Beruflich Dokumente

Kultur Dokumente

SERIES 35-53: Features

Hochgeladen von

Andre VPOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SERIES 35-53: Features

Hochgeladen von

Andre VPCopyright:

Verfügbare Formate

SERIES 35-53

12 VDC Microprocessor Based

Direct Spark Ignition Control 35.53.02

FEATURES

Optional combustion blower relay with selectable postpurge

System diagnostic LED indicator

Multiple tries for ignition (TFI)

Automatic reset 1 hour after lockout

Custom TFI, prepurge and interpurge timings

Remote or local flame sensing

Software conforms to UL 1998 requirements

Safe start

Heavy conformal coating

APPLICATIONS

Recreational Vehicles (including boats/marine)

Infrared Paving Repair Equipment

Outdoor Torches and Lanterns

Battery Powered Furnaces & Appliances

SPECIFICATIONS

INPUT VOLTAGES DESCRIPTION

DESCRIPTION

Input Power Control: 9.0 to 15 VDC from a storage battery

The Model 35-53 is a 12 VDC Microprocessor Based Direct or full wave rectified unfiltered 50/60 Hz AC

Spark Ignition Control designed for use in all types of heating 300 mA @ 12 VDC, combustion blower and

applications such as RV gas furnaces and other similar appliances. Input Current Drain gas valve relays energized (control only)

The control utilizes a microprocessor to continually and safely

Gas Valve Rating 1.0A @ 12 VDC

monitor, analyze and control the proper operation of the gas

Combustion Blower Rating 20.0A @ 12 VDC

burner. Value added features such as combustion blower control,

LED diagnostic output, and multiple ignition tries highlight the Operating Temperatue -40F to +176F ( -40C to +80C)

control's benefits. Combustion blower versions are fully backward Flame Sensitivity 0.7A minimum

compatible with all previous Fenwal 12VDC controls and Flame Failure Response Time 0.8 seconds maximum

competitive models. The control determines the unit configuration

Types of Gases Natural, LP, or manufactured

at the start of the heating sequence and disables the blower func-

tion if not required, allowing one part to address all service or OEM Spark Rate 16 sparks per second

needs. Size (LxWxH) 4.25 x 3.25 x 1.80 inches

10.80 x 8.25 x 4.57 cm

Agency Certifications Enclosure Uncovered with integral standoffs

or optional cover

Conformal coated to operate to 95% R.H.

Design certified to UL372, File MH8817 Moisture Resistance

Always avoid direct exposure to water

Design certified to ANSI Z21.20-1998 and CAN/CSA C22.2 Tries for Ignition One or three try versions available

No. 199-M89 - Report # C2180012 Trial for Ignition Period 5.0, 7.0, 10.0, or 25.0 seconds available

None, 15 or 25 seconds depending

Prepurge & Interpurge Timings on model. Without prepurge there is

a 1 second start-up delay.

Postpurge Timings Selectable 45, 90, 130, 150 seconds

www.fenwalcontrols.com 1-800-FENWAL-1 Series 35-53, 12 VDC DSI Control Page 1

SEQUENCE OF OPERATION / FLAME All connections should be made with UL approved, 105C rated,

18 gauge stranded wire with .054 miniumum insulation thickness, .054

RECOVERY/ SAFETY LOCKOUT thick insulated wire. Refer to the appropriate wiring diagram when con-

Start up - Heat Mode necting the 35-53 to other components in the system. High voltage spark

cables and control wiring harnesses are detailed on Page 3.

When a call for heat is received from the thermostat supplying 12 volts to

TH, the control will reset, perform a self check routine and verify no flame EDGE CONNECT TERMINALS

exists (safe start). After verifying the airflow switch input is open, the

Blower is energized and the airflow switch contacts close starting the

/SENSE

pre-purge delay. After the pre-purge delay the gas valve is energized and

sparks commence for the trial for ignition period.

When flame is detected during the trial for ignition, sparking stops and

the gas valve remains energized. The thermostat, airflow switch and main

burner flame are constantly monitored to assure that the system continues

to operate properly. When the thermostat is satisfied and the demand

WARNING: The 35-53 uses voltages of shock hazard potential.

for heat ends, the main valve is de-energized immediately, and after the Wiring and initial operation must be done by a qualified service technician.

post-purge period the blower is turned off.

Failure to Light - Lockout Terminal Designations

MULTI TRIAL MODEL TERMINAL DESCRIPTION TERMINAL TYPE LOC- WIRE

Should the main burner fail to light, or if the flame is not detected ATION COLOR

during the first trial for ignition period, the gas valve is de-energized

and the control goes through an interpurge delay before another ignition

PWR * + 12 VDC Power 3/16 Q.C. Terminal - -

attempt. The control will attempt two additional ignition trials before BLO * Blower 1/4 Q.C. Terminal - -

going into lockout after which the valve relay will remain de-energized AIR * Airflow Switch 6 Pin Edge Connector 1 Red

and the blower will turn off after a five minute delay. TH * Thermostat 6 Pin Edge Connector 2 Orange

SINGLE TRIAL MODEL NC NC Contact 6 Pin Edge Connector 3 Blue

Should the main burner fail to light, or flame is not detected during V1 Gas Valve 6 Pin Edge Connector 4 Brown

the trial for ignition period, the control will go into lockout. The valve TEST/SENSE Local Sense Unused 5 -

will be turned off immediately and the blower will turn off after a five Remote Sense 6 Pin Edge Connector 5 Black

minute delay.

GND Ground 6 Pin Edge Connector 6 Yellow

Recovery from lockout requires a manual reset by either resetting the

thermostat or removing 12 volt power for a period of 5 seconds. * Air terminal provides +12 VDC power for models without

blower control DWR, BLO and TH terminals are not used.

If the thermostat is still calling for heat after one hour the control will

automatically reset and attempt to ignite the burner again. CAUTION: Label all wires prior to disconnection when servicing

the control. Wiring errors can cause improper and dangerous operation.

Flame Failure A functional checkout of a replacement is recommended.

If the established flame signal is lost while the burner is operating, the WARNING: Operation outside specifications could result in failure

control will respond within 0.8 seconds. On re-cycle models, the gas of the Fenwal product and other equipment with injury or death to

valve is de-energized and a new interpurge and TFI sequence will people and damage to property.

begin. On optional re-ignition models, the gas valve will stay energized

and the HV spark will be energized for a trial for ignition period to TROUBLESHOOTING GUIDE

attempt to relight the burner. If the burner does not light the control will

de-energize the gas valve. Multi-try models will make two more SYMPTOM RECOMMENDED ACTIONS

1. Dead A. Miswired

attempts to relight the burner. If the burner does not relight the control

B. Transformer/battery bad

will go into lockout as noted above in "Failure to light. If flame is C. Fuse/circuit breaker bad

re-established, normal operation resumes. D. No voltage @ PWR or AIR

E. Bad control

Combustion Airflow Problems A. Miswired or failed air flow switch

2. Thermostat on -

No blower output B. Bad thermostat no voltage @ TH

If the airflow signal is lost, or the hi-limit opens during heat mode, the

C. Bad control

gas valve is immediately de-energized and the blower stays on. If the 3. Airflow Switch input okay

switch closes again, a normal ignition sequence will resume. If not and A. Miswired

but no trial for ignition

this condition persists for more than five minutes, the control will enter after purge delay B. Bad control

lockout with the blower off. A. Shorted electrode

4. Valve on, no spark B. Open HV cable

MOUNTING AND WIRING C. Miswired

D. Bad control

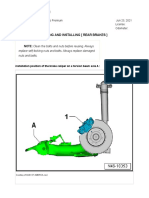

The 35-53 is not position sensitive and can be mounted vertically A. Valve coil open

or horizontally. The control may be mounted on any surface and B. Open valve wire

5. Spark on, no valve C. Bad control

fastened with #6 sheet metal screws. Secure the control in an area

that will experience a minimum of vibration and remain below the (check voltage between V1 & GND)

maximum ambient temperature of 80C (175F). A. Bad electrode

6. Flame okay during TFI, B. Bad HV wire

no flame sense (after TFI) C. Poor ground at burner

D. Bad control (check flame current)

Page 2 Series 35-53, 12 VDC DSI Control www.fenwalcontrols.com 1-800-FENWAL-1

CONTROL WIRE HARNESS Part Number: 22-100001-052

Select the proper harness based on the 35-53 control's termination

connection. Once the terminal configuration is determined, complete

the part number by replacing the last two digits ("XX") with the length

in inches ("l" dimension). Standard wire lengths are 12, 18, 24 30, 36

and 48 inches. Example 05-129927-024 = 24 inches. For other lengths,

please contact Fenwal

Local Sense Models

Part Number: 05-129927-0XX

Remote Sense Models

Part Number: 05-129927-2XX

REMOTE FLAME SENSE RODS

Part Number: 22-100001-080

ELECTRODE ASSEMBLIES

With over 1,000 configurations of spark electrodes and flame sense rods,

Fenwal has a design for almost any application. The latest state-of-the-art

wire forming and assembly equipment is used to accurately and efficiently

produce high quality electrodes that deliver the hottest spark. The

"Universal" electrodes depicted below are just a sampling of the 1,000

electrode styles available. These electrodes are designed for on-site

customization. Cut and bend these to fit your application and then send

the formed electrode back for Fenwal to detail or send us a print and

will provide you with a quote and samples.

Part Number: 22-100001-117

Part Number: 22-100001-110

www.fenwalcontrols.com 1-800-FENWAL-1 Series 35-53, 12 VDC DSI Control Page 3

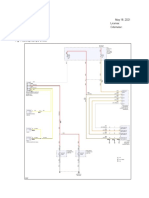

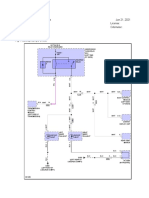

WIRING DIAGRAMS

LOCAL SENSE WITH BLOWER RELAY LOCAL SENSE WITHOUT BLOWER RELAY

REMOTE SENSE WITH BLOWER RELAY REMOTE SENSE WITHOUT BLOWER RELAY

DIMENSIONS

CASE AND COVER INTEGRAL STAND-OFF

Figure 1: Figure 2:

CONTROL CONFIGURATION

35 - 53 X XXX -XXX Description

Blower Relay Trial for Ignition Time (TFI)

0 = None 1 = 5 seconds 3 = 7 seconds

5 = Combustion Blower Relay 5 = 10 seconds 7 = 25 seconds

Configurations Inter-Purge Time

5 = Standard Model, Recycle on Flame Loss 0 = None 1 = 15 seconds

8 = Aftermarket Kit (may consist of control, high voltage 3 = 25 seconds

ignition wire,electrode and harness) Pre-Purge Time

9 = Non Standard Configuration 0 = None 3 = 25 seconds

1 = 15 seconds

A 9 in this location of the part number (i.e. 35-53 5 901 -113)

identifies this configuration as a non-standard design. The Number of Ignition Trials

and Flame Sense Method

part number does not follow the part numbering system.

0 = 1 try, local sense

The 9XX is a sequential part number assigned by Fenwal.

1 = 1 try, remote sense

Consult factory for operating characteristics of this control.

5 = 3 tries, local sense

6 = 3 tries, remote sense

Enclosure Configurations and Wiring Options

0 = Covered Module

5 = Integral Standoffs

400 MAIN STREET, ASHLAND, MA 01721 These instructions do not purport to cover all the details or variations in the equipment described, nor do they

TEL: (508) 881-2000 FAX: (508) 881-6729 provide for every possible contingency to be met in connection with installation, operation and maintenance.

www.fenwalcontrols.com All specifications are subject to change without notice. Should further information be desired or should

particular problems arise which are not covered sufficiently for the purchasers purposes, the matter should

2008 Kidde-Fenwal Printed in U.S.A. TAG be referred to KIDDE-FENWAL, Inc., Ashland, Massachusetts.

P/N 35.53.02 3/21/05

Page 4 Series 35-53, 12 VDC DSI Control www.fenwalcontrols.com 1-800-FENWAL-1

Das könnte Ihnen auch gefallen

- DS - 35-60 61Dokument7 SeitenDS - 35-60 61Andre VPNoch keine Bewertungen

- SERIES 35-53CE: FeaturesDokument5 SeitenSERIES 35-53CE: FeaturesAndre VPNoch keine Bewertungen

- SERIES 35-60: 24 VAC Microprocessor-Based Direct Spark Ignition ControlDokument6 SeitenSERIES 35-60: 24 VAC Microprocessor-Based Direct Spark Ignition ControlEmilio QuijanoNoch keine Bewertungen

- Fenwal 35 63J103 017 Submittal SheetDokument5 SeitenFenwal 35 63J103 017 Submittal Sheetjim perdigonNoch keine Bewertungen

- Series 35 65 - 24 VAC Hot Surface Ignition Control F 35 65 PDFDokument7 SeitenSeries 35 65 - 24 VAC Hot Surface Ignition Control F 35 65 PDFFernandoPitangaQuirinoNoch keine Bewertungen

- Ignition ControlDokument86 SeitenIgnition ControlLucian SinpetruNoch keine Bewertungen

- SERIES 35-63: FeaturesDokument4 SeitenSERIES 35-63: FeaturesAndre VPNoch keine Bewertungen

- Control de Flama Honeywell 215Dokument12 SeitenControl de Flama Honeywell 215Moreno NuevoNoch keine Bewertungen

- Manual Honeywell DLG 976 (En)Dokument6 SeitenManual Honeywell DLG 976 (En)Fernando M. AlaveNoch keine Bewertungen

- ACL-5100 - Operation ManualDokument16 SeitenACL-5100 - Operation ManualGianniNoch keine Bewertungen

- DLG 974/976 Gas Burner Safety ControlDokument6 SeitenDLG 974/976 Gas Burner Safety ControlPodaruNoch keine Bewertungen

- LOA2 LOA3 Oil Burner Controls2 PDFDokument10 SeitenLOA2 LOA3 Oil Burner Controls2 PDFAdamNoch keine Bewertungen

- R7184G Electronic Oil PrimaryDokument3 SeitenR7184G Electronic Oil PrimaryleogerguzNoch keine Bewertungen

- 0037 7516Dokument8 Seiten0037 7516Jared WhiteNoch keine Bewertungen

- GeniSys 7505 Control ManualDokument12 SeitenGeniSys 7505 Control Manualguillermo trejosNoch keine Bewertungen

- R4795A Flame Safeguard Primary Controls: S.Y. - Rev. 12-94 - ©honeywell Inc. 1994Dokument16 SeitenR4795A Flame Safeguard Primary Controls: S.Y. - Rev. 12-94 - ©honeywell Inc. 1994Freddy TamayoNoch keine Bewertungen

- Beckett GeniSys 7505 ManualDokument12 SeitenBeckett GeniSys 7505 ManualEdgardo GarridoNoch keine Bewertungen

- Sequence Cont. Manual PDFDokument6 SeitenSequence Cont. Manual PDFVijay BhureNoch keine Bewertungen

- 6lh9 - Tfi 812.2 Satronic En.Dokument4 Seiten6lh9 - Tfi 812.2 Satronic En.botosionNoch keine Bewertungen

- EmsDokument3 SeitenEmsmanoj nirgudeNoch keine Bewertungen

- Honeywell DKG972 PDFDokument6 SeitenHoneywell DKG972 PDFAriel RiveroNoch keine Bewertungen

- tmg740 3Dokument6 Seitentmg740 3tespakNoch keine Bewertungen

- Caterpillar XQ45 Towable Diesel Generator SetDokument5 SeitenCaterpillar XQ45 Towable Diesel Generator SetMacAllister MachineryNoch keine Bewertungen

- For 1-Or 2-Stage Oil Power Burners Up To 30kg/h Capacity and Intermittent Operations. Flame Detection: - Photoresistor MZ 770 S - Infrared-Flicker Detector IRD 1010 - UV Solid State Sensor UVD 970Dokument4 SeitenFor 1-Or 2-Stage Oil Power Burners Up To 30kg/h Capacity and Intermittent Operations. Flame Detection: - Photoresistor MZ 770 S - Infrared-Flicker Detector IRD 1010 - UV Solid State Sensor UVD 970mochammad RezaNoch keine Bewertungen

- DKG 972Dokument6 SeitenDKG 972rhuircanNoch keine Bewertungen

- TMO 720-4 Oil Burner Control BoxDokument6 SeitenTMO 720-4 Oil Burner Control BoxYanuar AndriyantoNoch keine Bewertungen

- Continuous 1356 kVA 1431 kVA: GAS Generator SetDokument4 SeitenContinuous 1356 kVA 1431 kVA: GAS Generator SetShwe Yaminn HtetNoch keine Bewertungen

- LEC1Dokument17 SeitenLEC1christophermrequintoNoch keine Bewertungen

- RA890F Flame Safeguard Primary Control: Application SpecificationsDokument12 SeitenRA890F Flame Safeguard Primary Control: Application SpecificationsDaniel Gomez MartinezNoch keine Bewertungen

- Caterpillar XQ100 Towable Diesel Generator SetDokument5 SeitenCaterpillar XQ100 Towable Diesel Generator SetMacAllister MachineryNoch keine Bewertungen

- Lehx0079 05Dokument4 SeitenLehx0079 05jose pedro garduza sosaNoch keine Bewertungen

- Siemens Lal 1 25 Burner ControllerDokument6 SeitenSiemens Lal 1 25 Burner ControllerBerhanu GebreyohannesNoch keine Bewertungen

- Cat 3520 Gas EngineDokument3 SeitenCat 3520 Gas EngineJafarShojaNoch keine Bewertungen

- Check Sheet For (C&P Section)Dokument7 SeitenCheck Sheet For (C&P Section)Noor Ahmad WahgoNoch keine Bewertungen

- Check Sheet For (M&G Section)Dokument7 SeitenCheck Sheet For (M&G Section)Noor Ahmad WahgoNoch keine Bewertungen

- Check Sheet For (Misc.)Dokument10 SeitenCheck Sheet For (Misc.)Noor Ahmad WahgoNoch keine Bewertungen

- Cummins 2011 PDFDokument4 SeitenCummins 2011 PDFcvergaraesNoch keine Bewertungen

- TLL13X Fozmula Liquid Level Sensor Data 8-6-33R2Dokument1 SeiteTLL13X Fozmula Liquid Level Sensor Data 8-6-33R2moisesNoch keine Bewertungen

- HW Ra890gcontrol Ds 60-2035Dokument2 SeitenHW Ra890gcontrol Ds 60-2035Jose Peña AlvarezNoch keine Bewertungen

- Honeywel S4560Dokument16 SeitenHoneywel S4560Carlos BrancoNoch keine Bewertungen

- Installation Instructions Operator: Save These Instructions For Future Use!Dokument8 SeitenInstallation Instructions Operator: Save These Instructions For Future Use!jabarnesNoch keine Bewertungen

- XQ30Dokument5 SeitenXQ30NimaNoch keine Bewertungen

- Lmof 123Dokument10 SeitenLmof 123Idham JaelaniNoch keine Bewertungen

- Manual Honeywell TFI 812Dokument4 SeitenManual Honeywell TFI 812Andi SopiandiNoch keine Bewertungen

- White-Rodgers 50A55-474 & 50A55-571 Install ManualDokument8 SeitenWhite-Rodgers 50A55-474 & 50A55-571 Install ManualSolomanTrismosinNoch keine Bewertungen

- Rmg88 62c2 Siemens ManualDokument21 SeitenRmg88 62c2 Siemens ManualDaniel Pacheco100% (2)

- Caterpillar XQ80 Towable Diesel Generator SetDokument5 SeitenCaterpillar XQ80 Towable Diesel Generator SetMacAllister MachineryNoch keine Bewertungen

- Gas Burned Siemens Landis LGA41Dokument11 SeitenGas Burned Siemens Landis LGA41Abelardo PeironeNoch keine Bewertungen

- S8910U Universal Hot Surface Ignition Module: Super TradelineDokument16 SeitenS8910U Universal Hot Surface Ignition Module: Super TradelineLuisNoch keine Bewertungen

- TFI 812 Gas Burner Control BoxDokument4 SeitenTFI 812 Gas Burner Control BoxgonzaloNoch keine Bewertungen

- Caterpillar XQ30 Towable Diesel Generator SetDokument5 SeitenCaterpillar XQ30 Towable Diesel Generator SetMacAllister Machinery100% (1)

- Neutral Grounding High VoltageDokument2 SeitenNeutral Grounding High VoltageABDUL GHAFOORNoch keine Bewertungen

- 001 GeniSys 7590 ManualDokument20 Seiten001 GeniSys 7590 Manualjose marcanoNoch keine Bewertungen

- User Manual: LG-10 Thru LG-30Dokument33 SeitenUser Manual: LG-10 Thru LG-30JaimeNoch keine Bewertungen

- Digicold Digicold Digicold Digicold: SeriesDokument4 SeitenDigicold Digicold Digicold Digicold: SeriesdbricchiNoch keine Bewertungen

- RMO-RMG Burner ControllerDokument21 SeitenRMO-RMG Burner ControllerTiyyagura RoofusreddyNoch keine Bewertungen

- Oil Burner Controls: Building TechnologiesDokument18 SeitenOil Burner Controls: Building TechnologiesSaheer AmbadanNoch keine Bewertungen

- Advanced Temperature Measurement and Control, Second EditionVon EverandAdvanced Temperature Measurement and Control, Second EditionNoch keine Bewertungen

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionVon EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsVon EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsBewertung: 3.5 von 5 Sternen3.5/5 (6)

- DAvE TC179x Series Dip Installation Procedure v1 2Dokument2 SeitenDAvE TC179x Series Dip Installation Procedure v1 2Andre VPNoch keine Bewertungen

- A3 Quatro 2015 Rear BrakeDokument22 SeitenA3 Quatro 2015 Rear BrakeAndre VPNoch keine Bewertungen

- Caravan 2001Dokument1 SeiteCaravan 2001Andre VPNoch keine Bewertungen

- Nissan XTrail T30 2005 Workshop ManualDokument56 SeitenNissan XTrail T30 2005 Workshop ManualAndre VP100% (2)

- Thermal Dynamics Cutmaster 52 Eng-SmDokument112 SeitenThermal Dynamics Cutmaster 52 Eng-SmAndre VPNoch keine Bewertungen

- A3 Quatro 2015 Rear BrakeDokument22 SeitenA3 Quatro 2015 Rear BrakeAndre VPNoch keine Bewertungen

- 2013fusion Steering 5Dokument58 Seiten2013fusion Steering 5Andre VPNoch keine Bewertungen

- Sorento 2017 2Dokument2 SeitenSorento 2017 2Andre VPNoch keine Bewertungen

- Exterior Lights: Ymms: May 18, 2021 Engine: 3.3L Eng License: Vin: Odometer: 2017 Kia Sorento SXDokument4 SeitenExterior Lights: Ymms: May 18, 2021 Engine: 3.3L Eng License: Vin: Odometer: 2017 Kia Sorento SXAndre VPNoch keine Bewertungen

- Sorento 2017 2Dokument2 SeitenSorento 2017 2Andre VPNoch keine Bewertungen

- Sentra 2014acDokument13 SeitenSentra 2014acAndre VPNoch keine Bewertungen

- RDX 2019ext LightDokument6 SeitenRDX 2019ext LightAndre VPNoch keine Bewertungen

- Air Conditioning: Ymms: Jun 21, 2021 Engine: 1.8L Eng License: Vin: Odometer: 2014 Nissan Sentra SLDokument5 SeitenAir Conditioning: Ymms: Jun 21, 2021 Engine: 1.8L Eng License: Vin: Odometer: 2014 Nissan Sentra SLAndre VP100% (1)

- F 2502016 AbsDokument2 SeitenF 2502016 AbsAndre VPNoch keine Bewertungen

- Fig 1: Detroit Diesel Engine Performance Wiring Diagram (DDEC III & DDEC IV - Series 60 Without EGR - 1 of 2)Dokument3 SeitenFig 1: Detroit Diesel Engine Performance Wiring Diagram (DDEC III & DDEC IV - Series 60 Without EGR - 1 of 2)Andre VP100% (1)

- 74HCT02D Datasheet en 20160524Dokument7 Seiten74HCT02D Datasheet en 20160524Andre VPNoch keine Bewertungen

- 2005 4.2 Ford 1Dokument1 Seite2005 4.2 Ford 1Andre VPNoch keine Bewertungen

- 2SJ553SDokument9 Seiten2SJ553SAndre VPNoch keine Bewertungen

- 2SJ553SDokument9 Seiten2SJ553SAndre VPNoch keine Bewertungen

- Eaton True Sine Wave Inverter Sales AidDokument2 SeitenEaton True Sine Wave Inverter Sales AidAndre VPNoch keine Bewertungen

- 74HCT02D Datasheet en 20160524Dokument7 Seiten74HCT02D Datasheet en 20160524Andre VPNoch keine Bewertungen

- Clarion Ph2971maDokument22 SeitenClarion Ph2971maAndre VPNoch keine Bewertungen

- 74HCT02D Datasheet en 20160524Dokument7 Seiten74HCT02D Datasheet en 20160524Andre VPNoch keine Bewertungen

- Versa 11Dokument13 SeitenVersa 11Andre VPNoch keine Bewertungen

- Installation ManualspeedometerDokument21 SeitenInstallation ManualspeedometerAndre VPNoch keine Bewertungen

- From Ross-Tech Wiki: SearchDokument2 SeitenFrom Ross-Tech Wiki: SearchAndre VPNoch keine Bewertungen

- 1Dokument1 Seite1Andre VPNoch keine Bewertungen

- Honda Goldwing GL1800 Panasonic RM-G45PA Radio Service Manual-83E8BDokument37 SeitenHonda Goldwing GL1800 Panasonic RM-G45PA Radio Service Manual-83E8BmotofleshNoch keine Bewertungen

- Cruise 2012Dokument5 SeitenCruise 2012Andre VPNoch keine Bewertungen

- Bw1800 Manual Alarma EcosportDokument16 SeitenBw1800 Manual Alarma Ecosportandrss100% (1)

- Touran No. 3 / 1: Trailer OperationDokument3 SeitenTouran No. 3 / 1: Trailer OperationVladimir NicolinNoch keine Bewertungen

- Crypt Column Pages From Package 96 Combined 29.09.22 PDFDokument17 SeitenCrypt Column Pages From Package 96 Combined 29.09.22 PDFOrlando LopesNoch keine Bewertungen

- 309 20Dokument116 Seiten309 20Heri Colorado MoraNoch keine Bewertungen

- Mannat Physics Activity FileDokument18 SeitenMannat Physics Activity FileAryan RajputNoch keine Bewertungen

- Tahan 2X Lebih Lama: September 2017 Retail CatalogueDokument4 SeitenTahan 2X Lebih Lama: September 2017 Retail CatalogueAdi SariNoch keine Bewertungen

- M 15Dokument2 SeitenM 15Александр ОстапенкоNoch keine Bewertungen

- 320D Excavator BZP00001-UP (MACHINE) POWERED BY C6.4 Engine (SEBP5228 - 25) - Basic Search PDFDokument11 Seiten320D Excavator BZP00001-UP (MACHINE) POWERED BY C6.4 Engine (SEBP5228 - 25) - Basic Search PDFedykuswari50% (4)

- Bolting Unit: Docmine Drill Steel Sup - 200X200 Plates 8999361000-001 Boltec SDokument10 SeitenBolting Unit: Docmine Drill Steel Sup - 200X200 Plates 8999361000-001 Boltec Scristian nahuelcuraNoch keine Bewertungen

- Check Spark PlugDokument2 SeitenCheck Spark PlugCơ Hương NguyễnNoch keine Bewertungen

- K OfeiDokument20 SeitenK OfeiPaaforiNoch keine Bewertungen

- 1 Detail: Gr. Elettrogeno Per Trattore ZG 100/3Dokument3 Seiten1 Detail: Gr. Elettrogeno Per Trattore ZG 100/3npNoch keine Bewertungen

- Grizzl e ManualDokument25 SeitenGrizzl e ManualMmmNoch keine Bewertungen

- Contractor'S Statement of Work Accomplished: Environmental Management Bureau 10Dokument3 SeitenContractor'S Statement of Work Accomplished: Environmental Management Bureau 10Razul DaranginaNoch keine Bewertungen

- NN G61arDokument20 SeitenNN G61arapi-3711045Noch keine Bewertungen

- Electronics Repair and Troubleshooting: How To Troubleshoot An AC/DC Power SupplyDokument4 SeitenElectronics Repair and Troubleshooting: How To Troubleshoot An AC/DC Power SupplyIra CervoNoch keine Bewertungen

- Micro Relay K (THT - THR) : Automotive Relays PCB Single RelaysDokument5 SeitenMicro Relay K (THT - THR) : Automotive Relays PCB Single RelaysIsmael ZerpaNoch keine Bewertungen

- Delta Wye ConnectionDokument11 SeitenDelta Wye ConnectionDevee AmbasNoch keine Bewertungen

- Valve Timing DiagramDokument5 SeitenValve Timing DiagramkaranNoch keine Bewertungen

- General Electric (Selector)Dokument134 SeitenGeneral Electric (Selector)Milton SantoNoch keine Bewertungen

- Boq Mo Jagdishpur-BhojpurDokument18 SeitenBoq Mo Jagdishpur-BhojpurSATYAM BISENNoch keine Bewertungen

- 2020 Duralee Furniture FINALDokument46 Seiten2020 Duralee Furniture FINALDanno NNoch keine Bewertungen

- Free Energy Inverter Schematics PDFDokument16 SeitenFree Energy Inverter Schematics PDFIvan LorgrenNoch keine Bewertungen

- Qdoc - Tips - Ddec IV Oem Wiring DiagramDokument1 SeiteQdoc - Tips - Ddec IV Oem Wiring DiagramAlberto RodríguezNoch keine Bewertungen

- Ultracruise-2 Form2784ADokument24 SeitenUltracruise-2 Form2784Atarek ahmedNoch keine Bewertungen

- (As Listed in The Respective TR) Program: Electrical Installation and Maintenance NC IiDokument2 Seiten(As Listed in The Respective TR) Program: Electrical Installation and Maintenance NC IiRommel SelgaNoch keine Bewertungen

- Actulux Manual SVM 24V 5A 8A Control Panel PDFDokument11 SeitenActulux Manual SVM 24V 5A 8A Control Panel PDFAna Carolina SantosNoch keine Bewertungen

- Flooring QtyDokument2 SeitenFlooring QtyJyoti SarkarNoch keine Bewertungen

- 2012.4 Patient Monitor Cable CatalogDokument27 Seiten2012.4 Patient Monitor Cable CatalogErwinCepedaNoch keine Bewertungen