Beruflich Dokumente

Kultur Dokumente

An Assessment of Environmental Impacts of Cassava Starch Extraction Technologies (ReserchGate)

Hochgeladen von

David PabónCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

An Assessment of Environmental Impacts of Cassava Starch Extraction Technologies (ReserchGate)

Hochgeladen von

David PabónCopyright:

Verfügbare Formate

See

discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/274960587

An assessment of environmental impacts of

cassava starch extraction technologies

Conference Paper January 2012

CITATIONS READS

0 29

8 authors, including:

Thierry Tran Guillaume Da

Cirad - La recherche agronomique pour le d Universit Paris-Est Crteil Val de Marne - Uni

25 PUBLICATIONS 152 CITATIONS 22 PUBLICATIONS 39 CITATIONS

SEE PROFILE SEE PROFILE

Martin Moreno Andrs Giraldo

Universidad del Valle (Colombia) 32 PUBLICATIONS 138 CITATIONS

3 PUBLICATIONS 10 CITATIONS

SEE PROFILE

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

primequal virus View project

All content following this page was uploaded by Guillaume Da on 14 April 2015.

The user has requested enhancement of the downloaded file.

An assessment of environmental impacts

of cassava starch extraction technologies

T. Trana,*, G. Dab, K. Piyachomkwanf, M. Morenoc,

G. Velezd, A. Giraldo-Toroe, K. Srirothf, D. Dufoura,e

a Centre de coopration internationale en recherche agronomique pour le dveloppement (CIRAD), Persyst Department,

UMR Qualisud, TA-B95/15, 73 rue JF Breton, 34398 Montpellier, France

b CERTES, Universit Paris-Est Crteil, 61 avenue du Gnral de Gaulle, 94000 Crteil, France

c Universidad del Valle (UniValle), Cali, Colombia

d Deriyuca LTDA. Carrera 89 # 10-80 apartamento 323 - Multicentro - Unidad 20-21, Cali, Colombia

e International Center for Tropical Agriculture (CIAT), Km 17 Recta Cali-Palmira, Cali, Colombia

f Cassava and Starch Technology Research Unit (CSTRU / BIOTEC), Kasetsart University, Jatujak, Bangkok 10900, Thailand

* Corresponding author: Tel +33-467615847; E-mail thierry.tran@cirad.fr

Introduction Results

The environmental impacts of the transformation of cassava roots into Energy and water consumption varied widely between technologies

starch were assessed for three contrasting technologies at small (ST1, (figures 2 & 3). The large scale technology required 702kWh/t starch,

ST2) and very large scale (VLT), meaning 1-2 and 100-200t starch per day, mainly (75%) from fuel oil used for the drying operation, but was the most

respectively. The goal of the study was to assess energy and water use for efficient in terms of water use (10m3/t starch) due to the practice of water

each unit operation, so as to identify high usage hotspots. The Life Cycle recycling between unit operations. The two small scale technologies were

Assessment (LCA) framework was applied in order to test its relevance as similar in terms of electricity use (59kWh/t starch), and were able to rely on

a tool to analyze unit operations environmental performance, for process solar energy for drying, due to the small volumes of production. In contrast,

eco-engineering purposes. water consumption varied from 20 to 60m3/t starch between the two small

scale technologies due to differences in the design of the rasping and

starch recovery (extraction) operations.

Fresh Cassava Roots

100% 100%

WASHING 3.6

28.4

80% 18.3

RASPING 80% 7.4

33.0 33.2 34.7 Drying - Fuel oil

Separation - Recycled

Drying - Elec Separation

60% 540.3

EXTRACTION Separation Extraction - Recycled

Factory

Extraction 60% 6.2

50.3 Extraction

Rasping 18.8

40% Rasping - Recycled

SEPARATION Root washing

31.9 Rasping

13.6 Water pump 6.9

Root washing - Recycled

40%

22.1

20% 28.4 Root washing

DEWATERING 33.0 45.6

50.3 8.1

45.6 2.3 20%

4.3 1.6 2.2

0% 11.8 2.8

DRYING 0.3

VLT VLT ST1; ST2;

9.1

Electricity + Electricity 59.2kWh/t 58.6kWh/t 2.0

fuel oil; only; 0%

Starch (12% moisture) 702.2kWh/t 161.9kWh/t VLT; 9.8m3/t ST1; 20.8m3/t ST2; 62.1m3/t

Figure 1: Unit operations of Figure 2: Energy consumption by unit operations of VLT, Figure 3: Freshwater consumption by unit operations of

the cassava starch ST1 and ST2 technologies (large, small 1 and small 2 VLT, ST1 and ST2 technologies. The figures within the

extraction process. The respectively). The figures within the bars and on the bars and on the horizontal axis indicate actual water use

dotted line represents the horizontal axis indicate actual energy use per operation per operation and total water use respectively, in m3/t

selected system boundaries. and total energy use respectively, in kWh/t starch. starch.

100% 100% 100%

Methods VLT

80%

60%

ST1

80%

60%

ST2

80%

60%

40% 40% 40%

The system boundaries were defined as the unit

20% 20% 20%

operations used to transform fresh cassava roots

0% 0% 0%

delivered at factory gate into loose, dry cassava

rtic al o um eple e

n

te rm y

Fr erre nisin orm n

hw ria g ra tion

n

Te e e oph tion

es ria hic n

ric M ter tox n

ur ine oto y

N Urb lan co icity

la d up y

tra cu ion

at rm n

n

ss ple n

ep n

rtic al o um eple e

te an to n

te rm y

Fr erre nisin orm ion

at l a dia n

n

Te e e oph tion

es ria hic n

at co tion

ur in ot ity

N Urb lan co icity

la d up ity

tra ccu tion

at rm n

n

ss ple n

ep on

H de nge

te an tox n

att rm ity

Fr erre nisin orm n

hw ria g ra tion

n

Te e ph tion

es ria hic n

ric M ter tox n

ur ine oto ity

Na Urb lan cot icity

y

tra ccu on

ate rm n

n

ss ple n

ep n

n

it

ult ar ec icit

al lan occ icit

it

T Io r f atio

Fr est op atio

Fr rest trop atio

H d ng

ula xid an tio

M er e cidif tio

a co tio

W sfo atio

M r de tio

Fo l de tio

il d tio

tio

H d ng

ula xid an tio

hw tria g ra tio

M er e cid tio

W sfo atio

M r de tio

Fo l de tio

tio

ra la cc icit

T Io r f atio

Fr est op atio

ula xid an tio

M r e cidif tio

a co tio

W sfo atio

M r de tio

Fo l de tio

il d tio

tio

m t fo xic

m t fo xic

ult ar ec ic

ur n d o toxic

il d ti

m t fo ic

ult ar ec ic

nd o pati

nd oc at

T Io r f at

a

a

at l a dia

in utr ica

hw l e a

a

a ple

le

in utr ica

hw l e a

a

le

le

ne cha

e x

x

ne cha

al e e ox

ric M er tox

rtic l o um ple

a

ate l a dia

in utro ica

hw l e a

a

a ple

le

ne cha

e x

tu an d o ox

starch (figure 1). The functional unit (FU) was

rr utr ic

n p

ic

n p

n to

at an d to

rr utr ic

n p

p

l la nd u

if

al lan cc

O ate

O ate

O a te

nd o

a

e

Drying Drying

e

Drying

lim

lim

lim

et

et

u

et

a

zo

zo

zo

at

at

C

defined as one ton of loose, dried cassava starch Centrifugation Sedimentation Sedimentation

e

es st

es st

es s

al

al

te

at a

ar

ar

ar

Separation Separation

a

Separation

Pa mic

Pa mic

Pa ic

m

ur

Extraction Extraction Extraction

he

he

he

(i.e. starch at 12% moisture content on a wet

Ag

Ag

Ag

oc

oc

oc

Rasping Rasping Rasping

ot

ot

ot

Ph

Ph

Washing Washing

Ph

Washing

weight basis, wwb), obtained at the end of the Figure 4: Environmental impacts characterization of the transformation of cassava roots into starch for the

manufacturing process. very large scale (VLT) and two small scale (ST1, ST2) technologies.

Primary data for ST1 and ST2 factories were

obtained from the authors own measurements in

collaboration with one cassava starch factory

based in Vietnam (suburban Hanoi region) and

Results (continued) Conclusions

one based in Colombia (Cauca department). Data The LCA characterizations (figure 4), Among the three technologies assessed, markedly

for the VLT factory and data related to water and using the ReCiPe method, indicated different levels of energy and water consumption were

chemicals consumption (e.g. alum, SO2) were that the main impact contributions were identified for some unit operations, such as extraction or

based on measurements published by at the drying operation for the large root washing, which indicates the potential for technology

Piyachomkwan et al. (2005), Sriroth (1996) and scale technology, and at the extraction transfers and improvements of the overall environmental

Sriroth et al. (2000) in Thailand. The factories operation for the small scale performance of the cassava starch industry.

surveyed were representative of the standard technologies, mainly because of energy This work demonstrates the feasibility and usefulness of

technology used in the three regions of the study. use, as well as water use in the case of applying LCA concepts for integrating environmental

the most water-intensive technology. performance indicators in the design and evaluation of

transformation processes for agro-industrial products. The

Acknowledgments

environmental dimension should come in addition to other

Stakeholders of the cassava starch industry in Vietnam and Colombia, and staff and students at HUST and aspects including process yields, microbial safety and

CIAT, who made possible the data collection. The support of Le Thanh Mai from HUST regarding the electricity product quality.

www. post er session. com

mix in Vietnam is gratefully acknowledged. The authors thank CIRAD and CIAT for financial support.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Pneumatic Maneuvering SystemDokument65 SeitenPneumatic Maneuvering Systemminhankyaw100% (3)

- Nasdaq Aaon 2002Dokument26 SeitenNasdaq Aaon 2002gaja babaNoch keine Bewertungen

- The Acidity and Basicity of Organic Acids and Bases For VULADokument24 SeitenThe Acidity and Basicity of Organic Acids and Bases For VULAZama MakhathiniNoch keine Bewertungen

- StandardsDokument76 SeitenStandardsSohaib ZafarNoch keine Bewertungen

- AP TSS General Safety Course For 2019cycleDokument141 SeitenAP TSS General Safety Course For 2019cycleFebry Dwi TranspuriNoch keine Bewertungen

- G20 Business Letter We Mean Business CoalitionDokument26 SeitenG20 Business Letter We Mean Business CoalitionComunicarSe-ArchivoNoch keine Bewertungen

- Myanmar Oil Field Info SummaryDokument19 SeitenMyanmar Oil Field Info SummaryhtutsweNoch keine Bewertungen

- Упражнения на отработку Second ConditionalDokument6 SeitenУпражнения на отработку Second ConditionalНаргиля ГаджиеваNoch keine Bewertungen

- Photoassociation Spectroscopy of A Spin-1 Bose-Einstein CondensateDokument5 SeitenPhotoassociation Spectroscopy of A Spin-1 Bose-Einstein Condensatee99930Noch keine Bewertungen

- Evading Thermal Imaging and Radar Detection-1Dokument8 SeitenEvading Thermal Imaging and Radar Detection-1kokiskoNoch keine Bewertungen

- Particulate Photocatalysts CRDokument67 SeitenParticulate Photocatalysts CRYiou WangNoch keine Bewertungen

- General Science: 1. Introduction and Role of ScienceDokument2 SeitenGeneral Science: 1. Introduction and Role of ScienceCh Shakeel Ahmed MayoNoch keine Bewertungen

- Javan 1961 - POPULATION INVERSION AND CONTINUOUS OPTICAL MASER OSCILLATION IN A GAS DISCHARGE CONTAINING A He-Ne MIXTUREDokument8 SeitenJavan 1961 - POPULATION INVERSION AND CONTINUOUS OPTICAL MASER OSCILLATION IN A GAS DISCHARGE CONTAINING A He-Ne MIXTURECayo Julio CesarNoch keine Bewertungen

- PU158TIDokument2 SeitenPU158TITrevor BurnettNoch keine Bewertungen

- Nissan Skyline R34 Workshop Manual EnglishDokument401 SeitenNissan Skyline R34 Workshop Manual Englishrecklessone0% (2)

- Carter Auto Water Pump Components 072420Dokument2 SeitenCarter Auto Water Pump Components 072420geniusNoch keine Bewertungen

- State of Art Research in AlgaeDokument20 SeitenState of Art Research in AlgaeSambhavNoch keine Bewertungen

- Final Et NotesDokument123 SeitenFinal Et NotesyounusmohamadNoch keine Bewertungen

- Asco Avtron 2000 Series With Sigma LT User Manual PDFDokument43 SeitenAsco Avtron 2000 Series With Sigma LT User Manual PDFfernandoNoch keine Bewertungen

- InternationalDokument11 SeitenInternationalheeral patelNoch keine Bewertungen

- He165 (A4)Dokument4 SeitenHe165 (A4)KennethWilfredoVegaOviedoNoch keine Bewertungen

- Metrode E2209 (B-60) ElectrodeDokument6 SeitenMetrode E2209 (B-60) ElectrodeClaudia MmsNoch keine Bewertungen

- Complex Fluid For Olga 5Dokument10 SeitenComplex Fluid For Olga 5angry_granNoch keine Bewertungen

- Brazil Chapter 12: Agriculture, Minerals, Industries & TradeDokument8 SeitenBrazil Chapter 12: Agriculture, Minerals, Industries & TradeHaseebullahNoch keine Bewertungen

- Accurate Power Demand Forecasting MethodsDokument15 SeitenAccurate Power Demand Forecasting MethodsRathinaKumarNoch keine Bewertungen

- IEDs; A Contemporary Viewpoint on Threats and PrecautionsDokument67 SeitenIEDs; A Contemporary Viewpoint on Threats and PrecautionsDeepak Mishra100% (2)

- CHE 511a - EditedDokument45 SeitenCHE 511a - EditedNicoole Tiu0% (1)

- OCR Advanced GCE Physics A - 2826/01 - Unifying Concepts in Physics - January 2007Dokument12 SeitenOCR Advanced GCE Physics A - 2826/01 - Unifying Concepts in Physics - January 2007Soham PatwardhanNoch keine Bewertungen

- 2004-01-0403 - Design and Analysis of Fuel Tank Baffles To Reduce The Noise Generated From Fuel Sloshing PDFDokument14 Seiten2004-01-0403 - Design and Analysis of Fuel Tank Baffles To Reduce The Noise Generated From Fuel Sloshing PDFCaio PaimNoch keine Bewertungen

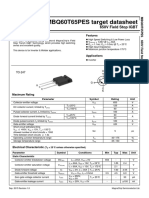

- MBQ60T65PES Target Datasheet: 650V Field Stop IGBTDokument1 SeiteMBQ60T65PES Target Datasheet: 650V Field Stop IGBTamrNoch keine Bewertungen