Beruflich Dokumente

Kultur Dokumente

Research Journal of Pharmaceutical, Biological and Chemical Sciences

Hochgeladen von

rio1995Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Research Journal of Pharmaceutical, Biological and Chemical Sciences

Hochgeladen von

rio1995Copyright:

Verfügbare Formate

ISSN: 0975-8585

Research Journal of Pharmaceutical, Biological and Chemical

Sciences

Formulation and Evaluation of Microbially Activated Osmotic Drug Delivery

System for Colon Targeted Tinidazole Tablets

S Srikanth*, S Senthil Kumar, K Sundaramoorthy, S Shanmugam and

T Vetrichelvan

Adhiparasakthi College of Pharmacy, Melmaruvathur-603 319, Tamilnadu, India.

ABSTRACT

The Microbially Activated Osmotic drugs Delivery for Colon targeted Tinidazole Tablets were developed.

The developed systems consisted of osmotic core (drug, osmotic agent and wicking agent), coated with semi

permeable membrane (SPM) containing Guar gum as pore former, coated core were then further coated with

enteric coating to protect the system from acidic environment of stomach. The effect of various formulation

variables namely the level of wicking agent (Sodium lauryl sulphate), osmotic agent in the osmotic core, the level

of pore former (Guar gum) in SPM, were studied on physical parameters and drug release characteristics of

developed formulations. The SEM studies showed the formation of in-situ delivery pores in the membrane from

where the drug release occurred, and the numbers of pores formed were directly related to the initial level of pore

former (Guar gum) in SPM. The results of in-vitro dissolution study and release kinetics showed the formulation F7

as the best formulation.

Keywords: Colon targeted; Tinidazole; semi permeable membrane; Guar gum; Microbially Activated; osmotic

technology.

*Corresponding author

Email:sripharma13@gmail.com

January March 2011 RJPBCS Volume 2 Issue 1 Page No. 469

ISSN: 0975-8585

INTRODUCTION

Tinidazole is the most preferred choice of drug for intestinal amoebiasis. This drug is to

be delivered to the colon for its effective action against Entamoebe histolytica wherein the

trophozoites reside in the lumen of the caecum and large intestine and also adhere to the

colonic mucus and epithelial layers. But the pharmacokinetic profile of Tinidazole indicates that

the drug is completely and promptly absorbed after oral administration [1]. The administration

of this drug in conventional Tablet dosage form provides minimal amount of Tinidazole for local

action in the colon, still resulting in the relief of amoebiasis, but with unwanted systemic

effects. Thus there is strong clinical need and market potential for a delivery system that will

deliver maximum amount of tinidazole to the colon in controlled manner [2].

Colon targeted delivery systems are well recognized and documented to deliver most of

the drugs to colon. In the past, various primary approaches for colon targeted delivery, such as,

prodrugs approach, pH, time and pressure dependent systems, have achieved limited success.

Osmotic drug delivery system (ODDS) utilizes the principle of osmotic pressure for controlled

delivery of drugs [3, 4, and 5]. Drug release from these systems is independent of pH and other

physiological parameter to a large extent and exhibit significant in-vitroin vivo correlation.

Drug delivery from ODDS follow zero-order kinetic hence provides better control over in-vivo

performance. Various types of osmotic pumps have been reported to target the drug to colon

for local or systemic therapy. These systems were essentially time dependent systems. High

variation of gastric retention time makes these systems complicated in predicting the accurate

location of drug release.

With all these considerations in mind, we designed microbially activated osmotic

delivery systems (MAODS) for colon-targeted delivery of tinidazole. Colon targeted delivery

systems of Tinidazole Tablets were developed based on osmotic technology. The developed

systems consisted of osmotic core (drug, osmotic agent and wicking agent), coated with semi

permeable membrane (SPM) containing Guar gum as pore former, coated core were then

further coated with enteric coating to protect the system from acidic environment of stomach.

The effect of various formulation variables namely the level of wicking agent (Sodium lauryl

sulphate), osmotic agent (Mannitol and Fructose) in the osmotic core, the level of pore former

(Guar gum) in SPM, and the thickness of SPM, were studied on drug release characteristics of

developed formulations.

During its transit through the GIT, MAODS remains intact in the stomach due to the

enteric-coating layer, but this layer will dissolve in the small intestine, where pH is above 6, and

fluid is imbibed into the core due to osmotic pressure gradient across SPM. The continuous

imbibition of core forms a saturated solution of drug within the device. When MAODS reaches

the colon, guar gum (pore former) in the semi permeable membrane is specifically degraded by

micro flora of the colon and thereby results in an in situ formation of delivery pores [6]. The

saturated solution of drug is delivered from these delivery pores at a relatively constant release

rate for up to 12 hr in the colon.

January March 2011 RJPBCS Volume 2 Issue 1 Page No. 470

ISSN: 0975-8585

MATERIALS AND METHODS

MATERIALS

Tinidazole was a gift sample from Spic Pharmaceutical Ltd., Chennai, India. Following

chemicals and excipients were purchased from commercial sources and used as such: Eudragit

S-100, Cellulose acetate, Polyvinyl pyrrolidone (PVP K-30), Microcrystalline cellulose (Avicel PH-

101), Magnesium stearate, Talc, Sodium chloride, Fructose, Mannitol, PEG-400, Sodium lauryl

sulphate, Guar gum were purchased from Loba Chemie Pvt.Ltd., Mumbai, India. Acetone,

methanol, ethanol were purchased from Fisher Scientifics, Mumbai, India.

METHODS

Differential Scanning Calorimetry (DSC)

The DSC analysis of pure drug, drug+ Mannitol, drug+ Fructose, drug+ Guar gum, drug+

SLS, drug+ Eudragit S-100 were carried out using a Shimadzu DSC 60, (Japan) to evaluate any

possible drug-polymer interaction. The 2 mg sample were heated in a hermetically sealed

aluminum pans in the temperature range of 25-300c at heating rate of 10c /min under

nitrogen flow of 30ml/min [7].

Characterization of Powder Blend

The Tablet blend were evaluated for their bulk density, tapped density, compressibility

index, angle of repose and Hausner ratio. The tapping method was used to determine the bulk

density, tapped density, percent compressibility index and Hausner ratio.

Compressibility index = [t-b / t] 100

Hausner ratio= t/ b

Where t = tapped density

b = initial bulk density of Tablet blend.

Angle of repose of the Tablet blend measures the resistance to particle flow and was

determined by fixed funnel method [8, 9].

January March 2011 RJPBCS Volume 2 Issue 1 Page No. 471

ISSN: 0975-8585

Preparation of Core Tablets

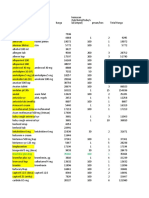

Table 1: Composition of Core Tablets

* Formulations

Sr.No. Ingredients

F1 F2 F3 F4 F5 F6 F7

1 Tinidazole 150 150 150 150 150 150 150

2 Mannitol 100 70 70 70 70 58 81

3 Fructose - 80 80 80 80 66 93

4 SLS - - 15 25 35 25 25

5 PVP K 30 15 15 15 15 15 15 15

6 MCC PH 102 85.8 35.8 20.8 10.8 0.8 36.8 -

7 Talc 7.2 7.2 7.2 7.2 7.2 7.2 7.2

8 Magnesium Stearate 2 2 2 2 2 2 2

*

All quantities are in mg.

Core Tablets of Tinidazole (150 mg) were prepared by direct compression and batch size

was kept as 100 Tablets. Formula of different core formulations of Tinidazole is listed in Table 1.

Tinidazole was mixed with fructose and Mannitol for 10 min. After passing this mixture through

#30 mesh sieve, Sodium lauryl sulphate (SLS) and Microcrystalline cellulose (MCC) were added

in geometric dilution and mixing continued for additional 10 min. To this mixture Talc and

Magnesium stearate each passed through #60 mesh sieve were added and mixing continued for

additional 10 min. The blend was then directly compressed into Tablets having average weight

of 360 mg using a sixteen station Tablet punching machine (Cadmach, Ahmadabad, India) fitted

with 9 mm round flat punches.

Preparation of Osmotic Delivery System (ODS)

Table 2: Composition of Osmotic Delivery System (ODS):

Sr.No. Ingredients Coating Formula

*

1 Cellulose Acetate 2.00

*

2 PEG 400 0.39

*

3 Guar Gum 0.60

#

4 Acetone 80

#

5 Methanol 20

*

All quantities are in mg;

#

All quantities are in ml.

ODS were prepared by coating of core Tablets with a SPM in a conventional laboratory

coating pan having outer diameter of 20 cm (Scientific Instrument, New Delhi, India) fitted with

three baffles placed at angle of 120 [10]. The composition of coating solutions used for coating

of Tinidazole Tablets is given in Table 2. Various components of coating solution were added to

solvent mixture in sequential manner. The component added first was allowed to dissolve

January March 2011 RJPBCS Volume 2 Issue 1 Page No. 472

ISSN: 0975-8585

before next component was added. Coating process was started on a batch of 100 Tablets; pan

speed was maintained at 20 rpm and hot air inlet temperature was kept at 38-42 C. The

manual coating procedure based on intermittent spraying and coating technique was used with

spray rate of 4-5 ml/min. Coat weight and thickness were controlled by the volume of coating

solution consumed in coating process. In all the cases coated Tablets were dried at 50 C for 10

h before further evaluation.

Preparation of Microbially Activated Osmotic Delivery Systems (MAODS)

MAODS were prepared by enteric coating of ODS with Eudragit S-100 (10% w/v in

ethanol) to give enteric coating. Coating process was started on a batch of 100 SPM coated

Tablets at a time and exactly same method was followed as explained above with hot air inlet

temperature was kept at 40- 42 C and spray rate of 2- 4 ml/min [11]. Coating was continued

until uniform coating was obtained on the SPM coated core Tablets. In all cases coated Tablets

were dried at 50 C for 4 h before further evaluation.

Evaluation of colon targeted tinidazole tablets

The prepared Colon Targeted Tinidazole Tablets were evaluated for Dimension

(Diameter and Thickness) using 10 Tablets (Vernier calipers), uniformity of weight using 20

Tablets (Shimadzu BL-220H analytical balance), hardness using 6 Tablets (Monsanto hardness

tester), friability using 20 Tablets (Roche type friabilator).

Drug content

Weighed and powdered 20 Tablets. Weighed accurately a quantity of the powder

containing about 0.15 g of Tinidazole, added 20 ml of methanol, shaken well and added

sufficient methanol to produce 100.0 ml. Mixed well and filtered. Diluted 10 ml of the solution

to 100 ml with methanol and further diluted 10 ml of this solution to 100 ml with methanol.

Measured the absorbance of the resulting solution at the maximum at about 310 nm.

Calculated the content of Tinidazole by taking 356 as the specific absorbance at 310 nm [12].

In-vitro release studies

The developed formulations of Tinidazole were subjected to in-vitro drug release

studies. These studies were carried out using a USP XXIV dissolution rate test apparatus

(Apparatus 1, 50 rpm, 37 C) (Campbell Electronics, Mumbai, India). The Tablets were tested for

drug release for 2 h in simulated gastric fluid (SGF) (pH 1.2, 900 ml) as the average gastric

emptying time is about 2 h. Then the dissolution medium was replaced with simulated

intestinal fluid (SIF) (phosphate buffer pH 7.4, 900 ml) and tested for drug release for 3 h as the

average small intestinal transit time is about 3 h. Then the dissolution medium was further

replaced with 900 ml of simulated colonic fluid (SCF)[13] (pH 6.8 phosphate buffered saline

containing 109 CFU/ml of Bacteroides fragilis).The Bacteroides fragilis was collected from rat

January March 2011 RJPBCS Volume 2 Issue 1 Page No. 473

ISSN: 0975-8585

fecus and cultured in alternate Thioglycollate medium using Resazurin as indicator [14,15]. The

dissolution study was continued for another 8 h. At various time intervals, 2 ml of the

dissolution sample was withdrawn and the samples were centrifuged; the supernatant filtered

and the filtrate was analyzed for Tinidazole by UV Visible spectrophotometer.

Scanning Electron Microscopy studies (SEM)

In order to elucidate the mechanism of drug release from developed formulations,

surface of coated Tablets, both before and after dissolution studies, was studied using scanning

electron microscope (SEM). The samples were placed on a spherical brass stub (12 mm

diameter) with a double backed adhesive tape. The Tablets (coated Tablets before dissolution

studies) were mounted as such on the specimen stub. On the other hand, small sample of the

coating membrane was carefully cut from the exhausted shells (after 13 h of dissolution

studies) and dried at 50 C for 6 h. The mounted samples were sputter coated for 5 to 10 min

with gold using fine coat ion sputter and examined under SEM (JEOL, JSM-6100, Japan) [16].

RESULT AND DISCUSSION

The prepared Colon Targeted Tinidazole Tablets were evaluated for thickness, weight

variation, hardness, friability, drug content, in- vitro drug dissolution studies and stability

studies. All the studies were performed in triplicate, and results are expressed as mean SD.

Characterization of powder blend

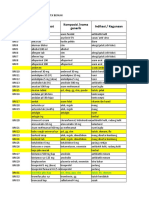

Table 3: Flow properties of powder

Tapped

Formulation Angle of Bulk density Hausner * Carrs index

* * density * Bulkiness *

Code repose () (gm/ml) * ratio (HR) (IC)

(gm/ml)

F1 24.300.44 0.65450.0067 0.75370.0088 0.86310.0098 1.53690.016 13.67330.98

F2 27.340.69 0.65710.0068 0.74950.0006 0.87660.0084 1.52190.015 12.32860.84

F3 26.56 0.64340.0011 0.77170.0096 0.83380.0113 1.55410.002 16.61191.12

F4 28.110.43 0.64970.0061 0.73970.0088 0.88010.0129 1.53910.014 12.16130.97

F5 28.260.22 0.63630.0062 0.75390.0094 0.84400.0164 1.54630.015 15.60021.64

F6 26.160.23 0.67060.0152 0.76130.0096 0.88110.0302 1.49150.034 11.88873.02

F7 25.360.70 0.64760.0064 0.76740.0091 0.84400.0161 1.54070.013 15.59521.61

*

All the values are expressed as mean SE, n=3.

The powders prepared for compression of Tablets were evaluated for their flow

properties, the results were shown in Table 3. Angle of repose was in the ranges between

24.300.44 and 28.260.43, indicating good flow property for all formulations. The bulk density

of the powder formulation was in the range of0.63630.0062gm/ml and 0.67060.0152 gm/ml;

the tapped density was in the range of 0.73970.0088 gm/ml and 0.77170.0096 gm/ml, which

January March 2011 RJPBCS Volume 2 Issue 1 Page No. 474

ISSN: 0975-8585

indicates that the powder was not bulky. The Carrs index was found to be in the range of below

16% indicating that the powders have a good compressibility. The Hausner ratio was found to

be in the range of <1.25, indicating good flow properties. These values indicate that the

prepared powder blend exhibited good flow properties.

Differential Scanning Calorimetry (DSC)

The possible drug polymer interaction can be studied by thermal analysis. Tinidazole

exhibits a sharp endothermic peak at 133.55 C shown in Figure 1a, which corresponds to its

melting point. The Tinidazole + Mannitol exhibit a sharp endothermic peak at 133.28C,

Tinidazole + Fructose exhibit a sharp endothermic peak at 126.39C, Tinidazole + Guar gum

exhibit a sharp endothermic peak at 130.32C, Tinidazole + SLS exhibit a sharp endothermic

peak at 130.84C, Tinidazole + Eutragit exhibit a sharp endothermic peak at 131.14C, shown in

Figure 1b, 1c, 1d, 1e and 1f respectively. Hence DSC study shows that there is no any drug

polymer interaction.

January March 2011 RJPBCS Volume 2 Issue 1 Page No. 475

ISSN: 0975-8585

Figure 1a: DSC thermal analysis of Tinidazole Figure 1b: DSC thermal analysis of Tinidazole + Mannitol

Figure 1c: DSC thermal analysis of Tinidazole + Fructose Figure 1d: DSC thermal analysis of Tinidazole + Guar gum

January March 2011 RJPBCS Volume 2 Issue 1 Page No. 476

ISSN: 0975-8585

Figure 1e: DSC thermal analysis of Tinidazole + SLS

Figure 1f: DSC thermal analysis of Tinidazole + Eutragit

January March 2011 RJPBCS Volume 2 Issue 1 Page No. 477

ISSN: 0975-8585

Physicochemical evaluation of colon targeted Tinidazole tablets

Table 4a: Evaluation of core Tablets

* Weight variation Hardness

Code Thickness (mm) 2 # % Friability

test (%) (kg/cm )

F1 3.1380.009 0.4240.459 5.160.25 0.092

F2 3.1410.011 0.3940.413 6.160.25 0.092

F3 3.1350.012 0.4030.475 6.500.31 0.076

F4 3.1420.008 0.3510.460 6.580.37 0.092

F5 3.1380.011 0.5520.665 6.330.25 0.077

F6 3.1410.009 0.2660.186 6.660.25 0.076

F7 3.1410.003 0.3270.277 6.750.27 0.074

* #

All the values are expressed as mean SD, n=10; All the values are expressed as mean SD, n=6.

Table 4b: Evaluation of Osmotic Delivery System

* Weight variation test 2 #

Code Thickness (mm) Hardness (kg/cm )

(%)

F1 3.2560.018 0.1370.070 6.830.25

F2 3.2640.015 0.2070.157 7.500.54

F3 3.2580.017 0.1720.184 8.250.27

F4 3.2540.016 0.1270.098 8.410.20

F5 3.2460.013 0.1270.176 7.750.27

F6 3.2620.016 0.2070.218 8.250.27

F7 3.2540.009 0.2570.186 7.750.52

* #

All the values are expressed as mean SD, n=10; All the values are expressed as mean SD, n=6.

Table 4c: Evaluation of Microbially Activated Osmotic Delivery System

* Weight variation test 2 # #

Code Thickness (mm) Hardness (kg/cm ) Drug Content (%)

(%)

F1 3.3620.014 0.1560.113 8.160.25 99.180.13

F2 3.3700.010 0.2390.111 9.080.37 99.540.15

F3 3.3680.013 0.2170.081 9.330.25 99.560.05

F4 3.3680.013 0.3100.239 9.080.37 99.410.18

F5 3.3680.010 0.2560.026 9.000.44 99.190.12

F6 3.3540.013 0.1830.090 9.250.27 99.290.07

F7 3.3640.015 0.1710.163 9.160.25 99.640.04

* #

All the values are expressed as mean SD, n=10; All the values are expressed as mean SD, n=6.

The Colon Targeted Tinidazole Tablets were off-white, smooth, and flat shaped in

appearance. The physicochemical characterizations of core Tablets, ODS and MAODS were

January March 2011 RJPBCS Volume 2 Issue 1 Page No. 478

ISSN: 0975-8585

performed and the results were shown in Table 4a, 4b and 4c respectively. The thickness of

Colon Targeted Tinidazole Tablets was measured by Vernier caliper and was ranged between

3.1350.012 and 3.3700.010mm. The weight variation for different formulations (F1 to F7)

was found to be 0.1270.098 % to 0.5520.665 %, showing satisfactory results as per Indian

Pharmacopoeia (IP) limit. The hardness of the Colon Targeted Tinidazole Tablets was measured

by Monsanto tester and was controlled between 5.160.25 and 9.250.27 kg/cm2 for both

uncoated and coated tablets. The friability of uncoated tablets was below 1% for all the

formulations, which is an indication of good mechanical resistance of the tablet. The

percentage of drug content for F1 to F7 was found to be in between 99.180.13 to 99.640.04

of Tinidazole, it complies with official specifications.

IN-VITRO RELEASE STUDY

Figure 2: In-vitro drug release profile of all formulation

In-vitro dissolution studies of all the formulations of Colon Targeted Tinidazole Tablets

were carried out in pH 1.2, pH 7.4, pH 6.8 buffer solutions. The study was performed for 14

hours, and percentage drug release was calculated at 1 hours time intervals. The results of in-

vitro dissolution studies of all formulations were shown in Figure 2. In-vitro release profiles of

these formulations were compared. The formulation F4 was containing 7% of SLS shows good

release on comparing with formulation F3 and F5 containing SLS 4% and 10% respectively.

Based on the formulation F4, the effect of osmotic agent was studied by decreasing the level of

Mannitol and Fructose concentration (34%) in formulation F6 and increasing the Mannitol and

Fructose concentration (46%) in formulation F7.The in-vitro drug release showed the

formulation F7 containing 46 % w/w osmotic agent shows release of 91.57% in 14 hours. It is

clearly evident that with increase in level of osmotic agent there is significant increase in drug

release.

January March 2011 RJPBCS Volume 2 Issue 1 Page No. 479

ISSN: 0975-8585

Kinetic modeling of drug release

The data obtained from in-vitro dissolution studies were fitted in different models viz.

zero order, first order, Higuchi and Korsemeyer- Peppas equation, the results were shown in

Table 5. The zero order plots were found to be fairly linear as indicated by their high regression

values (r2 = 0.9995 to 0.9999). To confirm the exact mechanism of drug release from these

tablets, the data were fitted according to zero order.

Scanning Electron Microscopy studies (SEM)

Figure 3a: SEM photograph of Formulation F7 before in-vitro studies

Figure 3b: SEM photograph of Formulation F7 after in-vitro studies

Results of SEM studies of Formulation F7 before and after in-vitro dissolution studies

were shown in Figure 3a and 3b. From this it is evident that the formation of pores in the

membrane after coming in contact with simulated colonic fluid and these pores will act as

orifice for the release of drug in colon.

January March 2011 RJPBCS Volume 2 Issue 1 Page No. 480

ISSN: 0975-8585

CONCLUSION

A microbially activated osmotic drug delivery (MAODS) for colon targeted Tinidazole

Tablets was developed and evaluated for physicochemical parameters such as appearance,

physical properties, drug content and in-vitro dissolution studies and stability studies. All the

physical characteristics of the formulations like thickness, hardness, friability, drug content, and

in-vitro dissolution study were found to be well within the limits and official standards. Based

on the in-vitro drug release pattern the formulation F7 was concluded as best formulation

among all prepared formulation for the treatment of Amoebiasis.

ACKNOWLEDGEMENTS

The authors are sincerely thankful to Adhiparasakthi College of pharmacy, Melmaruvathur,

Kanchipuram, for provided us infrastructure facilities and moral support to carry out this

research work.

REFERENCES

[1] Samuel L Stanley. Trends in Parasitology 2001; 17 (6):280-285.

[2] Naikwade Sonali R, Kulkarni Pratibha P, Jathar Shripad R, Bajaj Amrita N. DARU 2008; 16

(3): 119-127.

[3] Ahrabi S F, Madsen G, Dyrstad K, Sande S A, Graffner C. Eur J Pharm Sci 2000; 10: 43-52.

[4] Hu Z, Shimokawa T, Ohno T, Kimura G, Mawatari S, Kamitsnna M, Yoshikawa Y, Masuda

S, Takada K. J Drug Target 1999; 7: 223-232.

[5] Niwa K, Takaya T, Morimoto T, Takada I. J Drug Target 1995; 3: 83- 89.

[6] Sinha V R, Kumria R. Eur J Pharm Sci 2003; 18: 3-18.

[7] Patil S V, Kuchekar B S, Janugade B U. J Pharmacy Res 2009; 2(12): 1855-1856.

[8] Shah S H, Patel J K, Patel N V. Int J of PharmTech R 2009; 1: 823-833.

[9] Margret C R, Debjit B, Chiranjib, Jayakar B. Int J of Pharm Pharm Sci 2010; 2: 53-65.

[10] Ramakrishna N, Mishra B. Drug Dev Ind Pharm 2002; 28: 403-412.

[11] Abraham S, Srinath M S. Ind J Pharm Sci 2007; 69: 24-27.

[12] Indian Pharmacopoeia. Publications and information directorate (CSIR). New Delhi,

2007; (III): 1185.

[13] Krishnaiah Y S R, Muzib Y I, Bhaskar P, Satyanarayana V, Latha K. Drug Deliv 2003; 10:

263-268.

[14] www.aapsj.org/abstracts/AM_2008/AAPS2008-002500.PDF

[15] Kothawade Kishor B, Amrutkar Jitendra R, Gattani Surendra G, Patil Ulhas K. Int J

Pharma Excip 2008; 83- 88.

[16] Rajan K Verma, Sanjay Garg. European J Pharm Biopharm 2004; 57: 513525.

January March 2011 RJPBCS Volume 2 Issue 1 Page No. 481

Das könnte Ihnen auch gefallen

- GANDAPURA - 1 - Formulasi Dan Drug ReleaseDokument20 SeitenGANDAPURA - 1 - Formulasi Dan Drug ReleaseNadia Namira Devita SinagaNoch keine Bewertungen

- Floating Tablets of FamotidineDokument8 SeitenFloating Tablets of FamotidineRomah Cliquers LelledNoch keine Bewertungen

- 1 s2.0 S0939641102001200 Main PDFDokument8 Seiten1 s2.0 S0939641102001200 Main PDFCesar Rodolfo Angulo DelgadoNoch keine Bewertungen

- Development and Evaluation of Mucoadhesive Vaginal Tablet of Sertaconazole For Vaginal CandidiasisDokument8 SeitenDevelopment and Evaluation of Mucoadhesive Vaginal Tablet of Sertaconazole For Vaginal CandidiasisAnugrah ElfaNoch keine Bewertungen

- An Evaluation of The Potential Impact of Cherry Flavor On The Stability of Montelukast TabletsDokument8 SeitenAn Evaluation of The Potential Impact of Cherry Flavor On The Stability of Montelukast TabletsNurmawadha LaemboNoch keine Bewertungen

- JURNAL PEDIATRI 19-Vol.-3-Issue-1-Jan.-2012-RA-963-Paper-19Dokument3 SeitenJURNAL PEDIATRI 19-Vol.-3-Issue-1-Jan.-2012-RA-963-Paper-19AnditapitalokaNoch keine Bewertungen

- International Journal of PharmacyDokument6 SeitenInternational Journal of Pharmacygthic.underNoch keine Bewertungen

- Journal of Food EngineeringDokument7 SeitenJournal of Food EngineeringRaquel FernandesNoch keine Bewertungen

- Formulation and Evaluation of Floating Matrix Tablet of Losartan For Gastro-Retentive Drug DeliveryDokument6 SeitenFormulation and Evaluation of Floating Matrix Tablet of Losartan For Gastro-Retentive Drug DeliveryRaja AbhilashNoch keine Bewertungen

- Ijpsr10 01 08 04 PDFDokument11 SeitenIjpsr10 01 08 04 PDFStephanie FigueroaNoch keine Bewertungen

- Ijpir 16 403 - 98 110Dokument13 SeitenIjpir 16 403 - 98 110JeffNoch keine Bewertungen

- Studies On Formulation and Evaluation of Buccal Patch For Delivery of An Anti-Hypertensive DrugDokument8 SeitenStudies On Formulation and Evaluation of Buccal Patch For Delivery of An Anti-Hypertensive DrugInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- 407 415 PDFDokument9 Seiten407 415 PDFIIrsandi JohanNoch keine Bewertungen

- S1773-2247 (13) 50041-4 SemDokument7 SeitenS1773-2247 (13) 50041-4 SemRIZA ADHI SETIAWANNoch keine Bewertungen

- Capsule DeliveryDokument9 SeitenCapsule DeliveryADVOCATE ASHUTOSH SHARMANoch keine Bewertungen

- Sdarticle 2Dokument6 SeitenSdarticle 2setarehnaznazNoch keine Bewertungen

- Formulation, In-Vitro and In-Vivo Evaluation of Enteric Coated Pellets of Substituted Benzimidazole Proton Pump InhibitorDokument11 SeitenFormulation, In-Vitro and In-Vivo Evaluation of Enteric Coated Pellets of Substituted Benzimidazole Proton Pump InhibitorkavitaNoch keine Bewertungen

- Design and Evaluation of Ethyl Cellulose Sustained Release Matrix Tablets of TheophyllineDokument4 SeitenDesign and Evaluation of Ethyl Cellulose Sustained Release Matrix Tablets of TheophyllinePharmacist SsheenaamNoch keine Bewertungen

- Formulation and In-Vitro Characterisation of Sustained Releasemetronidazole Cocoa Butter SuppositoriesDokument7 SeitenFormulation and In-Vitro Characterisation of Sustained Releasemetronidazole Cocoa Butter SuppositoriesRowaidaNoch keine Bewertungen

- Research Article: Yash Paul, Sarvan Tyagi and Bhupinder SinghDokument11 SeitenResearch Article: Yash Paul, Sarvan Tyagi and Bhupinder SinghPUTRI DIVA AMARYLISNoch keine Bewertungen

- International Journal of Pharma and Bio Sciences V1 (2) 2010Dokument14 SeitenInternational Journal of Pharma and Bio Sciences V1 (2) 2010Ka KaaNoch keine Bewertungen

- Solid Dispersion ........Dokument31 SeitenSolid Dispersion ........Rishikesh ChakorNoch keine Bewertungen

- Cca 083 2010 371 377Dokument7 SeitenCca 083 2010 371 377vouudaosuNoch keine Bewertungen

- Gel FormulationDokument11 SeitenGel FormulationKhuncoro AdiNoch keine Bewertungen

- A Validated Stability Indicating Uplc Method For Montelukast Impurities in Montelukast Sodium Oral GranulesDokument12 SeitenA Validated Stability Indicating Uplc Method For Montelukast Impurities in Montelukast Sodium Oral GranulesHanimi ReddyNoch keine Bewertungen

- Formulation, Development and Evaluation of Gastroretentive Mucoadhesive Matrix Tablets Using Natural Polymers For Treatment of DepressionDokument15 SeitenFormulation, Development and Evaluation of Gastroretentive Mucoadhesive Matrix Tablets Using Natural Polymers For Treatment of DepressionabhitavNoch keine Bewertungen

- Formulation and Evaluation of Lansoprazole Delayed Release PelletsDokument19 SeitenFormulation and Evaluation of Lansoprazole Delayed Release PelletsUmair MazharNoch keine Bewertungen

- GC-MS Analysis of Phytocomponents On Whole Plant Extract Adiantum Capillus-Veneris L. - A Potential Folklore Medicinal PlantDokument6 SeitenGC-MS Analysis of Phytocomponents On Whole Plant Extract Adiantum Capillus-Veneris L. - A Potential Folklore Medicinal PlantRigotti BrNoch keine Bewertungen

- Development of Extended Release Matrix Tablets of Ranolazine Containing Polyacrylic and Ethylcellulose PolymersDokument12 SeitenDevelopment of Extended Release Matrix Tablets of Ranolazine Containing Polyacrylic and Ethylcellulose PolymersFaisal AbbasNoch keine Bewertungen

- Formulation and Evaluation of Atenolol Floating MicrospheresDokument6 SeitenFormulation and Evaluation of Atenolol Floating MicrospheresBaru Chandrasekhar RaoNoch keine Bewertungen

- Formulation and Evaluation of Prednisolone Tablet For Colon Targeted Drug Delivery SystemDokument11 SeitenFormulation and Evaluation of Prednisolone Tablet For Colon Targeted Drug Delivery SystemSiswa PomoNoch keine Bewertungen

- Preparation and Evaluation of Wound Healing Activity of Ursolic Acid Nanoemulgel Formulations in RatsDokument11 SeitenPreparation and Evaluation of Wound Healing Activity of Ursolic Acid Nanoemulgel Formulations in RatsRAPPORTS DE PHARMACIENoch keine Bewertungen

- Solubility Enhancement of Antihypertensive Agent by Solid Dispersion TechniqueDokument6 SeitenSolubility Enhancement of Antihypertensive Agent by Solid Dispersion Techniquedini hanifaNoch keine Bewertungen

- Experiment No:: Object/AimDokument9 SeitenExperiment No:: Object/AimSudeep KothariNoch keine Bewertungen

- Monte LukastDokument6 SeitenMonte LukastPham XuanNoch keine Bewertungen

- Metformin Hydrochloride Matrix TabletsDokument14 SeitenMetformin Hydrochloride Matrix TabletsSandeep KumarNoch keine Bewertungen

- FarfisDokument13 SeitenFarfisroslisilvia733Noch keine Bewertungen

- SpoDokument15 SeitenSpointan kusumaningtyasNoch keine Bewertungen

- Salbutamol Sulphate-Ethylcellulose Microparticles: Formulation and In-Vitro Evaluation With Emphasis On Mathematical ApproachesDokument8 SeitenSalbutamol Sulphate-Ethylcellulose Microparticles: Formulation and In-Vitro Evaluation With Emphasis On Mathematical ApproachesThiiwiie'thiiwiie PrathiiwiieNoch keine Bewertungen

- 2 Vinay (2012)Dokument15 Seiten2 Vinay (2012)Abdullah ZenNoch keine Bewertungen

- Final Research For PublicationDokument16 SeitenFinal Research For PublicationPriti DodejaNoch keine Bewertungen

- JDDR 139Dokument11 SeitenJDDR 139Earthjournal PublisherNoch keine Bewertungen

- Immediate Release Tablets of Telmisartan Using Superdisintegrant-Formulation, Evaluation and Stability StudiesDokument3 SeitenImmediate Release Tablets of Telmisartan Using Superdisintegrant-Formulation, Evaluation and Stability StudiesJosé Carlos Solís SuárezNoch keine Bewertungen

- ROSIGDokument8 SeitenROSIGSeptiani MarthaNoch keine Bewertungen

- Formulation and Evaluation of Mefenamic Acid Ointment Using Penetration EnhancersDokument5 SeitenFormulation and Evaluation of Mefenamic Acid Ointment Using Penetration EnhancersIndradewiNoch keine Bewertungen

- Formulation and Evaluation of MetronidazoleDokument16 SeitenFormulation and Evaluation of MetronidazoleInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- GSCBPS 2019 0082Dokument17 SeitenGSCBPS 2019 0082mwdhtirahNoch keine Bewertungen

- Chapter-4 Materials and MethodsDokument15 SeitenChapter-4 Materials and MethodsSunil ChaudharyNoch keine Bewertungen

- Full TextDokument7 SeitenFull TexttuayuNoch keine Bewertungen

- SR TabletDokument8 SeitenSR TabletKhánh ToànNoch keine Bewertungen

- Formulation and Evaluation of Buccal Patches of Simvastatin by Using Different PolymersDokument6 SeitenFormulation and Evaluation of Buccal Patches of Simvastatin by Using Different PolymersIsrawan AzisNoch keine Bewertungen

- Paper 2Dokument13 SeitenPaper 2Romah Cliquers LelledNoch keine Bewertungen

- Celecoxib NanosuspensionDokument8 SeitenCelecoxib NanosuspensionsundarNoch keine Bewertungen

- Pharmaceutics 12 00628Dokument21 SeitenPharmaceutics 12 00628Santiago LopezNoch keine Bewertungen

- Formulation and in Vitro Evaluation of Mucoadhesive Tablets of Ofloxacin Using Natural GumsDokument6 SeitenFormulation and in Vitro Evaluation of Mucoadhesive Tablets of Ofloxacin Using Natural Gumsabdi100% (1)

- 2459 FullDokument18 Seiten2459 FullEnggerianiNoch keine Bewertungen

- Attachment PDFDokument10 SeitenAttachment PDFHEPHZIBAH CHILAKANoch keine Bewertungen

- Formulation Development and In-Vitro Evaluation of Bucoadhesive Tablet of Chlorpheniramine Maleate and Phenylephrine Hydrochloride in Combined Dosage FormDokument11 SeitenFormulation Development and In-Vitro Evaluation of Bucoadhesive Tablet of Chlorpheniramine Maleate and Phenylephrine Hydrochloride in Combined Dosage FormNeerajNoch keine Bewertungen

- Physical and Release Properties of Metronidazole SuppositoriesDokument10 SeitenPhysical and Release Properties of Metronidazole SuppositoriesZainab Eassa JassimNoch keine Bewertungen

- Update Stock PT KMD 14-6Dokument46 SeitenUpdate Stock PT KMD 14-6rio1995Noch keine Bewertungen

- Semester 1 Pusk. PancurDokument60 SeitenSemester 1 Pusk. Pancurrio1995Noch keine Bewertungen

- KundiDokument10 SeitenKundirio1995Noch keine Bewertungen

- Price List Pt. Govindo Saudara Jaya Produk Pt. Berlico: NO Nama Barang Komposisi Kemasan Hna+PpnDokument42 SeitenPrice List Pt. Govindo Saudara Jaya Produk Pt. Berlico: NO Nama Barang Komposisi Kemasan Hna+Ppnrio1995Noch keine Bewertungen

- Templete Master Data PKM JebusDokument987 SeitenTemplete Master Data PKM Jebusrio1995Noch keine Bewertungen

- Rekapitulasi Oktober 2021Dokument13 SeitenRekapitulasi Oktober 2021rio1995Noch keine Bewertungen

- Laporan Mutasi Unit Gawat Darurat Semester 2 Tahun 2020Dokument23 SeitenLaporan Mutasi Unit Gawat Darurat Semester 2 Tahun 2020rio1995Noch keine Bewertungen

- Short Stories Circus Escape Transcript PDFDokument2 SeitenShort Stories Circus Escape Transcript PDFAmineGhobNoch keine Bewertungen

- Obat Apotek 1Dokument8 SeitenObat Apotek 1rio1995Noch keine Bewertungen

- Obat Apotek 1Dokument8 SeitenObat Apotek 1rio1995Noch keine Bewertungen

- Brochifar Plus Kap 35664 100 1Dokument15 SeitenBrochifar Plus Kap 35664 100 1rio1995Noch keine Bewertungen

- Nama Obat Indikasi / Kegunaan Komposisi /nama Generik: Brochifar Plus Kap PCT, DMP, Ppa, CTM Batuk, Flu, DemamDokument52 SeitenNama Obat Indikasi / Kegunaan Komposisi /nama Generik: Brochifar Plus Kap PCT, DMP, Ppa, CTM Batuk, Flu, Demamrio1995Noch keine Bewertungen

- Heart Attack-WPS OfficeDokument1 SeiteHeart Attack-WPS OfficeSadistJudger 1128Noch keine Bewertungen

- AaaaDokument57 SeitenAaaario1995Noch keine Bewertungen

- 168 477 1 SMDokument3 Seiten168 477 1 SMrio1995Noch keine Bewertungen

- Carbohydrates MetabolismDokument152 SeitenCarbohydrates Metabolismrio1995Noch keine Bewertungen

- In Vitro Antifungal Activity of Naphthoquinone Derivatives: Kenroh S, Hidetomo A, and Fumihiko YDokument2 SeitenIn Vitro Antifungal Activity of Naphthoquinone Derivatives: Kenroh S, Hidetomo A, and Fumihiko Yrio1995Noch keine Bewertungen

- Test Nilai by IndryDokument1 SeiteTest Nilai by Indryrio1995Noch keine Bewertungen

- DV November16 WebDokument26 SeitenDV November16 WebAndrew Van WyngardenNoch keine Bewertungen

- 11-6 Valeriewren PDFDokument9 Seiten11-6 Valeriewren PDFPierre A. RodulfoNoch keine Bewertungen

- Crown LengtheningDokument4 SeitenCrown LengtheningArdelvie YoandaNoch keine Bewertungen

- Anesthesia in Dentistry and Extraction of Tooth by Pratyasha ParipurnaDokument42 SeitenAnesthesia in Dentistry and Extraction of Tooth by Pratyasha ParipurnapariNoch keine Bewertungen

- Adult and Elder I. Nursing Care PlanDokument6 SeitenAdult and Elder I. Nursing Care PlanteresapazNoch keine Bewertungen

- Surgery: Epithelial FormationDokument12 SeitenSurgery: Epithelial FormationReuben AntiNoch keine Bewertungen

- Rangkuman TeratomaDokument22 SeitenRangkuman TeratomaFelicia Fernanda IskandarNoch keine Bewertungen

- Dha LastDokument197 SeitenDha LastCarlos Vidal Tudela89% (27)

- Post Operative and Pre Prosthetic ManagementDokument38 SeitenPost Operative and Pre Prosthetic ManagementTanzeelah RajawNoch keine Bewertungen

- Intrathecal Injection (LP) ENGDokument1 SeiteIntrathecal Injection (LP) ENGAlina RadescuNoch keine Bewertungen

- Red, Yellow and Green Flags For Low Back Pain: For Serious Underlying DiseaseDokument1 SeiteRed, Yellow and Green Flags For Low Back Pain: For Serious Underlying DiseaseShafira DianiNoch keine Bewertungen

- Chemical Properties of LycopeneDokument4 SeitenChemical Properties of LycopeneCliff Setya GazaliNoch keine Bewertungen

- Treatment and Management of AstrocytomaDokument2 SeitenTreatment and Management of AstrocytomaAqila MumtazNoch keine Bewertungen

- Jethani 2022Dokument3 SeitenJethani 2022febyolaNoch keine Bewertungen

- Mindful Medical Practice - Clinical Narratives and Therapeutic InsightsDokument169 SeitenMindful Medical Practice - Clinical Narratives and Therapeutic InsightsSkg KonNoch keine Bewertungen

- Presentation On STP (SBR)Dokument8 SeitenPresentation On STP (SBR)Leo VictorNoch keine Bewertungen

- Portable Toilet For Disaster Relief KinstedtDokument3 SeitenPortable Toilet For Disaster Relief KinstedtMustafa HyaliNoch keine Bewertungen

- Wilhelm Reich Contact With SpaceDokument6 SeitenWilhelm Reich Contact With Spacebubbaclem100% (2)

- KKDAT Lecture, Re PNP Program Trust For Illegal DrugsDokument43 SeitenKKDAT Lecture, Re PNP Program Trust For Illegal Drugsrochelle palino85% (33)

- Assessment Needs Nursing Diagnos IS Goal/Obj Ective Intervention Rationale EvaluationDokument10 SeitenAssessment Needs Nursing Diagnos IS Goal/Obj Ective Intervention Rationale EvaluationApol Pen67% (3)

- The Diagnosis and Treatment of Breakthrough Pain PDFDokument139 SeitenThe Diagnosis and Treatment of Breakthrough Pain PDFSantiago HerreraNoch keine Bewertungen

- PMLS Lesson 4Dokument3 SeitenPMLS Lesson 4Void MelromarcNoch keine Bewertungen

- Wikipedia - Couvelaire Uterus - Wikipedia, The Free EncyclopediaDokument2 SeitenWikipedia - Couvelaire Uterus - Wikipedia, The Free EncyclopediaPabloGBNoch keine Bewertungen

- OsteosarcomaDokument25 SeitenOsteosarcomaChaitra Mahesh67% (3)

- Nurs 103 - Scholarly Research AssignmentDokument8 SeitenNurs 103 - Scholarly Research Assignmentapi-315231385Noch keine Bewertungen

- Mindfulness Interventions For Nursing Students: Application of Modelling and Role Modelling TheoryDokument7 SeitenMindfulness Interventions For Nursing Students: Application of Modelling and Role Modelling Theoryagnesia yusupNoch keine Bewertungen

- NCP 1Dokument4 SeitenNCP 1Ke EjieNoch keine Bewertungen

- Postpartum Care: Emergency SignsDokument13 SeitenPostpartum Care: Emergency SignsJohnnette BedoniaNoch keine Bewertungen

- Chap.30 Complications From Heart Disease WordDokument6 SeitenChap.30 Complications From Heart Disease WordcaisakiNoch keine Bewertungen

- Jordo's Beginner's Guide To Healthy and Sustainable Dieting PDFDokument22 SeitenJordo's Beginner's Guide To Healthy and Sustainable Dieting PDFSol Albi100% (2)

- Advisor Vol 14Dokument8 SeitenAdvisor Vol 14ninh2dNoch keine Bewertungen

- Waste Management ProcedureDokument3 SeitenWaste Management ProcedureBoby ThomasNoch keine Bewertungen