Beruflich Dokumente

Kultur Dokumente

SV 033

Hochgeladen von

hagg0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

31 Ansichten10 SeitenOpen center

Originaltitel

sv033[1]

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenOpen center

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

31 Ansichten10 SeitenSV 033

Hochgeladen von

haggOpen center

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 10

SV-033

OPEN CENTRE

DIRECTIONAL CONTROL VALVE

250 BAR - 115 L/MIN.

SV-OBS cenrear vata

SECTIONAL CONTROL VALVES

SRN CICS

le een ee ere ee ea

spol valve aks

te ney

cee

Pe

Se ee ee

eee

ee nee

See

een eee ed

Pee ee

See ee ee ee

See ee

eee ety

ee ee

Pe ee

ore aera

Ce ne eee eer

eee nd

Pe

SV-O3S cenerat vata

INTRODUCTION

The $VO33 Control Valves at

port of the wide

range of David Brown Hydraulics products (see

page 11)

Careful attention to all details of design and

manufacture ensures that the versatility of a

sectional valve is achieved without compromising

performance

All our components and systems are backed by

First class Sales, Service and spares facilities,

ble around the world. Whether your

requirement is complex or straight forward - call

Us. Our technical expertise is freely available,

wherever you may be.

VALVE FEATURES

Relief & Ant-Cavitation Valves Page 4

Circuit Options Page 5

High Pressure Carry Over (HPCO) Page 5

Mic-Inlet Page 6

Spool & Mid-Inlet Sections Page7

Port Sizes Page 8

Valve Dimensions, Page 8

‘Operation & Positioning options Page 9

Spool Types Page 10

TECHNICAL DATA

oral werk contions.

Operating Temperature AoC + AC

“Ambient Temperate 40'C to + aC

Maier vscouy for

‘normal working condor 25a (Si)

Mlsimum permissible vscosty 10mm”)

Fe optim ‘i and eficany, uid vive shuld ben

5m (St dng nema working conditions,

lid eanaans

PRESSURE DROP: P-T spools in Neutral

20,

8

Pressure (bar

‘0 80100

Flow (Umin}

720140

[Nominal Capacity 115 Umin

‘Construction Sectional

Istaition No atitude limitation

[Number of spook: 11010

‘Operating Prescure Inet )&HPCO 250 barman)

Service) &(B) 345 bara)

Outer 1) 10ar (max)

For optimum peomance, Qutet pressure should tot exceed 10 ber under

(S0.4405 19/15 max

the range of 15 to

8SPOOL,

65POOL,

45POOL,

2 POOL

PRESSURE DROPS: PA, B-T or PB, A-T with spools salected

Flow (Lmin)

FIRST SPOOL.

BSPOOL VALVE

FIRST SPOOL

A'SPOOL VALVE

LAST sPooL -

ALL VALVES

‘NL DATAIS OBTAINED FROM AVERAGE PERFORMANCE OF REGULAR PRODUCTION VALVES USING GOOD QUALITY SAE. 10 MINERAL HYDRAULIC OM AT SOC

‘GENERALLY CORRESPONDING TO A VISCOSITY OF 23a.

SV-O33 GENERAL DATA

MAIN RELIEF VALVE (Limits pump pressure)

“The relief valve is adjustable in the range of 90 to 250 bar. Standard location is shown on the installation drawing on page 8.

‘Two-stage versions are also available in which extemal pilot pressure is used to either increase or decrease the pressure

setting

Pa

ep—rfi] Filot pressure to change the setting is Nominal 60 bar.

TL

Standard LS) 4 Maximum permissible: 250 bar

‘Typleal Characteristic

Two-stage

Pressure Inoreasing

3

fe

i

&

‘Two-stage,

Preseure Reducing

020 4560 80 100 120 140

low (Linie,)

‘SERVICE PORT RELIEF VALVE (Protects service lines)

‘These are available on all Service Ports. Relief setting ranges from 20 to 245 bar by pre-set stages. This valve may also be

‘combined with Ant-Covitation valves as shown below

‘Typkeal Characteristic

Sarvce pore A or

g 3

Pressure (ba)

g

9 20 40 60 80 100 120

Flow (Limin.)

ANTECAVITATION CHECK VALVE

‘These are available as single-function checks or combined with service-port relief valves. Available on all service ports.

sents pote her

RPE ason ref pl Cuca

ul i

Combined Anti-Cavitation and Service-Port Raliet: 2 6

‘Service ports A oF B a 4

i

‘Te

He rit | |

Bae 00 eo

Flow (Umin.)

SERVICE PORT LEAKAGE

Leakage from Service Ports A or B to T with spools in Neutral will not exceed *36mL/min at 140 bar.

>with fvid temperature 50°C, viscosity 23enm? /secteSt)

SPOOL OPERATING FORCES

Double Acting Spools: Maximum spring force 17BN, maximum operating force 278N.

SV-O3S33 circuit options

The use of Tandem, Parallel, Series or Mixed circuits in a system normally depends on the type of work cycle required.

For advice on the best type of circuit for your operating requirements consult David Brown Hydraulics sales departvent,

Typical TANDEM Circuit (SVTO33)

In Tandem circuit valves, the spool nearest the inlet

takes all the oil supply when fully selected

Essentially, the Tandem citeuit valve is intended to

feed the whole of the oil supply to one service at

atime,

Tandem circuit can be specified between any spools

in a valve bank, e.g. between Bucket and Lift spools.

in a Loading-Shovel valve.

Typical PARALLEL Circuit (SVPO33)

Parallel circuit valves have @ common internal

pressure gallery allowing simultaneous feed to any

number of work ports. The service at the lowest static

pressure will move first, unless its spoot is throttled to

build up sufficient pressure to operate other services,

‘The Paraliel circuit valve is able to divide the oi flow

between any number of services, providing full

pressure at any one or more, but with an operating

‘speed less than maximum for each service.

4

Lo i

3

‘Typical SERIES Circuit (SVSO33)

Series circuit valves allow simultaneous operation of

‘more than one service, but in this case, exhaust from

the spool nearest the inlet is the supply for the next

downstream spool operated. The operating pressure

con the last service is the back pressure on the

preceding upstream service and so on. Thus, high

speed is possible at simultaneously selected services,

but the total pressure is divided between them

Complete valve banks may be made up of Series

connected spoal sections.

Alternatively, a series-circuit section may be specified

in any position in a Parallel valve bank, e.g. to

provide Series connection between Slew and Boom

‘sp00!5 in an Excavator valve,

MIXED Circuit

The mixed circuit can be a combination of Parallel,

Tandem and Series circuits in the same valve

‘assembly,

High pressure Carry Over (HPCO)

The HPCO allows additional valves to be connected

downstream of the Control valve, using the high

pressure supplied to the first valve.

No secondary pump is required and the system

remains protected by the Main Relief valve of the frst

valve

Standard valves can be converted for HPCO by

Fiting an intemal plug in the tapped hole below the

outlet TI. For HPCO location, see page 8.

SV-OBS wiv-intet SsecTIONS

Mid-inlet sections enable two separate valve banks to be combined into a single package. Separate pumps supply the

upstream and downstream valve banks, and flows from these pumps can be separated or combined for the downstream bank.

‘Optional relief valves are available. A third version incorporates an unlosder valve.

Mic-inlet sections provide great flexbility of circuit design and packaging, David Brown Hydraulies would be pleased to

advise on which type is best suited to your requirements.

Separating Flows

‘Two completely independent pump-and-valve bank

circuits can be packaged so that there is only one.

vaive bank assembly, thus saving on installation

costs,

1 supplies the upstream spools and P2 supplies

the downstream spools. There is no connection of

pump flows.

‘Combining Flows

Upstream valve spools are supplied by P1.

50 long as no upstream spools are selected, the

Das könnte Ihnen auch gefallen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Servo Actuator POS 100Dokument2 SeitenServo Actuator POS 100haggNoch keine Bewertungen

- Abe32 10 2002 11 14Dokument4 SeitenAbe32 10 2002 11 14haggNoch keine Bewertungen

- ITI - Sim: Simulation ApplicationDokument5 SeitenITI - Sim: Simulation ApplicationhaggNoch keine Bewertungen

- E Series Proportional Pressure Controls: Pilot Relief / Relief / Reducing and RelievingDokument30 SeitenE Series Proportional Pressure Controls: Pilot Relief / Relief / Reducing and RelievinghaggNoch keine Bewertungen

- ITI - Sim: SimulationDokument13 SeitenITI - Sim: SimulationhaggNoch keine Bewertungen

- Thermostat AB-E 31-32: Adjustment Range 5 To 100°CDokument2 SeitenThermostat AB-E 31-32: Adjustment Range 5 To 100°ChaggNoch keine Bewertungen

- Piston Pressure Switch Hydraulic-ElectricDokument2 SeitenPiston Pressure Switch Hydraulic-ElectrichaggNoch keine Bewertungen

- Pressure Switch For Panel Mounting: Cutout in The Panel Section A-ADokument4 SeitenPressure Switch For Panel Mounting: Cutout in The Panel Section A-AhaggNoch keine Bewertungen

- Pressure SwitchesDokument4 SeitenPressure SwitcheshaggNoch keine Bewertungen

- Heat Exchanger AB-E 32-09: Oil / Water System: Single TubeDokument7 SeitenHeat Exchanger AB-E 32-09: Oil / Water System: Single TubehaggNoch keine Bewertungen

- Technical Catalogue: June JuneDokument9 SeitenTechnical Catalogue: June JunehaggNoch keine Bewertungen

- Piston Pressure Switch Hydraulic-ElectricDokument2 SeitenPiston Pressure Switch Hydraulic-Electrichagg100% (1)

- Oil Level Indicator AB-E 31-21: ND3 Sheet 1Dokument5 SeitenOil Level Indicator AB-E 31-21: ND3 Sheet 1hagg0% (1)

- Resistance Thermometer AB-E 31-17: 1 Area of ApplicationDokument3 SeitenResistance Thermometer AB-E 31-17: 1 Area of Applicationhagg0% (1)

- Abe21 14 2002 11 06Dokument2 SeitenAbe21 14 2002 11 06haggNoch keine Bewertungen

- Float Switches AB-E 31-06: Without Protective Tube, With One or Two Switching Contacts Sheet 1Dokument6 SeitenFloat Switches AB-E 31-06: Without Protective Tube, With One or Two Switching Contacts Sheet 1haggNoch keine Bewertungen

- Glycerine Filled Pressure Gauge AB-E 31-11: DN 63 and DN 100, Bottom ConnectionDokument4 SeitenGlycerine Filled Pressure Gauge AB-E 31-11: DN 63 and DN 100, Bottom ConnectionhaggNoch keine Bewertungen

- The Oil Level Switch With Technical and Economical Advantages!Dokument2 SeitenThe Oil Level Switch With Technical and Economical Advantages!haggNoch keine Bewertungen

- D O Cetop 3/Ng6: Irectional Control Valves Ther Operator IDokument3 SeitenD O Cetop 3/Ng6: Irectional Control Valves Ther Operator IhaggNoch keine Bewertungen

- Technical Catalogue FPDokument100 SeitenTechnical Catalogue FPhaggNoch keine Bewertungen

- Coils and ConnectorsDokument6 SeitenCoils and ConnectorshaggNoch keine Bewertungen

- PV BasicsDokument45 SeitenPV Basicshagg100% (2)

- Technical Results With Driving Power: Drive Systems For DecantersDokument6 SeitenTechnical Results With Driving Power: Drive Systems For DecantershaggNoch keine Bewertungen

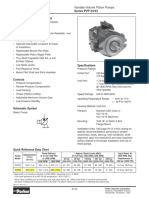

- Performance Information: Series PVP 23/33 Technical InformationDokument10 SeitenPerformance Information: Series PVP 23/33 Technical InformationhaggNoch keine Bewertungen

- Denison Parker R6VDokument15 SeitenDenison Parker R6VhaggNoch keine Bewertungen

- 285 Relee Tip URF Pentru ComutatoareDokument8 Seiten285 Relee Tip URF Pentru ComutatoarehaggNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)