Beruflich Dokumente

Kultur Dokumente

Columbus Castings Metal Grades PDF

Hochgeladen von

ksangeeth2000Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Columbus Castings Metal Grades PDF

Hochgeladen von

ksangeeth2000Copyright:

Verfügbare Formate

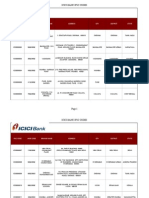

Common Industry Standards & Columbus Castings Metal Grade Mechanical Properties

Columbus

Tensile Reduction of

Industry Standard Castings Metal Yield Strength Elongation

Strength Area

Grade

ASTM A27 Gr. N2 B *

ASTM A216 Gr. WCA BM 60 30 24 35 **

ASTM A27 Gr. 65-35 B 65 35 24 35

ASTM A27 Gr. 70-36 B 70 36 22 30

ASTM A216 Gr. WCB B85M 70 36 22 35 **

AAR M201 Gr. B B 70 38 24 36

ASTM A27 Gr. 70-40 B85M 70 40 22 30

ASTM A216 Gr. WCC B85M, C1M 70 40 22 35 **

ASTM A148 Gr. 80-40 B85 80 40 18 30

ASTM A148 Gr. 80-50 C1 80 50 22 35

ASTM A487 Gr. 2N C1M/04 85 53 22 35 **

ASTM A148 Gr. 90-60 C1, CE 90 60 20 40

AAR M201 Gr. C C1 90 60 22 45

ASTM A487 Gr. 2Q CEM 90 65 22 40 **

ASTM A148 Gr. 105-85 CE 105 85 17 35

AAR M201 Gr. E CE 120 100 14 28

ASTM A148 Gr. 130-115 CE1, ME, B29 130 115 11 25

ASTM A148 Gr. 135-125 ME, B29 135 125 9 22

ASTM A148 Gr. 150-135 B29 150 135 7 18

HS160 B29M 160 140 6 16

HS170 B29M 170 150 6 15

HS180 B29M 180 155 6 14

* No mechanical property requirements

** Maximum specification on Tensile and Yield Strength.

Columbus Castings Metal Grade Chemical Properties

Columbus

Castings Metal C Mn P S Si Ni Cr Mo

Grade

B 0.22 - 0.28 0.55 - 0.75 0.020 0.012 0.30 - 0.50 0.20 0.20 0.15

B11 0.28 - 0.32 0.70 - 0.85 0.012 0.012 0.25 - 0.55 0.50 0.15 - 0.35 0.15

B85 0.28 - 0.32 0.75 - 0.85 0.012 0.012 0.35 - 0.60 0.50 0.30 - 0.40 0.06 - 0.08

NICKEL 0.17 - 0.25 0.55 - 0.85 0.020 0.012 0.30 - 0.60 2.00 - 3.00 0.15 0.15

C1 0.24 - 0.32 1.20 - 1.60 0.020 0.025 0.30 - 0.60 0.20 0.20 0.10 - 0.30

CE 0.24 - 0.30 1.30 - 1.50 0.020 0.025 0.30 - 0.50 0.20 0.15 - 0.40 0.15 - 0.30

CE1 0.22 - 0.32 1.45 - 1.55 0.012 0.015 0.30 - 0.60 0.50 0.20 - 0.30 0.25 - 0.35

ME 0.20 - 0.25 0.90 - 1.20 0.020 0.015 0.30 - 0.60 1.20 - 1.40 0.50 - 0.70 0.35 - 0.45

B29 0.16 - 0.24 0.90 - 1.20 0.015 0.015 0.40 - 0.55 1.60 - 1.90 1.00 - 1.20 0.30 - 0.50

Das könnte Ihnen auch gefallen

- Columbus Castings Metal Grades & Industry Standards Mechanical Properties ChartDokument1 SeiteColumbus Castings Metal Grades & Industry Standards Mechanical Properties Charteduardox11Noch keine Bewertungen

- Cast Steel Grades ChartDokument2 SeitenCast Steel Grades ChartMajdi JerbiNoch keine Bewertungen

- Alloys 2016Dokument1 SeiteAlloys 2016Dany ArriantoNoch keine Bewertungen

- Chemical Composition of ASTM ASME SA516 Grade 60 70 Steel PlateDokument2 SeitenChemical Composition of ASTM ASME SA516 Grade 60 70 Steel PlateVarun MalhotraNoch keine Bewertungen

- ASME SA516 Grade 60 70 Steel Plate Properties GuideDokument2 SeitenASME SA516 Grade 60 70 Steel Plate Properties GuideIbadurrahman KahfiNoch keine Bewertungen

- ASTM Steel PipeDokument3 SeitenASTM Steel Pipehilwa6_731153219Noch keine Bewertungen

- Astm SpecificationDokument9 SeitenAstm SpecificationHARSHANoch keine Bewertungen

- Plate Asme Sa516 Grade 70Dokument10 SeitenPlate Asme Sa516 Grade 70Deaz AmbrsNoch keine Bewertungen

- Casting Material CA15BASD PDFDokument4 SeitenCasting Material CA15BASD PDFAditya GuptaNoch keine Bewertungen

- Sunny Steel Enterprise LTD.: Collect Steel Pipe and Fitting ResourcesDokument6 SeitenSunny Steel Enterprise LTD.: Collect Steel Pipe and Fitting ResourcessanjeettirkeyNoch keine Bewertungen

- Applicable Standards: ASTM A792 ASTM A792 EN10215Dokument14 SeitenApplicable Standards: ASTM A792 ASTM A792 EN10215ersinNoch keine Bewertungen

- Piping Code Comparison TableDokument52 SeitenPiping Code Comparison TableRobert SmallNoch keine Bewertungen

- Nature of Engineering Materials ReportDokument162 SeitenNature of Engineering Materials ReportDryx LetranNoch keine Bewertungen

- Mechanical Properties: Chemical CompositionDokument1 SeiteMechanical Properties: Chemical CompositionHERSON FARID BUENO PIÑEROSNoch keine Bewertungen

- Cast Carbon Steels in AWS D1.1 PDFDokument3 SeitenCast Carbon Steels in AWS D1.1 PDFIndra NainggolanNoch keine Bewertungen

- ASTM A517 Grade B: General Product DescriptionDokument2 SeitenASTM A517 Grade B: General Product DescriptionBruno SantosNoch keine Bewertungen

- Chemical DetailsDokument3 SeitenChemical Detailsemmas18Noch keine Bewertungen

- ZXDokument6 SeitenZXPedro SilvaNoch keine Bewertungen

- CastMaterials E00510Dokument6 SeitenCastMaterials E00510samir basuniNoch keine Bewertungen

- Caas JPGDokument5 SeitenCaas JPGsalmanshahidkhan226Noch keine Bewertungen

- Matmatch is trusted by 2 million+ engineers for aluminum alloy 6063 dataDokument4 SeitenMatmatch is trusted by 2 million+ engineers for aluminum alloy 6063 datahardeep SinghNoch keine Bewertungen

- ASTM A672 Grade CC 60 EFW Pipe SuppliersDokument4 SeitenASTM A672 Grade CC 60 EFW Pipe SuppliersRELIABLE PIPES & TUBESNoch keine Bewertungen

- Piping Class - EC11Dokument2 SeitenPiping Class - EC11Дмитрий РыбаковNoch keine Bewertungen

- Certificado de Calidad de Brida de Acero WN RF Clase 300 SCH 120Dokument1 SeiteCertificado de Calidad de Brida de Acero WN RF Clase 300 SCH 120Rodrigo Sarrin AsteteNoch keine Bewertungen

- Astm A36 Asme Sa36Dokument3 SeitenAstm A36 Asme Sa36Mohamed IsmailNoch keine Bewertungen

- ASTM A126 (China Suggested Chemical Composition)Dokument3 SeitenASTM A126 (China Suggested Chemical Composition)EduardoNoch keine Bewertungen

- Caas4 JPGDokument1 SeiteCaas4 JPGsalmanshahidkhan226Noch keine Bewertungen

- Common Abbreviations in The Valve IndustryDokument10 SeitenCommon Abbreviations in The Valve IndustryNath BoyapatiNoch keine Bewertungen

- Tabela Acos Carbono PDFDokument1 SeiteTabela Acos Carbono PDFRafael PaivaNoch keine Bewertungen

- Materials Guide for Over 50 AlloysDokument8 SeitenMaterials Guide for Over 50 AlloysMark RomeroNoch keine Bewertungen

- GB3077-1999 English VersionDokument20 SeitenGB3077-1999 English VersionHermanto SupuNoch keine Bewertungen

- A537 CL2Dokument1 SeiteA537 CL2AssemNoch keine Bewertungen

- Steel: Statistical Analysis of Steel FormabilityDokument12 SeitenSteel: Statistical Analysis of Steel FormabilitynadhabindhuNoch keine Bewertungen

- A 595 - 98 R02 Qtu5ns1sruqDokument5 SeitenA 595 - 98 R02 Qtu5ns1sruqLimberhtNoch keine Bewertungen

- Sunny Steel Enterprise LTD.: Collect Steel Pipe and Fitting ResourcesDokument6 SeitenSunny Steel Enterprise LTD.: Collect Steel Pipe and Fitting ResourcesPrad1979Noch keine Bewertungen

- American Society For Testing and Materials Specification: Astm - AMS - Aerospace MaterialDokument10 SeitenAmerican Society For Testing and Materials Specification: Astm - AMS - Aerospace MaterialjleonosNoch keine Bewertungen

- Ductile Iron Casting Specifications SummaryDokument15 SeitenDuctile Iron Casting Specifications SummarySiriusNoch keine Bewertungen

- Boron Steel CHQ CatalogueDokument1 SeiteBoron Steel CHQ CatalogueSundarNoch keine Bewertungen

- Minfm67089 Astm A1011 Ss Grade 250 Type 1Dokument4 SeitenMinfm67089 Astm A1011 Ss Grade 250 Type 1أبومحمدالزياتNoch keine Bewertungen

- SPECIAL STEELS PRODUCT CODE :: PKG/RO/41Dokument9 SeitenSPECIAL STEELS PRODUCT CODE :: PKG/RO/41Pranav TripathiNoch keine Bewertungen

- Home About Us Products Display News Contact ProductsDokument8 SeitenHome About Us Products Display News Contact ProductsBosz InNoch keine Bewertungen

- STEEL TYPES AND PROPERTIESDokument1 SeiteSTEEL TYPES AND PROPERTIESBeatriz Ruiz UrueñaNoch keine Bewertungen

- Certificado de Calidad Brida Anillo GhasDokument1 SeiteCertificado de Calidad Brida Anillo GhasJKarlos Barrientos ÑufloNoch keine Bewertungen

- Abreviaturas Comunes en La Industria ValvuleraDokument10 SeitenAbreviaturas Comunes en La Industria Valvulerataz_007Noch keine Bewertungen

- Piping Class - AC21Dokument2 SeitenPiping Class - AC21Дмитрий РыбаковNoch keine Bewertungen

- Steel Castings, Carbon, For General ApplicationDokument5 SeitenSteel Castings, Carbon, For General ApplicationMeethaq AbedNoch keine Bewertungen

- Piping Class - DC11Dokument2 SeitenPiping Class - DC11Дмитрий РыбаковNoch keine Bewertungen

- Caracteristicas API 2HGr50 PDFDokument3 SeitenCaracteristicas API 2HGr50 PDFFernandoBarreraDominguezNoch keine Bewertungen

- pdf_NCDokument4 Seitenpdf_NCRoby MastreNoch keine Bewertungen

- Weld Consumable SelectionDokument25 SeitenWeld Consumable SelectionNisarg PandyaNoch keine Bewertungen

- Chemical Composition of ASTM A516 Grade 70 / ASME SA516 Grade 70Dokument4 SeitenChemical Composition of ASTM A516 Grade 70 / ASME SA516 Grade 70Abdul WahabNoch keine Bewertungen

- Cpe Ansi Process Pumps E10431Dokument24 SeitenCpe Ansi Process Pumps E10431FRANCISCO BADILLONoch keine Bewertungen

- ACAHeatresistant PDFDokument1 SeiteACAHeatresistant PDFDarryl007Noch keine Bewertungen

- NINGBO DONGXIN HIGH-STRENGTH NUT CO.,LTD TEST CERTIFICATEDokument1 SeiteNINGBO DONGXIN HIGH-STRENGTH NUT CO.,LTD TEST CERTIFICATEGLORIA MONSALVE SALAZARNoch keine Bewertungen

- BECOSA Preslia GT 46 (9-23)Dokument4 SeitenBECOSA Preslia GT 46 (9-23)jose manuelNoch keine Bewertungen

- Materials Data for Cyclic Loading: Low-Alloy SteelsVon EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsBewertung: 5 von 5 Sternen5/5 (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- 0581 s12 QP 21Dokument12 Seiten0581 s12 QP 21abhayNoch keine Bewertungen

- 0580 s12 QP 11 PDFDokument12 Seiten0580 s12 QP 11 PDFRunWellNoch keine Bewertungen

- Mathematics: Paper 0580/11 Paper 11 (Core)Dokument66 SeitenMathematics: Paper 0580/11 Paper 11 (Core)ksangeeth2000Noch keine Bewertungen

- Tax Invoice V.Ships Offshore Tuff Offshore Services ProjectDokument5 SeitenTax Invoice V.Ships Offshore Tuff Offshore Services Projectksangeeth2000Noch keine Bewertungen

- Ifsc-Code of Icici Bank Branches in IndiaDokument10.725 SeitenIfsc-Code of Icici Bank Branches in IndiaVenkatachalam KolandhasamyNoch keine Bewertungen

- Batam Port InformationDokument1 SeiteBatam Port Informationksangeeth2000Noch keine Bewertungen

- Appendix-F-Squall Governing ResultsDokument5 SeitenAppendix-F-Squall Governing Resultsksangeeth2000Noch keine Bewertungen

- 0580 s12 Ms 11Dokument4 Seiten0580 s12 Ms 11Ganesh SNoch keine Bewertungen

- Banff FPSO DescriptionDokument111 SeitenBanff FPSO Descriptionksangeeth2000Noch keine Bewertungen

- Climate Batam - 2020Dokument6 SeitenClimate Batam - 2020ksangeeth2000Noch keine Bewertungen

- Sample Business PlanDokument28 SeitenSample Business Planksangeeth2000Noch keine Bewertungen

- H D F CDokument10 SeitenH D F Cksangeeth2000Noch keine Bewertungen

- ADMIRALTY TotalTide TableDokument1 SeiteADMIRALTY TotalTide Tableksangeeth2000Noch keine Bewertungen

- Appendix-E-Wave Governing ResultsDokument3 SeitenAppendix-E-Wave Governing Resultsksangeeth2000Noch keine Bewertungen

- Wave and Load Case ParametersDokument8 SeitenWave and Load Case Parametersksangeeth2000Noch keine Bewertungen

- Facts About Water Injection DredgingDokument4 SeitenFacts About Water Injection Dredgingksangeeth2000100% (1)

- My Best FriendDokument2 SeitenMy Best Friendksangeeth2000Noch keine Bewertungen

- AL SHAHEEN Material Selection ReportDokument32 SeitenAL SHAHEEN Material Selection Reportksangeeth2000Noch keine Bewertungen

- The Crimean War: Treaty of ParisDokument1 SeiteThe Crimean War: Treaty of Parisksangeeth2000Noch keine Bewertungen

- ONAMDokument18 SeitenONAMksangeeth20000% (1)

- Type B Fairlead - 90° Results JustificationDokument14 SeitenType B Fairlead - 90° Results Justificationksangeeth2000Noch keine Bewertungen

- FPSO Project Awards With Mooring Systems - 2018Dokument1 SeiteFPSO Project Awards With Mooring Systems - 2018ksangeeth2000Noch keine Bewertungen

- Aqwa-Intro 14.5 L01 Introduction PDFDokument32 SeitenAqwa-Intro 14.5 L01 Introduction PDFksangeeth2000Noch keine Bewertungen

- ONAMDokument18 SeitenONAMksangeeth20000% (1)

- Slewing BearingDokument3 SeitenSlewing Bearingksangeeth2000Noch keine Bewertungen

- Crane CheckDokument2 SeitenCrane Checkksangeeth2000Noch keine Bewertungen

- Mirror ManufacturingDokument1 SeiteMirror Manufacturingksangeeth2000Noch keine Bewertungen

- 350 Chess DemoDokument15 Seiten350 Chess Demoarban bNoch keine Bewertungen

- Non Destructive TestingDokument2 SeitenNon Destructive Testingksangeeth2000Noch keine Bewertungen

- Promotion Broschüre EN - 2Dokument5 SeitenPromotion Broschüre EN - 2Горан ИлиевскиNoch keine Bewertungen

- 2023 Snellings Et Al - Future and Emerging Supplementary Cementitious MaterialsDokument23 Seiten2023 Snellings Et Al - Future and Emerging Supplementary Cementitious MaterialsjoaosarcinellisilvaNoch keine Bewertungen

- Reinforced Concrete Design PrinciplesDokument28 SeitenReinforced Concrete Design PrinciplesLenard GarciaNoch keine Bewertungen

- Relay 30A 24V SonChuaDokument11 SeitenRelay 30A 24V SonChuamylitalindaNoch keine Bewertungen

- Advantages and Disadvantages of Powder MetallurgyDokument2 SeitenAdvantages and Disadvantages of Powder Metallurgyvinslin67% (6)

- Adhesive and Coating ScienceDokument24 SeitenAdhesive and Coating ScienceHarsh ModiNoch keine Bewertungen

- S.J.M. Institute's Studies on A413 Intermetallic Alloy StructuresDokument20 SeitenS.J.M. Institute's Studies on A413 Intermetallic Alloy StructuresKiran SNNoch keine Bewertungen

- JDP-Tensar-AR-GN-Geocomposite-Data SheetDokument1 SeiteJDP-Tensar-AR-GN-Geocomposite-Data SheetBerat DalyabrakNoch keine Bewertungen

- TUGAS Highway Engineering Muhamad Farhan Santoso 2502059751Dokument1 SeiteTUGAS Highway Engineering Muhamad Farhan Santoso 2502059751Muhamad Farhan SantosoNoch keine Bewertungen

- Cost Est.-Oedc FenceDokument10 SeitenCost Est.-Oedc Fenceefren VidallonNoch keine Bewertungen

- 3.ME 310 - Insulation-1Dokument55 Seiten3.ME 310 - Insulation-1Alif RifatNoch keine Bewertungen

- Compatibility Test For Mineral and Ester OilDokument6 SeitenCompatibility Test For Mineral and Ester OilRamesh GopalanNoch keine Bewertungen

- Baundry WallDokument4 SeitenBaundry WallSUDEESH KUMAR GAUTAMNoch keine Bewertungen

- Mayor ShutdownDokument121 SeitenMayor ShutdownIrshad HussainNoch keine Bewertungen

- Topan MFF-B85 refractory product definitionDokument1 SeiteTopan MFF-B85 refractory product definitionDan SavinNoch keine Bewertungen

- Bill of Amount Breakdown for Construction ProjectDokument8 SeitenBill of Amount Breakdown for Construction ProjectShafiul AlamNoch keine Bewertungen

- Thumb RuleDokument1 SeiteThumb RulemuraliNoch keine Bewertungen

- Seismic Damage Assessment of Reinforced Concrete Bridge Columns PDFDokument17 SeitenSeismic Damage Assessment of Reinforced Concrete Bridge Columns PDFRosNoch keine Bewertungen

- Adhesion Strongly Depends On Film Thickness and Surface Roughness of SubstrateDokument2 SeitenAdhesion Strongly Depends On Film Thickness and Surface Roughness of SubstrateYan TengNoch keine Bewertungen

- Oralium ROI Brochure - Al Roof SheetDokument16 SeitenOralium ROI Brochure - Al Roof Sheet1pallabNoch keine Bewertungen

- HFY4-4215-01-GEN-TDR-0001 - 2-Technical Deliverables Register As in 03.07.2021Dokument2 SeitenHFY4-4215-01-GEN-TDR-0001 - 2-Technical Deliverables Register As in 03.07.2021Santo KuolNoch keine Bewertungen

- Spider Silk Reinforced Epoxy Composite Aircraft WindowDokument25 SeitenSpider Silk Reinforced Epoxy Composite Aircraft WindowUsaid ShariefNoch keine Bewertungen

- Suganya, Thirugnanasambandam E3244038519 - 2019Dokument5 SeitenSuganya, Thirugnanasambandam E3244038519 - 2019dhavamanidossNoch keine Bewertungen

- Ductile Iron FittingsDokument10 SeitenDuctile Iron Fittingsdol ananNoch keine Bewertungen

- Stiklu Centrs Catalogue Oct 2010Dokument4 SeitenStiklu Centrs Catalogue Oct 2010enkantoNoch keine Bewertungen

- E Catalogue Crucible GlobalDokument7 SeitenE Catalogue Crucible GlobalSylab InstrumentsNoch keine Bewertungen

- Brochure: Continuous Length Flexible ConduitDokument6 SeitenBrochure: Continuous Length Flexible Conduitqdod_waffiNoch keine Bewertungen

- Mech Forged Fitting and Wrought Fitting PWHT Scope InspectionDokument6 SeitenMech Forged Fitting and Wrought Fitting PWHT Scope InspectionSUNIL PandeyNoch keine Bewertungen

- Tribology International: Kh.A. Ragab, R. Abdel-Karim, S. Farag, S.M. El-Raghy, H.A. AhmedDokument8 SeitenTribology International: Kh.A. Ragab, R. Abdel-Karim, S. Farag, S.M. El-Raghy, H.A. AhmedAndra Florentina ModruzNoch keine Bewertungen

- Int J Adv Manuf Technol 104, 1075-1086 (2019)Dokument12 SeitenInt J Adv Manuf Technol 104, 1075-1086 (2019)Rafael EvangelistaNoch keine Bewertungen