Beruflich Dokumente

Kultur Dokumente

7.QP-Special Coaching Test 3

Hochgeladen von

vsureshkannanmsec0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

15 Ansichten1 SeiteThis document contains questions from a heat and mass transfer exam for a mechanical engineering course. It includes the following questions:

1. Estimating the thickness of a condensate film and local heat transfer coefficient for saturated steam condensing on a vertical tube.

2. Calculating the heat transfer rate and condensate mass per hour for dry saturated steam condensing on a vertical plate, and the exit temperatures for cooling oil in a double pipe counterflow heat exchanger.

3. Determining the area of a parallel flow heat exchanger using effectiveness-NTU approach to cool a hot water stream from 75C to 50C, and calculating the effectiveness and outlet temperatures for cooling a chemical from 120C using

Originalbeschreibung:

mn

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document contains questions from a heat and mass transfer exam for a mechanical engineering course. It includes the following questions:

1. Estimating the thickness of a condensate film and local heat transfer coefficient for saturated steam condensing on a vertical tube.

2. Calculating the heat transfer rate and condensate mass per hour for dry saturated steam condensing on a vertical plate, and the exit temperatures for cooling oil in a double pipe counterflow heat exchanger.

3. Determining the area of a parallel flow heat exchanger using effectiveness-NTU approach to cool a hot water stream from 75C to 50C, and calculating the effectiveness and outlet temperatures for cooling a chemical from 120C using

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

15 Ansichten1 Seite7.QP-Special Coaching Test 3

Hochgeladen von

vsureshkannanmsecThis document contains questions from a heat and mass transfer exam for a mechanical engineering course. It includes the following questions:

1. Estimating the thickness of a condensate film and local heat transfer coefficient for saturated steam condensing on a vertical tube.

2. Calculating the heat transfer rate and condensate mass per hour for dry saturated steam condensing on a vertical plate, and the exit temperatures for cooling oil in a double pipe counterflow heat exchanger.

3. Determining the area of a parallel flow heat exchanger using effectiveness-NTU approach to cool a hot water stream from 75C to 50C, and calculating the effectiveness and outlet temperatures for cooling a chemical from 120C using

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

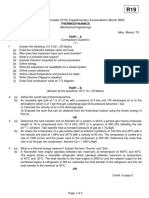

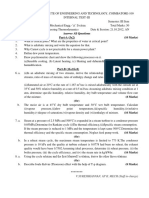

COIMBATORE INSTITUTE OF ENGINEERING AND (ii) Dry saturated steam at a pressure of 2.

45 bar condenses on the

TECHNOLOGY, COIMBATORE-109 surface of a vertical tube of height 1 m. The tube surface

DEPARTMENT OF MECHANICAL ENGINEERING temperature is kept at 117C. Estimate the thickness of the

condensate film and the local heat transfer coefficient at a distance

Special coaching test-III

of 0.2m from the upper end of the tube. (8)

Year : III Yr Semester: V Sem (Or)

Branch & Section : B.E., Mechanical Engg.-A Sec Total Marks: 60 b. (i) A vertical plate 0.5 m2 in area at temperature of 92C is

Subject Name : Heat and Mass Transfer exposed to steam at atmospheric pressure. If the steam is dry and

Date & Session : 25.09.2015, AN saturated, estimate the heat transfer rate and condensate mass per

Answer All Questions hour. The vertical length of the plate is 0.5 m. Properties of water

(Use of Heat and Mass Transfer data book and steam table is at film temperatures of 96C can be obtained from tables. (8)

(ii) It is desired to use a double pipe counter flow heat exchanger

permitted)

to cool 3 kg/s of oil (Cp=2.1 kJ/kgK) from 120C. Cooling water

Part A (6x2=12 Marks) at 20C enters the heat exchanger at a rate of 10 kg/s.The over all

1. What is meant by film wise condensation? heat transfer coefficient of the heat exchanger is 600 W/m2K and

2. Give the application of boiling and condensation. the heat transfer area is 6 m2. Calculate the exit temperatures of oil

3. What is meant by drop wise condensation? and water. (8)

4. What do you meant by fouling factor? State the causes of fouling.

5. What is heat exchanger? Where are they used? 9. a. A parallel flow heat exchanger has hot and cold water stream

6. Define effectiveness of the heat exchanger. running through it, the flow rates are 10 and 25 kg/min

Part B (3x 16=48 Marks) respectively. Inlet temperatures are 75 C and 25 C on hot and

7. a.(i) With a neat and labeled sketch, explain the various regimes cold sides. The exit temperature on the hot side should not exceed

50C. Assume hi= ho= 600 W/m2K. Calculate the area of heat

in boiling heat transfer.(10) exchanger using E -NTU approach.(16)

(ii) A nickel wire carrying electric current of 1.5mm diameter and (Or)

50 cm long, is submerged in a water bath which is open to b. A chemical having specific heat of 3.3 kJ/kgK at a rate of

atmospheric pressure. Calculate the voltage at the burn out point, 20000 kg/h enters a parallel flow heat exchanger at 120C. The

if at this point the wire carries a current of 200A. (6) flow rate of cooling water is 50000 kg/h with an inlet temperature

(Or) of 20C. The heat transfer area is 10 m2 and overall heat transfer

b. A tube of 2 m length and 25 mm outer diameter is to be used to co efficient is 1050 W/m2K. Find (i) The effectiveness of the heat

condense saturated steam at 100C while the tube surface is exchanger, (ii) Outlet temperature of water and chemical. Take Cp

maintained at 92C. Estimate the average heat transfer coefficient

of water as 4.186 kJ/kgK. (16)

and the rate of condensation of steam if the tube is kept horizontal.

The steam condenses on the outside of the tube. (16) *****

8. a. (i) It is desired to boil water at atmospheric pressure on a copper V.Sureshkannan, AP II, Mech

surface which electrically heated. Estimate the heat flux from the Faculty In-charge

surface to the water, if the surface is maintained at 110C and also

the peak heat flux. (8)

Das könnte Ihnen auch gefallen

- Equation of State of Ideal Gases With Cobra 4Dokument10 SeitenEquation of State of Ideal Gases With Cobra 4DanielLugoNoch keine Bewertungen

- Use of Heat and Mass Transfer Data Books, Steam Tables Are PermittedDokument4 SeitenUse of Heat and Mass Transfer Data Books, Steam Tables Are Permitted3rajaNoch keine Bewertungen

- Sri Ramanujar Engineering CollegeDokument3 SeitenSri Ramanujar Engineering CollegeVenkatesh ArumugamNoch keine Bewertungen

- Me6502 Nov Dec 2016 PDFDokument3 SeitenMe6502 Nov Dec 2016 PDFKannan MuthusamyNoch keine Bewertungen

- Heat Transfer Assignment QuestionsDokument2 SeitenHeat Transfer Assignment QuestionsMurali KrishnaNoch keine Bewertungen

- Me6502 Apr May 2017 PDFDokument4 SeitenMe6502 Apr May 2017 PDFKannan MuthusamyNoch keine Bewertungen

- HMT - Docx SSVDokument2 SeitenHMT - Docx SSVcyberlogxNoch keine Bewertungen

- Question Paper Code:: Reg. No.Dokument4 SeitenQuestion Paper Code:: Reg. No.kannanNoch keine Bewertungen

- CH8591 - Heat TransferDokument5 SeitenCH8591 - Heat TransferS9048 SUDHARSAN ANoch keine Bewertungen

- Exam QuestionsDokument3 SeitenExam Questionswameath100% (1)

- (Sem. Iv) Theory Examination 2013-14: PAPER ID: 151406Dokument2 Seiten(Sem. Iv) Theory Examination 2013-14: PAPER ID: 151406Sarvesh KumarNoch keine Bewertungen

- 2021 July CHT204-ADokument4 Seiten2021 July CHT204-ANikhilNoch keine Bewertungen

- Department of Mechanical Engineering: B. V. Raju Institute of Technology (Autonomous)Dokument2 SeitenDepartment of Mechanical Engineering: B. V. Raju Institute of Technology (Autonomous)Murali KrishnaNoch keine Bewertungen

- Question Paper Code:: Reg. No.Dokument3 SeitenQuestion Paper Code:: Reg. No.jgkgopiNoch keine Bewertungen

- r05320306 Heat TransferDokument8 Seitenr05320306 Heat TransferSrinivasa Rao GNoch keine Bewertungen

- Assignment 2Dokument2 SeitenAssignment 2PNNoch keine Bewertungen

- KCT 2010-2011 HTDokument4 SeitenKCT 2010-2011 HTask4krishnanNoch keine Bewertungen

- Question Paper HMT - CO Mapping - SampleDokument6 SeitenQuestion Paper HMT - CO Mapping - SamplejayanthikrishnanNoch keine Bewertungen

- R07 Set No. 2Dokument8 SeitenR07 Set No. 2bhaskar5377Noch keine Bewertungen

- JNTU Old Question Papers 2007Dokument8 SeitenJNTU Old Question Papers 2007Srinivasa Rao G100% (3)

- Heat Transfer Jan2003 NR 320305Dokument8 SeitenHeat Transfer Jan2003 NR 320305Nizam Institute of Engineering and Technology LibraryNoch keine Bewertungen

- B.Tech II Year II Semester (R19) Supplementary Examinations March 2022Dokument2 SeitenB.Tech II Year II Semester (R19) Supplementary Examinations March 2022MECH HODNoch keine Bewertungen

- Code No: 45081Dokument8 SeitenCode No: 45081SRINIVASA RAO GANTANoch keine Bewertungen

- Chn-201 Tutorial 2 - Autumn 16-17-1Dokument2 SeitenChn-201 Tutorial 2 - Autumn 16-17-1Prashant RajNoch keine Bewertungen

- Department of Chemical Engineering Indian Institute of Technology RoorkeeDokument2 SeitenDepartment of Chemical Engineering Indian Institute of Technology Roorkeepushkal0% (2)

- B.Tech. Degree Examination: Instructions: Each Module Carries 12 MarksDokument3 SeitenB.Tech. Degree Examination: Instructions: Each Module Carries 12 MarksKalidindi sai tharunNoch keine Bewertungen

- Digital Assignement II Summer II, 2018-19 MEE 2005-Heat Transfer Last Date of Submission: 27.06.2019 (Choose Any 5 If You Have Limited Time)Dokument1 SeiteDigital Assignement II Summer II, 2018-19 MEE 2005-Heat Transfer Last Date of Submission: 27.06.2019 (Choose Any 5 If You Have Limited Time)vedant hiwarkarNoch keine Bewertungen

- 07a40801 Process Heat TransferDokument8 Seiten07a40801 Process Heat TransferSRINIVASA RAO GANTANoch keine Bewertungen

- Internal Test II-21.03.2013Dokument1 SeiteInternal Test II-21.03.2013vsureshkannanmsecNoch keine Bewertungen

- Instructions:: Gujarat Technological UniversityDokument2 SeitenInstructions:: Gujarat Technological UniversityKislay ChoudharyNoch keine Bewertungen

- Heat Transfer (HT) QueDokument6 SeitenHeat Transfer (HT) QueAshutosh KushwanshiNoch keine Bewertungen

- QP1 PDFDokument3 SeitenQP1 PDFArasuNoch keine Bewertungen

- Heat Transfer 1990-2003 1643994287402Dokument22 SeitenHeat Transfer 1990-2003 1643994287402Anshu MeenaNoch keine Bewertungen

- Heat TransferDokument2 SeitenHeat TransferAmal JoyNoch keine Bewertungen

- Heat Transfer Paper - IV: B.Tech. Fifth Semester (Chemical Engineering) (C.B.S.)Dokument2 SeitenHeat Transfer Paper - IV: B.Tech. Fifth Semester (Chemical Engineering) (C.B.S.)Anurag TalwekarNoch keine Bewertungen

- HMT 113401 Anna UnivDokument5 SeitenHMT 113401 Anna Univsathiya_ramNoch keine Bewertungen

- Heat Transfer-HTDokument2 SeitenHeat Transfer-HTSuthari AmbikaNoch keine Bewertungen

- Exercise - Transport ProcessesDokument3 SeitenExercise - Transport ProcessesJan Mark FongfarNoch keine Bewertungen

- r05320306 Heat TransferDokument8 Seitenr05320306 Heat TransferSRINIVASA RAO GANTANoch keine Bewertungen

- Cycle Test 1 Set1Dokument6 SeitenCycle Test 1 Set1logeshboy007Noch keine Bewertungen

- SRM University: Part - A Answer ALL Questions (10 X 2 20 Marks)Dokument2 SeitenSRM University: Part - A Answer ALL Questions (10 X 2 20 Marks)Ruby SmithNoch keine Bewertungen

- (Ae8301)Dokument4 Seiten(Ae8301)aerochandru.87Noch keine Bewertungen

- Heat Transfer - R2015 - 23-10-2018Dokument2 SeitenHeat Transfer - R2015 - 23-10-2018G.Chaitanya KiranNoch keine Bewertungen

- Farooque PDFDokument17 SeitenFarooque PDFMandip KumarNoch keine Bewertungen

- Tutorial 3 SolutionDokument5 SeitenTutorial 3 Solutionngoc.nguyennhuNoch keine Bewertungen

- ME302-A April 2018 PDFDokument2 SeitenME302-A April 2018 PDFMechanical EngineeringNoch keine Bewertungen

- HmtsDokument2 SeitenHmtsYathish YathiNoch keine Bewertungen

- Heat Transfer May2004 NR 310803Dokument8 SeitenHeat Transfer May2004 NR 310803Nizam Institute of Engineering and Technology LibraryNoch keine Bewertungen

- Model Exam.2.2Dokument3 SeitenModel Exam.2.2Srinivasan PichandiNoch keine Bewertungen

- 4363 112 Heat TransferDokument6 Seiten4363 112 Heat Transferyogesh_b_kNoch keine Bewertungen

- AE8301 Aero Engineering Thermodynamics, QP, Model (2020 - 2021) - SDokument2 SeitenAE8301 Aero Engineering Thermodynamics, QP, Model (2020 - 2021) - SGurunath AeroNoch keine Bewertungen

- NTK/KW/15/7829Dokument4 SeitenNTK/KW/15/7829Anurag TalwekarNoch keine Bewertungen

- Heat Transfer: B.Tech. (Chemical Engineering) Fifth Semester (C.B.S.)Dokument2 SeitenHeat Transfer: B.Tech. (Chemical Engineering) Fifth Semester (C.B.S.)Anurag TalwekarNoch keine Bewertungen

- rr320306 Heat TransferDokument8 Seitenrr320306 Heat TransferSrinivasa Rao G100% (2)

- AUPHMTmj 07Dokument4 SeitenAUPHMTmj 07Khadeeja NicyNoch keine Bewertungen

- IES CONV Mechanical Engineering 1991Dokument7 SeitenIES CONV Mechanical Engineering 1991GURURAJ CNoch keine Bewertungen

- BKF2423 Heat Transfer Sem 2 1718Dokument5 SeitenBKF2423 Heat Transfer Sem 2 1718Tony AngNoch keine Bewertungen

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"Von EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"Noch keine Bewertungen

- Tutorial & AssignmentDokument6 SeitenTutorial & AssignmentvsureshkannanmsecNoch keine Bewertungen

- Coimbatore Institute of Engineering and Technology, Coimbatore-641109 Internal Test-IiiDokument2 SeitenCoimbatore Institute of Engineering and Technology, Coimbatore-641109 Internal Test-IiivsureshkannanmsecNoch keine Bewertungen

- Faculty In-Charge V.Sureshkannan, Ap Ii, MechDokument1 SeiteFaculty In-Charge V.Sureshkannan, Ap Ii, MechvsureshkannanmsecNoch keine Bewertungen

- 2.qp-Hmt-It IDokument1 Seite2.qp-Hmt-It IvsureshkannanmsecNoch keine Bewertungen

- Coimbatore Institute of Engineering and Technology, Coimbatore-641109 Internal Test-IDokument1 SeiteCoimbatore Institute of Engineering and Technology, Coimbatore-641109 Internal Test-IvsureshkannanmsecNoch keine Bewertungen

- Part A (5x2 10) : V.Sureshkannan, Ap Ii, MechDokument1 SeitePart A (5x2 10) : V.Sureshkannan, Ap Ii, MechvsureshkannanmsecNoch keine Bewertungen

- Part A (5x2 10) : V.Sureshkannan, Ap Ii, MechDokument1 SeitePart A (5x2 10) : V.Sureshkannan, Ap Ii, MechvsureshkannanmsecNoch keine Bewertungen

- 4.cycle Test Ii-03.09.13Dokument1 Seite4.cycle Test Ii-03.09.13vsureshkannanmsecNoch keine Bewertungen

- Part A (5x2 10) : V.Sureshkannan, Ap Ii, MechDokument1 SeitePart A (5x2 10) : V.Sureshkannan, Ap Ii, MechvsureshkannanmsecNoch keine Bewertungen

- 8.assignment Tutorial QPDokument13 Seiten8.assignment Tutorial QPvsureshkannanmsecNoch keine Bewertungen

- 8.assignment Tutorial QPDokument13 Seiten8.assignment Tutorial QPvsureshkannanmsecNoch keine Bewertungen

- 6.it Ii-RetestDokument1 Seite6.it Ii-RetestvsureshkannanmsecNoch keine Bewertungen

- Answer All Questions Part-A (5x2) (10 Marks) : V.SURESHKANNAN, AP II, MECH (Staff In-Charge)Dokument1 SeiteAnswer All Questions Part-A (5x2) (10 Marks) : V.SURESHKANNAN, AP II, MECH (Staff In-Charge)vsureshkannanmsecNoch keine Bewertungen

- Answer All Questions Part-A (5x2) (10 Marks)Dokument2 SeitenAnswer All Questions Part-A (5x2) (10 Marks)vsureshkannanmsecNoch keine Bewertungen

- Cycle Test I-10.09.13-Cse ADokument1 SeiteCycle Test I-10.09.13-Cse AvsureshkannanmsecNoch keine Bewertungen

- Internal Test III-cse ADokument1 SeiteInternal Test III-cse AvsureshkannanmsecNoch keine Bewertungen

- Coimbatore Institute of Engineering and Technology COIMBATORE-641 109 Internal Test-IDokument2 SeitenCoimbatore Institute of Engineering and Technology COIMBATORE-641 109 Internal Test-IvsureshkannanmsecNoch keine Bewertungen

- Internal Test II-21.03.2013Dokument1 SeiteInternal Test II-21.03.2013vsureshkannanmsecNoch keine Bewertungen

- Quantum Mechanical Carnot Engine: Journal of Physics A General Physics July 2000Dokument11 SeitenQuantum Mechanical Carnot Engine: Journal of Physics A General Physics July 2000Kin MattNoch keine Bewertungen

- Improvements in Strength and Stress Corrosion Cracking Properties in Aluminum Alloy 7075 Via Low-Temperature Retrogression and Re-Aging Heat Treatments PDFDokument9 SeitenImprovements in Strength and Stress Corrosion Cracking Properties in Aluminum Alloy 7075 Via Low-Temperature Retrogression and Re-Aging Heat Treatments PDFvijayNoch keine Bewertungen

- Heat Transfer: Anna University Question BankDokument6 SeitenHeat Transfer: Anna University Question BankaeroacademicNoch keine Bewertungen

- Design and Experimental Results For The S825 AirfoilDokument89 SeitenDesign and Experimental Results For The S825 AirfoilTakaya SakuraiNoch keine Bewertungen

- Pile Load Capacity Below Scour For Sump - 0.21ncorrected - SELF WEIGHTDokument18 SeitenPile Load Capacity Below Scour For Sump - 0.21ncorrected - SELF WEIGHTP Allen Samuel IgnatiusNoch keine Bewertungen

- CHEM 1332 Thermodynamics: DefinitionsDokument2 SeitenCHEM 1332 Thermodynamics: DefinitionszaneNoch keine Bewertungen

- Coolship Calc - Cylindrical and RectangularDokument5 SeitenCoolship Calc - Cylindrical and RectangularNicolas MossoNoch keine Bewertungen

- Progressive Failure Analysis of FRC Containing HoleDokument16 SeitenProgressive Failure Analysis of FRC Containing HoleaamirmubNoch keine Bewertungen

- Application of Diferential Scanning CalorimetryDokument4 SeitenApplication of Diferential Scanning CalorimetryUsman GhaniNoch keine Bewertungen

- AndreFarinha PDFDokument28 SeitenAndreFarinha PDFGianc87Noch keine Bewertungen

- Practice Problems On First Law For Closed SystemDokument3 SeitenPractice Problems On First Law For Closed SystemNetra PujarNoch keine Bewertungen

- BucklingDokument7 SeitenBucklingMohammad BurhanNoch keine Bewertungen

- Condensers PDFDokument29 SeitenCondensers PDFsandhya100% (1)

- Significance of Air Movement For Thermal Comfort in Warm ClimatesIndragantiDokument15 SeitenSignificance of Air Movement For Thermal Comfort in Warm ClimatesIndragantiAmit MendirattaNoch keine Bewertungen

- Structural Design and Drawing of Clarifloculator Chiragaon 10MLDDokument4 SeitenStructural Design and Drawing of Clarifloculator Chiragaon 10MLDShashank0% (1)

- Bomag HidraulicaDokument24 SeitenBomag HidraulicaDaniel Castillo Peña100% (1)

- Unit III (Multi Pressure and Evaporator VCC)Dokument4 SeitenUnit III (Multi Pressure and Evaporator VCC)Nyan Ye HtetNoch keine Bewertungen

- AISC Basic Steel Design Session 6 - Stability Analysis and Design I 10-29-2013Dokument28 SeitenAISC Basic Steel Design Session 6 - Stability Analysis and Design I 10-29-2013Eric RicoNoch keine Bewertungen

- Catalogo de Peças Mastro SPB 28 Vector - Inglês (20989739) R-1Dokument109 SeitenCatalogo de Peças Mastro SPB 28 Vector - Inglês (20989739) R-1dhmartiniNoch keine Bewertungen

- Me 6512 Thermal Engineering Lab Manual 2013 RegulationDokument94 SeitenMe 6512 Thermal Engineering Lab Manual 2013 RegulationSujith JNoch keine Bewertungen

- Pile Foundation Design: Dr. Magdi ZumrawiDokument19 SeitenPile Foundation Design: Dr. Magdi Zumrawiahmed_cv30Noch keine Bewertungen

- Simulation Sugarcane JuiceDokument9 SeitenSimulation Sugarcane JuiceYorman Zambrano SilvaNoch keine Bewertungen

- COACHING NOTES MATH 2.pptx Version 1Dokument221 SeitenCOACHING NOTES MATH 2.pptx Version 1AjayBravoNoch keine Bewertungen

- Attachment 3. Cooling Water BalanceDokument1 SeiteAttachment 3. Cooling Water Balanceandrieysyah2525Noch keine Bewertungen

- Bauschinger EffectDokument4 SeitenBauschinger EffectBishowkumar ShresthaNoch keine Bewertungen

- General Tank Data ExampleDokument6 SeitenGeneral Tank Data ExampleDAVE100% (1)

- Bolt ConnectionDokument10 SeitenBolt ConnectionHitesh Vishwakarma100% (2)

- Structural Design of Heavy Duty Block PavementDokument12 SeitenStructural Design of Heavy Duty Block PavementFay NandaNoch keine Bewertungen