Beruflich Dokumente

Kultur Dokumente

Attachment PDF

Hochgeladen von

Mahdi0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

9 Ansichten6 SeitenOriginaltitel

attachment.pdf

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

9 Ansichten6 SeitenAttachment PDF

Hochgeladen von

MahdiCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 6

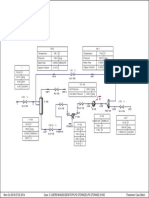

NGL Fractionation

Workshop

Recovery of natural-gas liquids (NGL) from natural gas is quite common

in natural gas processing. Recovery is usually done to:

- Produce transportable gas (free from heavier hydrocarbons which

may condense in the pipeline).

Meet a sales gas specification.

Maximize liquid recovery (when liquid products are more valuable

than gas).

Aspen HYSYS can model a wide range of different colunm configurations.

In this simulation, an NGL Plant will be constructed, consisting of three

columns:

+ De-Methanizer (operated and modeled as a Reboiled Absorber column)

+ De-Ethanizer (Distillation column)

+ De-Propanizer (Distillation colunm)

Learning Objectives

Once you have completed this section, you will be able to:

+ Add columns using the Input Experts.

+ Add extra specifications to columns.

NGL Fractionation Train

It's required to process a crude natural gas to remove the heavier hydrocarbons from it

tims the composition of it would be suitable for transportation by passing the crude gas

which comes from two different wells to three towers: De-Methanizer, De-Ethanizer

and De-Propanizer.

The first well at (-140 oF, 330 psia and flow sate of 3575 Ibmol/hr) have the following

conditions and compositions: (Fluid Package: Peng Robinson)

MN 0.0025 n-C4 0.0085

CO2z 0.0048 CS 0.0036

c 0.7041 C5 0.002

C2 0.1921 n-C6 0.0003

cs 0.0706 n-C7 0.0002

ics 2 C8 0.0001

The second one at (-120 °F, 332 psia and flow rate of 475 Ibmol/hr) have the following

conditions and composition

0.0057 n-C4 0.0197

0.0029 CS 0.0147

0.7227 a C5 0.0102

0.1176 mC6 0.0037

0.075 a C7 0.0047

i-c4 0.0204 _n-C8 0.0027

There's also an energy supplied to the De-Methanizer of (2e6 BTU/hs) which is used to

improve the efficiency of the separation.

‘The De-Methanizer (reboiled absorber) has the following specifications:

- Feed 1 Material Stream enters the column from the top stage inlet

~ Feed 2 Material stream enters from the 2nd stage

- Ex-duty Energy Stream enters from the 4th stage

- Number of stages = 10

- Top Stage pressure = 330 psia & Reboiler pressure = 335 psia

- Top Stage temperature = -125°F & Reboiler temperature = 80 °F

- Ovhd Prod Rate = 2950 lbmole/hr (1338 Kg/hr)

After running the column with the above specifications, the design is

then modified to ensure that the overhead molar fraction of the

methane is 0.96

Most of methane is removed from the top of the tower and the bottom

stream is pumped to 2790 kpa then it enters to the De-Ethanizer (distillation

Column) where most of the ethane in the crude is taken as an overhead

product then it is processed to use in different applications.

‘The de-ethanizer has the following specifications:

Connections

Name Dc2

No. of Stages 14

Inlet Stream/Stage DC2 Feedi6

Condenser Type Partial

Overhead Vapour Product DC2 Ovhd

Overhead Liquid Product C2 Dist

Bottoms Liquid Outlet DC2 Bim

Reboiler Duty Energy Stream DC2 Red Q

Condenser Duty Energy Stream DC2 Cond Q

Pressures

Condenser

2725 kPa (395 psia)

Condenser Delta P

35 kPa (5 psi)

Reboiler 2792 kPa (405 psia)

Temperature Estimates

Condenser -4°C (25°F)

Reboiler 95°C (200°F)

Specifications

Overhead Vapour Rate 320 kgmole/h (700 Ibmole/hr)

Distillate Rate 0 kgmole/h

Reflux Ratio 2.5 (Molar)

After running the column with the above specifications, the design is

modified to ensure that the bottom stream has ratio between C2/Cs =

0.01

Then the bottom product is sent to a valve where the pressure of it decrease

to 1690 kpa, the outlet flow from the valve is sent to a de-propanizer

(distillation Column) where most of propane is removed from the top and

the heavier hydrocarbons is removed from the bottom

The specifications of the de-propanizer are:

Connections

Name Dc3

No. of Stages 24

Inlet Streams/Stage DC3 Feed/11

Condenser Type Total

Ovhd Liquid Outlet DC3 Dist

Bottom Liquid Outlet DC3 Btm

Reboiler Duty Energy Stream DC3 RebQ

Condenser Duty Energy Stream DC3 Cond Q

Pressures

Condenser 1585 kPa (230 psia)

Condenser Delta P 35 kPa (5 psi)

Reboiler 1655 kPa (240 psia)

Temperature Estimates

Condenser 38°C (100°F)

Reboiler 120°C (250°F)

Specifications

Liquid Rate 110 kgmole/h (240 Ibmole/hr)

Reflux Ratio 1.0 Molar

After running the column with the above specifications, the design iy

modified to ensure that the overhead molar fraction of the i-C4 & n-

C4 -0.15 AND propane bottom product molar fraction = 0.02

‘De-Methanizer Specs:

~ Feed 1 Material Stream enters the column from the top stage inlet

~ Feed 2 Material stream enters from the 2nd stage

~ Ex.duty Energy Stream enters from the 4th stage

= Number of stages = 10

- Top Stage pressure = 330 psia

- Reboiler pressure = 335 psia

- Top Stage temperature = -125°F

- Reboiler temperature = 80 F

- Ovid Prod Rate = 2950 Ibmole/hr (1338 Kg/hr)

- C1 fraction in the Ovhd stream = 0.96

Das könnte Ihnen auch gefallen

- Plate Fine Exchanger AirDokument20 SeitenPlate Fine Exchanger AirMahdiNoch keine Bewertungen

- Methyl Die Than Ola MineDokument4 SeitenMethyl Die Than Ola MineMahdiNoch keine Bewertungen

- Tuning Surface Wettability of Poly (3-Sulfopropyl Methacrylate) Brushes by Cationic Surfactant-Driven InteractionsDokument5 SeitenTuning Surface Wettability of Poly (3-Sulfopropyl Methacrylate) Brushes by Cationic Surfactant-Driven InteractionsMahdiNoch keine Bewertungen

- Ultrathin Solid Polyelectrolyte-Surfactant ComplexDokument6 SeitenUltrathin Solid Polyelectrolyte-Surfactant ComplexMahdiNoch keine Bewertungen

- Final - LNG PDFDokument19 SeitenFinal - LNG PDFMahdiNoch keine Bewertungen

- Polyelectrolyte Adsorption Onto A Surface-Confined SurfactantDokument6 SeitenPolyelectrolyte Adsorption Onto A Surface-Confined SurfactantMahdiNoch keine Bewertungen

- Pipesim Training: 25 - Oct-04 To 29-Jul-04 GatwickDokument9 SeitenPipesim Training: 25 - Oct-04 To 29-Jul-04 GatwickMahdiNoch keine Bewertungen

- Natural Gas Sweetening Process DesignDokument13 SeitenNatural Gas Sweetening Process DesignJeyakumar Raja100% (1)

- Final - LNG PDFDokument19 SeitenFinal - LNG PDFMahdiNoch keine Bewertungen

- GOOD-10 1021@jp047462+Dokument10 SeitenGOOD-10 1021@jp047462+MahdiNoch keine Bewertungen

- Polyelectrolyte Adsorption Onto A Surface-Confined SurfactantDokument6 SeitenPolyelectrolyte Adsorption Onto A Surface-Confined SurfactantMahdiNoch keine Bewertungen

- Ultrathin Solid Polyelectrolyte-Surfactant ComplexDokument6 SeitenUltrathin Solid Polyelectrolyte-Surfactant ComplexMahdiNoch keine Bewertungen

- New Dembo2001Dokument6 SeitenNew Dembo2001MahdiNoch keine Bewertungen

- GOOD-10 1021@jp047462+Dokument10 SeitenGOOD-10 1021@jp047462+MahdiNoch keine Bewertungen

- Moradi 2016Dokument21 SeitenMoradi 2016MahdiNoch keine Bewertungen

- Fine-Tuning The Wetting Behavior of Polyelectrolyte Films With Sodium Dodecyl SulfateDokument4 SeitenFine-Tuning The Wetting Behavior of Polyelectrolyte Films With Sodium Dodecyl SulfateMahdiNoch keine Bewertungen

- Moradi 2016Dokument21 SeitenMoradi 2016MahdiNoch keine Bewertungen

- Fine-Tuning The Wetting Behavior of Polyelectrolyte Films With Sodium Dodecyl SulfateDokument4 SeitenFine-Tuning The Wetting Behavior of Polyelectrolyte Films With Sodium Dodecyl SulfateMahdiNoch keine Bewertungen

- Aspen HYSYS Training: Module 5: UtilitiesDokument8 SeitenAspen HYSYS Training: Module 5: UtilitiestaeebNoch keine Bewertungen

- Aspen HYSYS Training: Module 4: Logical OperationsDokument50 SeitenAspen HYSYS Training: Module 4: Logical OperationsMohamed RjebNoch keine Bewertungen

- Results E 2003 PDFDokument5 SeitenResults E 2003 PDFMahdiNoch keine Bewertungen

- Finalexercise Methanolprocess 150227020443 Conversion Gate01 PDFDokument6 SeitenFinalexercise Methanolprocess 150227020443 Conversion Gate01 PDFharryNoch keine Bewertungen

- Gas Measurement Requirements and Procedures ID 6849 ID 10250 ID 10703Dokument53 SeitenGas Measurement Requirements and Procedures ID 6849 ID 10250 ID 10703triminhdang_phar6701Noch keine Bewertungen

- 4 141019143230 Conversion Gate02Dokument1 Seite4 141019143230 Conversion Gate02MahdiNoch keine Bewertungen

- ExchangerDokument55 SeitenExchangerMahdiNoch keine Bewertungen

- Fundamental Principles of Diaphragm MetersDokument4 SeitenFundamental Principles of Diaphragm MetersMahdiNoch keine Bewertungen

- 10 1016/j Cjche 2017 01 014Dokument40 Seiten10 1016/j Cjche 2017 01 014MahdiNoch keine Bewertungen

- Physicochemical Properties Important For Carbon Dioxide Absorption in Aqueous MethyldiethanolamineDokument7 SeitenPhysicochemical Properties Important For Carbon Dioxide Absorption in Aqueous MethyldiethanolamineMahdiNoch keine Bewertungen

- Statistical Modelling of Error Measurement For Diaphragm Gas Meters at Different Ambient TemperaturesDokument4 SeitenStatistical Modelling of Error Measurement For Diaphragm Gas Meters at Different Ambient TemperaturesMahdiNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)