Beruflich Dokumente

Kultur Dokumente

Sip-Sop04-R0-2017 Sop DPT Level Calibration

Hochgeladen von

Dwi Mulyanti DwimulyantishopOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sip-Sop04-R0-2017 Sop DPT Level Calibration

Hochgeladen von

Dwi Mulyanti DwimulyantishopCopyright:

Verfügbare Formate

STANDARD OPERATION PROCEDURE

SIP-SOP-04

INSTRUMENT CALIBRATION PROCEDURE

DP LEVEL TRANSMITTER

Document No: SIP-SOP04-R0-2017

Date: 25.07.2017 Rev: 0 Created by: AAA Checked by: AAA

A. Overview

When it comes to calibrating a level transmitter, it is crucial for individuals to first understand exactly

what a level transmitter is. A level transmitter is a sensor whose primary purpose is to detect a variety

of factors based its electrical transmission output, including the bulk level of a liquid. There are five

primary types of level transmitters: the capacitive level transmitter, the float level transmitter, the

submersible level transmitter, the ultrasonic level transmitter, and the differential pressure (DP) level

transmitter. While all of these have different purposes and differentiators, the calibration of these

devices is largely universal. In this guide, we will be learning how to calibrate a DP level transmitter.

You should always check specific instructions for the make and model of your transmitter.

B. Calibrating a DP Level Transmitter

Materials Needed for Calibrating a DP Level Transmitter:

Pressure calibrator/air supply

Power supply (as required by the manufacturer, typically 24 volts)

Hand-held communicator

Digital Multimeter

Data sheet for the specific transmitter and tank.

Screwdriver

To Perform The Test

Before the process of calibrating a level transmitter can begin, it is important to fully comprehend the

three outputs of a level transmitter. The first output is the digital process variable. It is highly

recommended that this output be read using a hand-held communication device such as a HART

communicator. Next is the output current's digital value. Similar to the digital process variable, the

output current's digital value should be read using a hand-held communicator. The final output of the

level transmitter is the analog signal output, which you will read using the milli ammeter

or millimeter instead of the communicator.

Calibration Procedure-DP Level Transmitter Page 1

STANDARD OPERATION PROCEDURE

SIP-SOP-04

INSTRUMENT CALIBRATION PROCEDURE

DP LEVEL TRANSMITTER

Document No: SIP-SOP04-R0-2017

Date: 25.07.2017 Rev: 0 Created by: AAA Checked by: AAA

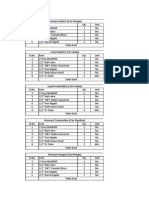

Step

Step Items Description

No.

Connect the transmitter to the test equipment.

The first step in this process is to power the transmitter by connecting it to an appropriate

power supply. Next, connect your pressure calibrator/air supply to the device as well. Lastly,

1

the multimeter is connected in series from the transmitters negative voltage to the mA

connector and from there back to the power supply. With no pressure being applied, the

multimeter should read around 4 mA.

Clean the high- and low-pressure ports.

2 Connect the air supply to the each port and blow air through for a few seconds to clean and

dry the port. Reconnect the air hose to the high side tap and leave the low side open to the

atmosphere.

Calibrate.

Using the data sheet for reference, set the pressure regulator on the air supply until it reads

the pressure in PSI associated with the LRV (lower range value), Using a screwdriver, make

3

minor adjustments to the zero screw, which is typically located on the top of the transmitter,

until the multimeter reads the proper voltage as shown on the data sheet. This process is

repeated for the URV (upper range value) by making adjustments to the span screw instead.

Repeat.

Once you have completed the URV adjustment, repeat Step 3 at least two more times to

verify the accuracy of the readings.

4 When dealing with level transmitters, it is important to ensure that the instruments are

properly calibrated. If they aren't, it could lead to poor equipment performance, inaccurate

material calculations, and equipment failure. You can find all the equipment you need for this

calibration on eBay. By going through the steps with patience and resolve, you can calibrate

a level transmitter without third-party assistance.

Calibration Procedure-DP Level Transmitter Page 2

Das könnte Ihnen auch gefallen

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsVon EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsNoch keine Bewertungen

- Calibration of Smart TransmittersDokument4 SeitenCalibration of Smart TransmittersLugabalugaNoch keine Bewertungen

- Flow & Level Calibration Notes: Differential Pressure Transmitter CalibrationDokument9 SeitenFlow & Level Calibration Notes: Differential Pressure Transmitter Calibrationterio16100% (1)

- Calibrate HART DP TransmitterDokument3 SeitenCalibrate HART DP TransmitterDwi Mulyanti Dwimulyantishop100% (1)

- Basic Inst.Dokument15 SeitenBasic Inst.mahesh4975Noch keine Bewertungen

- Standard Check List: Pressure TransmiterDokument3 SeitenStandard Check List: Pressure TransmiterROUNAK MANDALNoch keine Bewertungen

- Arun WoodDokument5 SeitenArun WoodArun KumarNoch keine Bewertungen

- Field Instrumentation (Oil and Gas)Dokument4 SeitenField Instrumentation (Oil and Gas)Mohamed RaeesNoch keine Bewertungen

- Appendix D: Engineering Standards Manual ISD 341-2Dokument17 SeitenAppendix D: Engineering Standards Manual ISD 341-2tadagidsNoch keine Bewertungen

- Spirax Sarco - Typical Steam Orifice Flowmeter Station PDFDokument3 SeitenSpirax Sarco - Typical Steam Orifice Flowmeter Station PDFnasirmuzaffarNoch keine Bewertungen

- D Pi 175Dokument2 SeitenD Pi 175reza329329Noch keine Bewertungen

- EG 15-14-1.2 Instrument Calibration: ScopeDokument21 SeitenEG 15-14-1.2 Instrument Calibration: ScopeaminNoch keine Bewertungen

- 50+ Instrumentation Interview QuestionsDokument14 Seiten50+ Instrumentation Interview Questionskrishna kumarNoch keine Bewertungen

- DPT Smart Pressure TransmitterDokument15 SeitenDPT Smart Pressure Transmitterprasanta_bbsrNoch keine Bewertungen

- Commissioning Issues and Solutions: Teo Puay Yong Pepperl+Fuchs Pte LTD SingaporeDokument52 SeitenCommissioning Issues and Solutions: Teo Puay Yong Pepperl+Fuchs Pte LTD Singaporesolo AdoNoch keine Bewertungen

- Instrumentation Interview QuestionDokument35 SeitenInstrumentation Interview Questionabbutalibb100% (1)

- Lab Report Temperature TransmitterDokument12 SeitenLab Report Temperature Transmitterathira sNoch keine Bewertungen

- E - Qamar Hassan Iqbal: ObjectiveDokument3 SeitenE - Qamar Hassan Iqbal: ObjectiveQamar Hassan Iqbal0% (1)

- DP Level Transmitters Calibration RangeDokument36 SeitenDP Level Transmitters Calibration RangeDuong NguyenNoch keine Bewertungen

- Example of Foundation Fieldbus Segment ConfigDokument1 SeiteExample of Foundation Fieldbus Segment ConfigamjadnawazNoch keine Bewertungen

- Inst DrawingsDokument25 SeitenInst DrawingsAyman AL-SheryaniNoch keine Bewertungen

- Project Quality Plan and Loop Testing ProceduresDokument3 SeitenProject Quality Plan and Loop Testing ProceduresOwais MalikNoch keine Bewertungen

- Flowmeter Calibration ProcedureDokument8 SeitenFlowmeter Calibration ProcedureShesadri ChakrabartyNoch keine Bewertungen

- Commissioning Engineer in NY Resume Jack de PagterDokument2 SeitenCommissioning Engineer in NY Resume Jack de PagterJackdePagterNoch keine Bewertungen

- FISCAL METERING SYSTEM DESIGN EVALUATIONDokument17 SeitenFISCAL METERING SYSTEM DESIGN EVALUATIONmatteo2009Noch keine Bewertungen

- Loop Checking and Field Instrument Testing ProcedureDokument3 SeitenLoop Checking and Field Instrument Testing Procedureamirubote4Noch keine Bewertungen

- 501-375 Testing Fieldbus Wiring With An FBT-6 and FBT-5Dokument5 Seiten501-375 Testing Fieldbus Wiring With An FBT-6 and FBT-5Exequiel PlazaNoch keine Bewertungen

- Transmitter and Smart TransmitterDokument57 SeitenTransmitter and Smart TransmitterBHAGSEN PARVATNoch keine Bewertungen

- Calibrate Pressure Transmitter in 4 StepsDokument2 SeitenCalibrate Pressure Transmitter in 4 StepssupercontrollerNoch keine Bewertungen

- Loop Check and ValveDokument1 SeiteLoop Check and ValveMohd A IshakNoch keine Bewertungen

- HandBook Pressure Transmitter-En PDFDokument32 SeitenHandBook Pressure Transmitter-En PDFcarloscieza100% (2)

- 5F. Pressure Transmitter (Electronic Type) CalibratorDokument6 Seiten5F. Pressure Transmitter (Electronic Type) CalibratorIsaalexNoch keine Bewertungen

- Rosemount 1151 User ManualDokument6 SeitenRosemount 1151 User ManualDwightFerrerNoch keine Bewertungen

- Flow Instrumentation 101: Dave SchmittDokument62 SeitenFlow Instrumentation 101: Dave SchmittAhmed HusseinNoch keine Bewertungen

- Flow ComputersDokument11 SeitenFlow ComputersKarthik ChockkalingamNoch keine Bewertungen

- MOHD AZWAN BIN MUHAMAD - Piping DesignerDokument3 SeitenMOHD AZWAN BIN MUHAMAD - Piping DesignerAzwanNoch keine Bewertungen

- Guhan K E&I Engineer & Atex Inspector: Professional SummaryDokument4 SeitenGuhan K E&I Engineer & Atex Inspector: Professional Summarykspguhan1987Noch keine Bewertungen

- Basics of Instrumentation & ControlDokument29 SeitenBasics of Instrumentation & ControlprathmeshNoch keine Bewertungen

- Introduction To Smart TransmittersDokument3 SeitenIntroduction To Smart Transmitterssleepfox9Noch keine Bewertungen

- Product List: Pressure MeasurementDokument6 SeitenProduct List: Pressure MeasurementSr FarezNoch keine Bewertungen

- Instr Loop Check PDFDokument3 SeitenInstr Loop Check PDFMohamed AdelNoch keine Bewertungen

- Control Valve Calibration Procedure (Fisher HC6010)Dokument14 SeitenControl Valve Calibration Procedure (Fisher HC6010)Karen Cain93% (15)

- Control Valve Positioner Calibration GuideDokument14 SeitenControl Valve Positioner Calibration GuideAnonymous JwOs90v6TUNoch keine Bewertungen

- Instrument Installation SpecificationDokument15 SeitenInstrument Installation SpecificationtadagidsNoch keine Bewertungen

- Course Title: Basic Instrumentation (Code: 3311701)Dokument5 SeitenCourse Title: Basic Instrumentation (Code: 3311701)Raja Prathap SinghNoch keine Bewertungen

- UET Lahore Report on Transmitters in Process IndustriesDokument12 SeitenUET Lahore Report on Transmitters in Process IndustriesUmar AdamuNoch keine Bewertungen

- Sop GSSDokument3 SeitenSop GSSArun MurugaiyanNoch keine Bewertungen

- Cold Loop CheckingDokument1 SeiteCold Loop CheckingZulkernain Omer TariqNoch keine Bewertungen

- Instrument QuestionDokument41 SeitenInstrument QuestionMallick100% (1)

- Chap 1a - Instrumentation and PID DiagramDokument20 SeitenChap 1a - Instrumentation and PID Diagramraj varmanNoch keine Bewertungen

- Model 1700 Training Activity TwoDokument12 SeitenModel 1700 Training Activity Twoyao nestorNoch keine Bewertungen

- Level Measurement (RADAR Trasnmitter)Dokument17 SeitenLevel Measurement (RADAR Trasnmitter)febri_bontangNoch keine Bewertungen

- Instruments Hookup BOQDokument2 SeitenInstruments Hookup BOQSijo JoyNoch keine Bewertungen

- Instrumentation and Control Valves 1Dokument31 SeitenInstrumentation and Control Valves 1Ahmed ElShoraNoch keine Bewertungen

- ATEX Ex-EDokument10 SeitenATEX Ex-EBrajan's B.Noch keine Bewertungen

- Qamar Hassan Iqbal CVDokument2 SeitenQamar Hassan Iqbal CVQamar Hassan IqbalNoch keine Bewertungen

- Calibration of Differential Pressure TransmitterDokument8 SeitenCalibration of Differential Pressure TransmitterLugabaluga100% (1)

- SIP-SOP03-R0-2017 SOP Temperature Transmitter CalibrationDokument2 SeitenSIP-SOP03-R0-2017 SOP Temperature Transmitter CalibrationDwi Mulyanti DwimulyantishopNoch keine Bewertungen

- DP CalibrationDokument12 SeitenDP CalibrationGeorge AsuncionNoch keine Bewertungen

- flow transmitter calibration - بحث GoogleDokument1 Seiteflow transmitter calibration - بحث Googlebasim.d.alshehriNoch keine Bewertungen

- 576560Dokument1 Seite576560Dwi Mulyanti DwimulyantishopNoch keine Bewertungen

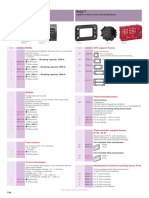

- Support frames selection chart for British, American and Italian standard boxesDokument1 SeiteSupport frames selection chart for British, American and Italian standard boxesDwi Mulyanti DwimulyantishopNoch keine Bewertungen

- TdsDokument1 SeiteTdsDwi Mulyanti DwimulyantishopNoch keine Bewertungen

- Wallis Complete Cat.Dokument7 SeitenWallis Complete Cat.Dwi Mulyanti DwimulyantishopNoch keine Bewertungen

- 89239Dokument1 Seite89239Dwi Mulyanti DwimulyantishopNoch keine Bewertungen

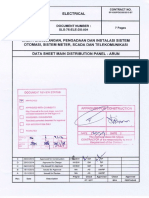

- SLS-75-ELE-DS-004 Data Sheet UPS System - Arun, Rev. 1 - AFC PDFDokument5 SeitenSLS-75-ELE-DS-004 Data Sheet UPS System - Arun, Rev. 1 - AFC PDFDwi Mulyanti DwimulyantishopNoch keine Bewertungen

- Support frames selection chart for British, American and Italian standard boxesDokument1 SeiteSupport frames selection chart for British, American and Italian standard boxesDwi Mulyanti DwimulyantishopNoch keine Bewertungen

- Arteor: Italian / US Standards 83.5 MM Fixing Centres - Flush Mounting Boxes, Support Frames and PlatesDokument1 SeiteArteor: Italian / US Standards 83.5 MM Fixing Centres - Flush Mounting Boxes, Support Frames and PlatesDwi Mulyanti DwimulyantishopNoch keine Bewertungen

- 572004Dokument1 Seite572004Dwi Mulyanti DwimulyantishopNoch keine Bewertungen

- Arteor: Italian / US Standards 83.5 MM Fixing Centres - Flush Mounting Boxes, Support Frames and PlatesDokument1 SeiteArteor: Italian / US Standards 83.5 MM Fixing Centres - Flush Mounting Boxes, Support Frames and PlatesDwi Mulyanti DwimulyantishopNoch keine Bewertungen

- Technical OfferDokument9 SeitenTechnical OfferDwi Mulyanti DwimulyantishopNoch keine Bewertungen

- XT SACE Tmax XTDokument18 SeitenXT SACE Tmax XTDwi Mulyanti DwimulyantishopNoch keine Bewertungen

- SLS-75-ELE-DS-001 Data Sheet LV Switchgear and MCC - Arun, Rev. 0 - AFCDokument7 SeitenSLS-75-ELE-DS-001 Data Sheet LV Switchgear and MCC - Arun, Rev. 0 - AFCDwi Mulyanti DwimulyantishopNoch keine Bewertungen

- CCTVDokument16 SeitenCCTVDwi Mulyanti Dwimulyantishop100% (1)

- SLS-75-ELE-CL-005 0.48 KV-0.4 KV Transformer Sizing - Arun, Rev. 0 - AFCDokument6 SeitenSLS-75-ELE-CL-005 0.48 KV-0.4 KV Transformer Sizing - Arun, Rev. 0 - AFCDwi Mulyanti DwimulyantishopNoch keine Bewertungen

- SLS-75-ELE-LI-002 Electrical Equipment List - Arun, Rev. 1 - AFCDokument5 SeitenSLS-75-ELE-LI-002 Electrical Equipment List - Arun, Rev. 1 - AFCDwi Mulyanti DwimulyantishopNoch keine Bewertungen

- SLS-75-ELE-DW-011 Grounding and Lightning Layout - Arun, Rev. 0 - AFCDokument2 SeitenSLS-75-ELE-DW-011 Grounding and Lightning Layout - Arun, Rev. 0 - AFCDwi Mulyanti DwimulyantishopNoch keine Bewertungen

- SLS-75-ELE-DS-004 Data Sheet UPS System - Arun, Rev. 1 - AFC PDFDokument5 SeitenSLS-75-ELE-DS-004 Data Sheet UPS System - Arun, Rev. 1 - AFC PDFDwi Mulyanti DwimulyantishopNoch keine Bewertungen

- SLS-75-ELE-DW-015 Electrical Connection Diagram For MOV - Arun, Rev. 0 - AFC PDFDokument1 SeiteSLS-75-ELE-DW-015 Electrical Connection Diagram For MOV - Arun, Rev. 0 - AFC PDFDwi Mulyanti DwimulyantishopNoch keine Bewertungen

- SLS-95-ELE-DW-010 Panel Schedule - Belawan, Rev. 1 - AFC PDFDokument1 SeiteSLS-95-ELE-DW-010 Panel Schedule - Belawan, Rev. 1 - AFC PDFDwi Mulyanti DwimulyantishopNoch keine Bewertungen

- SLS-95-ELE-DW-010 Panel Schedule - Belawan, Rev. 1 - AFCDokument1 SeiteSLS-95-ELE-DW-010 Panel Schedule - Belawan, Rev. 1 - AFCDwi Mulyanti DwimulyantishopNoch keine Bewertungen

- SLS-95-ELE-DW-001 Legend and Symbol - Belawan, Rev. 0 - AFCDokument1 SeiteSLS-95-ELE-DW-001 Legend and Symbol - Belawan, Rev. 0 - AFCDwi Mulyanti DwimulyantishopNoch keine Bewertungen

- SLS-75-ELE-DW-015 Electrical Connection Diagram For MOV - Arun, Rev. 0 - AFCDokument1 SeiteSLS-75-ELE-DW-015 Electrical Connection Diagram For MOV - Arun, Rev. 0 - AFCDwi Mulyanti DwimulyantishopNoch keine Bewertungen

- SLS-70-CIV-DW-002 Civil, Structure & Architecture General Notes, Rev-A, Rejected PDFDokument1 SeiteSLS-70-CIV-DW-002 Civil, Structure & Architecture General Notes, Rev-A, Rejected PDFDwi Mulyanti DwimulyantishopNoch keine Bewertungen

- SLS-70-CIV-DW-002 Civil, Structure & Architecture General Notes, Rev-A, RejectedDokument1 SeiteSLS-70-CIV-DW-002 Civil, Structure & Architecture General Notes, Rev-A, RejectedDwi Mulyanti DwimulyantishopNoch keine Bewertungen

- SLS-70-CIV-DB-001 Civil Design Basis, Rev B - App W CommentDokument36 SeitenSLS-70-CIV-DB-001 Civil Design Basis, Rev B - App W CommentDwi Mulyanti DwimulyantishopNoch keine Bewertungen

- SLS-95-ELE-DW-005 Electrical Equipment Layout at Electrical Room - Belawan, Rev. 0 - AFCDokument1 SeiteSLS-95-ELE-DW-005 Electrical Equipment Layout at Electrical Room - Belawan, Rev. 0 - AFCDwi Mulyanti DwimulyantishopNoch keine Bewertungen

- SLS-75-ELE-DW-011 Grounding and Lightning Layout - Arun, Rev. 0 - AFCsDokument1 SeiteSLS-75-ELE-DW-011 Grounding and Lightning Layout - Arun, Rev. 0 - AFCsDwi Mulyanti DwimulyantishopNoch keine Bewertungen

- Sls-70-Civ-db-001 Civil Design Basis, Rev. D - AfdDokument36 SeitenSls-70-Civ-db-001 Civil Design Basis, Rev. D - AfdDwi Mulyanti DwimulyantishopNoch keine Bewertungen

- SLS-70-CIV-DB-001 Civil Design Basis, Rev C - App W CommentDokument36 SeitenSLS-70-CIV-DB-001 Civil Design Basis, Rev C - App W CommentDwi Mulyanti DwimulyantishopNoch keine Bewertungen

- Ccu Sem (2010-05-05) PDFDokument181 SeitenCcu Sem (2010-05-05) PDFBích Đỗ DanhNoch keine Bewertungen

- Thermal Shock Resistant Neoceram Glass-CeramicDokument2 SeitenThermal Shock Resistant Neoceram Glass-CeramicAmândio PintoNoch keine Bewertungen

- Unu GTP SC 26 14Dokument30 SeitenUnu GTP SC 26 14Ernesto RomeroNoch keine Bewertungen

- Electrical Network of The Automotive Multi-Sectional Thermoelectric Generator With MPPT Based Device UsageDokument10 SeitenElectrical Network of The Automotive Multi-Sectional Thermoelectric Generator With MPPT Based Device UsageMouna MorchidNoch keine Bewertungen

- Graviner MK6 Oil Mist DetectorDokument4 SeitenGraviner MK6 Oil Mist DetectorDhanielNoch keine Bewertungen

- CV - Alok Singh - Tech HSE & Loss Prevention Engineer (May-2018)Dokument5 SeitenCV - Alok Singh - Tech HSE & Loss Prevention Engineer (May-2018)toalok4723Noch keine Bewertungen

- United States Patent (10) Patent No.: US 8,106,570 B2Dokument20 SeitenUnited States Patent (10) Patent No.: US 8,106,570 B2zahra sdeghiniaNoch keine Bewertungen

- 10 MW Unit 214.00 709 55.83 1972Dokument1 Seite10 MW Unit 214.00 709 55.83 1972Gangadhara P.K.Noch keine Bewertungen

- Question Paper Code:: Reg. No.Dokument2 SeitenQuestion Paper Code:: Reg. No.tamilarasi87thulasiNoch keine Bewertungen

- Introduction To Pressure TransducersDokument2 SeitenIntroduction To Pressure TransducersTEUKUNoch keine Bewertungen

- Every Emergency.: C Safe Marine Generator SetsDokument4 SeitenEvery Emergency.: C Safe Marine Generator SetsBrillyanNoch keine Bewertungen

- Unit 1Dokument36 SeitenUnit 1MonishNoch keine Bewertungen

- Optical Properties of MaterialDokument63 SeitenOptical Properties of MaterialNoviNoch keine Bewertungen

- TMX53DC 1607 121 (Drawings Electric)Dokument13 SeitenTMX53DC 1607 121 (Drawings Electric)ChristianNoch keine Bewertungen

- Power Generation: Selection GuideDokument114 SeitenPower Generation: Selection GuideRobiNoch keine Bewertungen

- (Geoffrey Lawrence, Kristen Lyons, Tabatha Walling (BookFi) PDFDokument321 Seiten(Geoffrey Lawrence, Kristen Lyons, Tabatha Walling (BookFi) PDFIManNoch keine Bewertungen

- Safety LOPADokument28 SeitenSafety LOPAnandorg1113100% (1)

- Fluid MechDokument10 SeitenFluid MechPrasant KumarNoch keine Bewertungen

- Solutions To ExercisesDokument47 SeitenSolutions To ExercisesNathan D. Gutzmann60% (5)

- Euler-Ship Mast LocationDokument61 SeitenEuler-Ship Mast LocationzeldaikNoch keine Bewertungen

- Energy Manipulation and MeditationDokument6 SeitenEnergy Manipulation and Meditationapi-246292178100% (1)

- Quality Policy and Quality ObjectivesDokument2 SeitenQuality Policy and Quality ObjectivesrabiulfNoch keine Bewertungen

- OSHA Citations Against O&G and Ducci ElectricDokument107 SeitenOSHA Citations Against O&G and Ducci ElectricRepublican-AmericanNoch keine Bewertungen

- Solex Adj ProcedureDokument6 SeitenSolex Adj Procedureprivate 2Noch keine Bewertungen

- Teco s310 User ManualDokument10 SeitenTeco s310 User ManualEhsan GhanbarzadehNoch keine Bewertungen

- Short and Open Circuit Test On TransformerDokument1 SeiteShort and Open Circuit Test On TransformerRyan DagsilNoch keine Bewertungen

- Microcontroller-Based Power Monitoring for COE RoomsDokument8 SeitenMicrocontroller-Based Power Monitoring for COE Roomskenneth_molenilla1475Noch keine Bewertungen

- EssayDokument3 SeitenEssayKarina RamirezNoch keine Bewertungen

- Wiring Diagram FH, NH: GroupDokument110 SeitenWiring Diagram FH, NH: GroupStefan AslamNoch keine Bewertungen

- 937 Letter AttchamentDokument8 Seiten937 Letter AttchamentNeeta RautelaNoch keine Bewertungen