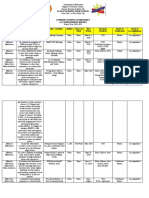

Beruflich Dokumente

Kultur Dokumente

Visual CV

Hochgeladen von

Ankur PandeyOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Visual CV

Hochgeladen von

Ankur PandeyCopyright:

Verfügbare Formate

ANKUR

NKUR KUMAR

PANDEY

Mobile: +91 91376 37579(India)

E-Mail:

Mail: Ankurpandey25@Gmail.com

CAREER SUMMERY

cd

Proactive, result focused Quality control/Assurance Welding Engineer with 3.5 years of working experience

within the Welding Industry, holding Bachelor of Engineering in Mechanical Engineering stream having

excellence

xcellence in Operations management, TTeam eam management, Client relationship & communications,

procurement, critical equipments analysis

analysis,, Root Cause analysis, preparation of progress reports and material

management.

Skilled at analyzing, problem solving, multitasking and motivating.

ba

Career Objective Core Competencies

CSWIP 3.1 - Welding Inspector - Level 2

To seek an assignment in Welding / Oil & Gas / (Certificate no- 80469/ Validity-

Validity 10/10/2018)

Manufacturing / Construction industries with IRCA Certified QMS/ISO 9001:2008 LEAD

extremely challenging environment industries Auditor. (Certificate no-9341)

no

where I can fully utilize my theoretical skills, Non Destructive Testing Level-II

Level as per ASNT

efficiency and responsibility, facilitating SNT-TC-1A1A (UT, RT, MPT, DPT). (Valid up to

growth of the organization and to grow with it. Dec, 2017)

Dimensional & Visual inspection of Welds

before, during & after Welding.

Destructive testing (Lab Testing)

Root causes Analysis (RCA).

Corrective Action Preventive action

Analysis(CAPA)

Preparation of Progress Reports.

Procurement (Spares, Consumables etc. )

Client Relationship Management.

Team Management.

Motivational / Multitasking

Multit Skills.

u Ankur Kumar Pandey uu +91 91376 37579 (India) u Ankupandey25@gmail.comu

Ankupandey25@gmail.com

WELSPUN CORP LTD:

SAW, MIG/MAG, GTAW,

SMAW Welding Processes.

Welspun Corp Ltd AUGUST 2010-PRESENT

Gas Fired Bogie Hearth

Furnace-Heat treatment.

Hot Pulled induction pipe

bending plant.

Designation : Engineer

Job Profile :-

Location : Kutch,

4 NDE inspection of Welds (Visual, UT, RT, MPT, DPT), Dimensional

Gujarat (INDIA)

inspection, Radiographic film Interpretation (RTFI) of Pipes/Bends,

Preparation of inspection reports.

4 Carryout/ Witness/ Monitor / Ensure Hydro testing and Heat Treatment

(viz. Stress Relieving, Normalizing, Annealing etc) as per approved

procedures and client requirements for Pipes, Bends, Spools, Fabricated

structures etc.

4 Knowledge in the use and operation / Inspection of basic shop

welding, cutting, metal forming, gas extraction and heat treatment

equipment (e.g. SMAW, MIG/MAG, GTAW, SAW, Bending machines,

PROFESSIONAL TRAININGS &

HT Furnace, PWHT etc.).

AFFILIATIONS:-

4 Monitor data for WPS/PQR/PQT and welder qualification and ensure

compliance of the same till end of campaign and record data as per

QMS requirement.

4 Co-ordinate with production & Lab team for Destructive testing (viz.

Bend tests, tensile tests, CVN, CTOD etc.) of weld samples after

Procedure qualification test or welder qualification and Test results

interpretation.

4 Non destructive testing activities in plant as per requirements/

Approved Procedures.

4 Preparation and updating of QMS (Quality Management system)

Audit checklists and conducting in house audits as per ISO 9001:2008.

4 Incoming material inspection i.e. welding wire, electrode, welding

flux, hot rolled steel coils, pipes for bend formation etc as per

approved procedures.

4 Equipments calibration (Measuring/Monitoring) with other agencies

on behalf of company

4 Preparation of Quality Reports and get it approved by TPIA/ Clients.

4 Carry out Root Cause Analysis for major problems identified during

campaign to optimize efficiency of process.

4 Preparation of Quality assurance Plan (QAP) and send for further

approval to concern.

4 Material Traceability by Color Coding (Pipe & Consumable Material).

4 Raising Surveillance audits & NCR for any non compliances/violation.

4 Attend weekly QA/QC coordination meeting & Pre-inspection

meeting with clients before execution of orders.

4 Routine documentation and reporting quality related issues to top

management.

u Ankur Kumar Pandey uu +91 91376 37579 (India) u Ankupandey25@gmail.comu

EDUCATION

4 Bachelors of Technology (Mechanical Engineering) from Ajmer Institute of technology affiliated to

Rajasthan Technical University with average 66% marks (First Class).

ACHIEVEMENTS & PERFOMANCE APPRECIATION

4 Awarded as Star GET at Welspun corp. Ltd in August, 2011.

4 Received Star performer of the Year Award from UNIT HEAD of Welspun corp. Ltd in the year

2012.

IT SKILLS :- CODES & STANDARDS AWARENESS:-

ERP Tools : SAP ERP 4.7 PP Module. 4 ISO 9001:2008

Designing and Drafting tool: AutoCAD 2004, 4 BS EN ISO 17637

Pro-E Wildfire. 4 ASME SEC II C

Office/Others Tools : MS Office, Internet and

4 ASME SEC VIII

Other basic applications.

4 ASME SEC IX

4 ASME B16.49

4 MSSSP-75

4 ISO15590-1

4 API 5L 45th Edition

PROFESSIONAL ENHANCEMENT PROGRAMS

4 Training programmes for Safety Measures in Confined space entry, hot work, Excavation, Working at

Height, PPE awareness & OHSAS 18001-2007 Awareness are attended at Welspun Corp. Ltd.

4 Practical Fire Fighter trainings & active member of Fire fighting mock drill committee.

PERSONALINFORMATION

PERSONAL INFORMATION

Full Name : Pandey Ankur Kumar Hansraj

Date of Birth : 25th May, 1989

Languages Known : English, Hindi, and Gujarati. (Read, Write, Speak)

Passport Number : K9350719 (Valid till Jan, 2023)

Valid driving licence : Having Valid Driving Licence in INDIA

Permanent Address : A/31, Surbhi Soc,

Nandewar Road,

Bharuch- 392 001

Gujarat-INDIA

Contact No : +91 91 376 375 79

Email ID : Ankurpandey25@gmail.com, Ankur25@in.com

References : Available on Request

u Ankur Kumar Pandey uu +91 91376 37579 (India) u Ankupandey25@gmail.comu

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Leeson Motor - 121815.00 - DataPack - 9Dokument5 SeitenLeeson Motor - 121815.00 - DataPack - 9Ankur PandeyNoch keine Bewertungen

- AMI Adapter Cables Product LineDokument1 SeiteAMI Adapter Cables Product LineAnkur PandeyNoch keine Bewertungen

- Standardization Qualification Inspection Challenges For Additive ManufacturingDokument23 SeitenStandardization Qualification Inspection Challenges For Additive ManufacturingAnkur PandeyNoch keine Bewertungen

- D17 2-D17 2M-2013PVDokument9 SeitenD17 2-D17 2M-2013PVAnkur PandeyNoch keine Bewertungen

- D17 2-D17 2M-2013PVDokument9 SeitenD17 2-D17 2M-2013PVAnkur PandeyNoch keine Bewertungen

- APQP WebinarDokument69 SeitenAPQP WebinarWahyu SupriyadiNoch keine Bewertungen

- APQP Elements: 1 Customer OrderDokument13 SeitenAPQP Elements: 1 Customer OrderShanmugam BalasubramaniamNoch keine Bewertungen

- Learner License FormDokument2 SeitenLearner License FormRohit JainNoch keine Bewertungen

- ReliabilityDokument5 SeitenReliabilityAnkur PandeyNoch keine Bewertungen

- Chemical of A105 and A106Dokument2 SeitenChemical of A105 and A106Ankur PandeyNoch keine Bewertungen

- Resume: Manas Kumar PandaDokument4 SeitenResume: Manas Kumar PandaAnkur PandeyNoch keine Bewertungen

- SHR I Manubhai Pancholi: Recipient of J Amnalal Bajaj Awar D For Constr Uctive Wor k-1996Dokument3 SeitenSHR I Manubhai Pancholi: Recipient of J Amnalal Bajaj Awar D For Constr Uctive Wor k-1996Ankur PandeyNoch keine Bewertungen

- Resume FormatDokument3 SeitenResume FormatAnkur PandeyNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Quorum Sensing PDFDokument9 SeitenQuorum Sensing PDFShareenMuneebNoch keine Bewertungen

- Single Conductor 15KV, Shielded, MV-105Dokument2 SeitenSingle Conductor 15KV, Shielded, MV-105henry hernandezNoch keine Bewertungen

- Buddhist 083011Dokument150 SeitenBuddhist 083011Mazzy S100% (1)

- Chinese Cinderella - MeDokument2 SeitenChinese Cinderella - Meapi-298120057100% (1)

- According To India International Coffee Festival in The TitledDokument4 SeitenAccording To India International Coffee Festival in The Titledsalman vavaNoch keine Bewertungen

- Gardobond 24d Imu Sds Ver1Dokument6 SeitenGardobond 24d Imu Sds Ver1stuart3962Noch keine Bewertungen

- References: ProblemsDokument14 SeitenReferences: ProblemsDiego AlejandroNoch keine Bewertungen

- Cocktail Making Techniques 13.3.11Dokument3 SeitenCocktail Making Techniques 13.3.11Ryan MenezesNoch keine Bewertungen

- 1101259L 580.752830 Pressure Washer ManualDokument64 Seiten1101259L 580.752830 Pressure Washer Manualgork1roguesNoch keine Bewertungen

- Owners Manual NCSP3CM (En)Dokument47 SeitenOwners Manual NCSP3CM (En)yurii volNoch keine Bewertungen

- Sensus 143-80 Service Regulator R-1301 R5Dokument11 SeitenSensus 143-80 Service Regulator R-1301 R5Paolita Auza BalderramaNoch keine Bewertungen

- Dan Zahavi Josef Parnas - Schizophrenic - Autism - Clinical - Phenomenology PDFDokument6 SeitenDan Zahavi Josef Parnas - Schizophrenic - Autism - Clinical - Phenomenology PDFAdelar Conceição Dos SantosNoch keine Bewertungen

- ISKCON Desire Tree - Brahma Vimohana LeelaDokument34 SeitenISKCON Desire Tree - Brahma Vimohana LeelaISKCON desire treeNoch keine Bewertungen

- Biological Activity of Bone Morphogenetic ProteinsDokument4 SeitenBiological Activity of Bone Morphogenetic Proteinsvanessa_werbickyNoch keine Bewertungen

- Grade 10 Chemistry Week 1Dokument3 SeitenGrade 10 Chemistry Week 1Nikoli MajorNoch keine Bewertungen

- Geotechnical Engineering GATE Previous QuestionsDokument35 SeitenGeotechnical Engineering GATE Previous QuestionsSurya ChejerlaNoch keine Bewertungen

- Winchester Model 9422 Lever Action Rifle Owner's Manual: LicenseeDokument0 SeitenWinchester Model 9422 Lever Action Rifle Owner's Manual: Licenseecarlosfanjul1Noch keine Bewertungen

- SOAP Progress NotesDokument11 SeitenSOAP Progress NotesShan SicatNoch keine Bewertungen

- Ashin Tejaniya: Questions & Answers WithDokument241 SeitenAshin Tejaniya: Questions & Answers WithharioNoch keine Bewertungen

- Good Boys Go To Heaven, Bad Boys Go EverywhereDokument32 SeitenGood Boys Go To Heaven, Bad Boys Go Everywherealcantaravic2006Noch keine Bewertungen

- Liquid Fertilizer PresentationDokument17 SeitenLiquid Fertilizer PresentationAnna RothNoch keine Bewertungen

- Ducted Exhaust Ventilation Fans: Low Noise, High Performance Air and Moisture ExtractionDokument4 SeitenDucted Exhaust Ventilation Fans: Low Noise, High Performance Air and Moisture ExtractionNicolas BaquedanoNoch keine Bewertungen

- Tutorials 2016Dokument54 SeitenTutorials 2016Mankush Jain100% (1)

- La Paz National High SchoolDokument19 SeitenLa Paz National High SchoolBon Ivan FirmezaNoch keine Bewertungen

- Presentation 2Dokument70 SeitenPresentation 2Vivek LathNoch keine Bewertungen

- Afcat Question Paper 01-2014 PDFDokument10 SeitenAfcat Question Paper 01-2014 PDFTuhin AzadNoch keine Bewertungen

- Water Distiller - ManualDokument2 SeitenWater Distiller - ManualSanjeevi JagadishNoch keine Bewertungen

- How To Self-Decontaminate After A Radiation Emergency - CDCDokument2 SeitenHow To Self-Decontaminate After A Radiation Emergency - CDCZankanotachiNoch keine Bewertungen

- 10.4324 9781315717289 PreviewpdfDokument179 Seiten10.4324 9781315717289 PreviewpdfMahdi GargouriNoch keine Bewertungen

- Method Setting Out of Drainage 2Dokument9 SeitenMethod Setting Out of Drainage 2amin100% (1)