Beruflich Dokumente

Kultur Dokumente

Engineering Information - Flow Charts - "C" Factors

Hochgeladen von

Lorena DávilaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Engineering Information - Flow Charts - "C" Factors

Hochgeladen von

Lorena DávilaCopyright:

Verfügbare Formate

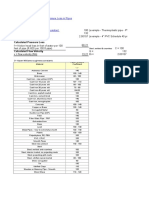

ENGINEERING INFORMATION - 16.

23

FLOW CHARTS - C FACTORS Rev. 4-99

Flow charts and C factors as head in feet lost per 1000 some larger sizes added and with

The flow charts feet of pipe at the various flows additional scales added for use in

The following three charts show in gallons per minute. estimating special pipes by actual

the corresponding friction losses inside diameters. For instance,

of cast iron and similar water Service line designers usu- the chart for Type K copper pipe

mains; of schedule 40 steel pipe; ally are interested in losses can be used for plastic pipe and

and Type K copper pipe. expressed in pounds per any smooth pipe where the actual

square inch. The flow charts inside diameter is known.

Most field contractors and engi- for schedule 40 steel pipe and

neers dealing with the construc- Type K copper pipe give the In a similar manner the flows

tion and design of water mains are losses as pounds per square through odd size pipes of similar

accustomed to thinking of losses inch lost in 100 feet of service internal roughness to schedule 40

in feet of water and flow of gal- line at various flows in gallons steel and cast iron pipe can also

lons per minute as determined by per minute. be estimated, since the auxillary

the Williams and Hazens for- inside diameter scales have like-

mula. The flow chart for cast iron These latter charts are taken wise been added to these charts.

and similar mains is based on this from the Bureau of Standards

formula and expresses the losses Publication BMS - 79, with

Williams and Hazen C fac- rior in fair condition. capacity over a long period of

tors* for use with flow chart New welded-steel pipe with years is somewhat impaired

shown on page Eng Info - 24 riveted girth joints. through tuberculation or

New cast iron, usual value. sedimentation. For sizes

Values of C recommended below 6 inches, somewhat

Old brass, copper, lead, tin.

for use in the Williams and Ha- lower values should be used.

zen Formula

C = 120 for smooth pipes, such Velocities in feet per second

C = 140 for extremely smooth and loss of head in feet per

as Smooth wooden pipes or

and straight pipes with 1,000 feet of pipe for C = 100

woodstave pipes. Ordinary

continuous interior and are given in Table XLIV (see

concrete.

welded or coupled joints, Piping Handbook).

such as New brass, copper,

C = 110 - 130 for new full-

lead, tin. New cast iron.

riveted steel or wrought-iron C = 95 for old full-riveted steel

New welded or seamless under the same conditions.

pipe, depending on thickness

steel. Smooth concrete (see

of plate and extent to which

Scobey concrete formula for C = 90 for brick sewers.

rivets are countersunk (see

full details on various degrees

also Scobey formula).

of roughness). C = 60 for corrugated pipe or

Smooth cement-lined cast badly tuberculated iron or

C = 110 for old cement-lined

iron or steel pipe. steel pipes.

pipe, or vitrified-crock sewers

Asbestos-Cement.

in good condition

* By permission from PIPING HANDBOOK,

4th Ed., by Sabin Crocker. Copyright, 1945.

C = 130 for very smooth pipes, McGraw- Hill Book Company, Inc.

C = 100 for old cast-iron or old

such as Welded or seamless

continu ous interior steel

steel with continuous inte

pipes where the carrying

Das könnte Ihnen auch gefallen

- 01 Samss 010Dokument12 Seiten01 Samss 010aamirtec301Noch keine Bewertungen

- VDAS LOP ROP Component List 16 06 2021 MinDokument31 SeitenVDAS LOP ROP Component List 16 06 2021 MinAndi SugiartoNoch keine Bewertungen

- QC Welding Inspector InterviewDokument286 SeitenQC Welding Inspector InterviewNDT CTC100% (7)

- How To Conduct A Damage Mechanism Review DMRDokument16 SeitenHow To Conduct A Damage Mechanism Review DMRRamya P100% (1)

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopVon EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopBewertung: 4.5 von 5 Sternen4.5/5 (2)

- APPENDIX 1: Recommended Roughness ValuesDokument2 SeitenAPPENDIX 1: Recommended Roughness ValuesalvinchuanNoch keine Bewertungen

- SAES-J-605 - Surge Relief Protection SystemsDokument16 SeitenSAES-J-605 - Surge Relief Protection SystemsyouaresweetNoch keine Bewertungen

- C ValueDokument2 SeitenC ValuePadmanabh Shetty0% (1)

- My CalculationsDokument39 SeitenMy CalculationsWaqas Khan ChannarNoch keine Bewertungen

- M3c Hazen WilliamsDokument8 SeitenM3c Hazen WilliamsTariq AfridiNoch keine Bewertungen

- Operation Manual 2 in 1 Filling Capping Full UpdatedDokument103 SeitenOperation Manual 2 in 1 Filling Capping Full UpdatedRiyoko Fillex100% (2)

- Charles Rig Supplies, Inc.: Instruction ManualDokument9 SeitenCharles Rig Supplies, Inc.: Instruction Manualashad100% (1)

- American Antique Weather Vanes: The Complete Illustrated Westervelt Catalog of 1883Von EverandAmerican Antique Weather Vanes: The Complete Illustrated Westervelt Catalog of 1883Bewertung: 3 von 5 Sternen3/5 (1)

- API 570 Day 2 Book (1 To 51)Dokument65 SeitenAPI 570 Day 2 Book (1 To 51)AbdulQuddus100% (3)

- Hazen William FormulaDokument4 SeitenHazen William FormulaShahbaz Manzoor100% (1)

- PipeDokument33 SeitenPipeDhakshina K100% (1)

- MothballingDokument130 SeitenMothballingrajeshpillai83Noch keine Bewertungen

- Comparative Study of Flare Dispersion Modeling MethodologiesDokument15 SeitenComparative Study of Flare Dispersion Modeling MethodologiesLorena DávilaNoch keine Bewertungen

- Section 3: American Ductile Iron PipeDokument35 SeitenSection 3: American Ductile Iron Pipejosesantimateo100% (2)

- BoqDokument88 SeitenBoqAbo FayrouzNoch keine Bewertungen

- PenstockDokument22 SeitenPenstockAbiued EjigueNoch keine Bewertungen

- Hazen-Williams Equation - Calculating Head Loss in Water PipesDokument8 SeitenHazen-Williams Equation - Calculating Head Loss in Water PipesJonnah Faye MojaresNoch keine Bewertungen

- AMERICAN Pipe Manual - Ductile Iron Pipe (5-14-15) PDFDokument35 SeitenAMERICAN Pipe Manual - Ductile Iron Pipe (5-14-15) PDFLmaoNoch keine Bewertungen

- Anderson Separator: Fuel Gas Skid General Arrangment - 250 PsigDokument2 SeitenAnderson Separator: Fuel Gas Skid General Arrangment - 250 PsigJhonny Rincones100% (1)

- Pipe Sizing and Pressure Drop CalculationDokument7 SeitenPipe Sizing and Pressure Drop Calculationvino2winNoch keine Bewertungen

- Hydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedVon EverandHydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedNoch keine Bewertungen

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyVon EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNoch keine Bewertungen

- Chilled Water Pipe Sizing Study PDFDokument34 SeitenChilled Water Pipe Sizing Study PDFNajam24Noch keine Bewertungen

- Hydraulics HydraulicAnalysis PDFDokument9 SeitenHydraulics HydraulicAnalysis PDFEduardo Abbadon ZavalaNoch keine Bewertungen

- Sistem Perpipaan: Darcy-Weisbach Diagram MoodyDokument32 SeitenSistem Perpipaan: Darcy-Weisbach Diagram MoodyRezi OktaviandriNoch keine Bewertungen

- Hazen Williams ConstantsDokument1 SeiteHazen Williams ConstantsabhijithavalNoch keine Bewertungen

- Lesson 2 - Plumbing Pipes and FittingsDokument39 SeitenLesson 2 - Plumbing Pipes and FittingsNicholas Bonn SingNoch keine Bewertungen

- Aluma FormDokument14 SeitenAluma FormRONALD HIDROBO CASTELLANONoch keine Bewertungen

- Modine Steam CoilsDokument8 SeitenModine Steam CoilsBrijeshNoch keine Bewertungen

- 1083ch2 29 PDFDokument10 Seiten1083ch2 29 PDFMauricio OñoroNoch keine Bewertungen

- Hazen Williams EquationDokument5 SeitenHazen Williams EquationAnonymous BJ9omONoch keine Bewertungen

- Section 01Dokument5 SeitenSection 01FAHAD HASSANNoch keine Bewertungen

- Fricc LosssesDokument6 SeitenFricc LosssesGabriel MurilloNoch keine Bewertungen

- Pressure Loss For Flow Through Pipe App1Dokument6 SeitenPressure Loss For Flow Through Pipe App1JeromeNoch keine Bewertungen

- Hazen Williams Roughnes ConstantDokument5 SeitenHazen Williams Roughnes ConstantAnonymous ynJByUsNoch keine Bewertungen

- 000 Drainage Pipes, Fiitings and JointsDokument41 Seiten000 Drainage Pipes, Fiitings and Jointselcid agsamosamNoch keine Bewertungen

- Hazen Williams Friction Loss Method: (Flow Against Lap)Dokument1 SeiteHazen Williams Friction Loss Method: (Flow Against Lap)SSudhakarNoch keine Bewertungen

- Hazen-Williams EquationDokument2 SeitenHazen-Williams Equationengyassin0% (1)

- All in " To 'Lo Feet. To Cells Olijeits - 215) - Resist FullDokument1 SeiteAll in " To 'Lo Feet. To Cells Olijeits - 215) - Resist FullreacharunkNoch keine Bewertungen

- Mimimum SizesDokument2 SeitenMimimum SizesRomeo Dequito JrNoch keine Bewertungen

- Land Telegraph LinesDokument26 SeitenLand Telegraph LinesAlex WarHorseNoch keine Bewertungen

- Rkah: Pipe, Steel, Black and Hot-Dipped, Zinc-Coated Welded and Seamless'Dokument22 SeitenRkah: Pipe, Steel, Black and Hot-Dipped, Zinc-Coated Welded and Seamless'alucard375Noch keine Bewertungen

- Hazen-Williams Equation: General Form Pipe EquationDokument4 SeitenHazen-Williams Equation: General Form Pipe EquationatokkuNoch keine Bewertungen

- 15060S02-Pipe and Pipe-Fitting ScheduleDokument5 Seiten15060S02-Pipe and Pipe-Fitting ScheduleNoushad P HamsaNoch keine Bewertungen

- Pipe & Wall Thickness Calculation: Submitted By:-Sandeep KrishnanDokument26 SeitenPipe & Wall Thickness Calculation: Submitted By:-Sandeep KrishnanMatthew Anthony MallariNoch keine Bewertungen

- Building Pipe Types & Properties: Water Supply, Drain Piping & Other Pipes in BuildingsDokument9 SeitenBuilding Pipe Types & Properties: Water Supply, Drain Piping & Other Pipes in BuildingsEquilibrium EngineersNoch keine Bewertungen

- 2016-CB - Di Flange-Pipe-SubmittalDokument3 Seiten2016-CB - Di Flange-Pipe-Submittalsidharth saraswatNoch keine Bewertungen

- 36 Normas FabricacionDokument1 Seite36 Normas FabricacionlechepinitoNoch keine Bewertungen

- D.I. Catalogue) 9th Edition) PDFDokument70 SeitenD.I. Catalogue) 9th Edition) PDFArunprasad MurugesanNoch keine Bewertungen

- PipingDokument7 SeitenPipingAshar HassanNoch keine Bewertungen

- Fluid Machinery: Marcelino N. Lunag JRDokument24 SeitenFluid Machinery: Marcelino N. Lunag JRJames Renan SabadoNoch keine Bewertungen

- Discussion 4 - Pipe FittingsDokument35 SeitenDiscussion 4 - Pipe FittingsShan Troy Jamero IbarraNoch keine Bewertungen

- 117 Section 6 Types of BrassDokument10 Seiten117 Section 6 Types of Brassrozanedeghat8942Noch keine Bewertungen

- Plumbing: MaterialsDokument8 SeitenPlumbing: MaterialsAaronNoch keine Bewertungen

- Chapter 8 Exercise ProblemsDokument12 SeitenChapter 8 Exercise ProblemsHalima Sibayan SawanganNoch keine Bewertungen

- Keybo缸D , Itis出E R臼Ponsibili可 To Ensure 出At His 也Lculator Opera也S C缸Ldidal臼 And 可Pe On 出EDokument4 SeitenKeybo缸D , Itis出E R臼Ponsibili可 To Ensure 出At His 也Lculator Opera也S C缸Ldidal臼 And 可Pe On 出ECheuk Yin NGNoch keine Bewertungen

- Features FlangedDuctileIronPipeandFittings PDFDokument5 SeitenFeatures FlangedDuctileIronPipeandFittings PDFGourav SharmaNoch keine Bewertungen

- Section 221116 - Domestic Water Piping-PexDokument16 SeitenSection 221116 - Domestic Water Piping-PexChase GietterNoch keine Bewertungen

- Excreta Drainage System PDFDokument28 SeitenExcreta Drainage System PDFAprilyn Vanessa DegamoNoch keine Bewertungen

- Fire Protection SpecificationDokument34 SeitenFire Protection Specification22-09441Noch keine Bewertungen

- Culvert Design 7 Structure Design v3 PDFDokument29 SeitenCulvert Design 7 Structure Design v3 PDFhalavath gopikrishnaNoch keine Bewertungen

- Diseño de Puentes Tipo AlcantarillaDokument29 SeitenDiseño de Puentes Tipo AlcantarillaAlvaroRuizValdiviesoNoch keine Bewertungen

- Corona Loss Measurements For The Design Of: Transmission VoltagesDokument8 SeitenCorona Loss Measurements For The Design Of: Transmission Voltagesboxeli2281Noch keine Bewertungen

- DIPRA Hydraulic Analysis of DI PipeDokument8 SeitenDIPRA Hydraulic Analysis of DI Pipehussien_azahariNoch keine Bewertungen

- The Water Supply of the El Paso and Southwestern Railway from Carrizozo to Santa Rosa, N. Mex. American Society of Civil Engineers: Transactions, No. 1170Von EverandThe Water Supply of the El Paso and Southwestern Railway from Carrizozo to Santa Rosa, N. Mex. American Society of Civil Engineers: Transactions, No. 1170Noch keine Bewertungen

- Visit For More Chinese Learning ResourcesDokument60 SeitenVisit For More Chinese Learning ResourcesLorena DávilaNoch keine Bewertungen

- Hsk3 SmallestDokument50 SeitenHsk3 SmallestLorena DávilaNoch keine Bewertungen

- Learn Korean Ep. 78: "Worth Doing": Action Verb Stem + (을/ㄹ) 만하다Dokument3 SeitenLearn Korean Ep. 78: "Worth Doing": Action Verb Stem + (을/ㄹ) 만하다Lorena DávilaNoch keine Bewertungen

- Visit For More Chinese Learning ResourcesDokument32 SeitenVisit For More Chinese Learning ResourcesLorena DávilaNoch keine Bewertungen

- Hsk4 SmallestDokument79 SeitenHsk4 SmallestLorena DávilaNoch keine Bewertungen

- Local Maximum Flame Length of Flares in A CrosswindDokument5 SeitenLocal Maximum Flame Length of Flares in A CrosswindLorena DávilaNoch keine Bewertungen

- Learn Korean Ep. 5: "Also" and "Again"Dokument3 SeitenLearn Korean Ep. 5: "Also" and "Again"Billy GoNoch keine Bewertungen

- Emissivity TableDokument7 SeitenEmissivity TableLorena DávilaNoch keine Bewertungen

- Flares and Stacks: G2 © ICARUS Corporation, 1998Dokument10 SeitenFlares and Stacks: G2 © ICARUS Corporation, 1998Lorena DávilaNoch keine Bewertungen

- A2-14 Noise Barrier Screening (06 Jul 09)Dokument1 SeiteA2-14 Noise Barrier Screening (06 Jul 09)Lorena DávilaNoch keine Bewertungen

- wl118 0308 Pressure20rating PDFDokument4 Seitenwl118 0308 Pressure20rating PDFLorena DávilaNoch keine Bewertungen

- Slug Catcher PDFDokument9 SeitenSlug Catcher PDFLorena DávilaNoch keine Bewertungen

- Wheatley Series 822 Check Valves FlyerDokument2 SeitenWheatley Series 822 Check Valves FlyerLorena DávilaNoch keine Bewertungen

- 08 2009 128 Nikollic 04Dokument12 Seiten08 2009 128 Nikollic 04Lorena DávilaNoch keine Bewertungen

- Bid No....... : Bid Date.... : Cust Quoted By.: Terms........ : Customer: Ship ToDokument17 SeitenBid No....... : Bid Date.... : Cust Quoted By.: Terms........ : Customer: Ship ToLorena DávilaNoch keine Bewertungen

- 4890 Guide Bar Installation For Weld TeesDokument2 Seiten4890 Guide Bar Installation For Weld TeesLorena DávilaNoch keine Bewertungen

- 4764 Typical Pipeline Bolt On Type Concrete Weight NEW GRAPHICSDokument2 Seiten4764 Typical Pipeline Bolt On Type Concrete Weight NEW GRAPHICSLorena DávilaNoch keine Bewertungen

- 4762-w0 Typical Canal Undercrossing, Lined or UnlinedDokument1 Seite4762-w0 Typical Canal Undercrossing, Lined or UnlinedLorena DávilaNoch keine Bewertungen

- Coiled Tubing Used As A Continuous-Sucker-Rod System in Slim HolesDokument2 SeitenCoiled Tubing Used As A Continuous-Sucker-Rod System in Slim HolesMarilyn Garzón AguirreNoch keine Bewertungen

- B 0000188Dokument20 SeitenB 0000188jose antonioNoch keine Bewertungen

- Cold RoomDokument2 SeitenCold RoomSALIMNoch keine Bewertungen

- Datasheet-Creo Piping and Cabling Extension-EnDokument5 SeitenDatasheet-Creo Piping and Cabling Extension-EnGovind RajNoch keine Bewertungen

- Aseptico ADU-10 Field Dental Unit - Service ManualDokument28 SeitenAseptico ADU-10 Field Dental Unit - Service ManualluisNoch keine Bewertungen

- Changeover ValvesDokument32 SeitenChangeover ValvesdlebreromNoch keine Bewertungen

- Catalogo General de Productos EMDEDokument12 SeitenCatalogo General de Productos EMDEeleon07Noch keine Bewertungen

- Control Valves: Environmental Pit Box GBMY 5050M2 SeriesDokument4 SeitenControl Valves: Environmental Pit Box GBMY 5050M2 SeriesMujahid SardarNoch keine Bewertungen

- 5a MSS SP 67 Butterfly ValvesDokument19 Seiten5a MSS SP 67 Butterfly ValvessghinausNoch keine Bewertungen

- Operation Manual: L Y S F 型系列陆用油水分离器 LYSF type oil-water separators for use on landDokument12 SeitenOperation Manual: L Y S F 型系列陆用油水分离器 LYSF type oil-water separators for use on landarief fardy yuskaNoch keine Bewertungen

- PEEK VictrexDokument16 SeitenPEEK VictrexmvinstrumentosNoch keine Bewertungen

- Data Rates Gate Works 13Dokument15 SeitenData Rates Gate Works 13vpmohammedNoch keine Bewertungen

- Final Varia OFC IDH-BayanaDokument22 SeitenFinal Varia OFC IDH-BayanasrdsoseeNoch keine Bewertungen

- Sepco Tube MillsDokument4 SeitenSepco Tube MillsKrv Babu BabuNoch keine Bewertungen

- Drip Irrigation ManualDokument13 SeitenDrip Irrigation ManualNimco CadayNoch keine Bewertungen

- Actuator Double ActingDokument3 SeitenActuator Double Actingandi nainggolanNoch keine Bewertungen

- Prep 16 Pipe Bevelling 3" To 16": Pipe Equipment Specialists LTDDokument5 SeitenPrep 16 Pipe Bevelling 3" To 16": Pipe Equipment Specialists LTDJorgeNoch keine Bewertungen

- SR Manual 100k-2gsr SN 128 - 130Dokument165 SeitenSR Manual 100k-2gsr SN 128 - 130carlos villarroyoNoch keine Bewertungen

- Resume - Nikhil GargDokument3 SeitenResume - Nikhil GargHarshit SharmaNoch keine Bewertungen