Beruflich Dokumente

Kultur Dokumente

Residential Guide 部分119

Hochgeladen von

xinghaijunCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Residential Guide 部分119

Hochgeladen von

xinghaijunCopyright:

Verfügbare Formate

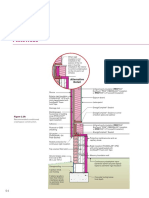

Unfaced cavity insulation (PROPINK

Wood or fiber cement siding EcoTouch PINK FIBERGLAS Insulation

or PROPINK L77 Loosefill Insulation)

Gypsum board

Air space

Latex paint

Furring or spacer strip EnergyComplete Sealant

EnergyComplete Sealant at corner

/2" OSB sheathing

1 of bottom plate and subfloor

Unfaced cavity insulation (PROPINK

EcoTouch PINK FIBERGLAS Insulation

Adhesive or PROPINK L77 Loosefill Insulation)

Rigid insulation Rigid insulation (FOAMULAR XPS)

(FOAMULAR XPS)

Gasket

Figure 2.46:

Recommended EnergyComplete

Sealant

vented crawlspace

Protection board

construction.

Crawlspace vent at top

Capillary break

of foundation wall

EnergyComplete Sealant

Masonry foundation wall Treated wood nailer

Continuous polyethylene vapor

barrier (all joints overlapped)

Ground slopes away

from wall at 5%

(6 in. per 10 ft.)

Dampproofing

Capillary break

over footing

If exterior grade is

lower than interior Concrete footing below frost depth

crawlspace grade,

no perimeter drain

is necessary

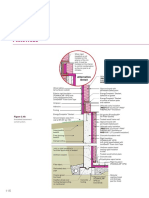

Unvented crawlspaces should only be considered where flooding is not a concern.

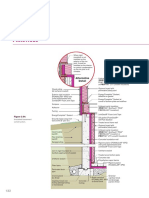

Figure 2.47 and Figure 2.48 are recommended approaches to constructing conditioned

crawlspaces. Note that protection board on the rigid insulation (FOAMULAR XPS Insulation)

protecting the rigid insulation from fire is required if crawlspace is used for storage or for

more than access for servicing equipment. Also note the fully-adhered membrane barrier for

insect control.

Basement foundations are principally insulated from the interior due to constructability

issues, thermal bridging issues with brick veneer construction, insect control and vermin

issues and cost issues.

113

Das könnte Ihnen auch gefallen

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Von EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Noch keine Bewertungen

- Recommended Vented Crawlspace Construction.: Rigid Insulation (FOAMULAR XPS)Dokument1 SeiteRecommended Vented Crawlspace Construction.: Rigid Insulation (FOAMULAR XPS)xinghaijunNoch keine Bewertungen

- Residential Guide 部分134Dokument1 SeiteResidential Guide 部分134xinghaijunNoch keine Bewertungen

- Residential Guide 部分100Dokument1 SeiteResidential Guide 部分100xinghaijunNoch keine Bewertungen

- Residential Guide 部分122Dokument1 SeiteResidential Guide 部分122xinghaijunNoch keine Bewertungen

- Residential Guide 部分138Dokument1 SeiteResidential Guide 部分138xinghaijunNoch keine Bewertungen

- Residential Guide 部分120Dokument1 SeiteResidential Guide 部分120xinghaijunNoch keine Bewertungen

- Residential Guide 部分132Dokument1 SeiteResidential Guide 部分132xinghaijunNoch keine Bewertungen

- Residential Guide 部分131Dokument1 SeiteResidential Guide 部分131xinghaijunNoch keine Bewertungen

- Residential Guide 部分140Dokument1 SeiteResidential Guide 部分140xinghaijunNoch keine Bewertungen

- Residential Guide 部分139Dokument1 SeiteResidential Guide 部分139xinghaijunNoch keine Bewertungen

- Residential Guide 部分133Dokument1 SeiteResidential Guide 部分133xinghaijunNoch keine Bewertungen

- SIRCONTEC Acoustic Floors: The Power of InnovationDokument24 SeitenSIRCONTEC Acoustic Floors: The Power of Innovationالعربية للصناعةNoch keine Bewertungen

- Es Prma Fa 25Dokument1 SeiteEs Prma Fa 25Jalaluddin MacadatoNoch keine Bewertungen

- Roofing and Protection Building Tech NotesDokument5 SeitenRoofing and Protection Building Tech Notescorazon philNoch keine Bewertungen

- Residential Guide 部分129Dokument1 SeiteResidential Guide 部分129xinghaijunNoch keine Bewertungen

- Kingspan Kooltherm k3 Product Datasheet en AuDokument8 SeitenKingspan Kooltherm k3 Product Datasheet en Aualex.rodenburgNoch keine Bewertungen

- CommercialComplete NFPA 285 BrochureDokument8 SeitenCommercialComplete NFPA 285 BrochureMehmet OzdenNoch keine Bewertungen

- Thickness of Foam Board Is Indicative The Subtrade Builtup Shall Be Provided On Site S Per SpecsDokument29 SeitenThickness of Foam Board Is Indicative The Subtrade Builtup Shall Be Provided On Site S Per Specsraed kassabNoch keine Bewertungen

- Mass Timber Window Connection Skylight Var. 1Dokument2 SeitenMass Timber Window Connection Skylight Var. 1deanNoch keine Bewertungen

- Aote Aviation BrochureDokument4 SeitenAote Aviation BrochureSaurabh UttamNoch keine Bewertungen

- Residential Guide 部分126Dokument1 SeiteResidential Guide 部分126xinghaijunNoch keine Bewertungen

- ACDsDokument36 SeitenACDsyisaac2225Noch keine Bewertungen

- Brosur Rigid Foam Polystyrene Board Atau Extruded Polystyrene (XPS)Dokument4 SeitenBrosur Rigid Foam Polystyrene Board Atau Extruded Polystyrene (XPS)titaNoch keine Bewertungen

- Neopor Roof Insulation EN PDFDokument16 SeitenNeopor Roof Insulation EN PDFJohn Martinos100% (1)

- Rainscreen Brochure - Reduced For EmailDokument6 SeitenRainscreen Brochure - Reduced For EmailkyleNoch keine Bewertungen

- Flooring Catalog 2019 ChampDokument61 SeitenFlooring Catalog 2019 ChampMichael A. PhilipsonNoch keine Bewertungen

- RBS EIFS e - BrochureDokument2 SeitenRBS EIFS e - BrochureSudiptaNoch keine Bewertungen

- UntitledDokument30 SeitenUntitledraed kassabNoch keine Bewertungen

- Exterior FinishesDokument4 SeitenExterior FinishesCatherineTiongNoch keine Bewertungen

- Sealco EcoTUFF BROCHURE 2021Dokument4 SeitenSealco EcoTUFF BROCHURE 2021sunx62Noch keine Bewertungen

- Series Anff: Adjustable Neoprene Floating FloorDokument4 SeitenSeries Anff: Adjustable Neoprene Floating FloorCarlos Torres OliverosNoch keine Bewertungen

- Mass Timber Window Connection Skylight Var. 2Dokument2 SeitenMass Timber Window Connection Skylight Var. 2deanNoch keine Bewertungen

- Bitumen Softboards: - For Expansion Joints in Concrete and Protection To Waterproofing MembranesDokument6 SeitenBitumen Softboards: - For Expansion Joints in Concrete and Protection To Waterproofing MembranesTakis ApostolidesNoch keine Bewertungen

- KNAUF 3.3.3 Timber Separating Walls PDFDokument10 SeitenKNAUF 3.3.3 Timber Separating Walls PDFBrad RimmNoch keine Bewertungen

- Xterior Nsulation Inish Ystems All Onstruction: E I F S (Eifs) W C DDokument2 SeitenXterior Nsulation Inish Ystems All Onstruction: E I F S (Eifs) W C Dkohatian27796105Noch keine Bewertungen

- HMT Deckmaster REV 2 1508 - BrochureDokument2 SeitenHMT Deckmaster REV 2 1508 - BrochureILya KryzhanovskyNoch keine Bewertungen

- Mass Timber Pitched Roof Eaves, SOLITEX ADHERO Var. 2Dokument2 SeitenMass Timber Pitched Roof Eaves, SOLITEX ADHERO Var. 2deanNoch keine Bewertungen

- 5732 en SureSeal Dusted NonReinforced EPDM Membranes Product Data Sheet PDSTDBDokument2 Seiten5732 en SureSeal Dusted NonReinforced EPDM Membranes Product Data Sheet PDSTDBSeif el dean MamdouhNoch keine Bewertungen

- Flexi: The Perfect Friction Fit For Framed ConstructionsDokument11 SeitenFlexi: The Perfect Friction Fit For Framed ConstructionsFadi HNoch keine Bewertungen

- Acoustic Wall Insulation - Design GuideDokument36 SeitenAcoustic Wall Insulation - Design GuideMeinard Tagz CuevasNoch keine Bewertungen

- GPG101 Energy Efficiency in New Housing Site Practice For Tradesmen Ground Floors Suspended Timber Floors (1993 Rep 1997) PDFDokument2 SeitenGPG101 Energy Efficiency in New Housing Site Practice For Tradesmen Ground Floors Suspended Timber Floors (1993 Rep 1997) PDFIppiNoch keine Bewertungen

- ErgonArmor PDFDokument6 SeitenErgonArmor PDFChinthamani PandiNoch keine Bewertungen

- Instalay BrochureDokument8 SeitenInstalay BrochureshanNoch keine Bewertungen

- Types of InsulationDokument14 SeitenTypes of Insulationnathan eyasuNoch keine Bewertungen

- Assignment 4.2Dokument5 SeitenAssignment 4.2JRayNoch keine Bewertungen

- Insulating Floors With StyrofoamDokument23 SeitenInsulating Floors With StyrofoamSteven SebastianNoch keine Bewertungen

- Elasto-Seal-Pro Bullbond Tds 2017rDokument4 SeitenElasto-Seal-Pro Bullbond Tds 2017rMark VillafloresNoch keine Bewertungen

- Mass Timber Window Sill Connection Var. 2Dokument2 SeitenMass Timber Window Sill Connection Var. 2deanNoch keine Bewertungen

- Elastoseal EPDM Roofing SystemsDokument8 SeitenElastoseal EPDM Roofing SystemsStephenNoch keine Bewertungen

- Khambati 8 Page ProfileDokument9 SeitenKhambati 8 Page ProfileAllan SuruciNoch keine Bewertungen

- LP Flameblock Builder Assemblies Brochure English PDFDokument6 SeitenLP Flameblock Builder Assemblies Brochure English PDFluis rodrigo salazar cerdaNoch keine Bewertungen

- Insulation TypesDokument16 SeitenInsulation TypesBrankoNoch keine Bewertungen

- Construction Materials For Acoustic DesignDokument35 SeitenConstruction Materials For Acoustic DesignRukminiPriyanka100% (1)

- Knauf Fire & Moisture Resistant Gypsum Boards (FM)Dokument2 SeitenKnauf Fire & Moisture Resistant Gypsum Boards (FM)Joe PsNoch keine Bewertungen

- Residentialcomplete™ Wall SystemsDokument5 SeitenResidentialcomplete™ Wall Systemscvpn55Noch keine Bewertungen

- Mass Timber Pitched Roof With Rafters Ridge, INTELLO PLUSDokument2 SeitenMass Timber Pitched Roof With Rafters Ridge, INTELLO PLUSdeanNoch keine Bewertungen

- 2 Gyproc Plasterboard Range: Main MenuDokument23 Seiten2 Gyproc Plasterboard Range: Main Menurealdaross100% (1)

- Everbuild® Black Jack® 908 D.P.M.: Product Data SheetDokument4 SeitenEverbuild® Black Jack® 908 D.P.M.: Product Data SheetJaysonn KayNoch keine Bewertungen

- Pereti Exteriori - Solutii - Varianta ScurtaDokument180 SeitenPereti Exteriori - Solutii - Varianta ScurtaZamfira OctavianNoch keine Bewertungen

- Residential Guide 部分181Dokument1 SeiteResidential Guide 部分181xinghaijunNoch keine Bewertungen

- Residential Guide 部分179Dokument1 SeiteResidential Guide 部分179xinghaijunNoch keine Bewertungen

- Residential Guide 部分175Dokument1 SeiteResidential Guide 部分175xinghaijunNoch keine Bewertungen

- Residential Guide 部分177Dokument1 SeiteResidential Guide 部分177xinghaijunNoch keine Bewertungen

- Appendix: Installation Instructions - RcwsDokument1 SeiteAppendix: Installation Instructions - RcwsxinghaijunNoch keine Bewertungen

- Residential Guide 部分180Dokument1 SeiteResidential Guide 部分180xinghaijunNoch keine Bewertungen

- Residential Guide 部分182Dokument1 SeiteResidential Guide 部分182xinghaijunNoch keine Bewertungen

- Residential Guide 部分174Dokument1 SeiteResidential Guide 部分174xinghaijunNoch keine Bewertungen

- Residential Guide 部分171Dokument1 SeiteResidential Guide 部分171xinghaijunNoch keine Bewertungen

- Figure A.4m:: Install Sill FlashingDokument1 SeiteFigure A.4m:: Install Sill FlashingxinghaijunNoch keine Bewertungen

- Figure A.4u:: Install Additional Furring Around WindowsDokument1 SeiteFigure A.4u:: Install Additional Furring Around WindowsxinghaijunNoch keine Bewertungen

- Residential Guide 部分170Dokument1 SeiteResidential Guide 部分170xinghaijunNoch keine Bewertungen

- Residential Guide 部分172Dokument1 SeiteResidential Guide 部分172xinghaijunNoch keine Bewertungen

- Residential Guide 部分166Dokument1 SeiteResidential Guide 部分166xinghaijunNoch keine Bewertungen

- Residential Guide 部分158Dokument1 SeiteResidential Guide 部分158xinghaijunNoch keine Bewertungen

- Figure A.4i:: Install One Layer of Insulating Sheathing (Foamular XPS Insulation)Dokument1 SeiteFigure A.4i:: Install One Layer of Insulating Sheathing (Foamular XPS Insulation)xinghaijunNoch keine Bewertungen

- Residential Guide 部分164Dokument1 SeiteResidential Guide 部分164xinghaijunNoch keine Bewertungen

- Residential Guide 部分162Dokument1 SeiteResidential Guide 部分162xinghaijunNoch keine Bewertungen

- Figure A.3G:: Tape (Jointsealr Foam Joint Tape) Seams of Insulating SheathingDokument1 SeiteFigure A.3G:: Tape (Jointsealr Foam Joint Tape) Seams of Insulating SheathingxinghaijunNoch keine Bewertungen

- Figure A.4e:: Install Sloping Head PieceDokument1 SeiteFigure A.4e:: Install Sloping Head PiecexinghaijunNoch keine Bewertungen

- Residential Guide 部分160Dokument1 SeiteResidential Guide 部分160xinghaijunNoch keine Bewertungen

- Figure A.3k:: Install Jamb FlashingDokument1 SeiteFigure A.3k:: Install Jamb FlashingxinghaijunNoch keine Bewertungen

- Figure A.3o:: Install Jamb FlashingDokument1 SeiteFigure A.3o:: Install Jamb FlashingxinghaijunNoch keine Bewertungen

- Residential Guide 部分156Dokument1 SeiteResidential Guide 部分156xinghaijunNoch keine Bewertungen

- Residential Guide 部分152Dokument1 SeiteResidential Guide 部分152xinghaijunNoch keine Bewertungen

- Residential Guide 部分149Dokument1 SeiteResidential Guide 部分149xinghaijunNoch keine Bewertungen

- Figure A.3c:: Install Plywood Window Extension BoxDokument1 SeiteFigure A.3c:: Install Plywood Window Extension BoxxinghaijunNoch keine Bewertungen

- Residential Guide 部分154Dokument1 SeiteResidential Guide 部分154xinghaijunNoch keine Bewertungen

- Appendix: Figure A.2e: Figure A.2fDokument1 SeiteAppendix: Figure A.2e: Figure A.2fxinghaijunNoch keine Bewertungen

- Residential Guide 部分148Dokument1 SeiteResidential Guide 部分148xinghaijunNoch keine Bewertungen

- Food Legumes Research and Production in NepalDokument12 SeitenFood Legumes Research and Production in Nepalnkyadav56Noch keine Bewertungen

- Daily Report Proforma CIVIL 14-02-2019Dokument10 SeitenDaily Report Proforma CIVIL 14-02-2019rajupetalokeshNoch keine Bewertungen

- Calender of Operation-ArecanutDokument4 SeitenCalender of Operation-ArecanutKumar GhNoch keine Bewertungen

- Plumbing Specifications: Catch Basin PlanDokument1 SeitePlumbing Specifications: Catch Basin PlanMark Allan RojoNoch keine Bewertungen

- Guy AnchorDokument1 SeiteGuy AnchorVijay KumarNoch keine Bewertungen

- BEHNKE-Caryophyllales - Evolution and Systematics (1994)Dokument338 SeitenBEHNKE-Caryophyllales - Evolution and Systematics (1994)JuanManuelAmaroLuisNoch keine Bewertungen

- Herbs and SpicesDokument338 SeitenHerbs and SpicesLei Huang100% (42)

- Vegetables: Chapter 20, The Idaho Master Gardener Program HandbookDokument31 SeitenVegetables: Chapter 20, The Idaho Master Gardener Program HandbookSharad Bhutoria100% (1)

- Hydrangea Production: Cultivar Selection and General Practices To Consider When Propagating and Growing HydrangeaDokument13 SeitenHydrangea Production: Cultivar Selection and General Practices To Consider When Propagating and Growing HydrangeajessphNoch keine Bewertungen

- Sweet MarjoramDokument3 SeitenSweet Marjorammohan_umesh1891Noch keine Bewertungen

- Biology Investigatory Project: PollinationDokument30 SeitenBiology Investigatory Project: PollinationMohamed LaqinNoch keine Bewertungen

- Ankur Plag Remove FileDokument4 SeitenAnkur Plag Remove FilesanjuNoch keine Bewertungen

- Cement Suppliers in IndoreDokument10 SeitenCement Suppliers in Indoresourabh_gupta_54Noch keine Bewertungen

- 01 Sep 2018 Civil Engg Standards of BisDokument8 Seiten01 Sep 2018 Civil Engg Standards of BisaNoch keine Bewertungen

- Heard PosterDokument1 SeiteHeard PosterAndres VbNoch keine Bewertungen

- EVS ProjectDokument24 SeitenEVS ProjectDebajeet Ghosh25% (4)

- Technical Advice Sheet 6 - Repointing Lime Mortar JointsDokument9 SeitenTechnical Advice Sheet 6 - Repointing Lime Mortar JointsHaitham SaeedNoch keine Bewertungen

- Introduction To Building Materials: Concrete Masonry Non MetalDokument23 SeitenIntroduction To Building Materials: Concrete Masonry Non MetalQISTINNA NAJIHA BINTI MUHAMAD FAISAL MoeNoch keine Bewertungen

- Sepakat Setia Perunding SDN BHD: Design of Up-Stand Wall or Headwall To Bs 5400Dokument4 SeitenSepakat Setia Perunding SDN BHD: Design of Up-Stand Wall or Headwall To Bs 5400Afiq SyahmiNoch keine Bewertungen

- Precast Prestressed Concrete Driven PilesDokument3 SeitenPrecast Prestressed Concrete Driven PilesPriodeep ChowdhuryNoch keine Bewertungen

- Soil Formula Civil BoosterDokument22 SeitenSoil Formula Civil BoosterZahid100% (2)

- 426-601 PDF PDFDokument6 Seiten426-601 PDF PDFNeural Spark Physics Cie100% (1)

- Flower Markets in JakartaDokument3 SeitenFlower Markets in JakartaDIAS MARIAHQIBTIAH1006780281Noch keine Bewertungen

- 02.010.0313 Base of Wall Single Wythe Block Proprietary Flashing and WeepsDokument1 Seite02.010.0313 Base of Wall Single Wythe Block Proprietary Flashing and WeepsYolanda Leah UrbanoNoch keine Bewertungen

- Barasingha HastinaprDokument58 SeitenBarasingha HastinaprSalang211Noch keine Bewertungen

- Cupflow: Cuspated / Dimple Sheet Drainage CompositeDokument13 SeitenCupflow: Cuspated / Dimple Sheet Drainage CompositeAnonymous CQ4rbzLVENoch keine Bewertungen

- Guidlines or The Design of Bored Concrete Piles in Expansive Soil of SudanDokument10 SeitenGuidlines or The Design of Bored Concrete Piles in Expansive Soil of Sudanmahmoud meslehNoch keine Bewertungen

- Bill of Materials: Item Description Structural WorksDokument11 SeitenBill of Materials: Item Description Structural WorksCarl Andrew PimentelNoch keine Bewertungen

- Acp Ncii - Conduct Field Layout - G11 - Q3 - W1Dokument14 SeitenAcp Ncii - Conduct Field Layout - G11 - Q3 - W1Romar N. SantosNoch keine Bewertungen

- Site Environmental Management Plan Information SheetDokument9 SeitenSite Environmental Management Plan Information Sheetnanthad74Noch keine Bewertungen