3" or 4 1/16" bore, and are rated 10,000 psi H2S

service. The Elmar Lightweight quick unions have been selected for optimum weight reduction and

to prevent unsafe cross-string assembly. Upper and lower adapters are available to connect

existing equipment. These are rated 5,000 psi or 10,000 psi depending on the type of connection.

Corrosion Resistant Tube made from high

strength NACE Certified Stainless Steel

Quick unions are coupled through Premium

Elmar Lite Coupling:

- Tube-to-union seal is metal-to-metal

backed-up by O-Ring

- Special handling tools supplied. Calibrated

torque is not required.

Bending stresses at the thread undercut are

12

minimised.

4 Elmar Lightweight Quick Unions:

- 3" ID: 4 3/4"- 4x2 (3.750" seal dia)

- 4 1/16" ID: 6 1/8"- 4x2 (4.750" seal dia)

ACCESSORIES

L-973957 3 Torque Tool

L-973958 4 1/16 Torque Tool

3 I.D. LIGHTWEIGHT LUBRICATOR

Buttress Type

Part Upper Lower Thread

Number Connections Connections I.D. W.P. Service L. W.

L-971246

4 3/4-4x2 (3.750) 4 3/4-4x2 (3.750)

3 10K H2S 4ft 54 lb

Up to

Elmar Box Elmar Pin

4 3/4-4x2 (3.750) 4 3/4-4x2 (3.750)

70%

L-971247 3 10K H2S 5ft 63 lb

Elmar Box Elmar Pin lighter

4 3/4-4x2 (3.750) 4 3/4-4x2 (3.750)

L-971248 Elmar Box Elmar Pin 3 10K H2S 6ft 72 lb

4 3/4-4x2 (3.750) 4 3/4-4x2 (3.750)

L-971249 Elmar Box Elmar Pin 3 10K H2S 8ft 90 lb

4 3/4-4x2 (3.750) 4 3/4-4x2 (3.750)

L-971251 Elmar Box Elmar Pin 3 10K H2S 10ft 108 lb

4 1/16 I.D. LIGHTWEIGHT LUBRICATOR

Part Upper Lower

Number Connections Connections I.D. W.P. Service L. W.

6 1/8-4x2 (4.750) 6 1/8-4x2 (4.750)

L-971846A Elmar Box Elmar Pin 4.06 10K H2S 4ft 96 lb

6 1/8-4x2 (4.750) 6 1/8-4x2 (4.750)

L-971846B Elmar Box Elmar Pin 4.06 10K H2S 5ft 113 lb

6 1/8-4x2 (4.750) 6 1/8-4x2 (4.750)

L-971846C Elmar Box Elmar Pin 4.06 10K H2S 6ft 129 lb

6 1/8-4x2 (4.750) 6 1/8-4x2 (4.750)

L-971846D Elmar Box Elmar Pin 4.06 10K H2S 8ft 161 lb

6 1/8-4x2 (4.750) 6 1/8-4x2 (4.750)

L-971846E Elmar Box Elmar Pin 4.06 10K H2S 10ft 193 lb

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL

EQUIPMENT

Chemical Injection Sub

The Elmar Chemical Injection Sub is designed to apply a de-icing agent or corrosion inhibitor to the

wireline during well service operations.

Installed below the grease injection control head or slickline stuffing box, the Elmar chemical

injection sub utilises replaceable felt packings to coat the wireline and prevent the chemical from

passing downhole.

The Elmar chemical injection sub consists of a one piece body with integral quick unions on both

ends, a quick union collar assembly, a manifold injection block assembly with integral check valve

and a felt packing retainer assembly. The check valve assembly is designed for easy and quick

replacement.

Elmar chemical injection subs are available in a full range of wire sizes, and 5,000 psi to 15,000 psi

working pressures.

1/8 NPT Thread

13

4

Check Valve

Assembly

Lightweight: L-972901/L-972877

One piece body with integral quick unions

Integral check valve

Available to suit all wire sizes

Other sizes available upon request

PART NUMBERS

Part Number Wire Size Working Pressure Service Quick Union

L-972901 .125 10,000 psi H2S 4 3/4-4x2 (3.750) Elmar

L-976217 .125 5,000 psi H2S 5-4thd (3.500) Otis

L-978641 .125 10,000 psi H2S 5 3/4-4thd (4.000) Otis

L-972877 .125 10,000 psi H2S 6 1/8-4x2 (4.750) Elmar

L-978049 .125 10,000 psi H2S 6 5/16-4thd (4.375) Bowen

L-972683 .125 10,000 psi H2S 6 1/2-4thd (4.750) Otis

L-970273 7/32 5,000 psi H2S 4 3/4-4thd (3.750) Bowen

L-976595 7/32 10,000 psi STD 4 3/4-4thd (3.750) Bowen

L-974664 7/32 15,000 psi H2S 6 1/4-4thd (4.000) Otis

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL

EQUIPMENT

Hydraulic Wireline Tool Catcher

The Elmar Hydraulic Tool Catcher is a safety device for installation below the Grease Injection Head

or Slick Line Stuffing Box. If the tool is pulled into the top of the lubricator and the wire stripped from

the rope socket, the Tool Catcher will engage the tool's fishing neck and prevent the loss of the tool

string into the well bore. The Tool Catcher is designed to be fail-safe: it is permanently in the catch

position and requires hydraulic pressure to release.

Elmar Hydraulic Tool Catchers for electric line are normally supplied with an integral ball check

valve assembly, and a top connection into which a grease head can be directly screwed.

For slick line operations Elmar Hydraulic Tool Catchers are available with quick unions top and

bottom.

Elmar Hydraulic Tool Catchers are available with ratings from 5,000 psi to 15,000 psi WP, STD and

H2S Service. Collet sizes vary from 1" to 1 3/4" fishing necks. Multi-catch options are available in

two ranges: 1" to 1 3/4" and 1 3/16" to 2 5/16".

PART NUMBERS

Part Collet Working Quick Union

Number Size Pressure Service Male Pin Top Connection

4 3/4-4x2

L-971167 1 3/16 10,000 psi H2S 2-10TPI Acme Box

(3.750) Elmar

4 3/4-4thd

L-974439 1 3/16 10,000 psi STD 2-6-60 Acme Box

(3.750) Bowen

4 3/4-4thd

L-974440 1 3/16 10,000 psi STD 2-10TPI Acme Box

(3.750) Bowen

Ball Check L-972218 1 3/16 10,000 psi H2S

6 1/8-4x2

(4.750) Elmar

2-10TPI Acme Box

Valve 6 5/16-4thd

L-974569 1 3/16 15,000 psi H2S 2-6-60 Acme Box

(3.750) Bowen

6 5/16-4thd

14 L-974661 1 3/16 10,000 psi H2S

(4.375) Bowen

2-6-60 Acme Box

4 8 1/4-4x2

L-974715 1 3/16 10,000 psi H2S 2-10TPI Acme Box

(6.000) Bowen

5 3/4-4thd

L-974816 1 3/8 10,000 psi H2S 2-10TPI Acme Box

(4.000) Otis

4 3/4-4thd

L-974919 1 3/16 5,000 psi H2S 2-10TPI Acme Box

(3.750) Bowen

4 3/4-4thd

L-974997 1 3/16 5,000 psi H2S 2-6-60 Acme Box

(3.750) Bowen

5 3/4-4thd

L-975268 1 3/16 10,000 psi H2S 2-10TPI Acme Box

(4.000) Otis

6 5/16-4thd

L-975279 1 3/16 10,000 psi H2S 2-10TPI Acme Box

(4.375) Bowen

8 1/4-4x2

L-975719 1 3/16 10,000 psi H2S 2-6-60 Acme Box

(6.000) Bowen

5-4thd

L-975846 1 3/16 5,000 psi STD 2-10TPI Acme Box

(3.500) Otis

8 1/4-4x2

Hydraulic L-976010 1 3/8 10,000 psi H2S

(6.000) Bowen

2-10TPI Acme Box

Tool Catcher 6 5/16-4thd 6 5/16-4thd

L-976157 1 3/16 10,000 psi H2S

(4.375) Bowen (4.375) Bowen

6 5/16-4thd

L-976245 1 3/8 10,000 psi H2S 2-10TPI Acme Box

(4.375) Bowen

Typical Elmar Combination Hydraulic

Tool Catcher/Ball Check Valve

ACCESSORIES

Part Number Description

Hand Pump Assembly

L-690730 6,500 psi (Steel)

HYDRAULIC HOSE ASSEMBLY

Part Number Description

Hose Assembly

L-690760 50ft 1/4 ID 100 R2AT Hose with

1/4 NPT Male Hose Ends

and Snaptite Male and Female Connectors

L-690740 100ft

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL Quick-Interchange Tool Catcher

EQUIPMENT for 1 3/8 Cable Head

The Elmar Quick-Interchange Tool Catcher allows the field crew to quickly and easily change

between slickline and electric line operations without remaking either rope socket.

This is made possible by the unique features of a 1.5

through-bore and a split tool stop that can be inserted after

the head is passed through the Tool Catcher body.

Stuffing Box

This configuration allows considerable savings in rig time,

minimises the use of consumable supplies and reduces the

risks of human error when making-up new rope sockets

Enviro

between runs. An optional Cable Head Protector Sleeve is

Line Wiper also available to protect the cable, head and rope

socket during interchange or transportation.

The slickline and electric line heads can be made up before

the operation after passing the lines through their respective

Stuffing Box and Ball Check Valve Assembly or Enviro

Grease Injection Head and Ball Check Valve Assembly. The

Cable Head Protector Sleeve is installed, connected to the

Slickline Stuffing Ball Check Valve Quick Union.

Box & Blowout Plug

When ready to rig up, the Protector Sleeve is removed, the

Tool Catcher is pumped open, the tool stop removed and

Grease Head the required cable head (slickline or electric line) is passed

through the 1.5 through bore of the Tool Catcher body.

After installing the split tool stop around the cable, the quick

union at the bottom of the Ball Check Valve is made up to the

Tool Catcher and the hydraulic pressure released, resetting

the Tool Catcher to the catch position.

The procedure is reversed to rig down one line and replace

it with the other.

15

Up to one hour of rig time is saved at each change-over. 4

The fishing neck size can be changed by installing the

corresponding collet assembly and tool stop.

BCV with

Elmar Quick QUICK-INTERCHANGE TOOL CATCHER SYSTEM

Part Number Description

Union

L-979540 Slickline Stuffing Box 10,000 psi, H2S, 0.108, 16 wheel

Electric Line L-979184 Slickline Stuffing Box 10,000 psi, H2S, 0.125, 16 wheel

Cable Head L-971444 Enviro Grease Injection Control Head 10,000 psi, H2S, 4 Concentric

Flotubes - wire size to be specified

Cable Head L-972019 Ball Check Valve 10,000 psi, H2S, with 3 3/4-5thd (2.500) Elmar male

pin and collar

Slickline Protector

L-975279 Combination Tool Catcher and Ball Check Valve, 10,000 psi, H2S, with

Cable Head Sleeve 6 5/16-4thd (3.750) Bowen male pin and collar - fish neck size to be

specified

L-978707 Combination Tool Catcher and Ball Check Valve, 10,000 psi, H2S, with

6 1/2-4thd (3.750) Otis male pin and collar - fish neck size to be

specified

Split Tool L-971167 Combination Tool Catcher and Ball Check Valve, 10,000 psi, H2S, with

Stop 4 3/4-4x2 (3.750) Elmar male pin and collar - fish neck size to be

specified

L-971174 Cable Head Protection Sleeve

L-972027 Tool Catcher Handling Sub for 3 3/4-5thd Elmar Union

Handling Sub

Similar equipment is available for alternative flotube types, quick union sizes, working pressures and

Elmar Quick services.

Union A Split Tool Stop is available for modification of many types of existing Elmar Combination Tool Catchers

Tool Catcher with Ball Check Valve so as to up-grade to the Quick-Interchange feature.

Please ask for details.

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL

EQUIPMENT

Hydraulic Stuffing Box

The SSR Stuffing Box is used when carrying out wireline operations with slickline under pressure.

The wireline is passed over the Sheave Wheel and fed down through packing in the Stuffing Box

Body. During operation the packing is tightened against the solid wireline by a packing nut which is

either manually or hydraulically actuated. This minimises any leakage of fluid resulting from well

pressure. The Stuffing Box incorporates a 'Blow-out' Plug, which in the event of the wireline

parting or being detached from the Rope Socket, will automatically seal and contain the well

pressure. The Stuffing Box includes a male quick union connection and is positioned on top of the

Lubricator Stack.

14 DIAMETER THROUGH BORE

Working Pressure Unions Wire Size Assembly Number

5,000psi 5 1/2" - 4x2 'BB' 0.092" A035-156

0.108" A035-117

5,000psi 5" - 4THD 'OO' 0.092" A035-152

0.108" A035-129

10,000psi 6 5/16" - 4THD 'BB' 0.092" A035-157

0.108" A035-105

10,000psi 5 3/4" - 4THD 'OO' 0.092" A035-096

0.108" A035-131

15,000psi 7" - 5THD 'BB' 0.092" A035-108

0.108" A035-107

16 DIAMETER THROUGH BORE

Working Pressure Unions Wire Size Assembly Number

5,000psi 5 1/2" - 4THD 'BB' 0.092" A035-155

0.108" A035-150

0.125" A035-115

5,000psi 5" - 4THD 'OO' 0.092" A035-122

0.108" A035-112

0.125" A035-124

16 10,000psi 6 5/16" - 4THD 'BB' 0.092" A035-154

0.108" A035-114

4 0.125" A035-120

10,000psi 5 3/4" - 4THD 'OO' 0.092" A035-095

0.108" A035-100

0.125" A035-123

15,000psi 7" - 5THD 'BB' 0.092" A035-177

0.108" A035-113

0.125" A035-178

'OO' - OTIS type Union 'BB' - BOWEN type Union

SSR Part Number A035-156

SPECIFICATIONS

Wire Size 0.092"/0.108"/0.125"

Sheave Size 14" and 16"

Pressure Rating Up to 15,000psi

Service H2S and Standard Service

ACCESSORIES

Stuffing Box Hand Pump L-690730

Hydraulic Hose Assembly 100ft. long L-690740

(SSR Product Line)

Hydraulic Hose Assembly 50ft. long L-690760

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL

EQUIPMENT Manual Stuffing Box

The SSR Stuffing Box is used when carrying out wireline operations with slickline, under pressure.

The Wireline is passed over the Sheave Wheel and fed down through packing in the Stuffing Box

body. During operation the packing is tightened against the solid wireline by a packing nut which

is manually actuated. This minimises any leakage of fluid resulting from well pressure. The Stuffing

Box incorporates a 'Blow-out' Plug, which in the event of the wireline parting or being detached from

the Rope Socket, will automatically seal and contain the well pressure. The Stuffing Box includes

a male quick union connection and is positioned on top of the Lubricator Stack.

14 DIAMETER SHEAVE WHEEL

Working Pressure Unions Wire Size Assembly Number

5,000psi 5 1/2" - 4x2 'BB' 0.092" A035-169

0.108" A035-170

5,000psi 5" - 4THD 'OO' 0.092" A035-171

0.108" A035-172

10,000psi 6 5/16" - 4THD 'BB' 0.092" A035-173

0.108" A035-174

10,000psi 5 3/4" - 4THD 'OO' 0.092" A035-175

0.108" A035-176

16 DIAMETER SHEAVE WHEEL

Working Pressure Unions Wire Size Assembly Number

5,000psi 5 1/2" - 4THD 'BB' 0.092" A035-158

0.108" A035-159

0.125" A035-160

5,000psi 5" - 4THD 'OO' 0.092" A035-161

0.108" A035-162

0.125" A035-163

10,000psi 6 5/16" - 4THD 'BB' 0.092" A035-164

0.108" A035-165

0.125" A035-166

10,000psi 5 3/4" - 4THD 'OO' 0.092" A035-167

0.108" A035-125

0.125" A035-168 17

4

'OO' - OTIS type Union 'BB' - BOWEN type Union

SSR Part Number A035-169

SPECIFICATIONS

Wire Size 0.092"/0.108"/0.125"

Sheave Size 14" and 16"

Pressure Rating Up to 10,000psi

Service H2S and Standard Service

(SSR Product Line)

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL

EQUIPMENT

Lightweight Stuffing Box

The Elmar Hydraulic Slickline Stuffing Box is designed to pack-off all sizes of solid wireline up to

0.125, with safety and convenience. It is lightweight, compact and simple to operate. Positioned at

the uppermost point of the pressure control equipment string, the Elmar slickline stuffing box

incorporates a blow-out plug to automatically shut-in the well pressure in the event of the slickline

breaking or being stripped from the rope socket.

The Elmar slickline stuffing box consists of a chamber which contains packing with an external

adjustable nut. The slickline passes through the packing and the nut is hydraulically tightened to

the point where leakage around the line, caused by well pressure, is reduced to a minimum. A 16

diameter sheave bracket assembly and a male quick union assembly are supplied with the stuffing

box as standard. If required a manual packing nut can be supplied.

Elmar slickline stuffing boxes are available for a full range of wire sizes, and from 5,000 psi to

15,000 psi working pressures.

LIGHTWEIGHT STUFFING BOX, LUBRICATOR & WIRELINE VALVE

Lightweight

Slickline

Stuffing Box

18

4

Lightweight

Lubricator

Section

3 Lightweight

Wireline Valve

PART NUMBERS

Part Wire Working Manual/

Number Size Pressure Service Hydraulic Bottom Connection

L-975765 .092 5,000 psi STD Manual 4 3/4-4thd (3.750) Bowen ACCESSORIES

L-975275 .108 5,000 psi H2S Manual 5 1/2-4x2 (4.375) Bowen L-690730 Stuffing Box Hand Pump

L-978779 .108 5,000 psi H2S Hydraulic 4 3/4-4thd (3.750) Bowen L-690740 Hydraulic Hose Assembly 100ft long

L-970281 .108 10,000 psi STD Hydraulic 4 3/4-4thd (3.750) Bowen L-690760 Hydraulic Hose Assembly 50ft long

L-978723 .108 5,000 psi STD Hydraulic 5-4thd (3.500) Otis

WEIGHTS AND DIMENSIONS

L-970134 .108 10,000 psi H2S Hydraulic 5 3/4-4thd (4.000) Otis Overall Height Weight

L-978775 .108 10,000 psi H2S Hydraulic 6 5/16-4thd (4.375) Bowen 85cm (33.5) 27kg (59lbs)

L-978394 .108 15,000 psi H2S Hydraulic 6 5/16-4thd (3.750) Bowen

L-977454 .108 15,000 psi H2S Hydraulic 6 1/4-4thd (4.000) Otis

L-977132 .125 5,000 psi H2S Hydraulic 7-5thd (5.250) Bowen

L-972551 .125 5,000 psi H2S Hydraulic 8 1/4-4x2 (6.750) Bowen

L-972176 .108/.125 10,000 psi H2S Hydraulic 2-10thd Acme

L-973827 .108/.125 5,000 psi H2S Hydraulic 5-4thd (3.500) Otis

L-972452 .108/.125 10,000 psi H2S Hydraulic 4 3/4-4x2 (3.750) Elmar

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL Liquid Seal Slickline

EQUIPMENT Control Head

The Elmar Liquid Seal Control Head is designed to seal around a slickline while minimising drag

and wear of both the slickline and the pack-off.

Positioned at the uppermost point of the Pressure Control Equipment string, the control head

consists of two major subassemblies, the hydraulic Pack-Off or Stuffing Box and the Flow Tubes

Assembly.

The Stuffing Box is meant to pack-off around the slickline when stationary. When the line is

moving the seal is achieved by injecting viscous grease into the flow tube stack at a pressure above

wellhead pressure. The flow tubes are closely fitting around the slickline, and the grease

seals-off effectively the narrow annular space.

The control head incorporates a ball check valve

to automatically shut-off the well pressure in the

event of pull-off or breakage of the line.

A 16" diameter sheave bracket is supplied as

standard.

The Elmar Liquid Seal Control Head is of

modular design: it can be ordered as two

separate assemblies:

Upper

Assembly A common Upper Assembly including the Stuffing

Box, Sheave Bracket, and the flow-tubes stack,

Grease always rated 15,000 psi, H2S Service

Return A Lower Assembly including the Ball Check Valve

Manifold 19

and a Male Quick Union, as required by the

4

Customer. This is rated according to the type of

Flowtubes

union chosen.

Individual flow tubes must be ordered according

Grease to the line size as part of the Line Size Kit.

Injection

Manifold

A compact, air operated Grease Injection and

Hydraulic Control Panel is available for use with

Lower Assembly the 10,000 psi rated Liquid Seal Control Head.

Alternatively separate Hydraulic Hand Pumps

and air-operated Grease Pumps can be used.

ACCESSORIES

WEIGHTS/DIMENSIONS (L-972506/L-972611)

Part Number Description

Height 65 inches 165cm

Weight 211lbs 96kg L-690644-VO1 Grease and Hydraulic Control Panel for 10,000 psi operations

PART NUMBERS L-690644-VO2 Grease and Hydraulic Control Panel for 15,000 psi operations

Part Working L-690730 Stuffing Box Hand Pump

Number Description Pressure Service Bottom Connection

L-690740 Hydraulic Hose Assembly 100ft long

L-972506 Upper SGI Assembly 15,000 psi H2S N.A.

L-840890 Grease Pump WIWA 235:1

L-972507 Lower SGI Assembly 10,000 psi H2S 5 3/4-4thd (4.000) Otis

L-440059 Grease Injection Hose x 120ft long

L-972611 Lower SGI Assembly 15,000 psi H2S 6.31-4thd (3.750) Bowen

L-440059 Grease Return Hose x 120ft long

L-972612 Lower SGI Assembly 15,000 psi H2S 7 1/2-4thd (5.500) Otis

L-972613 Lower SGI Assembly 15,000 psi H2S 7-5thd (4.375) Bowen

L-973047 Lower SGI Assembly 15,000 psi H2S 6 1/4-4thd (4.000) Otis

LINE SIZE KITS

Part Number Description Line Size

L-972506AL SGI Line Size Kit 0.108 0.108

L-972506BL SGI Line Size Kit 0.125 0.125

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL Electric Line Pressure Control

EQUIPMENT Equipment String

The Elmar Pressure Control Equipment String is designed for complete control of the well pressure

during electric/stranded line operations on a "live" well.

Elmar Pressure Control Equipment Strings are fully traceable and certified by independent

authorities. They are available with 5,000 psi, 10,000 psi, 15,000 psi working pressure rating, Std

and H2S service. ID ranges from 2 1/2" to 6 3/8".

Line Wiper: Wipes the moving cable clean of excess

grease when pulling-out of the well.

Wireline Stuffing Box: Packs-off around a stationary cable

if grease seal is lost.

Grease Injection Head: Controls and contains well

pressure while allowing cable travel in/out of a well.

Ball Check Valve: The Elmar Ball Check Valve is a safety

device for installation below the grease injection control

head. It will seal off the well in the event of the cable being

broken/pulled out of the Grease Injection Head.

Tool Catcher: The Elmar Tool Catcher is used to catch and

hold the tool safely both during pressure testing and in the

event of the cable being inadvertently pulled off at surface

thus preventing a possible fishing job.

20

4 Lubricator Sections: The Elmar Lubricators are used to

insert and retrieve a tool string on a well under pressure.

Tool Trap: The Elmar Hydraulic Tool Trap with External

Indicator protects the wellbore from inadvertent tools pull-off.

Quick Test Sub: The Elmar Quick Test Sub (QTS) is

designed to save substantial rig time while pressure testing

the Wireline Pressure Control Equipment String in multiple

run operations.

Wireline Valve: The Elmar Compact Wireline Valve is a

mono-block construction and is designed for use in single,

dual, triple or quad configuration - Multiline ram seals allow

the use of the same seal configuration for electric line and

slickline.

Pump-in Sub: The Elmar Pump-in Sub is designed to allow

introduction of high volumes of fluid into the well.

Wellhead Adapter Flange: The Elmar Wellhead Adapter

Flange provides a means of connecting in a safe manner

the Wireline Pressure Control Equipment String to the

wellhead.

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL Lightweight Pressure Control

EQUIPMENT Equipment String

The Elmar Lightweight Pressure Control Equipment String is designed for maximum weight

reduction. With a rating of 10,000 psi, H2S Service, the string uses the proven stainless steel

Elmar "Lite" lubricators.

3 I.D. 10,000 psi WORKING PRESSURE, H2S SERVICE

Weight: Weight: Weight: Weight:

Part (10k H2S, (5K H2S, (10K STD, (10K H2S,

Number Description Connections 4 3/4-4x2 4 3/4-4 4 3/4-4 6 5/16-4

Elmar Lite) Bowen) Bowen) Bowen)

Enviro Grease L-971444

Enviro

Grease

2-TPI

Acme Box 51kg 80kg* 80kg* 80kg*

Injection Control Injection (112 lb) (176 lb) (176 lb) (176 lb)

Control Head

Head Tool Catcher/ 4 3/4-4x2 42kg 57kg 62kg 65kg

L-971167 Ball Check (3.750) Elmar (92 lb) (125 lb) (137 lb) (143 lb)

Valve

Lubricator 4 3/4-4x2 25kg 45kg 46kg 75kg

L-971246 4ft long (3.750) Elmar (55 lb) (99 lb) (101 lb) (165 lb)

Lubricator 4 3/4-4x2 49kg 78kg 81kg 128kg

L-971251 10ft long (3.750) Elmar (108lb) (172 lb) (178 lb) (282 lb)

x 6 off x 6 off x 6 off x 6 off

Tool 4 3/4-4x2 49kg 76kg 72kg 85kg

L-971169 Trap (3.750) Elmar (108 lb) (167 lb) (158 lb) (187 lb)

Quick Test 4 3/4-4x2 35kg 62kg 65kg 82kg

L-971404 Sub (3.750) Elmar (77 lb) (136 lb) (143 lb) (180 lb)

Dual L/W 4 3/4-4x2 114kg 280kg 337kg 350kg

L-974111 Wireline Valve (3.750) Elmar (251 lb) (617 lb) (743 lb) (772 lb)

Vent Valve Pump-in 4 3/4-4x2 39kg 59kg 52kg 76kg

L-972052 Sub (3.750) Elmar (86 lb) (130 lb) (114 lb) (167 lb)

Ball Check Valve Total Weight per String of Equipment

649kg 1127kg 1200kg 1581kg

(1431 lb) (2485 lb) (2646 lb) (3486 lb)

Tool Catcher

4 1/16 I.D. 10,000 psi WORKING PRESSURE, H2S SERVICE

Weight: Weight: Weight:

Part (10k H2S, (5K H2S, (10K STD, 21

Number Description Connections 4 3/4-4x2 4 3/4-4 4 3/4-4 4

Elmar Lite) Bowen) Bowen)

Lubricator Sections Enviro 2-TPI

L-971444 Grease Acme Box 51kg 80kg* 80kg*

Injection (112 lb) (176 lb) (176 lb)

Control Head

Tool Catcher/ 6 1/8-4x2 49kg 80kg 80kg

L-972218 Ball Check (4.750) Elmar (108 lb) (176 lb) (176 lb)

Valve

Lubricator 6 1/8-4x2 44kg 112kg 138kg

Tool Trap L-971846A 4ft long (4.750) Elmar (97 lb) (246 lb) (304 lb)

Lubricator 6 1/8-4x2 88kg 174kg 240kg

L-971846E 10ft long (4.750) Elmar (194lb) (383 lb) (528 lb)

x 6 off x 6 off x 6 off

Tool 6 1/8-4x2 85kg 127kg 193kg

L-972219 Trap (4.750) Elmar (187 lb) (279 lb) (425 lb)

Quick Test 6 1/8-4x2 54kg 168kg 168kg

L-972222 Sub (4.750) Elmar (119 lb) (370 lb) (370 lb)

Triple Hydraulic 6 1/8-4x2 655kg 670kg 670kg

L-972223 Wireline Valve (4.750) Elmar (1444 lb) (1474 lb) (1474 lb)

Quick Test Sub Pump-in 6 1/8-4x2 57kg 118kg 118kg

L-972224 Sub (4.750) Elmar (125 lb) (260 lb) (260 lb)

1523kg 2399kg 2887kg

Lightweight Total Weight per String of Equipment

(3357 lb) (5289 lb) (6365 lb)

Wireline Valve

*Note: Includes line wiper return hose (29kg/64 lb) which is not required with the Enviro

Pump-in

Sub

Wellhead Adapter

Flange

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL

EQUIPMENT

Wellhead Adapter Flange

The Elmar Wellhead Adapter Flange provides a means of connecting the wireline valve and

lubricator assembly to the wellhead in a safe and secure manner.

The Elmar Wellhead Adapter Flange consists of a quick union machined on a standard API flange.

The upper end has a standard Bowen type, Otis type or Elmar quick union and can be supplied

with a blanking plug and collar if required.

Elmar wellhead adapter flanges are available in various bore sizes from 2 1/16" to 7 1/16" and

working pressure up to 15,000 psi.

Elmar will design and manufacture well-head adapter flanges for all API standard models. Elmar

adapter flanges are fully traceable and certified to API 6A.

TYPICAL ELMAR WELLHEAD ADAPTER FLANGE SECTION

Thread

Size

Seal Dia

Thread Per

Inch (TPI)

22

4

I.D.

API Ring

Groove

Typical Elmar Number

Adapter Flange L-972237

API Ring Gasket

PART NUMBERS

Part Flange Ring Working Quick Union

Number Size Groove Pressure Service Female Box

L-972237 3 1/16 BX-154 10,000 psi H2S 4 3/4-4x2 (3.750) Elmar

L-975187 3 1/16 BX-154 10,000 psi H2S 6 5/16-4thd (3.750) Bowen

L-974529 4 1/16 R-39 5,000 psi H2S 7-5thd (5.250) Bowen

L-976006 4 1/16 BX-155 10,000 psi H2S 7 1/2-4thd (5.500) Otis

L-972366 4 1/16 BX-155 10,000 psi H2S 6 1/8-4x2 (4.750) Elmar

L-974533 5 1/2 R-44 5,000 psi H2S 8 1/4-4x2 (6.750) Bowen

L-974775 7 1/16 R-46 5,000 psi H2S 9-4thd (6.750) Otis

L-978774 3 1/16 BX-154 15,000 psi H2S 7-5thd (4.375) Bowen

L-979123 4 1/16 BX-155 15,000 psi H2S 7-5thd (4.375) Bowen

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL

EQUIPMENT

Pump-in Sub

The Pump-In Sub (PIS) is normally positioned below the Wireline Valve and above the Wellhead.

Its main function is to allow well control by pumping fluid below a closed Wireline Valve.

The PIS has quick unions top and bottom, and a WECO (Hammer Union) type side connection.

Pump-in Subs are normally supplied with a blind plug & nut on the WECO port. A suitable valve is

needed to operate the PIS, replacing the blind plug. Pump-in Subs can also be used for fluid

sampling or inhibitor injection. Specially designed Pump-in Subs, with different top and bottom

unions are used as wellhead adapter x-overs.

PUMP-IN SUB IN POSITION

Quick Test Sub

Wireline Valve

23

4

Pump-in Sub

Plug

Valve

Wellhead

Adapter

Flange

ACCESSORIES

Typical Elmar 3 Pump-in Sub Part Number Description Working Pressure Service Connection

L-840805 Plug Valve 10,000 psi H2S 2 1502

L-840605 Plug Valve 15,000 psi H2S 2 2202

PART NUMBERS

Part Working

I.D. Service Connection Side Outlet

Number Pressure

L-972052 3 10,000 PSI H2S 4 3/4-4x2 (3.750) Elmar 2 1502

L-979873 3 10,000 PSI STD 4 3/4-4thd (3.750) Bowen 2 1502

L-979098 3 10,000 PSI H2S 5 3/4-4thd (4.000) Otis 2 1502

L-977282 3 10,000 PSI H2S 6 5/16-4thd (4.375) Bowen 2 1502

L-978771 3 15,000 PSI H2S 7-5thd (4.375) Bowen 2 2202

L-978110 4 10,000 PSI H2S 8 1/4-4x2 (6.000) Bowen 2 1502

L-972224 4.06 10,000 PSI H2S 6 1/8-4x2 (4.750) Elmar 2 1502

L-979733 4.5 15,000 PSI H2S 9 1/2-4thd (6.250) Otis 2 2202

L-978891 5.5 5,000 PSI H2S 8 1/4-4x2 (6.750) Elmar 2 1502

L-979264 6 3/8 10,000 PSI H2S 11 1/2-4thd (8.250) Otis 2 1502

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL

EQUIPMENT

Compact Wireline Valve

The Elmar Compact Wireline Valve is of mono-block construction and is designed for use in

either single, dual, triple or quad configurations.

The Valve gives positive protection during well service operations, when operating with slickline,

braided wireline and electric line. It is available in a full range of sizes and working pressures, from

2 1/2 to 6.70 bore sizes, and 5,000 psi to 15,000 psi working pressures. Additional sizes are

available on request.

All Elmar Compact Wireline Valves incorporate the following features as standard :-

Compact size, allowing shorter rig-up heights

Keyless ram bores, allowing ram inversion as and

when required

Quick coupled hydraulic cylinders, allowing fast

removal of cylinder for ram or seal replacement

Threaded quick unions, allowing the use of any

Bowen or Otis quick union without changing the

body (integral unions are available as an optional extra)

Ram position indicator rods

Hydraulic cylinder support arms for 4 - 6.70 wireline

valves

Manifold block with integral equalisation, glycol

and grease injection facilities

24 Triple Elmar Compact Wireline Valve TYPICAL TRIPLE MANIFOLD BLOCK TYPE C

4

PART NUMBERS

Part Working Single/Dual Manifold

I.D. Service Quick Union

Number Pressure Triple Block Type

L-979991 3 5,000 PSI STD Dual 4 3/4-4thd (3.750) Bowen C

L-980049 3 5,000 PSI STD Dual 5-4thd (3.500) Otis C

L-979992 3 10,000 PSI STD Dual 4 3/4-4thd (3.750) Bowen C

L-980050 3 5,000 PSI H2S Dual 5 3/4-4thd (4.000) Otis C

L-980051 3 5,000 PSI H2S Dual 5 1/2-4x2 (4.375) Bowen C

L-980027 3 10,000 PSI H2S Triple 6 1/2-4thd (4.750) Otis C

L-980052 3 10,000 PSI H2S Triple 6 5/16-4thd (4.375) Bowen C

L-979998 3 10,000 PSI H2S Dual 6 5/16-4thd (4.375) Bowen C

L-980253 3 10,000 PSI H2S Triple 7-5thd (4.375) Bowen C

L-972505 3 10,000 PSI H2S Single 4 3/4-4x2 (3.750) Elmar A

L-972142 3 10,000 PSI H2S Dual 4 3/4-4x2 (3.750) Elmar C Manifold type A : Equalisation and Pressure Gauge Connection Facility

Manifold type B : Equalisation, Pressure Gauge Connection and Grease Injection Facility

L-971402 3 10,000 PSI H2S Triple 4 3/4-4x2 (3.750) Elmar C Manifold type C : Equalisation, Pressure Gauge Connection and Grease and Glycol Injection Facility

L-972354 4 1/16 10,000 PSI H2S Single 6 1/8-4x2 (4.750) Elmar A

L-972353 4 1/16 10,000 PSI H2S Dual 6 1/8-4x2 (4.750) Elmar C MANIFOLD GAUGE KITS

L-972488 4 1/16 10,000 PSI H2S Triple 6 1/8-4x2 (4.750) Elmar C L-660492 5,000 psi W.P.

L-980053 4 10,000 PSI H2S Single 8 1/4-4x2 (6.000) Bowen A L-660493 10,000 psi W.P.

L-980054 4 10,000 PSI H2S Dual 8 1/4-4x2 (6.000) Bowen C

L-980007 4 1/16 10,000 PSI STD Dual 8 1/4-4x2 (6.000) Bowen C

L-979731 4 1/2 15,000 PSI H2S Triple 9 1/2-4thd (6.250) Otis B

L-980055 5 1/8 5,000 PSI H2S Dual 8 1/4-4x2 (6.750) Bowen B

L-980056 5 1/8 10,000 PSI H2S Dual 9-4thd (6.750) Otis B

L-980057 5 1/8 10,000 PSI H2S Triple 9-4thd (6.750) Otis B

L-980058 6 3/8 5,000 PSI H2S Dual 9 7/8-4x2 (8.000) Bowen B

PART NUMBERS

L-980059 6 3/8 10,000 PSI H2S Dual 11 1/2-4thd (8.250) Otis B

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL

EQUIPMENT

Lightweight Wireline Valve

The Elmar Lightweight Wireline Valve is available in 3 I.D., 10,000 psi working pressure, H2S

service, in either single, dual or triple configurations. (Soon to be available in 4, 5 and 6 3/8 I.D.)

The Elmar Lightweight Wireline Valve gives positive protection during well service operations,

when operating with slickline, braided wireline and electric line.

All Elmar Lightweight Wireline Valves are up to 60% lighter than previous generation Wireline

Valves and incorporate the following features as standard :-

Lightweight, allowing easier handling

3 Single 66kg, (146lb), Dual 114kg, (251lb)

and Triple 162kg, (357lb)

Compact size, allowing shorter rig-up heights

Back-up manual closure

Threaded quick unions, allowing the use of any

Bowen type or Otis type union without changing

the body

Ram position indicator rods

Manifold blocks with integral equalisation, glycol

and grease injection facilities

Maximum working pressure 10,000 psi H2S service

Maximum hydraulic working pressure 3,000 psi

API 6A and NACE compliant

Third Party Design Approval 25

Keyless Q-GUIDE ram design providing flexible 4

Part Number L-974111

(Patent Pending) ram configuration and positive wireline guiding

Multiline inner seal accommodating a range of

LIGHTWEIGHT BOP, LUBRICATOR AND STUFFING BOX

wireline sizes

PART NUMBERS

Part Working Single/Dual

I.D. Service Quick Union

Number Pressure Triple

L-974111 3 10,000 PSI H2S Single 4 3/4-4x2 (3.750) Elmar

L-974223 3 10,000 PSI H2S Dual 4 3/4-4x2 (3.750) Elmar

L-974224 3 10,000 PSI H2S Triple 4 3/4-4x2 (3.750) Elmar

Lightweight

Note: Ram line size to be specified at time of ordering

Slickline

Stuffing Box MANIFOLDS

Grease/Glycol Injection Bleed Off and Gauge

and Equalistion

Equalisation Valve

Lightweight

Lubricator

Glycol Bleed Off Gauge Port

Section Injection

Grease

3 Lightweight Injection

Manual

Wireline Valve Handle

Stored

Equalisation Valve

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL

EQUIPMENT

Quick Test Sub - QTS

The Elmar Quick Test Sub (QTS) is designed to save rig time while pressure testing the Wireline

Pressure Control Equipment String when multiple wireline runs are required.

The Elmar Quick Test Sub is inserted either above or below the wireline valve at the position of the

joint normally opened to insert and retrieve tools from the well. After performing the first pressure

test to check the integrity of the whole String, subsequent pressure tests can be made using the

Quick Test Sub to verify the integrity of the joint disconnected, rather than having to test the whole

assembly. This is achieved by connecting a small hydraulic hand-pump to the Quick Test Sub and

testing the joint O ring seal from the outside. It is estimated that the use of the Elmar Quick Test

Sub can reduce the time needed to pressure test the String at each subsequent test by more than

1/2 hour.

Saves time on pressure test due to design features

Eliminates prospect of contaminating well with

test fluids

Saves on glycol

Eliminates risks of pressure testing with

perforating guns

Metal to metal seal,

seals valve after

pressure test

26

4

Hand pump connection

PART NUMBERS

Part Working

Number I.D. Pressure Service Connections Seal Kit

L-971404 3 10,000 psi H2S 4 3/4-4x2 (3.750) Elmar L-971404K

L-972235 3 10,000 psi H2S 5 3/4-4thd (4.000) Otis L-972235K

L-970918 3 10,000 psi H2S 6 1/2-4thd (4.750) Otis L-970918K

L-971299 4 10,000 psi H2S 8 1/4-4x2 (6.000) Bowen L-971299K

L-972222 4.06 10,000 psi H2S 6 1/8-4x2 (4.750) Elmar L-972222K

HAND PUMP ASSEMBLY (10,000 PSI W.P.) L-973101 5.125 10,000 psi H2S 9-4thd (6.750) Otis L-973101K

Part Number

L-690573

HYDRAULIC HOSE ASSEMBLY

Part Number Description

Hose Assembly

25ft 6mm ID, 10,000psi Hose

L-690587

with Quick Connectors

and Dust Covers

L-690586 50ft

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL Hydraulic Tool Trap

EQUIPMENT with External Indicator

The Elmar Hydraulic Tool Trap with external indicator is installed between the Wireline Valve and

the lubricator string. It prevents the loss of wireline tools downhole in the event of the wire being

pulled-off the rope socket, by retaining the dropping tool on a flapper. The flapper has an opening

larger than the wireline, but smaller than the tool string.

The flapper is operated by a hydraulic actuator, through an external handle, connected to the

flapper with a low-torque pressure-balanced shaft. The external handle doubles as a tool passage

indicator. The tool string may be pulled freely upwards through the tool trap. The flapper will move

upwards, together with the external handle, indicating tool passage. As soon as the string bottom

has cleared the flapper, the flapper will drop back into the trap position, pushed by a torsion spring.

The flapper can be lifted remotely when running a tool in the well by activating the piston in the

hydraulic actuator. Pumping back the piston to its original position allows the flapper to return to its

trap position.

The hydraulic actuator can be operated by a dual output manual pump or with an Elmar Hydraulic

Control Module.

Lightweight: L-971169

Positive tool passage indicator

Pressure-balanced flapper shaft

Remote hydraulic operation. Enhanced

operational safety

Can be operated manually in case of hydraulic

failure

Hydraulic Option:

Actuator Manual Tool Trap with external indicator 27

CROSS SECTION DETAIL 4

Flapper

Handle

ACCESSORIES

Part Number Description

PART NUMBERS L-690750 Tool Trap Hand Pump

Part Number I.D. Working Pressure Service Quick Union

L-974814 2 1/2 15,000 psi H2S 6 5/16-4thd (3.750) Bowen

L-976271 2 1/2 10,000 psi H2S 6 5/16-4thd (4.375) Bowen L-690615 50ft Hose Assembly

L-971169 3 10,000 psi H2S 4 3/4-4x2 (3.750) Elmar

L-978383 3 5,000 psi H2S 5 3/4-4thd (4.000) Otis

L-974828 3 10,000 psi H2S 6 5/16-4thd (4.375) Bowen

L-974794 4 10,000 psi H2S 8 1/4-4x2 (6.000) Bowen

L-972219 4 1/16 10,000 psi H2S 6 1/8-4x2 (4.750) Elmar

L-978441 5 1/2 5,000 psi STD 8 1/4-4x2 (6.750) Bowen

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL Wireline Lubricator with

EQUIPMENT Integral Unions

The SSR Integral Lubricator Section is a pressure containing cylinder used when performing

wireline operations. Its purpose is to allow the Wireline Tool String to be raised above the wellhead

prior to and after wireline operations, thereby enabling the wellhead valve to be opened and closed,

allowing entry and exit from the well bore. During slickline operations, three Lubricator Sections are

normally used, each having a different ID, the uppermost section having the smallest, then

opening out to the lower section with largest ID. During electric line operations the lubricators

normally have the same ID.

3 DIAMETER THROUGH BORE

Working Pressure Unions Length Assembly Number

5,000psi 5 1/2" - 4x2 'BB' 8ft. A014-123

10ft. A014-137

5,000psi 5" - 4THD 'OO' 8ft. A014-098

10ft. A014-138

10,000psi 6 5/16" - 4THD 'BB' 8ft. A014-100

10ft. A014-139

10,000psi 5 3/4" - 4THD 'OO' 8ft. A014-116

10ft. A014-140

4 DIAMETER THROUGH BORE

Working Pressure Unions Length Assembly Number

5,000psi 7" - 5THD 'BB' 8ft. A016-059

10ft. A016-089

5,000psi 6 1/2" - 4THD 'OO' 8ft. A016-067

10ft. A016-076

10,000psi 8 1/4" - 4x2 'BB' 8ft. A016-060

(6.000") Seal Dia. 10ft. A016-090

10,000psi 8 3/8" - 4THD 'OO' 8ft. A016-091

10ft. A016-097

SPECIFICATIONS

28

Pressure Rating Up to 15,000psi

4

Service H2S and Standard Service

'OO' - OTIS type Union 'BB' - BOWEN type Union

SSR Integral Lubricator A014/A016

(SSR Product Line)

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL Wireline Lubricator with

EQUIPMENT Screwed Unions

The SSR Lubricator Section is used when performing wireline or electric line operations with 1/2

NPT Bleed Port Fitted. Quick Unions are of the screwed type with a SSR ACME thread, which

incorporates primary O Ring Seal with metal back-up. Det Norske Veritas and Lloyds Design type

approval is available if required.

2 1/2 DIAMETER THROUGH BORE

Working Pressure Unions Length Assembly Number

5,000psi 4 3/4" - 4THD BB 8ft. A012-002

10ft. A012-003

5,000psi 5" - 4THD 'OO' 8ft. A012-043

10ft. A012-044

10,000psi 6 5/16" - 4THD 'BB' 8ft. A012-006

10ft. A012-007

10,000psi 5 3/4" - 4THD 'OO' 8ft. A012-008

10ft. A012-009

3 DIAMETER THROUGH BORE

Working Pressure Unions Length Assembly Number

5,000psi 5 1/2" - 4x2 'BB' 8ft. A014-014

10ft. A014-015

5,000psi 5" - 4THD 'OO' 8ft. A014-092

10ft. A014-011

10,000psi 6 5/16" - 4THD 'BB' 8ft. A014-009

10ft. A014-003

10,000psi 5 3/4" - 4THD 'OO' 8ft. A014-019

10ft. A014-021

4 DIAMETER THROUGH BORE

Working Pressure Unions Length Assembly Number

5,000psi 7" - 5THD 'BB' 8ft. A016-004

10ft. A016-002

5,000psi 6 1/2" - 4THD 'OO' 8ft. A016-006

10ft. A016-007

10,000psi 8 1/4" - 4x2 'BB' 8ft. A016-008

(6.000") Seal Dia. 10ft. A016-026

10,000psi 8 3/8" - 4THD 'OO' 8ft. A016-009

10ft. A016-010

29

5 DIAMETER THROUGH BORE

Working Pressure Unions Length Assembly Number

4

5,000psi 8 1/2" - 4x2 'BB' 8ft. A018-009

(6.750") Seal Dia. 10ft. A018-010

5,000psi 8 1/4" - 4THD 'OO' 8ft. A018-055

10ft. A018-114

10,000psi 8 7/8" - 4x2 'BB' 8ft. A018-115

10ft. A018-001

10,000psi 9" - 4THD 'OO' 8ft. A018-013

10ft. A018-002

6 3/8 DIAMETER THROUGH BORE

Working Pressure Unions Length Assembly Number

5,000psi 9 7/8" - 4x2 'BB' 8ft. A020-005

10ft. A020-006

5,000psi 9 1/2" - 4THD 'OO' 8ft. A020-007

10ft. A020-008

10,000psi 12 1/4" - 4THD 'BB' 8ft. A020-116

10ft. A020-117

10,000psi 11 1/2" - 4THD 'OO' 8ft. A020-011

10ft. A020-012

SPECIFICATIONS

Pressure Rating Up to 15,000psi

Service H2S and Standard Service

'OO' - OTIS type Union 'BB' - BOWEN type Union

SSR Screwed Lubricator

(SSR Product Line)

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL

EQUIPMENT

Bleed-Off Sub

For applications when a bleed-off port is required on the lubricator string , subs are available with

a 1/2" NPT Port for connection of a suitable valve.

BLEED-OFF SUB IN POSITION

ELMAR

Slickline

Head

Ball Check Valve

Tool Catcher

Needle

Valve

Lubricator Sections

30

4 Bleed-Off Sub

Quick Test Sub

Lightweight

Wireline Valve

PART NUMBERS

Part Working Bleed

Number I.D. Pressure Service Quick Union Port

L-974292 3 10,000 psi H2S 4 3/4-4x2 (3.750) Elmar 1/2 NPT Pump-in

L-974293 4 1/16 10,000 psi H2S 6 1/8-4x2 (4.750) Elmar 1/2 NPT Sub

L-970915 3 10,000 psi STD 4 3/4-4thd (3.750) Bowen 1/2 NPT

L-970916 3 10,000 psi H2S 6 5/16-4thd (4.375) Bowen 1/2 NPT Wellhead Adapter

ACCESSORIES Flange

Part Number Description

L-500060 Needle Valve, 10,000 psi H2S 1/2 NPT

Copyright Varco International Inc, 2002 www.elmar.co.uk

PRESSURE CONTROL

EQUIPMENT

Lightweight Lubricator

The Elmar "Lite" lubricators enable the wireline tool string to be introduced or retrieved from a well

bore under pressure. They are normally positioned above the Wireline Valve, Tool Trap or Quick

Test Sub. By using high strength Stainless Steel Alloys, the weight of a lubricator section is reduced

by up to 70% with respect to conventional integral lubricators.

The Elmar "Lite" lubricator consists of four basic parts: a quick union collar, a male quick union, a

lubricator tube, and a female quick union. The quick unions are manufactured in H2S resistant alloy

steel to prevent galling.

Elmar "Lite" lubricators are supplied with a 3" or 4 1/16" bore, and are rated 10,000 psi H2S

service. The Elmar Lightweight quick unions have been selected for optimum weight reduction and

to prevent unsafe cross-string assembly. Upper and lower adapters are available to connect

existing equipment. These are rated 5,000 psi or 10,000 psi depending on the type of connection.

Corrosion Resistant Tube made from high

strength NACE Certified Stainless Steel

Quick unions are coupled through Premium

Elmar Lite Coupling:

- Tube-to-union seal is metal-to-metal

backed-up by O-Ring

- Special handling tools supplied. Calibrated

torque is not required.

Bending stresses at the thread undercut are

minimised. 31

Elmar Lightweight Quick Unions: 4

- 3" ID: 4 3/4"- 4x2 (3.750" seal dia)

- 4 1/16" ID: 6 1/8"- 4x2 (4.750" seal dia)

ACCESSORIES

L-973957 3 Torque Tool

L-973958 4 1/16 Torque Tool

3 I.D. LIGHTWEIGHT LUBRICATOR

Buttress Type

Part Upper Lower Thread

Number Connections Connections I.D. W.P. Service L. W.

L-971246

4 3/4-4x2 (3.750) 4 3/4-4x2 (3.750)

3 10K H2S 4ft 54 lb

Up to

Elmar Box Elmar Pin

4 3/4-4x2 (3.750) 4 3/4-4x2 (3.750)

70%

L-971247 3 10K H2S 5ft 63 lb

Elmar Box Elmar Pin lighter

4 3/4-4x2 (3.750) 4 3/4-4x2 (3.750)

L-971248 Elmar Box Elmar Pin 3 10K H2S 6ft 72 lb

4 3/4-4x2 (3.750) 4 3/4-4x2 (3.750)

L-971249 Elmar Box Elmar Pin 3 10K H2S 8ft 90 lb

4 3/4-4x2 (3.750) 4 3/4-4x2 (3.750)

L-971251 Elmar Box Elmar Pin 3 10K H2S 10ft 108 lb

4 1/16 I.D. LIGHTWEIGHT LUBRICATOR

Part Upper Lower

Number Connections Connections I.D. W.P. Service L. W.

6 1/8-4x2 (4.750) 6 1/8-4x2 (4.750)

L-971846A Elmar Box Elmar Pin 4.06 10K H2S 4ft 96 lb

6 1/8-4x2 (4.750) 6 1/8-4x2 (4.750)