Beruflich Dokumente

Kultur Dokumente

Consensus On Operating

Hochgeladen von

abdulrehman2010Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Consensus On Operating

Hochgeladen von

abdulrehman2010Copyright:

Verfügbare Formate

CRTD-Vol.

81

CONSENSUS ON OPERATING

PRACTICES FOR THE SAMPLING AND

MONITORING OF FEEDWATER

AND BOILER WATER CHEMISTRY

IN MODERN INDUSTRIAL BOILERS

AN ASME RESEARCH REPORT

prepared by the

Sampling and Monitoring Task Group and the Water Technology

Subcommittee of the Research and Technology Committee on

Water and Steam in Thermal Systems of the

American Society of Mechanical Engineers.

ASME, Three Park Avenue, New York, NY 10016, USA

Downloaded From: http://ebooks.asmedigitalcollection.asme.org/ on 08/23/2017 Terms of Use: http://www.asme.org/about-as

ASME shall not be responsible for statements or opinions advanced in papers or . . .

printed in its publications (B7.1.3). Statement from the Bylaws.

All rights reserved. Printed in the United States of America. Except as permitted under

the United States Copyright Act of 1976, no part of this publication may be repro-

duced or distributed in any form or by any means, or stored in a database or retrieval

system, without the prior written permission of the publisher.

INFORMATION CONTAINED IN THIS WORK HAS BEEN OBTAINED BY THE

AMERICAN SOCIETY OF MECHANICAL ENGINEERS FROM SOURCES BELIEVED

TO BE RELIABLE. HOWEVER, NEITHER ASME NOR ITS AUTHORS OR EDITORS

GUARANTEE THE ACCURACY OR COMPLETENESS OF ANY INFORMATION

PUBLISHED IN THIS WORK. NEITHER ASME NOR ITS AUTHORS AND EDITORS

SHALL BE RESPONSIBLE FOR ANY ERRORS, OMISSIONS, OR DAMAGES ARISING

OUT OF THE USE OF THIS INFORMATION. THE WORK IS PUBLISHED WITH THE

UNDERSTANDING THAT ASME AND ITS AUTHORS AND EDITORS ARE SUPPLYING

INFORMATION BUT ARE NOT ATTEMPTING TO RENDER ENGINEERING OR OTHER

PROFESSIONAL SERVICES. IF SUCH ENGINEERING OR PROFESSIONAL SERVICES

ARE REQUIRED, THE ASSISTANCE OF AN APPROPRIATE PROFESSIONAL SHOULD

BE SOUGHT.

For authorization to photocopy material for internal or personal use under those

circumstances not falling within the fair use provisions of the Copyright Act, contact

the Copyright Clearance Center (CCC), 222 Rosewood Drive, Danvers, MA 01923,

tel: 978-750-8400, www.copyright.com.

ISBN 0-7918-0248-5

2006 by ASME, Three Park Avenue, New York, NY 10016, USA (www.asme.org)

Downloaded From: http://ebooks.asmedigitalcollection.asme.org/ on 08/23/2017 Terms of Use: http://www.asme.org/about-as

CONSENSUS ON OPERATING

PRACTICES FOR THE SAMPLING

AND MONITORING OF

FEEDWATER AND BOILER WATER

CHEMISTRY IN

MODERN INDUSTRIAL BOILERS

r iii

Downloaded From: http://ebooks.asmedigitalcollection.asme.org/ on 08/23/2017 Terms of Use: http://www.asme.org/about-as

Downloaded From: http://ebooks.asmedigitalcollection.asme.org/ on 08/23/2017 Terms of Use: http://www.asme.org/about-as

r PREFACE r

The Water Technology Subcommittee of the ASME Research and

Technology Committee on Water and Steam in Thermal Systems has

established a "Consensus on Operating Practices for the Sampling and

Monitoring of Feedwater and Boiler Water Chemistry in Modern Industrial

Boilers". This publication provides recommendations for water chemistry

monitoring and is a companion to the ASME "Consensus on Operating

Practices for the Control of Feedwater and Boiler Water Chemistry in

Modern Industrial Boilers," "A Practical Guide to Avoiding Steam Purity

Problems in the Industrial Plant," and "Consensus on Operating Practices

for Control of Water and Steam Chemistry in Combined Cycle and

Cogeneration Power Plants". These documents provide guidance for

avoiding the penalties of severe corrosion or deposition in steam genera-

tion systems and end user equipment.

Individuals associated in the compilation and preparation of this docu-

ment consisted of manufacturers, operators and consultants involved in all

aspects of the design and operation of industrial and utility boilers, heat

recovery steam generators, boilers and the associated equipment in the full

power train. The members of the task group, committee and others making

significant contributions to this document are listed in the Acknowledge-

ment section.

The information in this document will be reviewed by the Research and

Technology Committee and revised and reissued as necessary to comply

with advances in boiler design or water treatment technology.

It is my pleasure to thank all of those individuals who contributed

considerable time, and freely shared their knowledge and experience, to

the preparation and publication of this consensus.

Robert T. Holloway

Chair, ASME Research and Technology

Committee on Water and Steam in

Thermal Systems

rv

Downloaded From: http://ebooks.asmedigitalcollection.asme.org/ on 08/23/2017 Terms of Use: http://www.asme.org/about-as

Downloaded From: http://ebooks.asmedigitalcollection.asme.org/ on 08/23/2017 Terms of Use: http://www.asme.org/about-as

r ACKNOWLEDGEMENTS r

This document was prepared by the Sampling and Monitoring Task

Group and the Water Technology Subcommittee of the Research and

Technology Committee on Water and Steam in Thermal Systems of the

American Society of Mechanical Engineers. Recognition is hereby given to

the following members of these groups for their contributions in the

preparation of this document.

I. J. Cotton Co Chair

R. W. Light Co Chair

A. Banweg C. M. Kulick

T. Beardwood R. W. Light

D. M. Bloom L. M. Machemer III

I. J. Cotton W. Moore

R. J. Cunningham L. Olavessen

D. Daniels J. O. Robinson

D. B. Dewitt-Dick J. Sabourin

S. B. Dilcer, Jr. K. A. Selby

J. C. Dromgoole D. E. Simon II

R. T. Holloway K. Sinha

J. Isaac T. J. Tvedt, Jr.

M. Janick D. K. Woodman

r vii

Downloaded From: http://ebooks.asmedigitalcollection.asme.org/ on 08/23/2017 Terms of Use: http://www.asme.org/about-as

Downloaded From: http://ebooks.asmedigitalcollection.asme.org/ on 08/23/2017 Terms of Use: http://www.asme.org/about-as

r CONTENTS r

1 r Introduction 1

2 r Scope 3

3 r Importance of Effective Monitoring 5

4 r Discussion of Parameters to be Monitored 7

5 r Sampling 9

6 r Analytical Testing 39

7 r Test Methods 41

Tables

1 r Guidelines for Sampling Frequency by Location and Test

Sodium Zeolite Make-up 13

2 r Guidelines for Sampling Frequency by Location and Test

High Purity Make-up 15

3 r Purge Times Required for Representative Sampling

of Water 18

4 r Test Methods 19

Figures

1 r Recommended Sample Point Locations

Softened Water Make-up 10

2 r Recommended Sample Point Locations

High Purity Make-up 10

3 r Sampling Nozzle Installation 11

Bibliography 43

r ix

Downloaded From: http://ebooks.asmedigitalcollection.asme.org/ on 08/23/2017 Terms of Use: http://www.asme.org/about-as

Downloaded From: http://ebooks.asmedigitalcollection.asme.org/ on 08/23/2017 Terms of Use: http://www.asme.org/about-as

Das könnte Ihnen auch gefallen

- Understanding Waterhammer in Pumping Systems and Surge Suppression OptionsDokument20 SeitenUnderstanding Waterhammer in Pumping Systems and Surge Suppression OptionsdeepakmathilakathNoch keine Bewertungen

- AP1000 Plant DescriptionDokument31 SeitenAP1000 Plant DescriptionAsier DCNoch keine Bewertungen

- Steam Power PlantsDokument4 SeitenSteam Power Plantsapi-3723333100% (6)

- Vacuum Systems: Key to Power Plant OperationDokument15 SeitenVacuum Systems: Key to Power Plant OperationzulryNoch keine Bewertungen

- 3 - MID-TD-0000-1 - Fuel Gas Spec Rev Sept 09Dokument14 Seiten3 - MID-TD-0000-1 - Fuel Gas Spec Rev Sept 09talebNoch keine Bewertungen

- GE Suit Against UptakeDokument41 SeitenGE Suit Against UptakeAnonymous 6f8RIS6100% (2)

- 15 VGB RDS PP Licensing FINALDokument13 Seiten15 VGB RDS PP Licensing FINALPietroNoch keine Bewertungen

- Heat Exchange Institute, Inc.: Standards ForDokument5 SeitenHeat Exchange Institute, Inc.: Standards ForDepid Prasetyo UNoch keine Bewertungen

- Vacuum Breaker ValveDokument2 SeitenVacuum Breaker ValveRaghunath YeturiNoch keine Bewertungen

- Tutorial Session Practical Approach To Surge and Surge Control SystemsDokument30 SeitenTutorial Session Practical Approach To Surge and Surge Control Systemspreetham108Noch keine Bewertungen

- Actuators and Valve Positioners GuideDokument6 SeitenActuators and Valve Positioners GuideMohamed Arriff100% (1)

- Turbine Bypass ValvesDokument6 SeitenTurbine Bypass ValvesadehriyaNoch keine Bewertungen

- Oilon oil, gas, and dual fuel burners technical guideDokument32 SeitenOilon oil, gas, and dual fuel burners technical guideHrishikesh RokadeNoch keine Bewertungen

- Parametric Study of Charging Inlet Part2Dokument18 SeitenParametric Study of Charging Inlet Part2mayurghule19100% (1)

- Robatherm Medical EngDokument11 SeitenRobatherm Medical EngSamiYousifNoch keine Bewertungen

- Main Steam Turbine Controls Retrofit ISA FinalDokument13 SeitenMain Steam Turbine Controls Retrofit ISA Finalvankayalasurya100% (1)

- Candu SystemDokument214 SeitenCandu SystemGuruxyzNoch keine Bewertungen

- Sense'' Testing Combined Cycle Plants Competitive: Performance FOR IN IndustryDokument11 SeitenSense'' Testing Combined Cycle Plants Competitive: Performance FOR IN IndustryharkiranrandhawaNoch keine Bewertungen

- Part 1 IntroductionDokument42 SeitenPart 1 Introductionandrew brownNoch keine Bewertungen

- HRSG OPERATION AND STARTUPDokument7 SeitenHRSG OPERATION AND STARTUPM Moarraf Naeem100% (1)

- Introducing Standards for AIR COOLED CONDENSERSDokument8 SeitenIntroducing Standards for AIR COOLED CONDENSERSSyed HafeezNoch keine Bewertungen

- Syed Ammal Engineering College Power Plant Engineering Question BankDokument16 SeitenSyed Ammal Engineering College Power Plant Engineering Question BankNizam MANoch keine Bewertungen

- Introduction To BoilersDokument22 SeitenIntroduction To BoilersaravindsnistNoch keine Bewertungen

- Deh Governing-LancoDokument35 SeitenDeh Governing-LancoPRAMOD KUMAR NANDANoch keine Bewertungen

- Turbine Auxiliaries - Arrangement of Turbine Auxiliaries - ALL ABOUT POWER PLANTDokument14 SeitenTurbine Auxiliaries - Arrangement of Turbine Auxiliaries - ALL ABOUT POWER PLANTKolahalam RakeshrajuNoch keine Bewertungen

- Mechanical Equipment: Nuclear Training Course 23001 (NEIT 230.1)Dokument59 SeitenMechanical Equipment: Nuclear Training Course 23001 (NEIT 230.1)abuhurairaqaziNoch keine Bewertungen

- AVEVA PADO - Sub Solution - Performance Monitoring System PMSDokument44 SeitenAVEVA PADO - Sub Solution - Performance Monitoring System PMSMuhammad RizaldiNoch keine Bewertungen

- HRSG Handbook BrochureDokument2 SeitenHRSG Handbook Brochuremahmoud_allam3Noch keine Bewertungen

- Rowen - Simplified - Mathematical - Representations - of - Heavy-Duty - Gas - Turbines 1983Dokument5 SeitenRowen - Simplified - Mathematical - Representations - of - Heavy-Duty - Gas - Turbines 1983Marcelo MolinaNoch keine Bewertungen

- Applicability: Steam Turbine Information ManualDokument4 SeitenApplicability: Steam Turbine Information ManualbikendiaguirreNoch keine Bewertungen

- Epri HPS PDFDokument152 SeitenEpri HPS PDFale sepulvedaNoch keine Bewertungen

- Extraction Condensing Steam Turbine PDFDokument2 SeitenExtraction Condensing Steam Turbine PDFAaronNoch keine Bewertungen

- Industrial Boilers Technical SpecificationsDokument13 SeitenIndustrial Boilers Technical Specificationsfaiq AlfaniNoch keine Bewertungen

- Gas Turbine Power Plant Operation - I&CDokument14 SeitenGas Turbine Power Plant Operation - I&CWidodo Hadi Prabowo100% (1)

- Stim-03.006 - en Control FluidDokument17 SeitenStim-03.006 - en Control Fluidbikendiaguirre100% (1)

- Super Critical Power PlantDokument27 SeitenSuper Critical Power PlantPrabir Kumar PatiNoch keine Bewertungen

- Yyoouu Ccaann Bbee Ssuurree ...... Iiff Iitt''Ss W WeessttiinngghhoouusseeDokument26 SeitenYyoouu Ccaann Bbee Ssuurree ...... Iiff Iitt''Ss W Weessttiinngghhoouusseeqcqapgh7748Noch keine Bewertungen

- IDBC-TS-OMSYS-000008 Rev C System Description Diesel Storage and Distribution - ForReview - Revised - 140513Dokument23 SeitenIDBC-TS-OMSYS-000008 Rev C System Description Diesel Storage and Distribution - ForReview - Revised - 140513TitusNoch keine Bewertungen

- Pump installation tips: General piping guidelinesDokument9 SeitenPump installation tips: General piping guidelinesYe tun KyawNoch keine Bewertungen

- Gas Turbine Simple Cycle SCRDokument20 SeitenGas Turbine Simple Cycle SCRJung Kyung WooNoch keine Bewertungen

- 77.42.01-1999 (Fossil Fuel Power Plant Feedwater Control System - Drum Type)Dokument34 Seiten77.42.01-1999 (Fossil Fuel Power Plant Feedwater Control System - Drum Type)cristhmart1971Noch keine Bewertungen

- Plant Performance CalculationsDokument2 SeitenPlant Performance CalculationsKalki Communication Technologies Ltd100% (1)

- Geothermal Plant SystemsDokument13 SeitenGeothermal Plant SystemsKant KanyarusokeNoch keine Bewertungen

- Asld PresentDokument50 SeitenAsld PresentAakanksha GahlautNoch keine Bewertungen

- ASME Code Section 8Dokument14 SeitenASME Code Section 8ShieeplNoch keine Bewertungen

- Steam TurbineDokument78 SeitenSteam TurbineSiddharth Sharma100% (1)

- NERC Modeling Notification - Gas Turbine Governor ModelingDokument7 SeitenNERC Modeling Notification - Gas Turbine Governor Modelingsaiko_searchNoch keine Bewertungen

- Furnace HVT Traverse StandardDokument8 SeitenFurnace HVT Traverse StandardpsatyasrinivasNoch keine Bewertungen

- Extending the Range of Single-Shaft Combined Cycle Power PlantsDokument12 SeitenExtending the Range of Single-Shaft Combined Cycle Power PlantsSrinivasa Rao PallelaNoch keine Bewertungen

- Requisition For HRSG Packages: (10301-H-PKG & 10401-H-PKG)Dokument206 SeitenRequisition For HRSG Packages: (10301-H-PKG & 10401-H-PKG)ThiruppathirajanNoch keine Bewertungen

- Key Parameters For Air Cooled Condenser DesignDokument12 SeitenKey Parameters For Air Cooled Condenser DesignmohantyomNoch keine Bewertungen

- Natural Gas Network Optimization and Power to Gas ApplicationsDokument479 SeitenNatural Gas Network Optimization and Power to Gas Applicationsmohamed352100% (1)

- Modern Developments in the Mechanics of ContinuaVon EverandModern Developments in the Mechanics of ContinuaSalamon EskinaziNoch keine Bewertungen

- Heat and Fluid Flow in Power System Components: Hmt The Science & Applications of Heat and Mass TransferVon EverandHeat and Fluid Flow in Power System Components: Hmt The Science & Applications of Heat and Mass TransferA. M. A. RezkNoch keine Bewertungen

- Thermal Cycles of Heat Recovery Power PlantsVon EverandThermal Cycles of Heat Recovery Power PlantsBewertung: 5 von 5 Sternen5/5 (2)

- Practical Chemical Thermodynamics for GeoscientistsVon EverandPractical Chemical Thermodynamics for GeoscientistsNoch keine Bewertungen

- aer aer aeraer aer aer(ASME Research Report._ CRTD (Series) 81) ASME Press-Consensus on Operating Practices for the Sampling and Monitoring of Feedwater and Boiler Water Chemistry in Modern Industrial Boilers _ an ASME ResDokument43 Seitenaer aer aeraer aer aer(ASME Research Report._ CRTD (Series) 81) ASME Press-Consensus on Operating Practices for the Sampling and Monitoring of Feedwater and Boiler Water Chemistry in Modern Industrial Boilers _ an ASME Resrawaronteks100% (1)

- Welding ProcessessDokument20 SeitenWelding Processessabdulrehman2010Noch keine Bewertungen

- HVAC Duct Sizing GuideDokument91 SeitenHVAC Duct Sizing GuidePrabir Bhowmik100% (1)

- New Microsoft Office Excel WorksheetDokument5 SeitenNew Microsoft Office Excel Worksheetabdulrehman2010Noch keine Bewertungen

- New Microsoft Office Excel WorksheetDokument5 SeitenNew Microsoft Office Excel Worksheetabdulrehman2010Noch keine Bewertungen

- 11 Chapter 3Dokument22 Seiten11 Chapter 3abdulrehman2010Noch keine Bewertungen

- Pub Not 22016Dokument4 SeitenPub Not 22016abdulrehman2010Noch keine Bewertungen

- Rough Rule of Thumb For Saturation Temperature of SteamDokument1 SeiteRough Rule of Thumb For Saturation Temperature of SteamRiteshNoch keine Bewertungen

- TeachingComprehension PDFDokument288 SeitenTeachingComprehension PDFabdulrehman2010100% (1)

- New Microsoft Office Excel WorksheetDokument5 SeitenNew Microsoft Office Excel Worksheetabdulrehman2010Noch keine Bewertungen

- Tag DramaDokument1 SeiteTag Dramaabdulrehman2010Noch keine Bewertungen

- Rankine CycleDokument20 SeitenRankine Cycleabdulrehman2010100% (1)

- Confined Space Safety EssentialsDokument28 SeitenConfined Space Safety EssentialsdgdhandeNoch keine Bewertungen

- Boiler CFBDokument6 SeitenBoiler CFBabdulrehman2010Noch keine Bewertungen

- ALL Purpose Worksheet (Conversions)Dokument20 SeitenALL Purpose Worksheet (Conversions)bryandownNoch keine Bewertungen

- Generation Licen TNB Liberty Power Ltd-Dated 30-08-2003Dokument28 SeitenGeneration Licen TNB Liberty Power Ltd-Dated 30-08-2003abdulrehman2010Noch keine Bewertungen

- Seattle Boiler and Pressure Vessel Code - 1999 Effective July 1, 1999Dokument30 SeitenSeattle Boiler and Pressure Vessel Code - 1999 Effective July 1, 1999abdulrehman2010Noch keine Bewertungen

- Impedance Test Results On Conductive ConcreteDokument1 SeiteImpedance Test Results On Conductive Concreteabdulrehman2010Noch keine Bewertungen

- PIEAS Sample Test Paper For BS EngineeringDokument12 SeitenPIEAS Sample Test Paper For BS EngineeringAitazaz Ahsan100% (4)

- Boilers 1Dokument29 SeitenBoilers 1Thakur Kamal Prasad50% (2)

- Higher Algebra - Hall & KnightDokument593 SeitenHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Higher Algebra - Hall & KnightDokument593 SeitenHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- SureFlowEquipmentInc US Price List Sept2012Dokument32 SeitenSureFlowEquipmentInc US Price List Sept2012mihailspiridonNoch keine Bewertungen

- ASME B16.10-2017 Face-To-Face and End-To-End Dimensions of ValvesDokument2 SeitenASME B16.10-2017 Face-To-Face and End-To-End Dimensions of Valvesscribd.vaNoch keine Bewertungen

- Asme A 13.1Dokument13 SeitenAsme A 13.1Eswin Paico de la Cruz100% (1)

- Radiographic Examination Engineering ProcedureDokument30 SeitenRadiographic Examination Engineering Proceduredanielpradeep100% (1)

- PNFJ8000Dokument71 SeitenPNFJ8000seenu189100% (1)

- UOP 2-12-5 Fired HeatersDokument45 SeitenUOP 2-12-5 Fired Heaterskaboomi47100% (7)

- SECRETS TO USING ASME SECTION IXDokument4 SeitenSECRETS TO USING ASME SECTION IXAsad Bin Ala Qatari0% (1)

- Rules and Regulation For Cross Country Pipeline in IndiaDokument14 SeitenRules and Regulation For Cross Country Pipeline in IndiaUpendra Nath BhaskarNoch keine Bewertungen

- Piping Fabrication and Erection SpecificationDokument19 SeitenPiping Fabrication and Erection Specificationahmedmoin1159Noch keine Bewertungen

- Sec 1 PT PFTDokument59 SeitenSec 1 PT PFTHarjeet SinghNoch keine Bewertungen

- 1.welding Repair ProcdureDokument7 Seiten1.welding Repair Procduresethu1091Noch keine Bewertungen

- PIP VECV1001 Vessel Design Criteria ASME Code Section VIII Divisions 1 and 2Dokument38 SeitenPIP VECV1001 Vessel Design Criteria ASME Code Section VIII Divisions 1 and 2Miguel A. GarciaNoch keine Bewertungen

- Inspection and Testing of Piping Systems GuideDokument44 SeitenInspection and Testing of Piping Systems Guideiran1362100% (2)

- ASME-AUC Joint Courses Specialization in Pressure Vessels & PipingDokument4 SeitenASME-AUC Joint Courses Specialization in Pressure Vessels & PipingwessamalexNoch keine Bewertungen

- CraneDokument32 SeitenCranesabes26100% (1)

- API 510 Pressure Vessel Inspection Code TrainingDokument157 SeitenAPI 510 Pressure Vessel Inspection Code TrainingSiraj KhanNoch keine Bewertungen

- Asme A18.1.2008 PDFDokument76 SeitenAsme A18.1.2008 PDFjackNoch keine Bewertungen

- Inspection and Testing of Piping Systems GuideDokument44 SeitenInspection and Testing of Piping Systems Guideiran1362Noch keine Bewertungen

- R 015987Dokument63 SeitenR 015987shaffeti100% (2)

- Pressure Relief Valve Engineering HandbookDokument93 SeitenPressure Relief Valve Engineering Handbookakrouti92% (12)

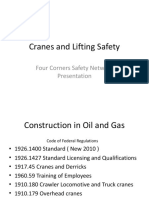

- Cranes and Lifting Safety: Four Corners Safety Network PresentationDokument45 SeitenCranes and Lifting Safety: Four Corners Safety Network PresentationMARJAN PETROVSKINoch keine Bewertungen

- Api 653Dokument1 SeiteApi 653BashMohandesssNoch keine Bewertungen

- B40 1Dokument41 SeitenB40 1chandruhbkk100% (1)

- b16 28Dokument20 Seitenb16 28Gustavo FamaNoch keine Bewertungen

- JERES-D-001 Design Criteria For Pressure VesselsDokument37 SeitenJERES-D-001 Design Criteria For Pressure VesselsThirukkumaranBalasubramanianNoch keine Bewertungen

- Method Statement For Underground Piping FCDokument17 SeitenMethod Statement For Underground Piping FCmister pogi94% (17)

- ASME B31.1 Power Piping Brochure 2014Dokument4 SeitenASME B31.1 Power Piping Brochure 2014Jozsef MagyariNoch keine Bewertungen

- Calc Hoop StressDokument11 SeitenCalc Hoop StressApril TrevinoNoch keine Bewertungen

- Welding and Grooving Procedure GuideDokument19 SeitenWelding and Grooving Procedure GuideAzhar Ali67% (3)

- Visual Weld InspectionDokument7 SeitenVisual Weld InspectioninsiderrNoch keine Bewertungen