Beruflich Dokumente

Kultur Dokumente

Xtra Strong (XS) Size Steel Pipe Weights TAble Calculator

Hochgeladen von

shownpuCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Xtra Strong (XS) Size Steel Pipe Weights TAble Calculator

Hochgeladen von

shownpuCopyright:

Verfügbare Formate

9/8/2017 Xtra Strong (XS) Size Steel Pipe Weights TAble Calculator | Engineers Edge | www.engineersedge.

com

Register

Xtra Strong (XS) Size Steel Pipe Weights Table Calculator

Engineering Metals and Materials | Strength of Materials

Standard Pipe Schedules ( Pipe Sizes ) Chart Data

Pressure Vessel Design & Engineering

Home

This calculator will determine the weights of xtra strong (XS) steel pipes with selected material content, per AISC Manual of Steel Construction, Engineering B

13th Edition CD Database for pipes from 1/2" through 12" dia. and itt grinnell pipe hanger engineering manual for pipes from 14in to 36. Engineering F

Excel App. Do

Online Books

CALCULATION OF INDIVIDUAL PIPE WEIGHTS Engineering N

For Extra Strong (XS) Weight Steel Pipe Engineering V

We've and Empty or Full of Contents, with/without Insulation, and with/without Ice Buildup Engineering C

detected that Engineering To

you're using Engineering Jo

adblocking Input Data:

GD&T Trainin

software or Geometric Dime

services. Specific Gravity of Contents = 1.00

Tolerancing

Insulation Thickness, t(insul) = 2.00 in. DFM DFA Tra

To learn Insulation Density = 9.00 pcf Training Onlin

more about Ice Thickness, t(ice) = 1.00 Engineering

in.

how you can Advertising Ce

help

Engineers Results: Cells colored Yellow are input Print Webpage

Edge remain

a free Combination Weights (plf) Copyright No

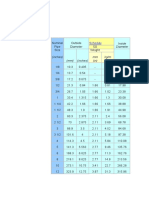

resource and Nominal Outside Inside Pipe Water Insulation Ice Pipe + Pipe + Pipe + Pipe + Pipe + Pipe +

not see Contents Contents Insulation

advertising Pipe Diameter Diameter Weight Weight Weight Weight Contents Contents + + + Insulation +

or this Dia. (in.) (in.) (plf) (plf) (plf) (plf) Insulation Insul. + Ice Ice Ice

message, 1/2XS 0.840 0.546 1.09 0.10 1.12 7.13 1.19 2.31 9.44 8.33 2.21 9.34

please visit 3/4XS 1.050 0.742 1.48 0.19 1.20 7.39 1.67 2.87 10.26 9.06 2.68 10.07

Membership. 1XS 1.315 0.957 2.17 0.31 1.30 7.72 2.48 3.78 11.50 10.20 3.47 11.19

1-1/4XS 1.660 1.278 3.00 0.56 1.44 8.14 3.56 4.99 13.13 11.69 4.44 12.57

1-1/2XS 1.900 1.500 3.63 0.77 1.53 8.43 4.40 5.93 14.36 12.83 5.16 13.59

2XS 2.375 1.939 5.03 1.28 1.72 9.01 6.31 8.03 17.04 15.32 6.75 15.76

2-1/2XS 2.875 2.323 7.67 1.84 1.91 9.62 9.51 11.42 21.04 19.13 9.58 19.21

3XS 3.500 2.900 10.30 2.86 2.16 10.38 13.16 15.32 25.71 23.55 12.46 22.84

3-1/2XS 4.000 3.364 12.50 3.85 2.36 11.00 16.35 18.71 29.70 27.35 14.86 25.85

4XS 4.500 3.826 15.00 4.98 2.55 11.61 19.98 22.53 34.14 31.59 17.55 29.16

5XS 5.563 4.813 20.80 7.88 2.97 12.91 28.68 31.65 44.56 41.59 23.77 36.68

6XS 6.625 5.761 28.60 11.30 3.39 14.20 39.90 43.28 57.49 54.10 31.99 46.19

8XS 8.625 7.625 43.40 19.79 4.17 16.65 63.19 67.36 84.01 79.83 47.57 64.22

10XS 10.750 9.750 54.80 32.35 5.01 19.24 87.15 92.16 111.40 106.40 59.81 79.05

12XS 12.750 11.750 65.50 46.99 5.79 21.69 112.49 118.28 139.97 134.17 71.29 92.98

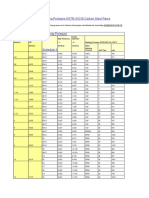

14XS 14.000 13.000 72.09 57.52 6.28 23.21 129.61 135.89 159.10 152.82 78.37 101.59

16XS 16.000 15.000 82.77 76.58 7.07 25.66 159.35 166.41 192.07 185.00 89.84 115.49

18XS 18.000 17.000 93.45 98.36 7.85 28.10 191.81 199.66 227.76 219.91 101.30 129.40

20XS 20.000 19.000 104.13 122.86 8.64 30.54 226.99 235.63 266.18 257.54 112.77 143.31

22XS 22.000 21.000 114.81 150.09 9.42 32.99 264.90 274.32 307.31 297.89 124.23 157.22

24XS 24.000 23.000 125.49 180.04 10.21 35.43 305.53 315.74 351.17 340.96 135.70 171.13

26XS 26.000 25.000 136.17 212.71 11.00 37.87 348.88 359.88 397.75 386.76 147.17 185.04

28XS 28.000 27.000 146.85 248.11 11.78 40.32 394.96 406.74 447.06 435.27 158.63 198.95

30XS 30.000 29.000 157.53 286.23 12.57 42.76 443.76 456.32 499.08 486.52 170.10 212.86

32XS 32.000 31.000 168.21 327.07 13.35 45.20 495.28 508.63 553.83 540.48 181.56 226.77

34XS 34.000 33.000 178.89 370.63 14.14 47.65 549.52 563.66 611.30 597.17 193.03 240.67

36XS 36.000 35.000 189.57 416.92 14.92 50.09 606.49 621.41 671.50 656.58 204.49 254.58

42XS 42.000 41.000 221.60 572.11 17.28 57.42 793.71 810.99 868.41 851.13 238.88 296.30

48XS 48.000 47.000 253.60 751.81 19.63 64.75 1005.41 1025.04 1089.80 1070.16 273.23 337.99

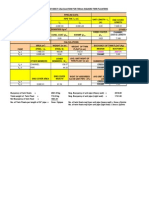

Formulas Used:

Pipe

Weight = (p*(OD2-ID2)/4)*(490/144) (Note: x-strong steel pipe weights shown in table are taken from references below.)

Contents

Weight = (SG*w(contents))*(p*ID2/4)/144 (Note: densitiy of water is assumed = 62.4 pcf.)

Insulation w(insul)*(t(insul)/12)*(p*

Weight = (OD+t(insul))/12)

Ice Weight

= w(ice)*(t(ice)/12)*(p*(OD+2*t(insul)+t(ice))/12) (Note: density of ice is assumed = 56.0 pcf.)

References:

1. AISC Manual of Steel Construction, 13th Edition CD Database (for pipes from 1/2" through 12" dia.)

2. Crane Technical Paper No. 410, "Flow of Fluids through Valves, Fittings, and Pipe" (1991) (for pipes from 14" through 36" dia.)

http://www.engineersedge.com/calculators/xs_pipe_weights/xs_pipe_weights_calculator.htm 1/2

Das könnte Ihnen auch gefallen

- Simplified Torsion Analysis For Steel Beams: Simple Span Beam With Eccentric Concentrated Load Applied at MidspanDokument4 SeitenSimplified Torsion Analysis For Steel Beams: Simple Span Beam With Eccentric Concentrated Load Applied at MidspanIhab El AghouryNoch keine Bewertungen

- Storage Tank Venting Calculations For Site Tank FarmDokument7 SeitenStorage Tank Venting Calculations For Site Tank FarmGusfi CarsurinNoch keine Bewertungen

- Eccentric Loads On L-Shaped Weld GroupsDokument1 SeiteEccentric Loads On L-Shaped Weld Groupsj_herndzNoch keine Bewertungen

- Sect Prop 28Dokument4 SeitenSect Prop 28abhi1789Noch keine Bewertungen

- Eccentric Loads On C-Shaped Weld GroupsDokument1 SeiteEccentric Loads On C-Shaped Weld Groupsj_herndzNoch keine Bewertungen

- Weight Calculation For 200 NB, 150, 100nb PipeDokument2 SeitenWeight Calculation For 200 NB, 150, 100nb PipeAnujGargNoch keine Bewertungen

- Saddle Angle - Formula K - 12.28.20Dokument2 SeitenSaddle Angle - Formula K - 12.28.20Rey FiedacanNoch keine Bewertungen

- Appendix XVI Technical Report On Geotechnical SurveyDokument25 SeitenAppendix XVI Technical Report On Geotechnical SurveyBinu Shankar PillaiNoch keine Bewertungen

- 07 Piping BOQDokument54 Seiten07 Piping BOQHRK65Noch keine Bewertungen

- Structural Equivalency SheetDokument73 SeitenStructural Equivalency Sheetboim1234Noch keine Bewertungen

- Thk. S.F. K.R.: Dish - Dish 2100Dokument3 SeitenThk. S.F. K.R.: Dish - Dish 2100jayvant jadhavarNoch keine Bewertungen

- Calculation of PipeReinforcement ASMEB31 1Dokument4 SeitenCalculation of PipeReinforcement ASMEB31 1threedlabsNoch keine Bewertungen

- Asme Pipe Wall ThicknessDokument3 SeitenAsme Pipe Wall ThicknessYoke ShuNoch keine Bewertungen

- Beam 20031213Dokument8 SeitenBeam 20031213Tabish IzharNoch keine Bewertungen

- Knife Gate Valves PDFDokument2 SeitenKnife Gate Valves PDFashish_pradhan75Noch keine Bewertungen

- ANSI B36.10 Steel PipesDokument8 SeitenANSI B36.10 Steel Pipesphoneme79Noch keine Bewertungen

- CN 05Dokument3 SeitenCN 05GousePeerzadeNoch keine Bewertungen

- Project: Date Jobno: Designed ACTIVITY: Utility Pipe/ Valve Workshop Checked SheetDokument36 SeitenProject: Date Jobno: Designed ACTIVITY: Utility Pipe/ Valve Workshop Checked SheetGeorge Georgian100% (1)

- Pipe SpecificationsDokument5 SeitenPipe Specificationsbabar.muetNoch keine Bewertungen

- Referencia Descripción PVP /UD Raee: TargettiDokument54 SeitenReferencia Descripción PVP /UD Raee: TargettiVEMATEL50% (2)

- Calculator - U Tubes - HSA & QtyDokument4 SeitenCalculator - U Tubes - HSA & QtyRey Fiedacan100% (1)

- Input Parameter Valve and Flange: Fluid Density (KG/M) Insulation Density (KG/M)Dokument12 SeitenInput Parameter Valve and Flange: Fluid Density (KG/M) Insulation Density (KG/M)ibmsherNoch keine Bewertungen

- Pin StressesDokument5 SeitenPin Stressesprajakt_pieNoch keine Bewertungen

- Time To Empty Out Vessel No Dished EndsDokument2 SeitenTime To Empty Out Vessel No Dished EndsHeiner PalaciosNoch keine Bewertungen

- Calculation BS 31.3Dokument1 SeiteCalculation BS 31.3prabhjot123Noch keine Bewertungen

- Flanges Carbon Chrome Blind RTJWN SMDokument11 SeitenFlanges Carbon Chrome Blind RTJWN SMvalli rajuNoch keine Bewertungen

- Sagging of The Pipe (F) Between 2 Pipe Clamps (1/"?") X LDokument7 SeitenSagging of The Pipe (F) Between 2 Pipe Clamps (1/"?") X LEdwardhutaurukNoch keine Bewertungen

- SWIODokument1 SeiteSWIOpreeti kumariNoch keine Bewertungen

- Calculation Sheet For 700mm SQ Metal FloatersDokument3 SeitenCalculation Sheet For 700mm SQ Metal FloatersAdagharaNoch keine Bewertungen

- AISC Properties ViewerDokument3 SeitenAISC Properties Viewerchriscivil12Noch keine Bewertungen

- Eccentric Loads On Vertical Parallel Weld GroupsDokument1 SeiteEccentric Loads On Vertical Parallel Weld GroupsPriodeep ChowdhuryNoch keine Bewertungen

- FlangeDokument13 SeitenFlangehuangjlNoch keine Bewertungen

- PIPE+STUB-IN Rev1Dokument4 SeitenPIPE+STUB-IN Rev1genergiaNoch keine Bewertungen

- AISC Properties ViewerDokument2 SeitenAISC Properties ViewerNoeBongaNoch keine Bewertungen

- Weight CalculatorDokument2 SeitenWeight CalculatorenjoygurujiNoch keine Bewertungen

- Lug CalcionulatDokument1 SeiteLug CalcionulatkurniawanandreasNoch keine Bewertungen

- ASME/ANSI B16.5: (Inches) (Inches) (Inches) (Inches)Dokument19 SeitenASME/ANSI B16.5: (Inches) (Inches) (Inches) (Inches)Harish PothepalliNoch keine Bewertungen

- Technical Evaluation HAM BAKERDokument1 SeiteTechnical Evaluation HAM BAKEReko123Noch keine Bewertungen

- STIFF (Version 1)Dokument33 SeitenSTIFF (Version 1)maheshbandhamNoch keine Bewertungen

- Line Sizing - Pouria SabbaghDokument1 SeiteLine Sizing - Pouria Sabbaghadil alameenNoch keine Bewertungen

- Steel Section Properties From ArcellorDokument69 SeitenSteel Section Properties From Arcellorsymon ellimacNoch keine Bewertungen

- Calculations For Rectangular Storage TankDokument44 SeitenCalculations For Rectangular Storage TankSiva ShankarNoch keine Bewertungen

- New Storage Tanks Design GuidelinesDokument6 SeitenNew Storage Tanks Design GuidelinespaaryNoch keine Bewertungen

- WL130 PE4710 FM Approved Pipe: IPS & DIPS Pipe Sizes - Class 150, 200 & 267Dokument3 SeitenWL130 PE4710 FM Approved Pipe: IPS & DIPS Pipe Sizes - Class 150, 200 & 267Tanwir AhmadNoch keine Bewertungen

- Reff: A Text Book of Machine Design - Chapter 10, RS. KHURMIDokument5 SeitenReff: A Text Book of Machine Design - Chapter 10, RS. KHURMIAsep MulyadiNoch keine Bewertungen

- A11Dokument1 SeiteA11liviu_dovaNoch keine Bewertungen

- CP Design OD (In) OD (MM) Length Area (m2)Dokument1 SeiteCP Design OD (In) OD (MM) Length Area (m2)mtuanlatoi9704Noch keine Bewertungen

- Support CalculationDokument16 SeitenSupport Calculationhosny1987Noch keine Bewertungen

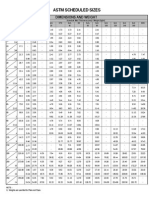

- Astm Scheduled Sizes: Dimensions and WeightDokument1 SeiteAstm Scheduled Sizes: Dimensions and WeightVikasShelkeNoch keine Bewertungen

- ASME B16.5 2013 FlangeRating 1.0Dokument4 SeitenASME B16.5 2013 FlangeRating 1.0sanjaysyNoch keine Bewertungen

- Design and Analysis of Pressure Vessel Skirt Considering Seismic Load As Per Uniform Building Code IJERTCONV4IS10007Dokument5 SeitenDesign and Analysis of Pressure Vessel Skirt Considering Seismic Load As Per Uniform Building Code IJERTCONV4IS10007RSalehNoch keine Bewertungen

- Chibro Press Fit Piping Data SheetDokument5 SeitenChibro Press Fit Piping Data SheetBoyd Johnston100% (1)

- Plaster Calculation V6Dokument34 SeitenPlaster Calculation V6bedianchoiNoch keine Bewertungen

- Torispherical Head TolvaDokument1 SeiteTorispherical Head TolvaFabio Augusto Hincapie HenaoNoch keine Bewertungen

- Maximum Working Pressure-ASTM A53 B Carbon Steel PipesDokument2 SeitenMaximum Working Pressure-ASTM A53 B Carbon Steel PipesBFEVietnamNoch keine Bewertungen

- Bolt or Pin in Double Shear Equation and Calculator - Engineers EdgeDokument2 SeitenBolt or Pin in Double Shear Equation and Calculator - Engineers EdgeYadav RahulNoch keine Bewertungen

- Minimum Thread Engagement Equation and Calculator ISO - Engineers EdgeDokument2 SeitenMinimum Thread Engagement Equation and Calculator ISO - Engineers EdgeAJIT LONDHENoch keine Bewertungen

- 3D Mesaurement Survey: Got It!Dokument2 Seiten3D Mesaurement Survey: Got It!Jesus Percy Garro EspinozaNoch keine Bewertungen

- Contact Us Search Our Services: Click To Enable Adobe Flash PlayerDokument2 SeitenContact Us Search Our Services: Click To Enable Adobe Flash Playert githenderNoch keine Bewertungen

- SayfaDokument1 SeiteSayfadoğancanNoch keine Bewertungen

- Rev 3Dokument35 SeitenRev 3Rathnakraja0% (1)

- Iecee Od-2025-B-2016Dokument21 SeitenIecee Od-2025-B-2016krivitskiNoch keine Bewertungen

- Resource Management in Construction Projects - A Case Study: September 2012Dokument7 SeitenResource Management in Construction Projects - A Case Study: September 2012TarsemNoch keine Bewertungen

- A06-90 Rock Bits CatalogDokument4 SeitenA06-90 Rock Bits CatalogtifonNoch keine Bewertungen

- Jason Bowtell: Professional ExperienceDokument3 SeitenJason Bowtell: Professional Experienceapi-211053266Noch keine Bewertungen

- Chapter1 - Technology ManagementDokument16 SeitenChapter1 - Technology ManagementJawad Ahmad SahibzadaNoch keine Bewertungen

- Installation Guideline: Technical InformationDokument40 SeitenInstallation Guideline: Technical InformationMohsen HalweniNoch keine Bewertungen

- Extended AbstractDokument4 SeitenExtended AbstractEdrian A. MañalongNoch keine Bewertungen

- Crane Components For Standard CraneDokument20 SeitenCrane Components For Standard CraneMacan SumatraNoch keine Bewertungen

- MB20-200 LMSP-DP STD en Glovebox Manual - MBraunDokument182 SeitenMB20-200 LMSP-DP STD en Glovebox Manual - MBraunbariumbitmapNoch keine Bewertungen

- MRFDokument11 SeitenMRFRohit Gunwani0% (1)

- فهرست گواهینامه ها و مدارک مورد نیاز کشتیDokument10 Seitenفهرست گواهینامه ها و مدارک مورد نیاز کشتیfajee_faridNoch keine Bewertungen

- Project PresentationDokument19 SeitenProject PresentationRaushan KumarNoch keine Bewertungen

- CemSyn Silica For Construction, Bee Chems, IndiaDokument2 SeitenCemSyn Silica For Construction, Bee Chems, IndiaDhan Raj Bandi0% (1)

- RN SeriesDokument8 SeitenRN SeriesCristian DiblaruNoch keine Bewertungen

- Product Leaflet - Portable CNC Cutting MachineDokument2 SeitenProduct Leaflet - Portable CNC Cutting Machineabhics67Noch keine Bewertungen

- AMSO User ManualDokument60 SeitenAMSO User ManualJab5450Noch keine Bewertungen

- lnk362 364 3310Dokument17 Seitenlnk362 364 3310achuthkumar100% (1)

- Presentation 22325 IT22325 Zero-To-CD AU16 Crawford SlidesDokument22 SeitenPresentation 22325 IT22325 Zero-To-CD AU16 Crawford SlidesSony JsdNoch keine Bewertungen

- ISTQB Question Paper20Dokument53 SeitenISTQB Question Paper20rashmikupsadNoch keine Bewertungen

- Bazooka CS1Bazooka CS1204 Manual204 ManualDokument8 SeitenBazooka CS1Bazooka CS1204 Manual204 ManualSvasta SvastarijaNoch keine Bewertungen

- DFMADokument12 SeitenDFMAbfazil100% (1)

- TP401 PDFDokument112 SeitenTP401 PDFDaniel Tovar Romero50% (2)

- Hypertherm Powermax 190C Plasma Operator Manual 3Dokument47 SeitenHypertherm Powermax 190C Plasma Operator Manual 3Steve Skinner100% (1)

- Checklist For Rope Suspended Platform HSE OCP 16Dokument1 SeiteChecklist For Rope Suspended Platform HSE OCP 16Mohamed KamalNoch keine Bewertungen

- (BS 2000-10-2011) - Methods of Test For Petroleum and Its Products. Determination of Kerosine Burning Characteristics 24-Hour MethodDokument16 Seiten(BS 2000-10-2011) - Methods of Test For Petroleum and Its Products. Determination of Kerosine Burning Characteristics 24-Hour MethodAdelNoch keine Bewertungen

- A Look at The Greenfield Foundries of 2020Dokument12 SeitenA Look at The Greenfield Foundries of 2020skluxNoch keine Bewertungen

- Unit-2 Components of CIMDokument20 SeitenUnit-2 Components of CIMMurali Krishnan SelvarajaNoch keine Bewertungen

- Quickspecs: ModelsDokument20 SeitenQuickspecs: ModelsNiCat IonNoch keine Bewertungen

- Swagelok VRC Metal Gasket Face Seal FittingsDokument20 SeitenSwagelok VRC Metal Gasket Face Seal FittingstotcsabNoch keine Bewertungen