Beruflich Dokumente

Kultur Dokumente

PRO 810354 02 Poster-SteamBoilerEquipment en

Hochgeladen von

bertan dağıstanlıOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PRO 810354 02 Poster-SteamBoilerEquipment en

Hochgeladen von

bertan dağıstanlıCopyright:

Verfügbare Formate

GESTRA Steam Boiler Equipment

For operation e.g. according to TRD 604 (72 h) or EN 12953 (24 h)

Control room

Service partner

Condensate Monitoring

Type Approvals:

EC approval

TV (Germany)

Swiss TS/SVTI (Switzerland)

TI (Slovakia)

ITI TV (Czech Republic)

TMB (Hungary)

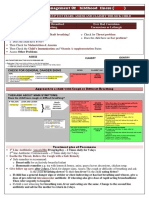

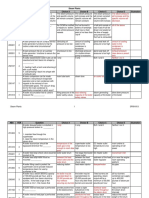

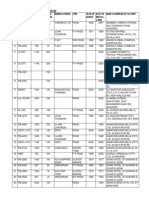

Example of a Steam-Boiler Plant Operating without Constant Supervision (72 h)

GESTRA Steam Boiler Equipment Condensate Monitoring

A Low-level limiter of high-integrity design: H Residual blowdown cooler S Electrical/pneumatic control valve V 725 1 Steam trap with trap test set, test chamber VKE,

level electrode NRG 16-40, level switch NRS 1-40.1 electrode NRG 16-19 and test unit NRA 1-3 for max. 16

J Blowdown receiver T Control terminal and display unit URB traps

B Modulating level controller with integrated 2nd water 2 Non-return valve RK 86

level and conductivity indicator: level probe NRG 26-40, K Safety temperature limiter: resistance thermometer U Control, regulation, operating and process data acquisi-

level controller NRR 2-40 TRG 5-65, temperature preamplifier TRV 5-40, tion via interfaces such as CAN, MODbus, Ethernet, OPC, Quality control for ingress of foreign matter, using type-ap-

level switch NRS 1-40.1 modem, Profibus (optional), SPECTORcontrol incl. the proved systems as per VdTV bulletin on water monitoring

C High-level alarm of high-integrity design: control functions B, D, E as well as operating procedures facilities (W 100)

level electrode NRG 16-41, level switch NRS 1-41 M Safety valve GSV 3 Monitoring for ingress of acids, blowdown, raw water etc.:

V Burner control via MODbus RTU interfacew conductivity electrode with integrated resistance thermo-

D E Conductivity measurement and continuous/intermittent N Pressure limiter

810354-02/1110 GESTRA AG Bremen Printed in Germany

meter LRG 16-9, conductivity switch LRS 1-7

blowdown: conductivity electrode LRG 16-41, continuous W Monitoring of the fresh water:

blowdown controller LRR 1-40, continuous blowdown O Pressure controller/transmitter 4 Monitoring for ingress of oil, grease etc.: oil and turbidity

valve BAE, intermittent blowdown valve MPA, 3/2-way Demineralization equipment using conductivity detector OR

pilot valve, strainer P Disco non-return valve RK 86 monitoring 5 Electrical/pneumatic three-way valve for discharging the

Partial demineralization equipment: by monitoring contaminated condensate

F Sample cooler Q Strainer GSF residual hardness (not part of our product range)

6 Main condensate tank

G Blowdown flash vessel R Stop valve GAV 7 Shutdown of the condensate-return system or interruption

of the safety chain

GESTRA AG Mnchener Str 77, D-28215 Bremen

P.O. Box 10 54 60, D-28054 Bremen

Telephone +49 (0) 421-35 03-0

Telefax +49 (0) 421-35 03-393

E-Mail gestra.ag@flowserve.com

Internet www.gestra.de

Das könnte Ihnen auch gefallen

- Titan GelDokument6 SeitenTitan GelVladi Salas100% (1)

- Instrumentation and Test Gear Circuits ManualVon EverandInstrumentation and Test Gear Circuits ManualBewertung: 5 von 5 Sternen5/5 (1)

- Radical Candor Scott enDokument2 SeitenRadical Candor Scott enbertan dağıstanlıNoch keine Bewertungen

- (Computational Risk Management) David L. Olson, Desheng Wu (Auth.) - Predictive Data Mining Models (2017, Springer Singapore)Dokument105 Seiten(Computational Risk Management) David L. Olson, Desheng Wu (Auth.) - Predictive Data Mining Models (2017, Springer Singapore)bertan dağıstanlı100% (2)

- Condensate PresentationDokument1 SeiteCondensate PresentationPrudhvi RajNoch keine Bewertungen

- Famous Bombers of The Second World War - 1st SeriesDokument142 SeitenFamous Bombers of The Second World War - 1st Seriesgunfighter29100% (1)

- Dust-Hog SUPRA-CONIC Owner's ManualDokument40 SeitenDust-Hog SUPRA-CONIC Owner's Manualbertan dağıstanlı100% (1)

- Bill of Quantities of M. S. Pipe Fittings (O-14027)Dokument4 SeitenBill of Quantities of M. S. Pipe Fittings (O-14027)Tanmoy DuttaNoch keine Bewertungen

- Boiler Steam CostingDokument10 SeitenBoiler Steam CostingSomnath SinghNoch keine Bewertungen

- AIC - AirROCT35 - Spare Parts ManualDokument153 SeitenAIC - AirROCT35 - Spare Parts ManualMuhammad Arqam Al Ajam67% (3)

- JBC Common Boiler FormulasDokument12 SeitenJBC Common Boiler Formulasnesrine10Noch keine Bewertungen

- 400kgs Steam Boiler Oil FiredDokument5 Seiten400kgs Steam Boiler Oil FiredManikandanNoch keine Bewertungen

- SMP - Boiler Prs Part-R02Dokument41 SeitenSMP - Boiler Prs Part-R02Kathir Siva100% (1)

- IMCI UpdatedDokument5 SeitenIMCI UpdatedMalak RagehNoch keine Bewertungen

- Ohio Special Operating and Maintenance Guide-Wetback 100-225HP PDFDokument135 SeitenOhio Special Operating and Maintenance Guide-Wetback 100-225HP PDFIrvinSerranoJNoch keine Bewertungen

- Tugas BoilerDokument33 SeitenTugas BoilerAgus Dwi Nurcahyo JemberNoch keine Bewertungen

- MODEL: PFTA 1500-4: Ratings & Performance DataDokument4 SeitenMODEL: PFTA 1500-4: Ratings & Performance DataAnonymous izGbhcNoch keine Bewertungen

- Steam TablesDokument23 SeitenSteam TablesNoerby AntoNoch keine Bewertungen

- Steam Boiler Systems From Bosch: Highly Efficient and Reliable Process HeatDokument19 SeitenSteam Boiler Systems From Bosch: Highly Efficient and Reliable Process Heatnemi90Noch keine Bewertungen

- The Asset Management Landscape: Second Ed T OnDokument57 SeitenThe Asset Management Landscape: Second Ed T Onbertan dağıstanlıNoch keine Bewertungen

- SITONG Quotation of 3ton and 5ton Natural Gas Steam Boiler - 20221217Dokument22 SeitenSITONG Quotation of 3ton and 5ton Natural Gas Steam Boiler - 20221217TabzirtNoch keine Bewertungen

- Stainless Steel ANSI Pipe Flanges - A Guide: 1. What Type of Flange Is Required?Dokument5 SeitenStainless Steel ANSI Pipe Flanges - A Guide: 1. What Type of Flange Is Required?Utada HikaruNoch keine Bewertungen

- Omv enDokument50 SeitenOmv enMuhamad Saukie100% (1)

- EPRF Report Com Fulton Steam BoilersDokument13 SeitenEPRF Report Com Fulton Steam BoilersBlackzero68Noch keine Bewertungen

- DZL 4-1.25-AiiDokument10 SeitenDZL 4-1.25-AiiSamulaNoch keine Bewertungen

- Ygnis Ingl+ S Multiflam 170.1-200.1Dokument24 SeitenYgnis Ingl+ S Multiflam 170.1-200.1DihorulNoch keine Bewertungen

- Economiser Coil - DrawingDokument1 SeiteEconomiser Coil - DrawingAnjaneya ReddyNoch keine Bewertungen

- Miura Boilers Steam GeneratorsDokument2 SeitenMiura Boilers Steam GeneratorsDhonyAhmedPradjoegoNoch keine Bewertungen

- Longitudinal Section B-B Transverse Section A-A: Welding Details Not To ScaleDokument1 SeiteLongitudinal Section B-B Transverse Section A-A: Welding Details Not To ScalebunkeringNoch keine Bewertungen

- Research Study Diesel To BiomassDokument9 SeitenResearch Study Diesel To BiomassDarrel MagnoNoch keine Bewertungen

- 750 204 OM Profire D LND Apr08Dokument120 Seiten750 204 OM Profire D LND Apr08Rosanny Borges ChirinosNoch keine Bewertungen

- Boiler Comp. For 250bhpDokument2 SeitenBoiler Comp. For 250bhpNewaz KabirNoch keine Bewertungen

- Fulton ModSync Wiring DiagramDokument3 SeitenFulton ModSync Wiring DiagramjrodNoch keine Bewertungen

- Project On Conservation of Steam in Electroplating in Hero CyclesDokument7 SeitenProject On Conservation of Steam in Electroplating in Hero Cyclessharanjeet4uNoch keine Bewertungen

- SSGC New ConnectionDokument19 SeitenSSGC New ConnectionmimranislamNoch keine Bewertungen

- Steam PlantsDokument228 SeitenSteam PlantsMark Allen San Antonio100% (1)

- Bangladesh Datasheets January 2017 Wee ChieftainDokument1 SeiteBangladesh Datasheets January 2017 Wee ChieftainFAVIONoch keine Bewertungen

- 2ND CLASS Boilers in Lahore CircleDokument14 Seiten2ND CLASS Boilers in Lahore CircleGoldenshakehandNoch keine Bewertungen

- KSR Kuebler Transparent Level Gauge Attc 5Dokument56 SeitenKSR Kuebler Transparent Level Gauge Attc 5Hassan Sleem100% (1)

- Claver Brooks General Boiler InformationDokument10 SeitenClaver Brooks General Boiler Informationnecio77Noch keine Bewertungen

- Groundfos CR 10-10Dokument8 SeitenGroundfos CR 10-10defriyantoNoch keine Bewertungen

- Aalborg XW SuperheaterDokument2 SeitenAalborg XW SuperheaterPanagiotisNoch keine Bewertungen

- Costing of Sea Water RO Plant KPT Manora Design at 100,000 IGPD at 35,000 PPMDokument3 SeitenCosting of Sea Water RO Plant KPT Manora Design at 100,000 IGPD at 35,000 PPMMohtashim KazmiNoch keine Bewertungen

- ICI BX Instruktion EN v0100 2009 12 01 ICIDokument24 SeitenICI BX Instruktion EN v0100 2009 12 01 ICIadza30100% (1)

- Fulton RBCDokument112 SeitenFulton RBCYolan Lopez100% (1)

- Borderer Boiler Complete ManualDokument228 SeitenBorderer Boiler Complete ManualNitrogeno MPDNoch keine Bewertungen

- 78 - Triumph Stoker BrochureDokument2 Seiten78 - Triumph Stoker BrochureMatias MancillaNoch keine Bewertungen

- Boiler Parts and DefinitionDokument3 SeitenBoiler Parts and DefinitionKarlFrederickNoblezaNoch keine Bewertungen

- RO-MAN Reverse Osmosis Manual For 200 and 300 GPD SystemsDokument15 SeitenRO-MAN Reverse Osmosis Manual For 200 and 300 GPD SystemsasankandessNoch keine Bewertungen

- Instruction, Operation, and Maintenance Manual Fulton Oil Fired/Gas Fired Steam BoilersDokument63 SeitenInstruction, Operation, and Maintenance Manual Fulton Oil Fired/Gas Fired Steam BoilersKarla Sofia Torres Wong100% (1)

- Nrs 1-50 GestraDokument28 SeitenNrs 1-50 Gestramike tsakirisNoch keine Bewertungen

- Waste Water Treatment PlantDokument10 SeitenWaste Water Treatment PlantBoiler ScrubberNoch keine Bewertungen

- Greenoxe SeriesDokument32 SeitenGreenoxe SeriesLorenzo MasottiNoch keine Bewertungen

- 1 TPH 10.54 KG, Vapi Care PharmaDokument16 Seiten1 TPH 10.54 KG, Vapi Care PharmashastrysnNoch keine Bewertungen

- Control Box - Boiler Parts - Boilerparts - Co.keDokument26 SeitenControl Box - Boiler Parts - Boilerparts - Co.keboilerpartsNoch keine Bewertungen

- NATCO TurbulatorDokument2 SeitenNATCO TurbulatorshansalNoch keine Bewertungen

- Pump Manual - Single Plunger AmbicaDokument24 SeitenPump Manual - Single Plunger AmbicaHimTex /JaswinderNoch keine Bewertungen

- Vdocuments - MX Boiler Book Cleaver BrooksDokument1.391 SeitenVdocuments - MX Boiler Book Cleaver BrooksTecnico A Lazaro CardenasNoch keine Bewertungen

- Result: Economizer Heating Surface and Outlet Flue Gas Temperature CalculationDokument2 SeitenResult: Economizer Heating Surface and Outlet Flue Gas Temperature CalculationjagjitNoch keine Bewertungen

- Document Submission Status: FOR APPROVAL: Vung Ang 1 Thermal Power Plant 2 X 600Mw Lot M4A Cooling Water System (Bop)Dokument10 SeitenDocument Submission Status: FOR APPROVAL: Vung Ang 1 Thermal Power Plant 2 X 600Mw Lot M4A Cooling Water System (Bop)khang10182Noch keine Bewertungen

- Spiral Wound Gasket: Bharat Heavy Electricals Limited Tiruchirappalli-620 014Dokument54 SeitenSpiral Wound Gasket: Bharat Heavy Electricals Limited Tiruchirappalli-620 014Ramalingam PrabhakaranNoch keine Bewertungen

- 06 - MedupiGx - C2 SC3 Pricing Data - Aux Boiler SparesDokument33 Seiten06 - MedupiGx - C2 SC3 Pricing Data - Aux Boiler SparesTrịnh Đức HạnhNoch keine Bewertungen

- X20AT4222-Entrada RTDDokument10 SeitenX20AT4222-Entrada RTDWillian ErthalNoch keine Bewertungen

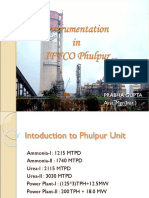

- Inst PrabhaDokument29 SeitenInst Prabharaj guptaNoch keine Bewertungen

- X20at4222-Eng V3.12Dokument10 SeitenX20at4222-Eng V3.12Asif MehmoodNoch keine Bewertungen

- Stackflow 200: SP IPDokument2 SeitenStackflow 200: SP IPHuidulescu AndreiNoch keine Bewertungen

- Gestra Level Control Monitoring LimitationDokument7 SeitenGestra Level Control Monitoring LimitationVoicu StaneseNoch keine Bewertungen

- User ManualDokument55 SeitenUser Manualbertan dağıstanlıNoch keine Bewertungen

- User'S Manual: Acer Chromebook 15Dokument31 SeitenUser'S Manual: Acer Chromebook 15bertan dağıstanlıNoch keine Bewertungen

- Cartridge Dust Collector Owners ManualDokument20 SeitenCartridge Dust Collector Owners Manualbertan dağıstanlıNoch keine Bewertungen

- Installation, Operation and Maintenance Manual: Rotoclone LVNDokument23 SeitenInstallation, Operation and Maintenance Manual: Rotoclone LVNbertan dağıstanlıNoch keine Bewertungen

- Data Sheet ZSP-NN-02 PDFDokument1 SeiteData Sheet ZSP-NN-02 PDFbertan dağıstanlıNoch keine Bewertungen

- Dust-Hog SUPRA-CONIC Troubleshooting GuideDokument44 SeitenDust-Hog SUPRA-CONIC Troubleshooting Guidebertan dağıstanlıNoch keine Bewertungen

- Installation, Operation and Maintenance Manual: Rotoclone LVNDokument23 SeitenInstallation, Operation and Maintenance Manual: Rotoclone LVNbertan dağıstanlıNoch keine Bewertungen

- 3VL9400 3HF05 PDFDokument2 Seiten3VL9400 3HF05 PDFbertan dağıstanlıNoch keine Bewertungen

- Data Sheet ZAS89R501Dokument1 SeiteData Sheet ZAS89R501bertan dağıstanlıNoch keine Bewertungen

- Fondarex Vacuum System HIGHVAC Progress BrochureDokument22 SeitenFondarex Vacuum System HIGHVAC Progress Brochurebertan dağıstanlı50% (2)

- Data Sheet BS5 PDFDokument1 SeiteData Sheet BS5 PDFbertan dağıstanlıNoch keine Bewertungen

- 3VL9400 3HF05Dokument2 Seiten3VL9400 3HF05bertan dağıstanlıNoch keine Bewertungen

- Frequency-Based Analysis of Financial Time Series: Mohammad Hamed IzadiDokument39 SeitenFrequency-Based Analysis of Financial Time Series: Mohammad Hamed Izadibertan dağıstanlıNoch keine Bewertungen

- Osisense Xs & XT - Xs4p12pa340dDokument6 SeitenOsisense Xs & XT - Xs4p12pa340dbertan dağıstanlıNoch keine Bewertungen

- ZSP-NN-02: Protection Housing SetDokument1 SeiteZSP-NN-02: Protection Housing Setbertan dağıstanlıNoch keine Bewertungen

- A General Treatment of Orbiting Gyroscope PrecessionDokument25 SeitenA General Treatment of Orbiting Gyroscope Precessionbertan dağıstanlıNoch keine Bewertungen

- High-Accuracy Surface Scanning MethodDokument10 SeitenHigh-Accuracy Surface Scanning Methodbertan dağıstanlıNoch keine Bewertungen

- WP Correct Weight-Handling enDokument4 SeitenWP Correct Weight-Handling enbertan dağıstanlıNoch keine Bewertungen

- Hydraulics Course FileDokument81 SeitenHydraulics Course FileSwarna LathaNoch keine Bewertungen

- 5 160 1 PBDokument13 Seiten5 160 1 PBLotkomoaidone Harahu TukambaNoch keine Bewertungen

- Lec22 Mod 5-1 Copper New TechniquesDokument24 SeitenLec22 Mod 5-1 Copper New TechniquesAaila AkhterNoch keine Bewertungen

- 4MA0 4H MSC 20140306Dokument14 Seiten4MA0 4H MSC 20140306HaiqaPervezNoch keine Bewertungen

- Unit 3 InfiltrationDokument5 SeitenUnit 3 InfiltrationHRIDYA MGNoch keine Bewertungen

- IDRW MagazineDokument10 SeitenIDRW MagazineVirarya100% (1)

- Section 08630 Metal-Framed SkylightDokument4 SeitenSection 08630 Metal-Framed SkylightMØhãmmed ØwięsNoch keine Bewertungen

- Assignment 1 - Statistics ProbabilityDokument3 SeitenAssignment 1 - Statistics ProbabilityAzel Fume100% (1)

- Mono 108Dokument438 SeitenMono 108pasaricaNoch keine Bewertungen

- Bsi MD Ivdr Conformity Assessment Routes Booklet Uk enDokument15 SeitenBsi MD Ivdr Conformity Assessment Routes Booklet Uk enGuillaumeNoch keine Bewertungen

- Technical Design of The Bukwimba Open Pit Final 12042017Dokument31 SeitenTechnical Design of The Bukwimba Open Pit Final 12042017Rozalia PengoNoch keine Bewertungen

- WL4000Dokument1 SeiteWL4000Laser PowerNoch keine Bewertungen

- Radiation Formula SheetDokument5 SeitenRadiation Formula SheetJakeJosephNoch keine Bewertungen

- Moisture and Total Solids AnalysisDokument44 SeitenMoisture and Total Solids AnalysisNicholas BoampongNoch keine Bewertungen

- Problem-Based Learning ReportDokument24 SeitenProblem-Based Learning Reporterdayu86Noch keine Bewertungen

- The Field-Effect Transistor - August 1972 Popular ElectronicsDokument5 SeitenThe Field-Effect Transistor - August 1972 Popular Electronicsmac9papNoch keine Bewertungen

- Moldex Realty, Inc. (Linda Agustin) 2.0 (With Sound)Dokument111 SeitenMoldex Realty, Inc. (Linda Agustin) 2.0 (With Sound)Arwin AgustinNoch keine Bewertungen

- Annotated Bib-BirthingDokument3 SeitenAnnotated Bib-Birthingapi-312719022Noch keine Bewertungen

- Manual de Electronica HardbookDokument970 SeitenManual de Electronica HardbookninoferNoch keine Bewertungen

- Unemployment in IndiaDokument9 SeitenUnemployment in IndiaKhushiNoch keine Bewertungen

- Joseph Conrad - Heart of DarknessDokument86 SeitenJoseph Conrad - Heart of DarknessCaztor SscNoch keine Bewertungen

- SFT PresentationDokument16 SeitenSFT Presentationapna indiaNoch keine Bewertungen

- Dwnload Full Psychology Core Concepts 7th Edition Zimbardo Test Bank PDFDokument13 SeitenDwnload Full Psychology Core Concepts 7th Edition Zimbardo Test Bank PDFcomfortdehm1350100% (7)

- Course On Quantum ComputingDokument235 SeitenCourse On Quantum ComputingAram ShojaeiNoch keine Bewertungen

- Prakab Export 20.8.2018 UkDokument260 SeitenPrakab Export 20.8.2018 UkREN JTNNoch keine Bewertungen

- Air System Sizing Summary For NIVEL PB - Zona 1Dokument1 SeiteAir System Sizing Summary For NIVEL PB - Zona 1Roger PandoNoch keine Bewertungen