Beruflich Dokumente

Kultur Dokumente

Mitigation Plan Tiein Schedule

Hochgeladen von

ThirukkumaranBalasubramanianOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Mitigation Plan Tiein Schedule

Hochgeladen von

ThirukkumaranBalasubramanianCopyright:

Verfügbare Formate

C

D

E

B

F

BB

A (mm ITEM INDEX (mm (m ITEM INDEX (mm (Kg/cm2

S.S.

S.S.

S.S.10.

S.S.13.

S.S.8.2

S.S.21.

S.S.11.

S.S.

S.S.4

UPSS.S.

S.S.8.2

8.4

9.1

8.9

5.5

21

8

7

S.S.

6.8 REV.

UPS (DEG C) 01 (m

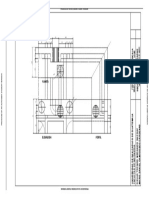

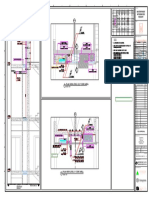

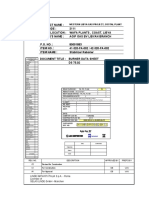

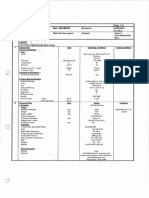

Wafa Field Mitigation Plan - Tie-in Schedule DATE 07/03/2016

Rev Tie-In System Description P & ID New Line Existing Line Operating Design (Hold 2)

Plant

Number

Shutdown Tie in Type Remarks

Size New Line Pipe Insulation Size Existing Line Insulation Temperature Flow Temperature Required

Drawing Number Pipe Class Pressure (barg) Pressure (barg)

(inch) Number Class Type (inch) Number Type ( ) (m3/hr) ( )

Tie-in of NG-1 Gas Trunkline at downstream

01 1 130 of Check Valve RC052A to new Common J-52-D-O-1013-01 16 XXX CA731 Z 16 52 CA731 Z 53.0 74.0 100 89.0 No A3 See Notes.

Header

This Drawing is based on

Tie-in to Split SG1 gas production (J-52-D-O- Doument (D-52-1225-123j

01 2 130 16 XXX CA731 Z 16 010 CA731 Z 55.0 74.0 100 89.0 No A3 See Notes.

1013-01 SHT 3OF 4) Revision F1) (J-52-D-O-1013-

01 SHT 3OF 4)

01 3 130 Tie-in to Gas Slug Catcher 20-130-VQ-002 J-52-D-O-1013-02 24 XXX CA731 Z 36 062 CA731 Z 46 to 48 19 - 74 100 89.0 No A1 See Notes.

Tie-in to upstream of Gas Slug Catcher OVHD

01 4 130 J-52-D-O-1013-021 24 XXX CA731 Z 36 062 CA701 Z 46 TO 48 19 -74 100 89 No A1 See Notes.

Separators 20-130-VZ-002

Tie-in to Upstream of Gas Slug Catcher K.O.

01 5 300 J-52-D-O-1030-03 24 XXX CA701 I 30 02 CA701 I 44 - 47 15.5 - 70.5 80 79 No A3 See Notes.

Drum 10-300-VA002

Tie-in to upstream of inlet Gas Compression

01 6 300 J-52-D-O-1036-01-1/3 24 XXX CA602 I 20 006 CA602 I 60.0 75.0 125 79 No A1 See note 1

from Raw Gas 10-300-VA-002

Tie-in toinlet Gas Compression FILTER from

01 7 361 J-53-D-O-1036-14-1/2 24 XXX CA602 I 24 201 AA601 I 51.8 8.5 80 18 Yes A1 See note 1

Raw Gas 10-361-CA001A

Revision History General Notes

REV O1 Preliminary Issue '1. Operating and design conditions are all as per existing P&IDs.

Insulation Types Insulation Types

Tie In Type Code

Code Description Code Description

A Line emptied and gas freed: B Line emptied but not gas freed:

B Underground Lines (Bitumen) T Steam Tracing

A1 Cut and buttweld B1 Cold cut, plug, weld flange, bolt on new

E Electric Heat Tracing W Jacketing

A2 Cut, weld flange, bolt new B2 Other (per Remarks)

F Cold Insulation (Temp. from -273 to +5C) X Acoustic Insulation (-10 dB)

A3 Flanged (or screwed) joint C Line not emptied:

I Heat Conservation (Above 5C) Y Antisweet Insulation

A4 Modify existing spool off site C1 Hot tap

N Not Insulation and Not Paiting Z Painting

A5 Other (per Remarks) C2 Stopple

Das könnte Ihnen auch gefallen

- Plano Acotado PDFDokument1 SeitePlano Acotado PDFSusy CifuentesNoch keine Bewertungen

- Starboard Side: Drawing To Thickness MeasurementDokument1 SeiteStarboard Side: Drawing To Thickness MeasurementdhabriNoch keine Bewertungen

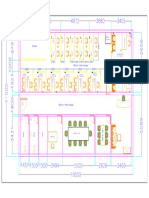

- 01 Office Floor Plan DWG Free Download Bcb977c721-ModelDokument1 Seite01 Office Floor Plan DWG Free Download Bcb977c721-ModelMr: Saykat khanNoch keine Bewertungen

- Terrace or Mumty PlanDokument1 SeiteTerrace or Mumty Planশান্তনু বৰুৱাNoch keine Bewertungen

- OfficeDokument1 SeiteOfficeMr: Saykat khanNoch keine Bewertungen

- Onset Rime ActivityDokument41 SeitenOnset Rime Activityapi-345632136Noch keine Bewertungen

- A B CD E F A B CD E F: Roof Framing Plan Structural Roof Framing PlanDokument1 SeiteA B CD E F A B CD E F: Roof Framing Plan Structural Roof Framing PlanJefferson SubilNoch keine Bewertungen

- Applicant Checklist TemplateDokument1 SeiteApplicant Checklist TemplateMusadyaNoch keine Bewertungen

- Site SLB DimensiDokument1 SeiteSite SLB Dimensibagus arizaNoch keine Bewertungen

- Hse Departmental Meeting Attendance SheetDokument1 SeiteHse Departmental Meeting Attendance SheetJunard Lu HapNoch keine Bewertungen

- 4 BaseDokument1 Seite4 BaseMauricio TonatoNoch keine Bewertungen

- Site Safety Training Attendance SheetDokument1 SeiteSite Safety Training Attendance SheetJunard Lu HapNoch keine Bewertungen

- 11 Lighting LayoutDokument1 Seite11 Lighting LayoutB R PAUL FORTINNoch keine Bewertungen

- P Final Part3Dokument4 SeitenP Final Part3api-346075502Noch keine Bewertungen

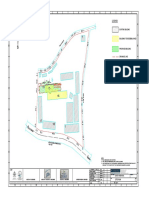

- 5 SiteplanDokument1 Seite5 SiteplanGianina Ariella Timothea HakimNoch keine Bewertungen

- P e Arkaim-L1Dokument1 SeiteP e Arkaim-L1Valentina OsorioNoch keine Bewertungen

- Zona Comercial: Cuarto Nivel - ESC. 1:200Dokument1 SeiteZona Comercial: Cuarto Nivel - ESC. 1:200leonardo palma salasNoch keine Bewertungen

- oe471Dokument2 Seitenoe471Rudy GamezNoch keine Bewertungen

- Plano 01111Dokument1 SeitePlano 01111Huayanay coronel taylor juniorNoch keine Bewertungen

- Diktati Za Srednju SkoluDokument4 SeitenDiktati Za Srednju SkoluLazar L. RadojaNoch keine Bewertungen

- DISEÑO 7X20-ModelDokument1 SeiteDISEÑO 7X20-ModelEDWIN NEHEMIAS ALTAMIRANO CERNANoch keine Bewertungen

- Thesun 2009-04-07 Page12 Cimb To Close 60 Surplus BranchesDokument1 SeiteThesun 2009-04-07 Page12 Cimb To Close 60 Surplus BranchesImpulsive collectorNoch keine Bewertungen

- TheSun 2009-04-10 Page17 PAC To Call Up Protom Over MV Agusta SaleDokument1 SeiteTheSun 2009-04-10 Page17 PAC To Call Up Protom Over MV Agusta SaleImpulsive collectorNoch keine Bewertungen

- Jadwal Semester 2 - Siswa - 2.Dokument1 SeiteJadwal Semester 2 - Siswa - 2.Wily WilliamNoch keine Bewertungen

- Farm Building Layout GuideDokument1 SeiteFarm Building Layout GuidePrasadNoch keine Bewertungen

- Jadwal 23-24Dokument1 SeiteJadwal 23-24Nia PawitriNoch keine Bewertungen

- NUEVO PARAISO-Presentación1Dokument1 SeiteNUEVO PARAISO-Presentación1Huayanay coronel taylor juniorNoch keine Bewertungen

- EBCI (Charleroi Airport)Dokument6 SeitenEBCI (Charleroi Airport)Roshan UppalNoch keine Bewertungen

- Toothbrushing Checklist 2022 Monthly TemplateDokument1 SeiteToothbrushing Checklist 2022 Monthly TemplateJessiebel Libot100% (1)

- LUNA - DE - XELAJU - 4 voces-CARLOS PÉREZDokument5 SeitenLUNA - DE - XELAJU - 4 voces-CARLOS PÉREZCARLITOSAX perez cunNoch keine Bewertungen

- Mars Wanita GerejaDokument2 SeitenMars Wanita Gerejaחשבון כלליותNoch keine Bewertungen

- 50c-1066 DRWDokument2 Seiten50c-1066 DRWmadhivananspNoch keine Bewertungen

- Tenor 1 Autum LeavesDokument1 SeiteTenor 1 Autum LeavesFundacion RapsodiaNoch keine Bewertungen

- JEE Main Quiz-26 (Student Copy)Dokument11 SeitenJEE Main Quiz-26 (Student Copy)ashutosh.mishra0051Noch keine Bewertungen

- Final 1Dokument1 SeiteFinal 1Taniya Sara PhilipNoch keine Bewertungen

- Monologue Rubric AssessmentDokument2 SeitenMonologue Rubric AssessmentGRRLYSLOTHNoch keine Bewertungen

- Saniyah Desain2Dokument1 SeiteSaniyah Desain2achmadzaini1435Noch keine Bewertungen

- RazmjestajModel PDFDokument1 SeiteRazmjestajModel PDFNihad HodzicNoch keine Bewertungen

- COMPLDokument1 SeiteCOMPLALEENA ASLAMNoch keine Bewertungen

- Siteplancolour KadakkalDokument1 SeiteSiteplancolour KadakkalRahul K JNoch keine Bewertungen

- PRACTICA 2.2 FINAL-Model DIBUJO TECNICO MECANICODokument1 SeitePRACTICA 2.2 FINAL-Model DIBUJO TECNICO MECANICOMario DanNoch keine Bewertungen

- Architectural plan visualization and measurementsDokument1 SeiteArchitectural plan visualization and measurementsMario Vallejo PadillaNoch keine Bewertungen

- Thimmaipalle 01Dokument1 SeiteThimmaipalle 01balasridhar chandragiriNoch keine Bewertungen

- Working Drawings of Proposed Residence at Amritsar: Demarcation PlanDokument1 SeiteWorking Drawings of Proposed Residence at Amritsar: Demarcation PlanSaurish ChopraNoch keine Bewertungen

- I Want It That Way - Accapella SATBDokument2 SeitenI Want It That Way - Accapella SATBLeoNoch keine Bewertungen

- ErrrDokument1 SeiteErrrRafael CruzNoch keine Bewertungen

- Plate No: College of Industrial Technology Bsit 3-A Drafting TechnologyDokument1 SeitePlate No: College of Industrial Technology Bsit 3-A Drafting TechnologyShandy UrbanoNoch keine Bewertungen

- HKN Transmit 070999 Archive 4Dokument1 SeiteHKN Transmit 070999 Archive 4sandamaliNoch keine Bewertungen

- 004.plan Subsol 1Dokument1 Seite004.plan Subsol 1Marius MargineanNoch keine Bewertungen

- Ibis Data FileDokument18 SeitenIbis Data FileAmit NikoseNoch keine Bewertungen

- HKN Transmit 070999 Archive 2Dokument1 SeiteHKN Transmit 070999 Archive 2sandamaliNoch keine Bewertungen

- Attendance Monitoring ReportDokument4 SeitenAttendance Monitoring ReportANABELLE C. DALIN-MENDOZANoch keine Bewertungen

- Nodal displacement in global Z for loadcase 2Dokument1 SeiteNodal displacement in global Z for loadcase 2Aleksandar SiljkovicNoch keine Bewertungen

- TV Uptown BGC DysonDokument1 SeiteTV Uptown BGC DysonJean Lindley JosonNoch keine Bewertungen

- Area and dimensions of public spaces in urban plansDokument1 SeiteArea and dimensions of public spaces in urban plansRenzoGNoch keine Bewertungen

- Chicagooo PDFDokument1 SeiteChicagooo PDFRenzoGNoch keine Bewertungen

- November: Pt. Nasmoco Pemuda - Aftersales SectionDokument1 SeiteNovember: Pt. Nasmoco Pemuda - Aftersales SectionDream AutoNoch keine Bewertungen

- Etabs 2016 16.2.0 8/2/2018Dokument1 SeiteEtabs 2016 16.2.0 8/2/2018Min KhantNoch keine Bewertungen

- Master Plan: Produced by An Autodesk Student VersionDokument1 SeiteMaster Plan: Produced by An Autodesk Student VersionGrishma RajpalNoch keine Bewertungen

- Job Description-Piping EngineerDokument1 SeiteJob Description-Piping EngineerThirukkumaranBalasubramanianNoch keine Bewertungen

- INITIAL RISK REVIEW - WAFA Cold CutDokument6 SeitenINITIAL RISK REVIEW - WAFA Cold CutThirukkumaranBalasubramanianNoch keine Bewertungen

- CEIL Engineering FinHR Advt 202324 02Dokument6 SeitenCEIL Engineering FinHR Advt 202324 02ThirukkumaranBalasubramanianNoch keine Bewertungen

- Job Description-Process EngineerDokument1 SeiteJob Description-Process EngineerThirukkumaranBalasubramanianNoch keine Bewertungen

- Execution of Tie-Ins Without A Plant ShutdownDokument3 SeitenExecution of Tie-Ins Without A Plant ShutdownThirukkumaranBalasubramanianNoch keine Bewertungen

- CUI Risk Factors on Insulated PipingDokument21 SeitenCUI Risk Factors on Insulated PipingRenan Soares KieferNoch keine Bewertungen

- D2-001-AM Part 1Dokument118 SeitenD2-001-AM Part 1ThirukkumaranBalasubramanianNoch keine Bewertungen

- Job Description-Mechanical EngineerDokument1 SeiteJob Description-Mechanical EngineerThirukkumaranBalasubramanianNoch keine Bewertungen

- DS 7502Dokument4 SeitenDS 7502ThirukkumaranBalasubramanianNoch keine Bewertungen

- Visual Inspection WeldDokument53 SeitenVisual Inspection Weldshifa100% (1)

- PALL FILTER - Process Data SheetDokument2 SeitenPALL FILTER - Process Data SheetThirukkumaranBalasubramanianNoch keine Bewertungen

- Cold CuttingDokument2 SeitenCold CuttingThirukkumaranBalasubramanianNoch keine Bewertungen

- Summarized Technical - Information Data'sDokument1 SeiteSummarized Technical - Information Data'sThirukkumaranBalasubramanianNoch keine Bewertungen

- Final Report TOTAL EP MYANMARDokument24 SeitenFinal Report TOTAL EP MYANMARThirukkumaranBalasubramanianNoch keine Bewertungen

- Guide to Failure Analysis in Oil and Gas IndustryDokument6 SeitenGuide to Failure Analysis in Oil and Gas IndustryThirukkumaranBalasubramanian100% (1)

- Mellitah Oil & Gas BV: Welding Procedure Specification For Stainless Steel PipingDokument9 SeitenMellitah Oil & Gas BV: Welding Procedure Specification For Stainless Steel PipingThirukkumaranBalasubramanianNoch keine Bewertungen

- Non Oily Wastewater To The SeaDokument1 SeiteNon Oily Wastewater To The SeaThirukkumaranBalasubramanianNoch keine Bewertungen

- Mellitah Oil & Gas BV: Field Bending OF LinepipeDokument4 SeitenMellitah Oil & Gas BV: Field Bending OF LinepipeThirukkumaranBalasubramanianNoch keine Bewertungen

- Aspee Hi-Tech: Knapsack SprayerDokument2 SeitenAspee Hi-Tech: Knapsack SprayerThirukkumaranBalasubramanianNoch keine Bewertungen

- Atlas Grade Datasheet - All Datasheets Rev Aug 2013 PDFDokument57 SeitenAtlas Grade Datasheet - All Datasheets Rev Aug 2013 PDFMikku KattaNoch keine Bewertungen

- Mellitah Oil & Gas BV: Wafa Gathering ProcedureDokument583 SeitenMellitah Oil & Gas BV: Wafa Gathering ProcedureThirukkumaranBalasubramanian0% (1)

- Mellitah Oil & Gas BV: Wafa Gathering ProcedureDokument19 SeitenMellitah Oil & Gas BV: Wafa Gathering ProcedureThirukkumaranBalasubramanianNoch keine Bewertungen

- Mellitah Oil & Gas BVDokument12 SeitenMellitah Oil & Gas BVThirukkumaranBalasubramanianNoch keine Bewertungen

- PSG 15 Repairs or Modifications Dated 13th Nov 2013 PDFDokument13 SeitenPSG 15 Repairs or Modifications Dated 13th Nov 2013 PDFThirukkumaranBalasubramanianNoch keine Bewertungen

- JERES-D-001 Design Criteria For Pressure VesselsDokument37 SeitenJERES-D-001 Design Criteria For Pressure VesselsThirukkumaranBalasubramanianNoch keine Bewertungen

- Installation PlanDokument28 SeitenInstallation PlanThirukkumaranBalasubramanianNoch keine Bewertungen

- JERES-D-001 Design Criteria For Pressure VesselsDokument37 SeitenJERES-D-001 Design Criteria For Pressure VesselsThirukkumaranBalasubramanianNoch keine Bewertungen

- DataSheet 105723Dokument2 SeitenDataSheet 105723ThirukkumaranBalasubramanianNoch keine Bewertungen

- Reference ListDokument28 SeitenReference ListThirukkumaranBalasubramanianNoch keine Bewertungen

- DataSheet 105723Dokument2 SeitenDataSheet 105723ThirukkumaranBalasubramanianNoch keine Bewertungen

- Studies On The Production of Defatted Sunflower Meal With Low Polyphenol and Phytate Contents and Its Nutritional ProfileDokument4 SeitenStudies On The Production of Defatted Sunflower Meal With Low Polyphenol and Phytate Contents and Its Nutritional Profileamco2kNoch keine Bewertungen

- Astm 1351 1 REPLICADokument6 SeitenAstm 1351 1 REPLICAmaheshNoch keine Bewertungen

- Advanced Manufacturing Technology 2-Marks Question and Answer Unit-IDokument44 SeitenAdvanced Manufacturing Technology 2-Marks Question and Answer Unit-IM.ThirunavukkarasuNoch keine Bewertungen

- Engineering Vol 56 1893-11-10Dokument35 SeitenEngineering Vol 56 1893-11-10ian_newNoch keine Bewertungen

- Homogenization and Lysis (2021!06!12)Dokument22 SeitenHomogenization and Lysis (2021!06!12)Wreck of HeartsNoch keine Bewertungen

- Group 4 Lab Exercise on Vapor-Liquid EquilibriumDokument21 SeitenGroup 4 Lab Exercise on Vapor-Liquid EquilibriumEUNICE JOI SARCONNoch keine Bewertungen

- Square Duct Board Installation ManualDokument4 SeitenSquare Duct Board Installation ManualApurv GoyalNoch keine Bewertungen

- Solution Manual Chemical Reaction Engineering, 3rd EditionDokument137 SeitenSolution Manual Chemical Reaction Engineering, 3rd Editionboni_briantoni75% (8)

- PIP PCECV001 Guidelines For Application of Control ValvesDokument39 SeitenPIP PCECV001 Guidelines For Application of Control ValvesAndresNoch keine Bewertungen

- (VESBO) Catalog en 100317Dokument55 Seiten(VESBO) Catalog en 100317AnhNguyen100% (1)

- Istory of Jellyfish Envenomation: 3.1.1. Class Cubozoa - Cubozoan JellyfishDokument16 SeitenIstory of Jellyfish Envenomation: 3.1.1. Class Cubozoa - Cubozoan JellyfishRangsiyo BeabeoNoch keine Bewertungen

- Chapter 4 and 5Dokument51 SeitenChapter 4 and 5Kyla Gabrielle TutoNoch keine Bewertungen

- Lubricant Properties CalculatorDokument14 SeitenLubricant Properties CalculatorzamijakaNoch keine Bewertungen

- 2 - Cleaning and Shaping in EndodonticsDokument299 Seiten2 - Cleaning and Shaping in EndodonticsElisabeth MarofNoch keine Bewertungen

- Astm A181-2001 PDFDokument3 SeitenAstm A181-2001 PDFMohammed TariqNoch keine Bewertungen

- Sierra Gorda - Feasibility (2011)Dokument240 SeitenSierra Gorda - Feasibility (2011)Nicolas CarrascoNoch keine Bewertungen

- Class 10 science lab exam MCQ questionsDokument4 SeitenClass 10 science lab exam MCQ questionsDonkeyNoch keine Bewertungen

- 2020-Intrinsic and tunable ferromagnetism in Bi0.5Na0.5TiO3 through CaFeO3-δ modification-Scientific Reports (10), 6189 (2020)Dokument15 Seiten2020-Intrinsic and tunable ferromagnetism in Bi0.5Na0.5TiO3 through CaFeO3-δ modification-Scientific Reports (10), 6189 (2020)Lương Hữu Bắc100% (1)

- Deltaweld 652Dokument26 SeitenDeltaweld 652Hugo RodriguezNoch keine Bewertungen

- Wolter Jetfan Broschuere English 2017 PDFDokument15 SeitenWolter Jetfan Broschuere English 2017 PDFViệt Đặng XuânNoch keine Bewertungen

- Flexible Packaging Solutions For Liquids: Packaging and Specialty PlasticsDokument12 SeitenFlexible Packaging Solutions For Liquids: Packaging and Specialty PlasticsSupermobile 786Noch keine Bewertungen

- Johnson Industrial Screens PDFDokument20 SeitenJohnson Industrial Screens PDFjaime palenzuela rodriguezNoch keine Bewertungen

- Solid Waste Management Not FinishDokument32 SeitenSolid Waste Management Not FinishMans LaderaNoch keine Bewertungen

- Cementing Operation - Part IDokument26 SeitenCementing Operation - Part IDoni KurniawanNoch keine Bewertungen

- Sunward SWE08B Operator's ManualDokument96 SeitenSunward SWE08B Operator's ManualIisakki50% (2)

- Agoo Montessori Learning Center and High School Inc.: Fruit Waste As Biodegradable PlasticDokument6 SeitenAgoo Montessori Learning Center and High School Inc.: Fruit Waste As Biodegradable PlasticAlejandro De la GarzaNoch keine Bewertungen

- SeminarDokument15 SeitenSeminarAditi ChandraNoch keine Bewertungen

- MD - Ziaul AlamDokument2 SeitenMD - Ziaul AlamAvijit DasNoch keine Bewertungen

- Schunk Carbon Technology Sealring Bearing SiSiC SSiC EN PDFDokument2 SeitenSchunk Carbon Technology Sealring Bearing SiSiC SSiC EN PDFMUHAMMAD ASYRAAF BIN ANUARNoch keine Bewertungen

- 309-King Agar-110991 PDFDokument1 Seite309-King Agar-110991 PDFSneyder MurciaNoch keine Bewertungen