Beruflich Dokumente

Kultur Dokumente

Questions Flange Breaking Containment

Hochgeladen von

Micky Plumb0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

102 Ansichten2 Seiten1. The candidate was asked questions about handling antifoam chemicals safely, hazards of flange management, and the safe method for breaking flanged joints.

2. When asked to describe a torqueing procedure, the candidate explained the correct bolting sequence and percentages for tightening nuts to apply even pressure on the gasket.

3. The candidate demonstrated knowledge of what markings on a flange indicate, such as the manufacturer, size, class/rating, and material specification.

Originalbeschreibung:

Breaking Containment Q's

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument melden1. The candidate was asked questions about handling antifoam chemicals safely, hazards of flange management, and the safe method for breaking flanged joints.

2. When asked to describe a torqueing procedure, the candidate explained the correct bolting sequence and percentages for tightening nuts to apply even pressure on the gasket.

3. The candidate demonstrated knowledge of what markings on a flange indicate, such as the manufacturer, size, class/rating, and material specification.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

102 Ansichten2 SeitenQuestions Flange Breaking Containment

Hochgeladen von

Micky Plumb1. The candidate was asked questions about handling antifoam chemicals safely, hazards of flange management, and the safe method for breaking flanged joints.

2. When asked to describe a torqueing procedure, the candidate explained the correct bolting sequence and percentages for tightening nuts to apply even pressure on the gasket.

3. The candidate demonstrated knowledge of what markings on a flange indicate, such as the manufacturer, size, class/rating, and material specification.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

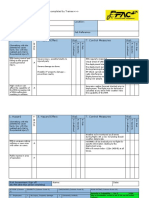

Question Record QR2

ASSET COMPETENCY AND TRAINING DEPARTMENT

Mechanical Maintenance

Question Record

CPF DS1 DS2 - Wells DS2

Candidate Name He Mohsin - 6805

Assessor Name Michael Sherriffs

OGOS/L2 MM03 Distributive Systems - PD Pump

Standards

OGOS/L2 MM03 Distributive Systems - Piping & Pipe Connections

Evidence Ref No QR2

Question Question Candidate Response Knowledge

No (include details of when asked) Criteria

1 4/12/15 OBS2. How do we know Use the MSDS sheet, (PW7 attached) follow K4.2, K4.3,

the properties and safety the advice given, wear neoprene gloves, K4.4

precautions to be taken when wear mask, inform team of what to do

handling antifoam? What should they come into contact with the

particular precautions will you chemical.

take?

2 4/12/15 OBS2. Identify some of Injury K4.6

the hazards that are associated Objects under compression

with flange management. Pressure release

Lifting or falling objects

3 4/12/15 OBS2. Explain the safe Verify the isolation, confirming the job is K4.4

method and technique you would tagged and isolated.

employ in the breaking of flanged Check that piping is drained and

depressurised, always assume the piping

joints. has trapped pressure.

Start unbolting the flange at a bolt away

from you; do not lean over the flange joint.

4 4/12/15 OBS2. If you observed Training - certification K4.4

somebody breaking a flange what Use of PTW

checks would you look for if you Isolations - LOTO

wanted to see he was able to He is using the correct gasket, nuts

and bolts for the flange / equipment

carry out the task? to be tightened up.

5 4/12/15 OBS2. Describe what a With some help with the English and K3.2

torqueing procedure should translation from the Arab speaking

contain and your understanding supervisor He was able to answer the

following:

of a bolting sequence and why it is

required Choose the Gasket as per manufacturers

guideline, we use green spiral wound today

as stated in the work order, I should check

the gaskets for defects and check the flange

face. Check for Alignment, parallelism and

lateral, check correct bolt/nut selection.

Torque down in correct pattern to keep

even pressure on the gasket 30%-60%-

100% and final torque.

6 4/12/15 OBS2. Explain the He showed me and explained to me the K3.2

details of what the markings following:

stamped to a flange relate to and Manufacturer

what the relevance of these is? Size

ASSET COMPETENCY AND TRAINING DEPARTMENT

Mechanical Maintenance

Question Record

Class/Rating

Material Specification

7 4/12/15 OBS2. Why would you In case pressure or chemical was still in the K3.3

not fully untighten the nuts pipe, so that I could tighten back up

before breaking the joint? quickly.

Assessor

Signature Date 6/12/15

Candidate

Signature Date

Version 1 June 2014 2

Das könnte Ihnen auch gefallen

- Design and Finite Element Assessment of Mounded Bullet PDFDokument14 SeitenDesign and Finite Element Assessment of Mounded Bullet PDFc0g100% (1)

- 11110d-2 Obround Nozzle Revised DesignDokument1 Seite11110d-2 Obround Nozzle Revised DesignSivateja NallamothuNoch keine Bewertungen

- Credit For Internal Cladding-RevDokument3 SeitenCredit For Internal Cladding-RevAhmedNoch keine Bewertungen

- TSG R0004 2009Dokument76 SeitenTSG R0004 2009bikobelloNoch keine Bewertungen

- Applied Thermal Engineering: Farhad Nemati Taher, Sirous Zeyninejad Movassag, Kazem Razmi, Reza Tasouji AzarDokument7 SeitenApplied Thermal Engineering: Farhad Nemati Taher, Sirous Zeyninejad Movassag, Kazem Razmi, Reza Tasouji AzarememNoch keine Bewertungen

- Vessel Manways, Handholes Pose Special Sealing Challenges: Flanged PlatesDokument6 SeitenVessel Manways, Handholes Pose Special Sealing Challenges: Flanged PlatesalokbdasNoch keine Bewertungen

- ASME UM Audit Preparation ListDokument2 SeitenASME UM Audit Preparation ListMd Anamul Hoque100% (1)

- Tubesheet: Design of Collar BoltDokument1 SeiteTubesheet: Design of Collar Boltpippo2378793Noch keine Bewertungen

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDokument5 SeitenASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaNoch keine Bewertungen

- Hydrogen Compressor Flange Bolts FailureDokument8 SeitenHydrogen Compressor Flange Bolts FailurePablo ScottNoch keine Bewertungen

- Geg A: Bolt-Up Procedure For Flanged Connections 670.210Dokument9 SeitenGeg A: Bolt-Up Procedure For Flanged Connections 670.210puwarin najaNoch keine Bewertungen

- Estudo de Caso - Asme 2398Dokument6 SeitenEstudo de Caso - Asme 2398biancogallazziNoch keine Bewertungen

- B.16.5 Interpretation PDFDokument68 SeitenB.16.5 Interpretation PDFmohdluthfiNoch keine Bewertungen

- BreechLock HEDokument1 SeiteBreechLock HEibrahim1961Noch keine Bewertungen

- Thermowell Calculation Guide V1.3Dokument19 SeitenThermowell Calculation Guide V1.3AymanelorbanyNoch keine Bewertungen

- Installation, Operation and Maintenance - LOK-FLANGE ® Multitube Heat ExchangersDokument5 SeitenInstallation, Operation and Maintenance - LOK-FLANGE ® Multitube Heat ExchangersCLIFFORDPANoch keine Bewertungen

- Class 1 Vs Class 2 Pressure Vessels - Hedderman ConsultingDokument3 SeitenClass 1 Vs Class 2 Pressure Vessels - Hedderman ConsultinglorenzoNoch keine Bewertungen

- How To Use Code Case in PV EliteDokument2 SeitenHow To Use Code Case in PV EliteMukeshChopraNoch keine Bewertungen

- FEA Basic Safety Guidelines Manufacturing 3rd EditionDokument42 SeitenFEA Basic Safety Guidelines Manufacturing 3rd EditionSaertu LogarNoch keine Bewertungen

- B16 Case 12Dokument2 SeitenB16 Case 12InaamNoch keine Bewertungen

- Girth Flange Load Calculation Using by FEA TechniquesDokument12 SeitenGirth Flange Load Calculation Using by FEA TechniqueskingstonNoch keine Bewertungen

- TorquingDokument7 SeitenTorquingVicky KumarNoch keine Bewertungen

- Asme Sec Viii D2 Ma App 5 PDFDokument15 SeitenAsme Sec Viii D2 Ma App 5 PDFMarín HernándezNoch keine Bewertungen

- ASMEDokument25 SeitenASMEAnonymous bENWheBNoch keine Bewertungen

- BREECH LOCK Presentation Dec2004 Tcm24 226146Dokument24 SeitenBREECH LOCK Presentation Dec2004 Tcm24 226146Harinarayanan Samsari Kizhake VeetilNoch keine Bewertungen

- 2015-Xii. P&id PDFDokument71 Seiten2015-Xii. P&id PDFFitria Nur HayatiNoch keine Bewertungen

- Pveng: Vessel With Large Opening Pve Sample VesselDokument1 SeitePveng: Vessel With Large Opening Pve Sample VesselSivateja NallamothuNoch keine Bewertungen

- Ceng Ebook PDFDokument14 SeitenCeng Ebook PDFMahnooranjumNoch keine Bewertungen

- Effect of Poorly Shaped ElementsDokument5 SeitenEffect of Poorly Shaped ElementsShamik ChowdhuryNoch keine Bewertungen

- Fem For Inclined Pressure VesselDokument5 SeitenFem For Inclined Pressure VesselPrayas SubediNoch keine Bewertungen

- Maximum Allowable Stress: Mechanical Design of Pressure VesselsDokument17 SeitenMaximum Allowable Stress: Mechanical Design of Pressure Vesselsfauzi100% (1)

- Comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2/comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2 PDFDokument13 SeitenComparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2/comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2 PDFruponline1Noch keine Bewertungen

- FEA Review Checklist Item Completed Documented Planning and Pre-ProcessingDokument1 SeiteFEA Review Checklist Item Completed Documented Planning and Pre-ProcessingSuryaprakashNoch keine Bewertungen

- Studded Outlet HSB News Letter PDFDokument4 SeitenStudded Outlet HSB News Letter PDFG.SWAMINoch keine Bewertungen

- ASME Formula DerivationDokument1 SeiteASME Formula Derivationvm153748763Noch keine Bewertungen

- 2018 January HSB Pressure PointsDokument5 Seiten2018 January HSB Pressure PointszaheerNoch keine Bewertungen

- Pressure Vessel RT TestDokument3 SeitenPressure Vessel RT TestAriq FauzanNoch keine Bewertungen

- Sample Design Calculation - Vessel Supported On LugsDokument11 SeitenSample Design Calculation - Vessel Supported On Lugsandry4jc100% (1)

- News Letter For Expansion Bellow PDFDokument4 SeitenNews Letter For Expansion Bellow PDFAsma Khan100% (1)

- Jun 97Dokument349 SeitenJun 97homer hullezaNoch keine Bewertungen

- VERIFICATIONDokument3 SeitenVERIFICATIONshaishavNoch keine Bewertungen

- Mechanical Engineer-Syed Zain AliDokument5 SeitenMechanical Engineer-Syed Zain AliSyedZainAliNoch keine Bewertungen

- Heat ExchangerDokument36 SeitenHeat ExchangerUsman MansuriNoch keine Bewertungen

- Jacketed PipingDokument4 SeitenJacketed Pipingbinukumar100100% (1)

- 03 Metal Packing Support PlatesDokument3 Seiten03 Metal Packing Support PlatesypatelsNoch keine Bewertungen

- Toaz - Info Lifting Lug Calculation On Dish End PRDokument156 SeitenToaz - Info Lifting Lug Calculation On Dish End PRandry4jcNoch keine Bewertungen

- Post Weld Heat Treatment Procedure: Doc No: STS/QAC/SOP/12Dokument18 SeitenPost Weld Heat Treatment Procedure: Doc No: STS/QAC/SOP/12mohd as shahiddin jafriNoch keine Bewertungen

- Diaphragm Elimination Using Taper-Lok - NPRADokument11 SeitenDiaphragm Elimination Using Taper-Lok - NPRAN. S. PanditNoch keine Bewertungen

- WRC 107 WRC 297 Co MP PDFDokument11 SeitenWRC 107 WRC 297 Co MP PDFIqbal Muhammad100% (1)

- Stiffening Ring Design On PV Elite For External Pressure Acting On Thin Walled Cylindrical Mounded VesselDokument4 SeitenStiffening Ring Design On PV Elite For External Pressure Acting On Thin Walled Cylindrical Mounded VesselEstuardo Javier Gan RodríguezNoch keine Bewertungen

- Nozzle PDFDokument8 SeitenNozzle PDFtavo1293Noch keine Bewertungen

- Paulin Research Group - FE107 Experimental ValidationDokument5 SeitenPaulin Research Group - FE107 Experimental ValidationNikunj KNoch keine Bewertungen

- 16 Preiss Study en 13445 Asme ViiiDokument26 Seiten16 Preiss Study en 13445 Asme ViiiDubaiHMARNoch keine Bewertungen

- PV Newsletter - Skirt Connections PDFDokument5 SeitenPV Newsletter - Skirt Connections PDFDivyesh PatelNoch keine Bewertungen

- TEMA Standards Inquiries 2020Dokument24 SeitenTEMA Standards Inquiries 2020Nisarg Patel100% (1)

- Needle ValveDokument8 SeitenNeedle ValveMuhammad Chilmi100% (1)

- Method - Statement - Damaged Paint Repair RahulDokument11 SeitenMethod - Statement - Damaged Paint Repair RahulrimshadtpNoch keine Bewertungen

- CSP-12 - Rev.4 PDFDokument34 SeitenCSP-12 - Rev.4 PDFfilzah yusopNoch keine Bewertungen

- TS MJI 11 v1-1 ReleaseDokument5 SeitenTS MJI 11 v1-1 ReleaseMicky PlumbNoch keine Bewertungen

- Ra Operating and Testing Weber Hydraulic EquipmentDokument4 SeitenRa Operating and Testing Weber Hydraulic EquipmentMicky PlumbNoch keine Bewertungen

- TS MJI 10 v7-1 ReleaseDokument5 SeitenTS MJI 10 v7-1 ReleaseMicky PlumbNoch keine Bewertungen

- 1.read This First Read This First Read This FirstDokument2 Seiten1.read This First Read This First Read This FirstMicky PlumbNoch keine Bewertungen

- Air Navigation Act, B.E. 2497Dokument88 SeitenAir Navigation Act, B.E. 2497Micky PlumbNoch keine Bewertungen

- 7 Simple Risk Assessment Form-V1Dokument3 Seiten7 Simple Risk Assessment Form-V1Micky PlumbNoch keine Bewertungen

- FAC-51 Trademark - PNGDokument1 SeiteFAC-51 Trademark - PNGMicky PlumbNoch keine Bewertungen

- Unit 11 Acid StimulationDokument16 SeitenUnit 11 Acid StimulationMicky PlumbNoch keine Bewertungen

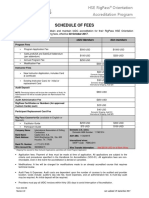

- SCO-06 FeeSched Rev22Dokument1 SeiteSCO-06 FeeSched Rev22Micky PlumbNoch keine Bewertungen

- Strength of Materials PDFDokument35 SeitenStrength of Materials PDFromeo08100% (1)

- OEUP-InT1000-SOP-OPS-0031 PE Flange Assembly Bolt and Nut TighteningDokument16 SeitenOEUP-InT1000-SOP-OPS-0031 PE Flange Assembly Bolt and Nut TighteningHasan Sevim100% (2)

- Nucor Fastener Finished Hex Nuts Are All Formed On PreciDokument2 SeitenNucor Fastener Finished Hex Nuts Are All Formed On PreciJuan DomeNoch keine Bewertungen

- Del OI ERHARD Nozzle Check Valve DN80 600 enDokument18 SeitenDel OI ERHARD Nozzle Check Valve DN80 600 enpppppp5Noch keine Bewertungen

- Flange Hydraulic Torque Tightening Procedure PDFDokument18 SeitenFlange Hydraulic Torque Tightening Procedure PDFInzi100% (2)

- CERTEX Wire Rope Terminations LRDokument26 SeitenCERTEX Wire Rope Terminations LRAlberto CárdenasNoch keine Bewertungen

- 0630SRM794 1482607 (05 2000) en PDFDokument26 Seiten0630SRM794 1482607 (05 2000) en PDFFernando CidreNoch keine Bewertungen

- Screw Threadlec12 MergedDokument90 SeitenScrew Threadlec12 MergedJames EstradaNoch keine Bewertungen

- TMC 331 PDFDokument175 SeitenTMC 331 PDFabhi aroteNoch keine Bewertungen

- Whirlpool 7mwt9601ww0 Manual de UsuarioDokument12 SeitenWhirlpool 7mwt9601ww0 Manual de UsuarioMARTIN CABRERANoch keine Bewertungen

- Land Rover Freelander 2006 - 2010 (Ingles)Dokument3.208 SeitenLand Rover Freelander 2006 - 2010 (Ingles)Guillermo Granados100% (3)

- HINO động cơ J05E-TB (Tiếng Anh) PDFDokument294 SeitenHINO động cơ J05E-TB (Tiếng Anh) PDFBình Âu100% (4)

- Anchorage To ConcreteDokument6 SeitenAnchorage To ConcreteLam TranNoch keine Bewertungen

- Catalog - Jinan Rainbow Metalwork Co .,LTD 1Dokument21 SeitenCatalog - Jinan Rainbow Metalwork Co .,LTD 1Alexander MattosNoch keine Bewertungen

- FileDokument20 SeitenFileAaron Mulenga100% (3)

- Gestra Pa46 Mpa46 Pa47 Mpa47 Installation..Dokument32 SeitenGestra Pa46 Mpa46 Pa47 Mpa47 Installation..cadhoaNoch keine Bewertungen

- Calibracion Actuador Valvula Variable c11Dokument5 SeitenCalibracion Actuador Valvula Variable c11Jordan RaveloNoch keine Bewertungen

- STC-EOS Samurai Transfer Case Cradle InstallationsDokument25 SeitenSTC-EOS Samurai Transfer Case Cradle Installationsfm.gruianuNoch keine Bewertungen

- Fichas Tecnicas PDFDokument56 SeitenFichas Tecnicas PDFAlexander Alvarez VegaNoch keine Bewertungen

- 1KR FE+Service+ManualDokument2.784 Seiten1KR FE+Service+ManualCajas Automaticas David100% (5)

- Rules of ASIA-BRICOM-2019 PDFDokument23 SeitenRules of ASIA-BRICOM-2019 PDFHusnik Maulidya Tungga DewiNoch keine Bewertungen

- Shop Manual: 4D98E 4D106 S4D106Dokument204 SeitenShop Manual: 4D98E 4D106 S4D106Julio Alvarado Morales100% (1)

- Min-Max HoseDokument193 SeitenMin-Max HoseAsisten WorkshopNoch keine Bewertungen

- Madass Parts ManualDokument59 SeitenMadass Parts ManualDario Gabriel Coz RojasNoch keine Bewertungen

- Intellian v240C Installation and Operation ManualDokument177 SeitenIntellian v240C Installation and Operation ManualpetrusltNoch keine Bewertungen

- Toyota Forklift 6FG - 6FD10-30 Service Repair ManualDokument41 SeitenToyota Forklift 6FG - 6FD10-30 Service Repair ManualRolandas Petkus75% (4)

- Load Plus Fitment InstructionsDokument2 SeitenLoad Plus Fitment InstructionsmarkyzrazakzNoch keine Bewertungen

- Automobile Wheel Attachment Design Considerations: Jon D. ParisenDokument10 SeitenAutomobile Wheel Attachment Design Considerations: Jon D. Parisenhassan eijy100% (1)

- 2 WaydistributorDokument53 Seiten2 WaydistributormbhaditNoch keine Bewertungen

- Ariel Corporation - Arielcorp - Com11Dokument1 SeiteAriel Corporation - Arielcorp - Com11Anwar SadatNoch keine Bewertungen