Beruflich Dokumente

Kultur Dokumente

EXB Cast Iron Junction Boxes: Explosionproof, Dust-Ignitionproof, Integrally Cast Mounting Feet

Hochgeladen von

alexmontellOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

EXB Cast Iron Junction Boxes: Explosionproof, Dust-Ignitionproof, Integrally Cast Mounting Feet

Hochgeladen von

alexmontellCopyright:

Verfügbare Formate

K-40

Class I, Div. 1 and 2

Group D EXB Cast Iron Junction Boxes:

Class II, Div. 1 and 2 Groups E,F,G Explosionproof, Dust-Ignitionproof,

Class III

Integrally Cast Mounting Feet

Drilled and tapped openings 1/2 thru 6 as specified.

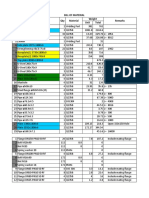

Nom. Inside Approx. Max. Nom. Inside Approx. Max.

Dimensions Side Wall Conduit Dimensions Side Wall Conduit

in Inches Thickness Size Catalog in Inches Thickness Size Catalog

LxWxD in Inches (In.) Number LxWxD in Inches (In.) Number

4x4x4 0.47 2 EXB040404 18x12x6 0.81 3-1/2 EXB181206

6x6x4 0.63 2 EXB060604 18x12x8 0.81 5 EXB181208

6x6x6 0.63 3-1/2 EXB060606 18x12x12 0.81 6 EXB181212

8x6x4 0.63 2 EXB080604 18x18x6 0.88 3-1/2 EXB181806

8x6x6 0.63 3-1/2 EXB080606 18x18x8 0.88 5 EXB181808

8x8x4 0.63 2 EXB080804 18x18x12 0.88 6 EXB181812

8x8x6 0.63 3-1/2 EXB080806 24x12x8 0.81 5 EXB241208

8x8x8 0.63 5 EXB080808 24x12x10 0.81 6 EXB241210

10x8x4 0.63 2 EXB100804 24x12x12 0.81 6 EXB241212

10x8x6 0.63 3-1/2 EXB100806 24x18x6 0.94 3 EXB241806

10x8x8 0.63 5 EXB100808 24x18x8 0.94 6 EXB241808

10x10x4 0.63 2 EXB101004 24x18x10 0.94 6 EXB241810

10x10x6 0.63 3-1/2 EXB101006 24x18x12 0.94 6 EXB241812

10x10x8 0.63 5 EXB101008 24x24x8 0.94 5 EXB242408

12x8x4 0.63 2 EXB120804 24x24x12 0.94 6 EXB242412

12x12x4 0.69 2 EXB121204 30x12x10 1.06 6 EXB301210

12x12x6 0.69 3-1/2 EXB121206 30x24x8 1.06 5 EXB302408

12x12x8 0.69 5 EXB121208 30x24x10 1.06 6 EXB302410

12x12x10 0.69 6 EXB121210 30x24x12 1.06 6 EXB302412

12x12x12 0.69 6 EXB121212

18x12x4 0.81 2 EXB181204

See EXB Ordering Information page for

Factory Installed Options drilling and tapping options.

Description Suffix

Mounting Plate WYM*

Hinges HNG

* Refer to page C-10 for Mounting Plate

details.

K

Features: EXB Series

(Cast Iron)

Wide selection of sizes and locations Hinges (Malleable Iron, Hot Dip Galvanized)

for drilled and tapped openings. EXB Box Size Catalog No. No. of Hinges

Cast iron box and cover with hot dip Per Set

galvanized finish.

Up to 12 x 12 AHNG-22G 2

Extra wide, accurately ground

AHNG-23G

mating surfaces with closely spaced Up to 24 x 18 2

stainless steel hex-head cap screws Up to 30 x 12 AHNG-24G 2

assure a flame-tight joint.

Provided with mounting lugs. Larger than 30 x 12 AHNG-34G 3

Standard Materials:

EXB: cast iron bodies and covers.

Standard Finish:

EXB cast iron bodies and covers:

hot-dip galvanized.

Compliances:

UL Standard 886

Effective September, 2005 800-621-1506

Copyright 2005 www.appletonelec.com

PAGE 40

K-41

Ordering Information: EXB Boxes:

Blank Bodies for Drilling and Tapping

Determine catalog number as follows: Minimum Recommended Spacing Between Conduit Openings

(1) select EXB junction box catalog Allowance made for clearance over bushings. When unions or seals are used, additional

number; (2) select Conduit Opening space must be allowed.

Arrangement Diagram number; and (3) Table shows minimum distances between conduit-opening centerlines in various size com-

select symbols that represent conduit binations. For example, if 1-1/2 and 3/4 openings are to be drilled and tapped into one

opening sizes from Symbol Table. side of box, the minimum spacing between centerlines would be 2.13.

Where no opening is required, the Conduit Minimum space between conduit opening centerlines, Inches

symbol 0 must be inser ted. Add Size (Inches) 1/2 3/4 1 1-1/4 1-1/2 2 2-1/2 3 3-1/2 4

Suffix for other optional features. The

various divisions of the complete catalog 1/2 1.25

number should be separated by 3/4 1.38 1.50

dashes. 1 1.56 1.69 1.88

Example: 1-1/4 1.88 2.00 2.19 2.44

T h e j u n c t i o n b ox s e l e c t e d i s 1-1/2 2.00 2.13 2.31 2.63 2.75

EXB181208 with steel mounting plate 2 2.38 2.50 2.69 2.94 3.13 3.44

and the Conduit Opening Arrange- 2-1/2 2.50 2.63 2.81 3.13 3.25 3.63 3.75

ment is diagram #1. Opening a is

to be 1/2; b, 1-1/4; c, no opening 3 2.88 3.00 3.19 3.44 3.63 3.94 4.13 4.44

needed; and d, 1-1/2. 3-1/2 3.13 3.25 3.44 3.75 3.88 4.25 4.38 4.75 5.00

In this example, the complete catalog 4 3.44 3.56 3.75 4.05 4.19 4.56 4.69 5.06 5.31 5.63

number is:

EXB1812081AD0EWYM-1812-1 Diameters of Bushings, Unions, Conduit and Seals, Inches

Conduit Diameters of Fittings for 1/2 thru 4 Conduit

Size (Inches) 1/2 3/4 1 1-1/4 1-1/2 2 2-1/2 3 3-1/2 4

Standard Conduit Opening Arrangement

Diagrams BBU Bushing 1.06 1.31 1.56 1.94 2.19 2.69 3.19 3.88 4.38 4.88

Opening a is always TOP of box BU Bushing 1.13 1.25 1.63 2.06 2.31 2.94 3.25 3.88 4.56 5.06

UNY/UNF (R) Union 1.50 1.75 2.00 2.81 3.06 3.75 4.94 5.44 5.94 6.50

Conduit .88 1.06 1.38 1.69 1.94 2.38 2.88 3.50 4.00 4.50

Diag. Diag. EYM-EYF Seals T.R. 1.06 1.19 1.38 1.75 2.06 2.31 2.69 3.13 3.44 3.69

#1 #2

T.R. is Turning Radius.

K

All Conduit Openings will be locat-

Diag. Diag. ed in centerline of walls and evenly

#3 #4 spaced unless otherwise specified.

If a Standard Conduit Opening

Arrangement is not suitable for the

application,or when openings are to

be more accurately spaced, submit drill

Symbol Table and tap schedule on page K-46.

Drilling and Tapping (Five Threads Min.)

Size Symbol Size Symbol

Blank 0 2 F

1/2 A 2-1/2 G

3/4 B 3 H

1 C 3-1/2 J

1-1/4 D 4 K

1-1/2 E 5 L

6 M

Effective September, 2005 800-621-1506

Copyright 2005 www.appletonelec.com

PAGE 41

K-46

EXB and DTX Series:

Drill and Tap Schedule

Ordering Information:

ARE INDICATED CON-

DUIT SIZES WITHIN THE

CATALOG PUBLISHED

MAXIMUM ON PAGES K-

40 AND K-43?

CHECK FOR MINIMUM

SPACING BETWEEN

CONDUIT OPENINGS

PER CONDUIT SPACING

TABLE, ON PAGE K-41.

K

ENCLOSURE

Effective September, 2005 800-621-1506

Copyright 2005 www.appletonelec.com

PAGE 46

Das könnte Ihnen auch gefallen

- Slide Mount Inner SizesDokument6 SeitenSlide Mount Inner SizesJosé António QuintanilhaNoch keine Bewertungen

- BOM For Tank 127 & 128: SL - No Description Size Unit Tank 127-D-19M, H-12.6M Foreign MaterialDokument1 SeiteBOM For Tank 127 & 128: SL - No Description Size Unit Tank 127-D-19M, H-12.6M Foreign MaterialSADMAN AOWALNoch keine Bewertungen

- Resume NDokument4 SeitenResume NBrenyi Zanabria ConchaNoch keine Bewertungen

- Air Conditioner (Yn20m00078f1)Dokument2 SeitenAir Conditioner (Yn20m00078f1)carlosNoch keine Bewertungen

- Designation:-Stack Detail Drg No 460SK1 Rev No φ1600 Tot Wt (Kgs) S. No. Description Item No QtyDokument28 SeitenDesignation:-Stack Detail Drg No 460SK1 Rev No φ1600 Tot Wt (Kgs) S. No. Description Item No QtykamleshyadavmoneyNoch keine Bewertungen

- Teamagri Industrial Corporation: 103 West City Plaza, 66 West Ave., Quezon City Tel. No. +632921-1983, 709-9689Dokument6 SeitenTeamagri Industrial Corporation: 103 West City Plaza, 66 West Ave., Quezon City Tel. No. +632921-1983, 709-9689leslieNoch keine Bewertungen

- 220kv NMB ' B'Dokument28 Seiten220kv NMB ' B'Anurag SinghNoch keine Bewertungen

- DF560L Type 18102 maintenance scheduleроDokument2 SeitenDF560L Type 18102 maintenance scheduleроДамир НазиповNoch keine Bewertungen

- 224 MMSDokument26 Seiten224 MMSharshNoch keine Bewertungen

- Price 1Dokument4 SeitenPrice 1leslieNoch keine Bewertungen

- Bolts For Flange Connections PDFDokument1 SeiteBolts For Flange Connections PDFLASCARZAMFIRESCUNoch keine Bewertungen

- Bolts For Flange ConnectionsDokument1 SeiteBolts For Flange ConnectionsCorespondenta CL5-CVNoch keine Bewertungen

- Harga Bahan 2017Dokument4 SeitenHarga Bahan 2017Jhon NextNoch keine Bewertungen

- Raychem RPG Copper Mesh & BraidsDokument16 SeitenRaychem RPG Copper Mesh & BraidsKhora2k2Noch keine Bewertungen

- Trash Rack Rotary AdiyasaDokument1 SeiteTrash Rack Rotary AdiyasaHengki f Sukresno100% (1)

- 08 Brushes PDFDokument48 Seiten08 Brushes PDFbelan_80Noch keine Bewertungen

- BOM-2P - 1MW SandonaciDokument3 SeitenBOM-2P - 1MW Sandonacidomenico.viapianaNoch keine Bewertungen

- Trash Rack Rotary TipalaDokument1 SeiteTrash Rack Rotary TipalaHengki f SukresnoNoch keine Bewertungen

- Summary of Stock Maintenance Report: As of - SR. No. Item Description Stock in Stock Out Stock BalanceDokument3 SeitenSummary of Stock Maintenance Report: As of - SR. No. Item Description Stock in Stock Out Stock Balancemarissa ramosNoch keine Bewertungen

- FLANGE Connection Standard - by Kato and Hirose (1984)Dokument2 SeitenFLANGE Connection Standard - by Kato and Hirose (1984)Eko Pulianto ZESBNoch keine Bewertungen

- Best Tech KoreanDokument8 SeitenBest Tech KoreanUkay Dedi SukardiNoch keine Bewertungen

- Aa BomDokument6 SeitenAa Bomfauzan tarmiziNoch keine Bewertungen

- Boom Assy 5.65 M (18FT. 6in.)Dokument3 SeitenBoom Assy 5.65 M (18FT. 6in.)carlosNoch keine Bewertungen

- Abrasives: Cut-Off Wheels & AccessoriesDokument1 SeiteAbrasives: Cut-Off Wheels & Accessoriesherysyam1980Noch keine Bewertungen

- Rekap Material Update 18.9.19 105.CEORIAU - Loa.07.19-1Dokument38 SeitenRekap Material Update 18.9.19 105.CEORIAU - Loa.07.19-1Fha Ayank TieNoch keine Bewertungen

- Detailed Packing List - PKBDokument3 SeitenDetailed Packing List - PKBirmanNoch keine Bewertungen

- POS Code Qty. Dimensions Material Total Weight Detail AreaDokument3 SeitenPOS Code Qty. Dimensions Material Total Weight Detail AreaOrxan QulamhuseynovNoch keine Bewertungen

- Rexnord Leaf - Chains - CatalogueDokument8 SeitenRexnord Leaf - Chains - CatalogueVolodymуr VorobetsNoch keine Bewertungen

- Mini Satellite-Antenna Rotator Mkii - Construction Notes: Parts ListDokument9 SeitenMini Satellite-Antenna Rotator Mkii - Construction Notes: Parts Listmjd rNoch keine Bewertungen

- Job Order: 7184 Exelon Power Solution (A)Dokument12 SeitenJob Order: 7184 Exelon Power Solution (A)Jhade AceroNoch keine Bewertungen

- Commander 114 CS PDFDokument642 SeitenCommander 114 CS PDFAurimas Rukas100% (1)

- Arm Assy, 50 FT Long Reach, 6.35 M (20 Ft. 11 In.)Dokument3 SeitenArm Assy, 50 FT Long Reach, 6.35 M (20 Ft. 11 In.)carlosNoch keine Bewertungen

- Estimate For Shashi Loan Purpose One RoomDokument13 SeitenEstimate For Shashi Loan Purpose One RoomHarpreet SinghNoch keine Bewertungen

- Commander 115 CS PDFDokument644 SeitenCommander 115 CS PDFAurimas RukasNoch keine Bewertungen

- Creeping Wave ProbesDokument1 SeiteCreeping Wave ProbesFrank Pinedo LopezNoch keine Bewertungen

- C900Dokument4 SeitenC900ger80Noch keine Bewertungen

- 7X2,7x3,7x4 8x2,8x3,8x4 9x2,9x3,9x4 10x3,10x4, 10x5Dokument1 Seite7X2,7x3,7x4 8x2,8x3,8x4 9x2,9x3,9x4 10x3,10x4, 10x5njnnNoch keine Bewertungen

- Dual Power Assembly NH 5610SDokument4 SeitenDual Power Assembly NH 5610SJazael RodriguezNoch keine Bewertungen

- Heat-Resistant and Gas-Impermeable Rubber SheetsDokument1 SeiteHeat-Resistant and Gas-Impermeable Rubber Sheetsari wiliamNoch keine Bewertungen

- Lenox Catalog 2017Dokument52 SeitenLenox Catalog 2017LuizEduardoBragaNoch keine Bewertungen

- Kebutuhan Material Pipe Baja & SUS 304 SUNRISEDokument34 SeitenKebutuhan Material Pipe Baja & SUS 304 SUNRISEfaiz ubaidillahNoch keine Bewertungen

- John Deere - Parts Catalog - Frame 9Dokument2 SeitenJohn Deere - Parts Catalog - Frame 9Jorge MendozaNoch keine Bewertungen

- Lista de Precios General en $ y Bs 24.08.2020Dokument16 SeitenLista de Precios General en $ y Bs 24.08.2020Alejandra RamirezNoch keine Bewertungen

- Opt. Material Estructural Escalera Marinera CDokument3 SeitenOpt. Material Estructural Escalera Marinera CAlexandra OrtaNoch keine Bewertungen

- Terrano 6.4 GX Parts Catalog 2018Dokument94 SeitenTerrano 6.4 GX Parts Catalog 2018Juli PNoch keine Bewertungen

- Hit Material Maintenance Warehouse Rev.1Dokument2 SeitenHit Material Maintenance Warehouse Rev.1wahyumufthiNoch keine Bewertungen

- R1410867-Assembly Instructions-A3681821Dokument27 SeitenR1410867-Assembly Instructions-A3681821ThuderboyNoch keine Bewertungen

- Pedido Moto Jhon DeereDokument4 SeitenPedido Moto Jhon DeereValentina Santos MartinezNoch keine Bewertungen

- S. No Cable Size Qty Unit Double Compressor Gland For Unarmoured AblesDokument2 SeitenS. No Cable Size Qty Unit Double Compressor Gland For Unarmoured AblesSarathkumar KNoch keine Bewertungen

- S. No Cable Size Qty Unit Double Compressor Gland For Unarmoured AblesDokument2 SeitenS. No Cable Size Qty Unit Double Compressor Gland For Unarmoured AblesSarathkumar KNoch keine Bewertungen

- Bill of MaterialDokument3 SeitenBill of MaterialBhavesh ShiyaniNoch keine Bewertungen

- Brzeszczoty Lenox - Piły SzablasteDokument12 SeitenBrzeszczoty Lenox - Piły SzablasteJózek JózekNoch keine Bewertungen

- Engine Hood AccessoriesDokument2 SeitenEngine Hood AccessoriesmetanirvanaNoch keine Bewertungen

- Price Comparison For Angle Bars, C-Purlins and TubularDokument1 SeitePrice Comparison For Angle Bars, C-Purlins and TubularMaRkZzz081Noch keine Bewertungen

- PCB CalculatorDokument7 SeitenPCB CalculatorNelson RañolaNoch keine Bewertungen

- Bolts For Flange ConnectionsDokument1 SeiteBolts For Flange Connectionsklatheesh72Noch keine Bewertungen

- BOM (Bolt, Nut & Washer) Silo Stair TowerDokument6 SeitenBOM (Bolt, Nut & Washer) Silo Stair TowerIlham KelanaNoch keine Bewertungen

- 220kv - NMB - Type TowerDokument17 Seiten220kv - NMB - Type Towerpavan3961Noch keine Bewertungen

- 三维焊接工装选配出厂 4.月份TKDokument12 Seiten三维焊接工装选配出厂 4.月份TKalung lungNoch keine Bewertungen

- Pusri 4Dokument20 SeitenPusri 4alexmontellNoch keine Bewertungen

- VEGA Source Return PolicyDokument1 SeiteVEGA Source Return PolicyalexmontellNoch keine Bewertungen

- Bently 3300 - 55 ManualDokument6 SeitenBently 3300 - 55 Manualwagner machado de moraesNoch keine Bewertungen

- Hi 903 and Hi 913 Shaker Calibration Manual Doc 101060Dokument21 SeitenHi 903 and Hi 913 Shaker Calibration Manual Doc 101060alexmontellNoch keine Bewertungen

- MSDSDokument1 SeiteMSDSalexmontellNoch keine Bewertungen

- 3 Planning PusriDokument16 Seiten3 Planning PusrialexmontellNoch keine Bewertungen

- Juntas Segun Ejma.20150301.12Dokument10 SeitenJuntas Segun Ejma.20150301.12Oswaldo GuerraNoch keine Bewertungen

- Expansion Joint TitaniumDokument1 SeiteExpansion Joint TitaniumalexmontellNoch keine Bewertungen

- Development and Design of Antisurge and Performance Control Systems For Centrifugal CompressorsDokument34 SeitenDevelopment and Design of Antisurge and Performance Control Systems For Centrifugal Compressorsjhchung111Noch keine Bewertungen

- Expansion Joint BasicsDokument35 SeitenExpansion Joint BasicsRajivharolikarNoch keine Bewertungen

- U.S. Bellows 101: Expansion Joint BasicsDokument70 SeitenU.S. Bellows 101: Expansion Joint Basicsalexmontell100% (1)

- Expansion Joints Guide Module 4a - Lateral Expansion Joints General - Standard Program (EFB) - Installation InstructionsDokument16 SeitenExpansion Joints Guide Module 4a - Lateral Expansion Joints General - Standard Program (EFB) - Installation InstructionsEmre ÖZDEMİRNoch keine Bewertungen

- Ijme Ncrame P125 PDFDokument6 SeitenIjme Ncrame P125 PDFAlvia AhramNoch keine Bewertungen

- Ep03257006nwb1 PDFDokument9 SeitenEp03257006nwb1 PDFalexmontellNoch keine Bewertungen

- Thrust Position Trend Increase On LP CompressorDokument5 SeitenThrust Position Trend Increase On LP CompressoralexmontellNoch keine Bewertungen

- 7ha Constructability Pitch ExternalDokument51 Seiten7ha Constructability Pitch ExternalSofianeLeksir0% (1)

- Thrust Position Trend Increase On LP CompressorDokument5 SeitenThrust Position Trend Increase On LP CompressoralexmontellNoch keine Bewertungen

- Historical Incidents and Incentives For ChangeDokument8 SeitenHistorical Incidents and Incentives For ChangealexmontellNoch keine Bewertungen

- Figure: Surge Event On Shaft Relative Vibration, Half Spectrum WaterfallDokument1 SeiteFigure: Surge Event On Shaft Relative Vibration, Half Spectrum WaterfallalexmontellNoch keine Bewertungen

- New Methodology For The Determination of The Failure Times in An Ammonium Carbamate CondenserDokument6 SeitenNew Methodology For The Determination of The Failure Times in An Ammonium Carbamate CondenseralexmontellNoch keine Bewertungen

- Centrifugal Pump Shaft DeflectionDokument1 SeiteCentrifugal Pump Shaft DeflectionalexmontellNoch keine Bewertungen

- Ep03257006nwb1 PDFDokument9 SeitenEp03257006nwb1 PDFalexmontellNoch keine Bewertungen

- Safety Manual: Direct Acting Pneumatic Trip With Partial StrokeDokument11 SeitenSafety Manual: Direct Acting Pneumatic Trip With Partial StrokealexmontellNoch keine Bewertungen

- GroundingDokument12 SeitenGroundingB Ram MundelNoch keine Bewertungen

- CVS Controls Sample Heater July 09Dokument2 SeitenCVS Controls Sample Heater July 09alexmontellNoch keine Bewertungen

- Control Diagram Servo STGDokument1 SeiteControl Diagram Servo STGalexmontellNoch keine Bewertungen

- Winding Failures of Electrical Motors: Winding Shorted Turn-To-Turn Winding With Shorted CoilDokument4 SeitenWinding Failures of Electrical Motors: Winding Shorted Turn-To-Turn Winding With Shorted CoilalexmontellNoch keine Bewertungen

- MTL4531 - MTL5531 Vibration Transducer Interface: SpecificationDokument1 SeiteMTL4531 - MTL5531 Vibration Transducer Interface: SpecificationalexmontellNoch keine Bewertungen

- CVS 870 Limit Switch: Instruction ManualDokument4 SeitenCVS 870 Limit Switch: Instruction ManualalexmontellNoch keine Bewertungen

- Electrical ScheduleDokument5 SeitenElectrical Schedulerizwan266Noch keine Bewertungen

- Chapter 1Dokument90 SeitenChapter 1chala nigussieNoch keine Bewertungen

- Aec Mc007 Nelson MCT Cable Transit SystemDokument7 SeitenAec Mc007 Nelson MCT Cable Transit Systembakien-canNoch keine Bewertungen

- Chapter 16: Plastics: Plastic ManufacturingDokument3 SeitenChapter 16: Plastics: Plastic ManufacturingSkeletonBaakohaNoch keine Bewertungen

- Manufacturing BOM / Multi LevelDokument4 SeitenManufacturing BOM / Multi LevelJulver Goyzueta ArceNoch keine Bewertungen

- Astm C 330Dokument4 SeitenAstm C 330Muhammad NaumanNoch keine Bewertungen

- Corus Prevention of Corrosion On Structural Steelwork PDFDokument28 SeitenCorus Prevention of Corrosion On Structural Steelwork PDFvonipkoNoch keine Bewertungen

- Rockwool Firepro: Comprehensive Range of Passive Fire Protection Products and SolutionsDokument109 SeitenRockwool Firepro: Comprehensive Range of Passive Fire Protection Products and Solutionsewqeq100% (1)

- BTV 2000Dokument12 SeitenBTV 2000Felipe Gamboa GálvezNoch keine Bewertungen

- Stainless Steels and Alloys - Why They Resist Corrosion and How They FailDokument15 SeitenStainless Steels and Alloys - Why They Resist Corrosion and How They FailMarcos LeiteNoch keine Bewertungen

- Inspection & Testing Requirements Scope:: Test and Inspection PerDokument2 SeitenInspection & Testing Requirements Scope:: Test and Inspection PerWael ChouchaniNoch keine Bewertungen

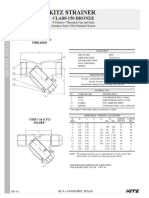

- Filtro FI180 Marca KitsDokument1 SeiteFiltro FI180 Marca KitsDianalys ArriecheNoch keine Bewertungen

- Brickwork Layout PatternsDokument4 SeitenBrickwork Layout PatternsBoy SacnamudNoch keine Bewertungen

- AWS Vs CSADokument29 SeitenAWS Vs CSAEl Shin100% (2)

- 6f1 Aluminum Production & PropDokument17 Seiten6f1 Aluminum Production & PropYudhaPrawiraNoch keine Bewertungen

- 美国焊接协会标准清单-AWS standard list - 百度文库 PDFDokument39 Seiten美国焊接协会标准清单-AWS standard list - 百度文库 PDFDantego3210Noch keine Bewertungen

- Schedule of Rates For Electrical Installation Works in Sarawak 2018Dokument19 SeitenSchedule of Rates For Electrical Installation Works in Sarawak 2018Yves L100% (3)

- Improving Detailing For MasonryDokument10 SeitenImproving Detailing For MasonryAdam JonesNoch keine Bewertungen

- Stress CorrosionDokument13 SeitenStress Corrosionseraj ibramemNoch keine Bewertungen

- As10 Air ValveDokument1 SeiteAs10 Air ValveChris KNoch keine Bewertungen

- 101106038 (1)Dokument2 Seiten101106038 (1)Sagar IngleNoch keine Bewertungen

- 2" Flowgrid 250 Regulator & Shutoff Valve Assembly: Parts ListDokument1 Seite2" Flowgrid 250 Regulator & Shutoff Valve Assembly: Parts ListJbr IrvingNoch keine Bewertungen

- Installation of Sprinkler Piping SystemDokument6 SeitenInstallation of Sprinkler Piping SystemJosef MadronaNoch keine Bewertungen

- California Strawbale Code Extract AB1314Dokument10 SeitenCalifornia Strawbale Code Extract AB1314Carlos D. GuiradosNoch keine Bewertungen

- Plating and MetPLATING & METAL FINISHING SPECIFICATIONS ISO 9001:2008, Nadcap, ITAR, Federal Fire Arms Licenseal Finishing SPECDokument1 SeitePlating and MetPLATING & METAL FINISHING SPECIFICATIONS ISO 9001:2008, Nadcap, ITAR, Federal Fire Arms Licenseal Finishing SPECStas Zabarsky0% (1)

- Masonry Reinforcement and WindpostsDokument16 SeitenMasonry Reinforcement and WindpostsJessi JohnsonNoch keine Bewertungen

- 16mo3 MıgMagDokument4 Seiten16mo3 MıgMagKerem İnanNoch keine Bewertungen

- BS en 01519 1 2000 2002Dokument34 SeitenBS en 01519 1 2000 2002Attef BedawyNoch keine Bewertungen

- Evodeck: Species UnicaDokument14 SeitenEvodeck: Species UnicaRamses TorrealbaNoch keine Bewertungen

- Copper Grounding AccessoriesDokument7 SeitenCopper Grounding AccessoriesSudath KularathnaNoch keine Bewertungen