Beruflich Dokumente

Kultur Dokumente

样本 - 土压平衡式盾构机 (英文)

Hochgeladen von

walk111Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

样本 - 土压平衡式盾构机 (英文)

Hochgeladen von

walk111Copyright:

Verfügbare Formate

A Wide Range of Applications,

Earth Pressure

Balanced Shields from Soft to Water-Bearing Degraded

Gravel Strata

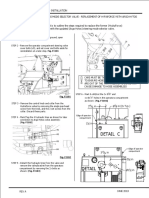

Earth pressure balanced shield Features Automatic tunnel face support system Control chart

The earth pressure balanced shield excavates the strata Applicable to various strata, from soft soil to gravel, because This system automatically adjusts

with cutter bits, injects the additive into excavated soil, the excavated soil can be changed to muddy soil with high the discharge of excavated soil TJ discharge Shield advance

TJ volume speed Excavated soil

and forcibly kneads it with the kneading blades at the plastic fluidity and impermeability. according to the advance of shield manual control volume

TJ Thrust

Tunnel face can be sustained by muddy soil pressure to machine, no more, no less. This V1

rear of cutter head to improve its plastic fluidity and hyd. pump jack

minimize ground settlement. helps maintain the tunnel face at V

impermeability. The resulting muddy soil is fully filled in Stockpiled Soil pressure

the cutter chamber and the screw conveyor. Using the Ground water can be cut off with the impermeable layer rest. In short, to properly balance soil volume in chamber

formed by muddy soil in the cutter chamber and screw the volume of excavated soil and TJ

thrust jacks increases the pressure of the excavated soil stroke/speed

conveyor. that of discharged soil detector

P

in the cutter chamber to counterbalance the tunnel face Appropriate backgrouting control can be achieved, because (i.e., rotational speed of the screw

earth pressure at rest plus groundwater pressure. When the muddy soil is filled in the chamber and at the periphery of conveyor ), the discharging rate of SC SC SC

hyd. pump V2

the shield advances, the discharge of excavated soil is the shield to shut out the backgrouting agent. excavated soil is adjusted controller

hyd. pump hyd. motor

Soil discharge

controlled with the soil pressure detector at the No full-scale muck treatment facility is required, because automatically with soil pressure SC N volume

delivery volume

bulkhead. Thus the advance of the shield and the muck can be discharged by belt conveyor and muck car, or changes in the cutter chamber.

Rotational

discharge of the excavated soil are kept in balance discharging pump to the surface of ground, and is carried out This always keeps the soil pressure speed

detector

during tunneling operation. by dump trucks to a disposal yard after solidification. in the cutter chamber at the desired N Soil pressure

level. Face support V

detector

Manual/auto control

Kneading selector computer

Cutter chamber blade Articulated steering jack Segment aligning device Manual/auto

select signal P

SC manual control

Shield machine and ground TJ: Trust jack

Screw conveyor SC: Screw conveyor

Control system

Mud-making agent

injection port

System explanation

The shied system comprises the shield, additive injection

device, additive production plant, and other facilities.

Central kneading In the tunnel are the shield power unit car,

device power transformer car, segment carriage, muck car, etc.

On the ground are the additive production plant, Monorail crane

backgrouting agent plant, soil hopper, portal crane, electric

power facility, etc.

Additive plant Portal crane

Backgrouting agent plant

Cutter head Thrust jack Erector Soil hopper

Electric power

facility

8.96 m dia. earth pressure balanced shield

Application Subway

Strata Sand, clay, gravel

Overburden 22 m

Overhead crane

Excavation distance 502 m

Radius of curvature 125 m

Description Double-track subway section excavation Shield Operation Unit Control Transformer Muck pit

Articulated steering device machine car car car car

Segment Muck Muck Battery- Cable

carriage car car powered car

locomotive

Earth Pressure Balanced

Shields/Slurry Shields Remarkable Achievements

Typical Earth Pressure Balanced Shields Typical Slurry Shields

7.75 m dia. earth pressure balanced shield 14.14 m dia. slurry shield

Application Sewerage Application Trans-Tokyo Bay Highway (Sea bottom tunnel)

Strata Clayey gravel (up to 600 mm diameter) Strata Clay, sand

Overburden 22.249 m Overburden 19.3 m (water depth 31.071 m)

Excavation distance 1 950 m Excavation distance 1 742 m

Radius of curvature 30 m Radius of curvature Straight

Description Articulated steering device (articulated angle 7 ) Description Long-distance excavation

Spherical joint secondary and third screws High water pressure (sea bottom excavation)

Underground docking using ground freeze

method

7.15 m dia. earth pressure balanced shield 9.60 m dia. slurry shield

Application Subway Application Subway

Strata Silty clay, gravel Strata Clay, sand

Overburden 17.7 m Overburden 22.84 m

Excavation distance 682 m Excavation distance 1 653 m

Radius of curvature 500 m Radius of curvature 850 m

Description Foam shielding using secondary Description Double-track subway section excavation

and third screws Long-distance excavation

Wear detection bits

Collapse detection device

5.54 m dia. earth pressure balanced shield 8.25 m dia. slurry shield

Application Subway Application Subway

Strata Gravel, sand, clay Strata Diluvial sand

Overburden 34.18 m Overburden 25 m

Excavation distance 1 017 m Excavation distance 875 m

Radius of curvature 132.25 m Radius of curvature 600 m

Description Roller bits Description Single-track subway section excavation

Automatic direction control (crossing under river and subway)

Cutter head with earth pressure sensor

at the end of copy cutter

Das könnte Ihnen auch gefallen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- 意大利casappa(凯斯帕)股份公司 Strada 定量斜轴式柱塞泵选型样本Dokument4 Seiten意大利casappa(凯斯帕)股份公司 Strada 定量斜轴式柱塞泵选型样本walk111Noch keine Bewertungen

- Sectional ValvesDokument107 SeitenSectional Valveswalk111Noch keine Bewertungen

- Hydraulic Remote ControlsDokument64 SeitenHydraulic Remote Controlswalk111Noch keine Bewertungen

- Selector ValvesDokument23 SeitenSelector Valveswalk111Noch keine Bewertungen

- WackerNeuson 850Dokument2 SeitenWackerNeuson 850walk111Noch keine Bewertungen

- Fi 01 TestDokument1 SeiteFi 01 Testwalk111Noch keine Bewertungen

- Fi 01 DraftDokument4 SeitenFi 01 Draftwalk111Noch keine Bewertungen

- Replacing Hyraforce With Argo-Hytos: Removal and Installation ProcedureDokument4 SeitenReplacing Hyraforce With Argo-Hytos: Removal and Installation Procedurewalk111Noch keine Bewertungen

- Jeffrey Half-Door Protection System Installation GuideDokument3 SeitenJeffrey Half-Door Protection System Installation Guidewalk111Noch keine Bewertungen

- 7088 10507 1 SM PDFDokument6 Seiten7088 10507 1 SM PDFwalk111Noch keine Bewertungen

- Half-Door Kit Installation Cover Pages PDFDokument1 SeiteHalf-Door Kit Installation Cover Pages PDFwalk111Noch keine Bewertungen

- Volvo EC330Cl Excavator SpecsDokument12 SeitenVolvo EC330Cl Excavator Specswalk111Noch keine Bewertungen

- 695SR 26061062GBDokument16 Seiten695SR 26061062GBwalk111Noch keine Bewertungen

- ADAMS/View Tools, Menus, and ShortcutsDokument14 SeitenADAMS/View Tools, Menus, and Shortcutswalk111Noch keine Bewertungen

- 移动式破碎机S ZR450JC规格说明书 PDFDokument1 Seite移动式破碎机S ZR450JC规格说明书 PDFwalk111Noch keine Bewertungen

- 移动式破碎机S ZR450JC规格说明书Dokument1 Seite移动式破碎机S ZR450JC规格说明书walk111Noch keine Bewertungen

- A 66Dokument2 SeitenA 66walk111Noch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- MacGregor Crane-1 2 GLB2526-3Dokument532 SeitenMacGregor Crane-1 2 GLB2526-3RusHostel TVNoch keine Bewertungen

- Separator OSD 6-18-35 60 enDokument2 SeitenSeparator OSD 6-18-35 60 enapityan85Noch keine Bewertungen

- 6000 Eco 1234 - GBDokument2 Seiten6000 Eco 1234 - GBDragan SimovicNoch keine Bewertungen

- (Hydraulic & Pneumatic) Quiz #1Dokument2 Seiten(Hydraulic & Pneumatic) Quiz #1mellon3duwen100% (1)

- Stratoflex ACSUpdated EligibilityDokument42 SeitenStratoflex ACSUpdated EligibilityAdventures AviationNoch keine Bewertungen

- Workshop Manual Common RailDokument43 SeitenWorkshop Manual Common RailAnderson London90% (10)

- Ikpjt (V: Tl-Fati-Ra-FDokument23 SeitenIkpjt (V: Tl-Fati-Ra-FSanthan NaniNoch keine Bewertungen

- LV 2000LowVolumeDokument2 SeitenLV 2000LowVolumeDian MiauNoch keine Bewertungen

- Camion Bomba HalliburtonDokument2 SeitenCamion Bomba Halliburtonfernando6897100% (3)

- Lampiran D.3 Data Spesifikasi Teknis PompaDokument21 SeitenLampiran D.3 Data Spesifikasi Teknis PompaEddy ArryNoch keine Bewertungen

- Basic Service Training: Cooling Circuit R600a and R134aDokument64 SeitenBasic Service Training: Cooling Circuit R600a and R134aKyaw San OoNoch keine Bewertungen

- TP1028ENDokument21 SeitenTP1028ENramkeshmit_413125668Noch keine Bewertungen

- Thermax Double Effect Steam Fired Vam BrochureDokument24 SeitenThermax Double Effect Steam Fired Vam BrochureMinhazur Rahman Sakib100% (1)

- Adobe Scan May 09, 2023Dokument8 SeitenAdobe Scan May 09, 2023krushna DeshmukhNoch keine Bewertungen

- Heating Controller RVL470 and RVL469 Basic Documentation enDokument84 SeitenHeating Controller RVL470 and RVL469 Basic Documentation ene-genieclimatique.comNoch keine Bewertungen

- Incline Haulage TrucksDokument2 SeitenIncline Haulage Trucksgarves007Noch keine Bewertungen

- Recommended Practice - Davey PumpDokument32 SeitenRecommended Practice - Davey PumpAlghazee Abo-jlalNoch keine Bewertungen

- GB Instruction for use POWERTEX Hydraulic Toe Jack PTJ-S1 GuidelineDokument9 SeitenGB Instruction for use POWERTEX Hydraulic Toe Jack PTJ-S1 GuidelineSanthoshNoch keine Bewertungen

- Marine Motors Three Phase Squirrel Cage Induction Motors: MarellimotoriDokument8 SeitenMarine Motors Three Phase Squirrel Cage Induction Motors: MarellimotorimigblagonNoch keine Bewertungen

- FP HDDokument10 SeitenFP HDcesarNoch keine Bewertungen

- Twin Shaft Mixer Instruction ManualDokument87 SeitenTwin Shaft Mixer Instruction ManualSotiris Andronis100% (2)

- Installation and Operation of Jockey Pump ControllersDokument14 SeitenInstallation and Operation of Jockey Pump Controllersjulchab100% (1)

- TSC Mud Pump and Spare PartsDokument5 SeitenTSC Mud Pump and Spare PartsAlice Mi50% (2)

- Part1 Q A Marine EngineerDokument7 SeitenPart1 Q A Marine EngineerSamir Alshaar100% (1)

- Experiment 5 Series and Parallel PumpDokument20 SeitenExperiment 5 Series and Parallel Pumpgongweejie9333% (3)

- Water Ace PumpDokument20 SeitenWater Ace PumpDana Milner100% (1)

- Oral Candy Meo Class 4Dokument32 SeitenOral Candy Meo Class 4deepanck0% (2)

- Cat 3306 Ta - Spec PDFDokument12 SeitenCat 3306 Ta - Spec PDFAdrian Cojocaru100% (1)

- HK Govt building air conditioning testing guideDokument223 SeitenHK Govt building air conditioning testing guideEMSTFHKEH EMSTFNoch keine Bewertungen